0040-6090/04/$ - see front matter䊚 2003 Elsevier B.V. All rights reserved. doi:10.1016/j.tsf.2003.09.006

Moisture resistance and thermal stability of fluorine-incorporation

siloxane-based low-dielectric-constant material

Y.L. Cheng , Y.L. Wang

a,b a,c,*, Y.L. Wu , C.P. Liu , C.W. Liu , J.K. Lan , M.L. O’Neil , Chyung Ay ,

d f a b e cM.S. Feng

bTaiwan Semiconductor Manufacturing Co., Ltd, Hsinchu, Taiwan, ROC a

Department of Material Science and Engineering, National Chiao-Tung University, Hsin-Chu, Taiwan, ROC b

Department of Applied Physics, National Chiayi University, Chiayi, Taiwan, ROC c

Department of Electrical Engineering, National Chi-Nan University, Nan-Tou, Taiwan, ROC d

Air Products and Chemicals, Inc., 7201 Hamilton Blvd., Allentown, PA, 18195, USA e

Department of Material Science Engineering, National Cheng-Kung University, Tanani, Taiwan, ROC f

Abstract

The low dielectric constant (low-k) of organo-silica-glass (OSG) and fluorine-incorporated OSG (OFSG) materials produced from plasma-enhanced chemical vapor deposition of trimethylsilane are thermally stable to greater than 600 8C. FTIR analysis indicates that Si–CH bonds and Si–F bonds remain intact to temperatures well above that normally encountered during integrated3

circuit manufacture, allowing these materials to maintain a low-k value. While OFSG materials proved to have less hydrolytic

resistant than their non-fluorinated analogs during high pressure, high temperature water exposure (pressure cooker test), their leakage current was found to be lower than OSG films before and after wafer exposure. The measured properties of OFSG blanket films suggest that this material is sufficiently robust to ensure stability of reliability after the fabrication.

䊚 2003 Elsevier B.V. All rights reserved.

Keywords: Organo-silicate-glass; Heat resistance; Moisture resistance; Low dielectric constant(low-k)

1. Introduction

Low parasitic capacitance multilevel interconnects using low dielectric constant interlayer dielectrics are essential for high-speed ultra large-scale integrated

cir-cuits w1–3x. Organo-silica-glass (OSG, ks2.8–3.3)

deposited by plasma-enhanced chemical vapor deposi-tion (PECVD) has received more attention recently due to their potential to fit into existing processing schemes

w4,5x. It is the reduced mechanical strength of OSG

materials as a result of replacement of oxygen from the

silicate network with organic groups such as Si–CH3

bonds that is the main issue for integrated circuit fabrication w6x. Here we study that the heat and moisture

resistance of a newly developed low-k material,

organ-ofluorosilicate glass (OFSG), within fluorine is

incor-porated into the structure as Si–F only. The resulting material is endowed with higher mechanical strength,

*Corresponding author. Tel.: 2000; fax: q886-6-505-2081.

E-mail address: ylwang@tsmc.com.tw(Y.L. Wang).

providing enhanced resistance to cracking of multi-layer structures and film peeling due to chemical–mechanical planarization.

To ensure high process yield, device performance and reliability over its lifetime, the electrical properties

(dielectric constant, breakdown voltage and leakage

current) of interlayeryintermetal dielectric materials

were resistant to thermal and moisture stresses. The heat resistance is necessary since wafers are exposed to temperatures over 400 8C during fabrication of upper-level interconnects. Since thermal treatment is required after completion of each level of the interconnect struc-ture, the lower level interlayer dielectrics are subjected to many hours of heating w7x. Additionally, moisture resistance is necessary for long-term reliability after packaging. In real operating conditions, the ILDs are subjected to moisture penetrating from the outside envi-ronment. The effect of this moisture penetration is commonly evaluated by accelerated humidity tests.

The effects of heat and moisture exposure on OSG and OFSG films are investigated in this paper. The

682 Y.L. Cheng et al. / Thin Solid Films 447 – 448 (2004) 681–687

Table 1

Process conditions and film properties of OFSG and OSG film

OFSG OSG Process conditions 3MS(sccm) 540 540 O2(sccm) 150 150 SiF4(sccm) 250 RF power(W) 600 600 Pressure(Torr) 4 4 Temperature(8C) 4 4 Film properties Refractive index 1.45 1.41 Dielectric constant 3.2 3.3 Modulus(GPa) 12.5 8 Hardness(H, GPa) 1.98 1.76

Deposition rate(mmymin) 450 670

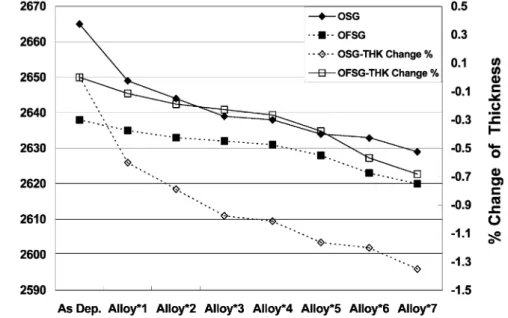

Fig. 1. Heating test(425 8C alloy) on thickness change for OSG and OFSG films.

effect of fluorine addition to the silicate network is assessed by physical and reliability properties of these films. The result of the relationships between the dielec-tric constant stability, surface chemical composition and electric properties are reported and discussed.

2. Experimental

The deposition of the OSG and OFSG films were carried out in an enhanced plasma PECVD system with 13.56 MHz operating r.f. The substrates used in this study were B-doped p-type 200-mm silicon wafers with

(1 0 0) orientation. The deposition temperature was both

maintained at 350 8C; process pressure and r.f. power were set at 4 mm Torr and 600 W, respectively. Except

for the addition of SiF , both materials were deposited4

using trimethylsilane(Z3MS娃) and oxygen under

sim-ilar conditions. The optimized process conditions and film properties are shown in Table 1. Films 300–500 nm thick were analyzed for thickness and refractive

index (RI, at 248 and 633 nm) by reflectometry (SCI

Film Tek 2000) andyor ellipsometer (Nano-Spec 9100).

Transmission FTIR spectra were measured using

Bio-Rad spectrometer at 4ycm resolution. All spectra are an

average of 32 scans and were background corrected to a silicon reference. Dielectric constant and leakage current were measured by mercury probe at 1 MHz frequency. Atomic composition was determined by X-ray photoelectron spectroscopy using a Physical Elec-tronics 5000LS ESCA spectrometer after sputter with

Arq beam to remove the top 20 A of film.

Thermal stability of the films was assessed by 1 h furnace anneal in nitrogen ambient at temperature rang-ing from 300 to 700 8C. Thermal cyclrang-ing 7 times for 1 h at 425 8C in nitrogen ambient was used to mimic stress encountered during copper alloy process. Moisture resistance was determined by exposing films to 120 8C, and 100% relative humidity at 2 atmosphere pressure for up to 168 h.

3. Results and discussions

The results of different times of heating tests at 425

8C for 1 h are shown in Figs. 1–3. The thickness of the

OSG and OFSG films decreases continuously upon 425

8C heating tests (Fig. 1). The maximum thickness

reduction was found after the first time heating test, decrease slightly for each subsequent cycle, with OSG films showing higher shrinkage than OFSG films. The dielectric constant of OSG and OFSG films was

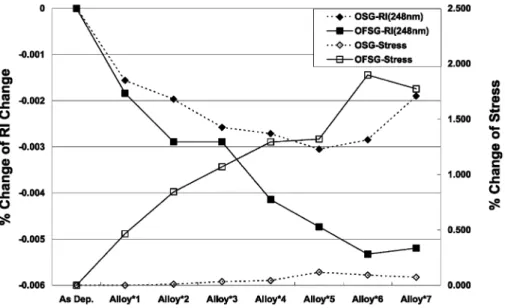

Fig. 2. Heating test(425 8C alloy) on RI and stress change for OSG and OFSG films.

Fig. 3. Effect of heating test(425 8C alloy) on dielectric constant for OSG and OFSG films.

of RI and stress for OSG and OFSG films (Fig. 2)

indicates that magnitude of change for RI of OFSG films is actually larger than that for OSG films. While the trends in RI and stress differ in direction, the relative change is in good agreement.

The possible explanation is that OFSG films have higher bonding strength to against the heating tests. The stability of film properties upon thermal cycling suggests that both OSG and OFSG films would retain their desirable properties through the thermal stresses experi-enced as a result of the copper alloy process. This clearly indicates that the OSG and OFSG films are

suited for intermetal dielectrics on semiconductor since there is at least 7–8 layers interconnect fabrication process and 400 8C is a minimal backend process for an interconnect fabrication process.

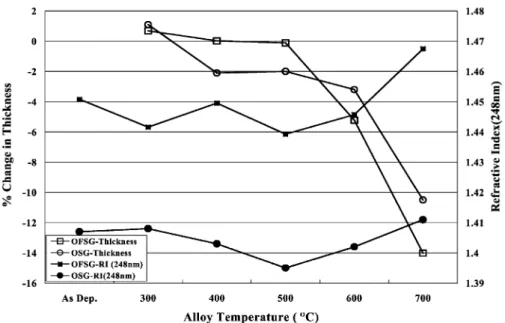

Figs. 4 and 5 show the change of thickness, RI and dielectric constant for furnace anneals from 300 to 700

8C for 1 h. Thek-value for both of the OSG and OFSG

films were stable(ks3.2–3.3) up to 600 8C, however,

exposure to temperature of 700 8C resulted in sharp

increase in the k-value for both films. We infer that

specific bonds in OSG and OFSG films, such as

684 Y.L. Cheng et al. / Thin Solid Films 447 – 448 (2004) 681–687

Fig. 4. Effect of different heating test temperature on the change of thickness and RI for OSG and OFSG films.

Fig. 5. Effect of different heating test temperature on the change of dielectric constant for OSG and OFSG films. 8C. This further exemplifies that both OFSG and OSG

films have sufficient thermal resistance to withstand the normal interconnect fabrication processes which do not typically exceed 400 8C.

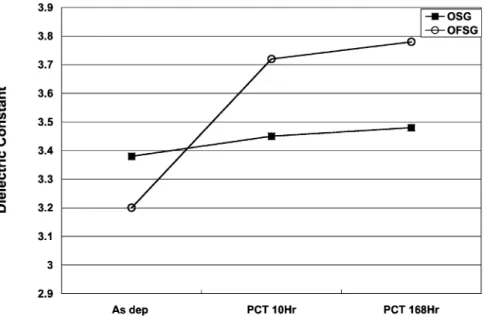

The moisture stress test results are shown in Fig. 6.

While the k values of the OSG film degraded slightly

after 168 h PCT test, similar to the result of Takeshi et

al. On the other hand, the k-value of the OFSG films

increase significantly to 3.8 only after the 10 h PCT

test. Based on this result, attention should be paid to the

moisture penetration when using the OFSG as low-k

interconnect.

Leakage current tests(Fig. 7) for films pre- and

post-PCT test indicate that both OFSG and OSG films increase significantly in current leakage after exposure. Breakdown voltages were also found to decrease from

6.3 and 7.0 MVycm to 5.6 and 6.6 MVycm for OSG

Fig. 6. The change of dielectric constant of OSG and OFSG films for pressure cooker test.

Fig. 7. Effect of PCT test on leakage current for OSG and OFSG films.

indicates that the leakage current of OFSG films after exposure is still lower than that of OSG film even before the PCT test.

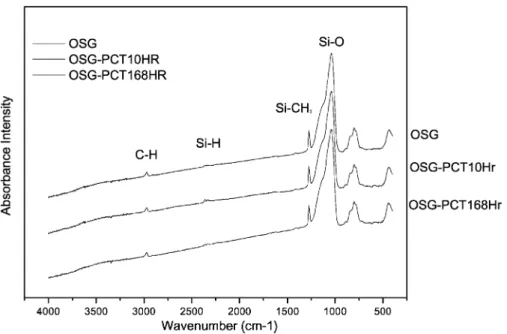

The FTIR spectra of the OSG and OFSG films before and after PCT test are displayed in Figs. 8 and 9, respectively. The FTIR spectrum of OFSG film shows a

very weak absorbance at 3500ycm appearing after PCT,

suggestive of Si–OH bonds formation. From the analysis result, the 425 8C heating process would cause Si–H bonds to decompose. The decomposition was gradual;

the resulting films still contains Si–H bonds, and the films contains a little moisture. During the PCT test, however, the Si–H is found to decompose drastically; at the same time, fewer Si–F bonds is also decomposed due to the moisture absorption. Therefore, it results in

much moisture absorption (Si–OH and H–OH). The

reactions of Si–F, Si–CH or Si–H bonds and H O can3 2

be expressed as the following formulas, respectively:

686 Y.L. Cheng et al. / Thin Solid Films 447 – 448 (2004) 681–687

Fig. 8. FTIR spectrum change of OSG film during PCT test.

Fig. 9. FTIR spectrum change of OFSG film during PCT test.

Si–HqH O™Si–OHqH2 2 (2)

Si–CH qH O™Si–OHqCH3 2 4 (3)

2Si–OH™Si–O–SiqH O2 (4)

During the PCT tests, the greater moisture absorption resulted in drastical decomposition and incomplete

con-densation. This result significantly increases both the

k-value and leakage current, so the films degrade as shown in Figs. 5 and 6.

Compared to the difference between the OFSG films and OSG films, OFSG films have less Si–H bonding and additional Si–F bonding due to mainly Si–H bond-ing in OSG films that was replaced by Si–F bondbond-ing. Therefore, OSG film contains originally the Si–C–Si bonds and Si–O–Si bonds, and also contains fewer Si–H

enough when compared with the content of Si–CH3 bonding. According to the results of Furusawa et al. w7x, the Si–C–Si did not decompose during the heating test at 700 8C or higher. The heat resistance of the films is determined by the decomposition of the Si–H and

Si–CH bonds; the decomposition temperature of Si–H3

and Si–CH bonds was approximately 700 8C and the3

bonds will be completely decomposed at higher temper-ature, no decomposition was observed for Si–C–Si, Si–H

and Si–CH3 bonds. On the other hand, partial Si–H

bonds were replaced by the Si–F bonds. And Si–F bonds did not decompose until the curing temperature is as high as 700 8C or higher. As a consequence, thickness shrinkage of the OFSG films was less than that of the OSG films. However, the moisture resistance of Si–F bonds is poor, even worse than Si–H bonds. Therefore, the moisture resistance of OFSG films is not strong enough compared to OSG films.

4. Conclusions

The resistance of OSG and OFSG films against heat and moisture stress test was investigated. Compared with OSG films, the OFSG films were shown to be

thermally stable. The k-value was stable after a heating

test at 600 8C. However, a degradation of the OFSG films after the PCT test was found due to the un-stability

of Si–F or Si–CH bonds through the moisture stress3

test. Consequently, the moisture resistance of the OFSG film should pay more attention to implement this film

as low-k interconnect dielectrics.

Acknowledgments

The authors gratefully acknowledge Taiwan Semi-conductor Manufacturing Company Ltd. for technical and financial support. As well, the authors wish to acknowledge the Electronics Speciality Gases Division, Semiconductor Process Applications Group, and Cor-porate Research Services Department of Air Products and Chemicals, Inc. for support.

References

w1x V. Ligatchev, T.K.S. Wong, B. Liu, Rusli, J. Appl. Phys. 92 (2002) 4605.

w2x Z.-C. Wu, Z.W. Shiung, C.C. Chiang, W.H. Wu, M.C. Chen,

S.M. Jeng, W. Chang, P.F. Chou, S.M. Jang, C.H. Yu, M.S. Liang, J. Electrochem. Soc. 148(2002) F115.

w3x W. Chang, S.M. Jang, C.H. Yu, S.C. Sun, M.S. Liang, in:

Proceedings of 1999 IEEE IITC, May 24–26(1999) 131. w4x J.Y. Kim, M.S. Hwang, Y.H. Kim, H.J. Kim, Y. Lee, J. Appl.

Phys. 90(2001) 2469.

w5x H.J. Lee, Y.H. Kim, J.Y. Kim, E.K. Lin, B.J. Bauer, W. Wu,

H.J. Kim, in: Proceedings of 2002 IEEE VLSI(2002) 54. w6x L.M. Han, J.S. Pan, S.M. Chen, N. Balasubramanian, J. Shi,

L.S. Wong, P.D. Foo, J. Electrochem. Soc. 148(2001) F148. w7x T. Furusawa, D. Ryuzaki, R. Yoneyama, Y. Homma, K. Hinode,