The Assessment of the Business-IT Fit in E-Procurement Systems:

A Case Study

Hsin-Lu Chang Assistant Professor Department of MIS National Chengchi U. Taipei 116, Taiwan hlchang@nccu.edu.tw Iris Chiu Engineer SQA Department Quanta Computer Inc.Tao Yuan, Taiwan Iris.chiu@quantatw.com Ching-Mei Tseng Department of MIS National Chengchi U. Taipei 116, Taiwan 94356009@ mis.nccu.edu.tw Kai Wang Assistant Professor Department of IM Ming Chuan U. Taipei 116, Taiwan kwang@mcu.edu.tw

Abstract

Because of the influence of globalization and updated information technologies (IT), firms face more and more uncertainties when they conduct daily procurement activities. This research aims to examine the fit of business and IT environment and study its impacts on the performance of alternative e-procurement systems (EP). A multiple-case study was taken in Taiwan PC-Notebook industry to verify the research framework. We find the firms’ external and internal factors do affect the performance of EP, and the influence is mediated by the levels of system integration. Low-integrated EP leads to greater performance under lower environment, partnership, and process uncertainty, and lives up to more benefits under lower knowledge skills. We also observe that lack of fit between procurement practices and EP produces extra burdens and costs at both buyer side and supplier side. Therefore, the contribution of this research can be two-folded: first, practitioners who can use this framework to diagnose their environment condition and then align to the appropriate type of EP. Second, researchers who can build upon this model to further examine the fit impact on EP performance.

Keywords: Business IT fit, Electronic procurement, Alignment, Case study, E-Business.

1. Introduction

With most organizations spending at least one third of their income on purchasing goods and services, procurement holds significant business value (Gebauer and Segev 1998). It is even possible that many organizations spending 50% to 60% of their revenue on purchasing goods and services (Kalakota and Robinson 1999). A close survey on supply chain management made at Forrester Research 2002 revealed that 62% of $1B+ the manufacturing firms surveyed deployed procurement and sourcing packaged applications and 35% of the firms could extend the applications to partners.

While more and more firms use electronic procurement systems (EP) to achieving purchasing efficiencies, they find IT alone can’t guarantee good performance. This drives us to the question how EP can deliver the promised benefits. A key concern of this question is alignment – applying IT in an appropriate and timely way and in harmony with business strategies, goals, and needs (Luftman and Brier 1999). The external environment should also be considered into the issue of alignment, since the EP can be viewed as the IT-enabled inter-organizational processes which involve multiple trading partners with a wide range of communication and IT. Although

there is no doubt that a good fit between the EP and the requirements of the business environment has positive impact on system performance, how to align is still open to question. This study attempts to better examine the business-IT alignment, and our focus will be on the EP in direct purchasing. The research questions are as follows:

(1) What impacting factors retard or encourage the successful implementation of corporate procurement systems?

(2) Under different environment conditions, which type of procurement system is more suitable for organizations in terms of the system performance?

2. Literature Review

2.1 Use of Electronic Procurement Systems

In this study, EP is defined as the application of electronic commence in procurement. It involves the use of various forms of Internet technology to automate and streamline the procurement process in business organizations (de Boer et al. 2002). Some EPs are implemented as a form of application to application (AP-to-AP) connection, some use EC Turnkey, like EDI, and others are web-based procurement systems. According to Choudhury’s typology (1997), application to application (i.e. AP-to-AP) connection and EC Turnkey are the examples of electronic dyads, where a buyer (seller) establishes individual logical links with each of a selected number of sellers (buyers) for a product. Web-based procurement system, on the other hand, is the example of multilateral IOISs, which, allows a firm to communicate with a large, potentially unlimited, number of trading partners over a single logical inter-organizational link. The system integration level is usually higher in the former type.

These technologies have been reported to have positive impacts on firm performance by some authors. Mukhopadhyay and Kekre (2002) showed in full detail that how EDI brings strategic and operational benefits for both suppliers and buyers. Other studies explored the value of web-based procurement systems (Subramaniam and Shaw 2002). Yet how to get these values is still uncertain. Therefore, we can not simply expect that firms can successfully implement EP as long as they have learned about a specific technology and found it valuable for their needs. There should be other factors which impact the performance of EP.

2.2 Studies of IT and Uncertainty

As Yu et al. (2003) argued, EP could create changes in the way organizations conduct business internally and externally and can bring many dynamic changes both outside and inside the organization. This creates a high level of turbulence and, as a result huge uncertainty to involved parties. We summarize four major types of uncertainty that could affect EP performance in the following paragraphs.

Environment uncertainty is the most obviously and wildly discussed one in the literature. It stems from the complexity of the environment and dynamism, or the frequency of changes to various environmental variables (Duncan 1972; Premkumar et al. 2005). Thus, Firms competing in an environment that existing higher uncertainty should need more reliable and timely information when they conduct purchasing decision, and therefore, challenge the performance of

EP. The second uncertainty is about partnership. Given the interorganizational nature of the EP, partner’s behavior in the future is highly uncertain to firms (Bensaou and Venkatraman 1995). Usually, firms develop long-term relationships with a few suppliers and make relationship-specific investments to minimize transaction risks (Premkumar et al. 2005). Thus, lower partnership uncertainty encourages greater information sharing between two firms, and therefore provides a closer collaboration for EP usage.

Process characteristics are categorized as the third uncertainty to EP performance. In their recent research on the value of EP, Subramaniam and Shaw (2004) referred to the fact that not all transaction processes are similar in terms of their search requirements, processing time and efforts, and errors, and so do their needs to EP. We may, therefore, reasonably expect the characteristics of the B2B process to greatly influence the realization of EP benefits. The last factor we want to emphasize is organizational knowledge. According to Grant (1996), knowledge resides in specialized form among individual organizational members and the essence of organizational capability is the integration of individuals’ specialized knowledge. A close survey on supply chain integration made by Chen et al. (2004) revealed that the technology ability and application level of SMEs would highly constrain the degree of system automation. Thereby, a firm’s knowledge to EP is a key determinant to EP performance.

2.3 The Fit Concept

The notion of fit in IS research has been an object of study for a long time. Over the past few decades a considerable number of studies have been made by using the task-technology fit (TTF) theory (Goodhue 1995). While TTF is focused on use performance and user evaluation of IT and does not use structural contingency theory of fit as its basis (Khazanchi 2005), some authors argued that there is a need for investigating fit that expands beyond the individual and task levels of analysis to organizational level of analysis. For example, Gribbins et al. (2004) expanded Goodhue and Thompson’s TTF (1995) to process-technology fit for better understanding of the acceptance and use of EP systems in organizations. In contrast to TTF, other authors use Galbraith’s information processing theory (1973) to examine the fit between information processing needs and information processing capability. The first scholars to give much attention on information process theory were Bensaou and Venkatraman (1995). Following that, Premkumar et al. (2005) investigated fit in the interorganizational level of analysis and empirically examined its effect on performance.

Although above studies are important to examine the relationship of alignment, there is no comprehensive framework to consider all important factors together. Therefore, we propose that there is a need to consider both internal and external business environment when understanding the usage of EP. There are several reasons for this proposition. First, while TTF scholars focus on internal characteristics, other IOIS scholars give much attention to external characteristics and interaction relationship. Both views are quite unsatisfactory, given that they only consider one perspective of the problems. As EP is an IOIS which creates changes in the way organizations conduct business internally and externally and can bring many dynamic changes both outside and inside the organization (Yu et al. 2003), its performance should be influenced by both internal and external corporate environment.

Second, more and more scholars believe that the individual and task level of analysis are not applicable to EP study (Gribbins et al. 2004; Khazanchi 2005). They argue that organizations usually pursue excellence as a whole, rather than simply at individual’s task. Besides, EP is a process-based IT solution which can consist of a suite of applications that are integrated to support the processes rather than independent tasks (Gribbins et al. 2004). Therefore, it seems reasonable to examine process rather than task characteristics. Third, to realize the strategic importance of EP, previous research has spent plenty effort to exploit barriers and facilitators. However, organizations differ greatly in their abilities to utilize the application and translate it into tangible benefit. Adopting a technology is one thing, having the capability to use it is another. Organization’s own knowledge base would be a key part of business environment, but is not well discussed in previous IT alignment studies.

3. Development of the Business-IT Fit Framework

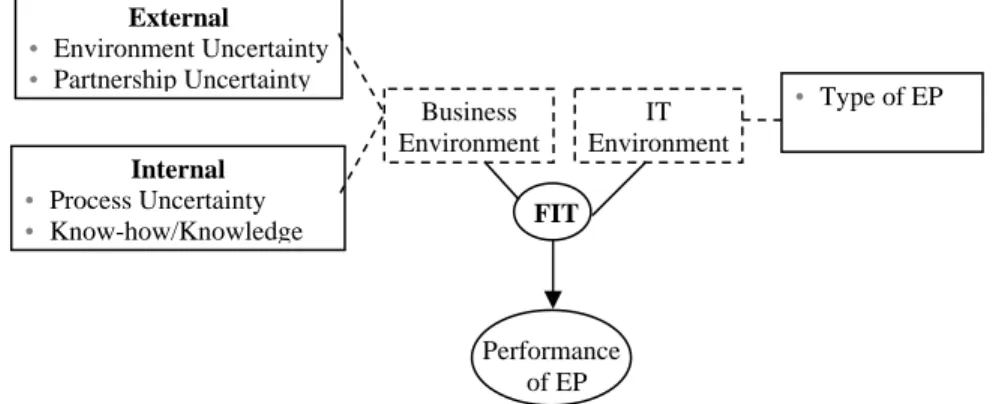

Due to the insufficiencies of previous works which are mentioned above, we aim to synthesize the previous research to develop a comprehensive framework that evaluates the impact of EP usage on firm performance under the consideration of corporate external environment, internal processes, and organizational knowledge. The proposed business-IT fit framework is shown in Figure 1. External y Environment Uncertainty y Partnership Uncertainty Business Environment Performance of EP IT Environment Internal y Process Uncertainty y Know-how/Knowledge y Type of EP FIT

Figure 1. Research framework for the development of business-IT fit

As to the type of EP, we have summarized three different EP technologies: AP-to-AP, EC turnkey, and web-based procurement systems, each having different degrees of integration between suppliers and customers. To simplify the analysis, we categorize them into two groups: low-integrated EP and high-integrated EP.

3.1 External Uncertainty vs. IT Environment

3.1.1 Environment Uncertainty

In the procurement context, the changes in demand and supply are the major environment uncertainty that influences firm’s information need (Premkumar et al. 2005). When the uncertainties are high, firms need to communicate the frequent changes of demand with their suppliers. Under such conditions, EP that provides near-real-time structure information to trading partners is preferred (Premkumar et al. 2005). On the other hand, product customization is another resource of such uncertainty (Bensaou and Venkatraman 1995). The arrangement of high-integrated EP system reduces coordination costs over those incurred in a market by eliminating the firm’s effort to gather and analyze a great deal of information about different

trading partners. Therefore, under high environment uncertainty, we expect that firms with tight integration between their trading partners would reduce more coordination costs and achieve better performance. Therefore, our proposition is as follows,

Proposition 1: A highly integrated EP can lead to greater performance under higher levels of environment uncertainty.

3.1.2 Partnership Uncertainty

Firms and suppliers are more certain about their partnership when they have made reciprocal investments, because these investments provide a strong signal to the other party about their desire for long-term relationships (Premkumar et al. 2005). In line with reciprocal investments, trust between firms and partners is recognized as an effective mechanism to reduce the partnership uncertainty (Premkumar et al. 2005). As firms have confidence that the behavior of their suppliers conforms to their own expectation, the perception of risk associated with partners’ opportunistic behavior can be highly reduced, and therefore encourages grater information sharing between both. Since both reciprocal investments and trust can promote good relationship, we can derive that, the coordination costs that take into account the costs of gathering information, negotiating contracts, and protecting against the risks of opportunistic bargaining are relatively high in an uncertain partnerships. The previous discussion points out the coordination costs can be highly reduced in the arrangement of highly integrated EP system, thereby we proposing:

Proposition 2: A highly integrated EP can lead to greater performance under higher levels of partnership uncertainty.

3.2 Internal Uncertainty vs. IT Environment

3.2.1 Process Uncertainty

According to Subramaniam and Shaw (2002, 2004), there are following types of procurement on the two ends of a continuum. At the one end is the structured procurement of which processes are highly automated and product specifications do not change frequently. At the other end is the unstructured procurement of which processes are manually initiated and the technical or design requirement for the products are difficult to predict accurately. The needs of EP systems vary in each procurement type (Subramaniam and Shaw 2004). For unstructured procurement, firms need to exchange information more frequently with its trading partners, and trading partners need to deal with several different sources of information to process procurement activities successfully (Premkumar et al. 2005). Therefore, a more integrated EP which allows firms and trading partners to access relevant information timely is preferred. Since the complexities and dynamisms of processes and underlying products are higher for unstructured procurement than structured procurement, we can propose that,

Proposition 3: A highly integrated EP can lead to greater performance under higher process uncertainty.

3.2.2 Know-how/Knowledge

Past literature recognized that the key skills and know-how of firms have persisting effects on relative performance (Kogut and Zander 1992). The theory of diffusion of innovation helps account for this statement. Rogers (1995) stated that organizations often delay adoption of complex technologies until they obtain sufficient know-how to implement the computer innovation successfully. Chen (2004) also mentioned that a lack of technical knowledge is a

barrier to IT implementation. In contrast to technical knowledge which is explicit and codifiable, managerial IT skills are tacit and often developed over longer periods of time through the accumulation of experience by trial and error learning (Mata et al. 1995, Yu et al. 2003). Mata et al. (1995) referred that in addition to technical IT skills firm needs to possess managerial IT skills to realize the full potential of EP (Mata et al. 1995). We can expect that a highly integrated EP requires more technical and managerial skills than EP at low levels of integration. Hence, we put forward the following proposition:

Proposition 4: EP usage in the form of low-integrated system can lead to greater performance under lower knowledge skills.

4. Research Analysis

4.1 Case Background

A multiple-case study is used to test our framework. We study four Taiwanese-owned Chinese companies in the Personal Computer (PC)-Notebook (NB) industry. All these four companies are suppliers to a large PC OEM and they are currently using a web-based EP system initiated by the OEM to facilitate their procurement process. A summary of these four companies is presented in Table 2.

Table 2. Cases Background

Firm 1 A mechanical supplier provides casting materials to the OEM. The casting material means the top cover and upper/bottom case of a NB.

Firm 2 A packaging supplier provides label materials to the OEM. The label material means the colorful stickers in the low case of a NB.

Firm 3 An electrical engineering supplier provides cable materials to the OEM. The cable material means all kinds of cables in a NB, such as power cable, monitor cable, USB cable, data cable and so forth. Firm 4 Another electrical engineering supplier provides passive components to the OEM.

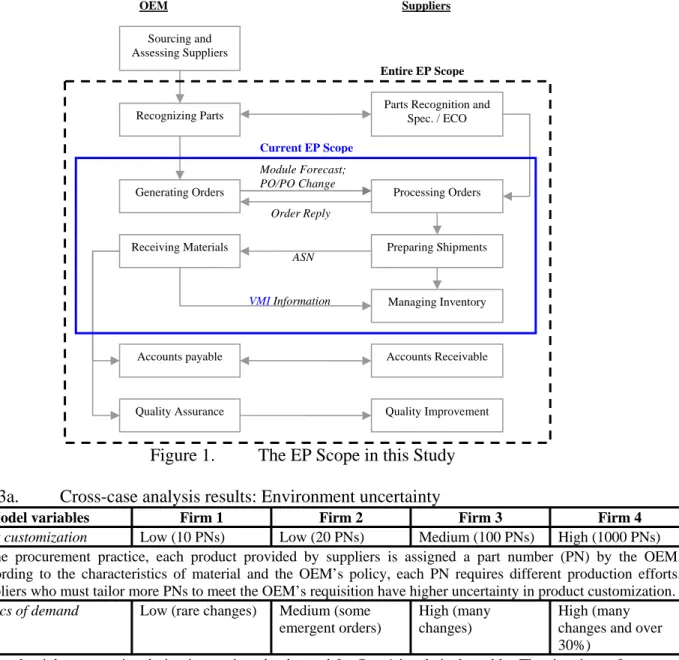

4.2 System Background in the Cases

Before analyzing the cases, we first introduce the underlying EP system used in each firm. Given “procurement” is an overall term; it is composed of sourcing and purchasing (Favre and Brooks, 2002). For the OEM, the operation of sourcing is done by its Headquarter in Taiwan, including activities such as strategy definition, suppliers pre-qualification, contracts negotiation, and supplier relationship management etc. The daily purchasing is done by local procurement departments, which is facilitated by the underlying EP system shown in Figure 2. Although this EP system initially attempted to automate the entire purchasing cycle (indicated as the dotted rectangular of Figure 2), its activated functions are merely ordering and shipping processes by now. Via the system, suppliers can transform purchase orders (PO) into advanced shipping notices (ASN). However, system to system integration is not available. OEM buyers need to re-key the ASN into their ERP and then generate the invoices in a monthly basis. In the circumstance of vendor-managed inventory (VMI), extra hub information is sent to the suppliers for decision making.

4.3Framework Application

In different environmental conditions, is the EP in this case more suitable than in other cases in terms of the system performance? How does each case company accommodate the EP to better align with its corporate environment? To answer these questions, we next interpret the cases in light of the research framework we proposed in the earlier section (Figure 2).

4.3.1 Environment uncertainty

We use product customization, demand dynamics and supply dynamics to capture the external environment uncertainty (Duncan 1972). In general, firm 1 has the lowest environment uncertainty due to few parts number (PN), rare order changes, and less coordination required during the shipment. The analysis is summarized in Table 3a.

Figure 1. The EP Scope in this Study

OEM Suppliers Sourcing and Assessing Suppliers Recognizing Parts Generating Orders Receiving Materials

Parts Recognition and Spec. / ECO Processing Orders Preparing Shipments Managing Inventory Accounts Receivable Quality Improvement Accounts payable Quality Assurance Module Forecast; PO/PO Change Order Reply VMI Information ASN Current EP Scope Entire EP Scope

Table 3a. Cross-case analysis results: Environment uncertainty

Model variables Firm 1 Firm 2 Firm 3 Firm 4

Product customization Low (10 PNs) Low (20 PNs) Medium (100 PNs) High (1000 PNs) In the procurement practice, each product provided by suppliers is assigned a part number (PN) by the OEM. According to the characteristics of material and the OEM’s policy, each PN requires different production efforts. Suppliers who must tailor more PNs to meet the OEM’s requisition have higher uncertainty in product customization.

Dynamics of demand Low (rare changes) Medium (some emergent orders)

High (many changes)

High (many changes and over 30%)

Due to the tight cooperative design interaction, the demand for firm 1 is relatively stable. The situations of emergent order often occur for firm 2 due to its labeling material is needed at the end of production stage. Firm 3 incurs a huge gap between forecast and actual order, making them “confirm the demand every day”. The informant of firm 4 reflected that “in the usual case, there is over 30% of product specifications and usage change after the order submission.”

Dynamics of supply Low-medium (Goods return problems)

Low (Emergent PO) High (Need Coordination of extra support person)

High (Hub delivery)

backups. The updated shipping information is therefore needed for firm 1 to handle goods returned. Firm 2 conducts direct shipping. The supply availability could be affected due to the emergent orders. The shipments of firm 3 and firm 4 are unsettled. In firm 3’s circumstance, it even deploys an extra support person to stand by in the OEM’s warehouse and coordinate shipment. As to firm 4, though there is no fixed shipping schedule, it must maintain approximately 10 days’ inventory level in the hub.

Environment uncertainty: Low Low-medium Medium-high High

4.3.2 Partnership uncertainty

In terms of partner uncertainty, Bensaou and Venkatraman (1995) identified three variables to capture the transaction risks—the focal firm’s asset specificity, partner’s asset specificity, and mutual trust, which were latter used by Premkumar et al. (2005) to represent the uncertainty in a customer-seller relationship. We use the similar conceptualization to measure partnership uncertainty but combine the focal firm’s and partner’s asset specificity as one single item, reciprocal investment. Firm 1 again has the lowest partnership uncertainty as it has intensive co-design activity and has long-lasting cooperation history with the OEM. The analysis is shown in Table 3b.

Table 3b. Cross-case analysis results: Partnership uncertainty

Model variables Firm 1 Firm 2 Firm 3 Firm 4

Reciprocal investment Medium (Iterative Co-design) Medium-low (Co-design) Low (Standard products, No R&D interaction) Low (Standard products, No R&D interaction)

Reciprocal investment is mostly occurred at the cooperative design activities. Firm 3 and firm 4 have relatively few mutual investments than the other two firms because cable materials and passive components, which are standard products and can be reused in several models, do not need much R&D interaction with the OEM.

Trust High (Mutual trust) Medium (Loses

track of shipments) Medium-low (Suspicion of allocation changes) Low (Suspicion of allocation changes and Hub problem) The informant of Firm 1 talked about a long lasting cooperation history with the OEM and held a very positive view about their efforts on this EP system development. Firm 2’s trust to the OEM is moderate. A lack of a well-developed communication system to deal with order exceptions reduces the trust between Firm 2 and the OEM. For firm 3 and firm 4 the trust with the OEM is even worse. We found both firm 3 and firm 4 suspected that the procurement executives of the focal firm changed contract allocation among suppliers arbitrarily. Especially for firm 4 who delivers products through Hub, felt extremely frustrated.

Partnership uncertainty: Low-medium Medium High High

4.3.3 Process uncertainty

Process uncertainty refers to the dynamisms and complexity of the procurement process and of the underlying products (Bensaou and Venkatraman 1995, Choudhury 1997, Subramaniam and Shaw 2002, 2004; Premkumar et al. 2005).Firm 2 has the lowest process uncertainty of all the other three firms due to its simple order management process, and special but simple products (i.e. labeling materials). More details can be referred to Table 3c.

Table 3c. Cross-case analysis results: Process uncertainty

Model variables Firm 1 Firm 2 Firm 3 Firm 4

Dynamics of process Medium (Fulfill order, return process)

Low (Fulfill order) High (Fulfill order, contact extra support person)

High (Fulfill order, coordinate hub delivery)

The major tasks of the order management process are diverse among 4 cases. For firm 1, the sales representatives are responsible of fulfilling order, coordinating and contacting RD personnel of both sides, and managing the return of

defective items. In contrast, firm 2’s sales people only need to manage order fulfillment and trace the design drawing in case of missing, since their RD design and reverse logistics is not as complicated as firm 1. On the other hand, the sales people of firm 3 need to spend extra efforts to manage order fulfillment. They must get contact with the procurement executives of the focal firm and their assistants there to get shipping information. Accordingly, most of their working time is spent on PO maintenance. For firm 4, the sales people pour great efforts in fulfilling order as well. However, contact subjects are slightly different. They need to coordinate with Hub personnel besides the procurement executives of the focal firm to ensure the fulfillment is done. In their opinion, the Hub personnel are too passive and insufficient in cooperation, resulting in a very poor exceptions handling. At most of the time, they still need to strive alone.

Dynamics of product High (Change by every module in the form, function and structure etc.) Low-medium (Change by every module in graph.) Low (Standard material) Low (Standard material)

In firm 1’s case, casting materials are special materials which are incompatibly across different modules. Namely, a cast only corresponds to a single NB module. Before providing such product, firm 1 need to discuss the form, the operation, the material, the function and the structure of a cast. On the contrary, firm 2, firm 3 and firm 4 have no cooperative R&D problems, given that labels are simple materials and cables as well as passive components are relatively standard materials. However, firm 2 face more frequent product change, for the context of labels is set along with the specifications of separate modules, and the specifications sometimes change with the requirements of customers or the upgrades of NB versions.

Complexity of product High (Special and dedicated material)

Low (Special but simple material)

Medium (Standard material)

Low-medium (Standard material) The casting materials produced by firm 1 belong to dedicated/special materials and must go through several stages before commercial production (Lead time: 1 month; Duration of a batch production: 3~5 days). The product complexity is relatively high compared with the other three. The labeling materials provided by firm 2 are part of dedicated materials, but there is no complicated R&D or material recognition (Lead time: 1 week; Duration of a batch production: 1 day). The cable materials supplied by firm 3 are standard materials with medium technology complexity (Lead time: 1 month; Duration of a batch: 1~2 days). Firm 4 produces passive components, which are standard materials with low technology complexity (Lead time: 1~2 months; Duration of a batch production: 3days).

Process uncertainty: Medium-high Low Medium Low-medium

4.3.4 Know-how/Knowledge

Technical IT skills and managerial IT skills are used to measure the knowledge and know/how required for EP use (Mata et al. 1995, Yu et al. 2003). Firm 4 have the highest technical and managerial skills for its various IT connections and abundant IT implementation experience. Table 3d summarizes the result.

Table 3d. Cross-case analysis results: Knowledge/Know-how

Model variables Firm 1 Firm 2 Firm 3 Firm 4

Technical skills Medium (No

difficulty with current EP) Medium (No difficulty with current EP) Medium (No difficulty with current EP)

High (Even has EDI and RosettaNet conncection capability)

Since all these four companies run the EP system smoothly, we may say that all of them have certain degree of IT capabilities. To discuss their technical skills further, we looked into their transactions with other firms. No surprisingly, they do business with others via various EP systems and some of the systems require higher level of technical skills. For instance, firm 4 has also built EDI and RosettaNet connections.

Managerial skills Low (Not shown) Medium-low (coordination skills) Medium (on-site support) High (“Willing” to do further via advanced system) Firm 1 didn’t suffer much environmental uncertainty, so they did not show many managerial skills about current procurement practice. Firm 2 and firm 3 show apparent coordination skills in the form of their frequent interaction

with the executives of the focal firm. To support delivery and transportation, firm 3 even sent an extra assistant to the focal firm’s warehouse. As for firm 4, it spent great effort to coordinate procurement activity as well. In order to avoid the due date delay firm 4 proposed a solution which directly linked the EP to their organizational system via EDI to maintain the status of order automatically. Though the proposition was denied eventually, there is no doubt that firm 4 have sufficient ability and willingness to improve the performance of procurement activities.

Know-how/Knowledge Medium-low Medium Medium High

4.4.5 Performance

The performance of EP can be measured from several different perspectives. Mukhopadhyay and Kekre (2002) proposed a two-stage model of benefits in which IT are viewed as creating direct, first-order benefits, which in turn generate indirect, second-order benefits. According to them, the first-order benefits include: (a) direct strategic benefits typically in terms of sales gains, and (b) direct operational benefits typically in terms of process-based operational measures, such as the improvement of order-processing cycle and timeliness of payments. The second-order benefits are indirect strategic benefits that are influenced by direct benefits created by IT and accrue over an extended period of time. In our paper, we only consider the first-order benefits. Of all the case companies, firm 1 had the least complaints about the EP system and mentioned the most operational benefits related with time and error reduction. The analysis can be found in Table 3e.

Table 3e. Cross-case analysis results: EP Performance

Model variables Firm 1 Firm 2 Firm 3 Firm 4

Operational benefits High (Great benefits in term of time and error reduction and ASN)

Medium (Benefits from error reduction & ASN; (few complaints))

Low-medium (Benefits from ASN ; (many complaints))

Low (Few benefits)

Operational benefits such as time and error reductions related to payments and order confirmation and increasing accuracy of order processing are mentioned in firm 1, firm 2, and firm 3 in some extent. Given that the EP system can transform PO into advanced shipping notice (ASN) automatically, the inconsistencies between PO and shipping notice mitigate greatly. Despite these benefits, firm 2 and firm 3 mentioned more or less that current system fails to support their procurement practices, especially in firm3’s case. For firm 4, their sales didn’t think the EP brings much convenience to their daily operation. Instead, they complained most information provided by the system is inaccurate and out of date. And unfortunately, because of Hub delivery instruction, ASN is useless in firm 4’s case.

Performance: High Medium Low-medium Low

5. Discussion

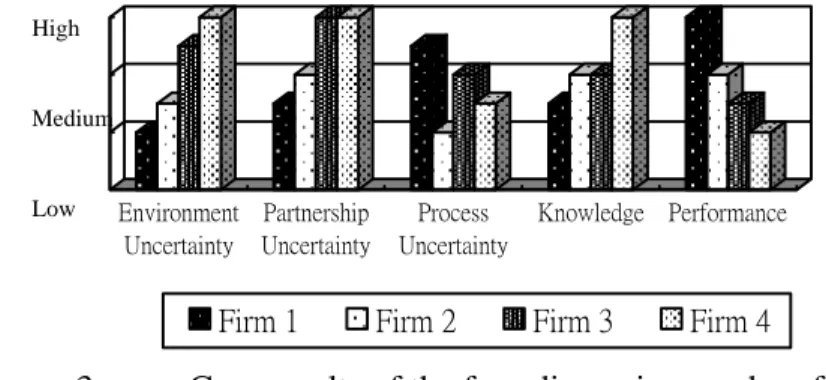

A simple bar chat shown as following figure 3 summarizes the case analysis. As the diagram indicates, firm 1 and firm 2 belong to a low level of environmental uncertainty, while firm 3 and firm 4 belong to a high level of environment uncertainty. The need of accurate and timely forecasts and shortage information are emphasized in the cases of firm 3 and firm 4 since they have to deal with greater dynamics of demand and supply. However, the forecasts may come from various sources. EP systems which can help integrate such information from different sources should be especially beneficial to suppliers like firm 3 and firm 4.

Figure 3 also shows that partnership uncertainty increases progressively from firm 1 to firm 4. It seems that the reciprocal investment does not impact the performance much in our cases since the level of reciprocal investment is quite indiscriminate in all cases. We find that firm 2, firm 3, and firm 4 suspect that the OEM doesn’t conform to its pre-determined order allocation. These

suspicions lead to low perceived benefits of the current EP system and give rise to more information need to handle the perception of risk associated with partners’ opportunistic behavior.

The situation of process uncertainty is more complicated. In previous literature, as we have seen, the complexity of procurement process is highly related to the products upon them. However, we find that they are negatively related in these four cases. Specifically, the less specific and dynamic the materials are, the more suppliers competed in the market. Therefore, each supplier has smaller power and is asked to follow the rule made by the buyer. Suppliers in such circumstance need to pay additional efforts to process the transaction successfully. In fact, firm1, firm3 and firm4 do express that the current EP system can’t support them to process order fulfillments successfully. Environment Uncertainty Partnership Uncertainty Process Uncertainty Knowledge Performance

Firm 1 Firm 2 Firm 3 Firm 4

High

Medium

Low

Figure 3. Case results of the four dimensions and performance

Finally, the level of knowledge skills is higher in firm3 and firm4. Firm 4 who shows the most mature capability in both IT and managerial skills has better know-how in technology. But for other suppliers, they do not have such strong knowledge bases as firm 4. Besides, the OEM, in our case, spends few efforts training the suppliers using the EP systems. Most of the suppliers admit that they grope for the system’s function on their own. We also find that even with lower knowledge skills, firm 1 and firm 2 still view the current web-based EP system simple enough for them to get familiar in the short run.

In summary, these four suppliers can be roughly divided into two groups. Firm 1 and firm2 have relatively lower external uncertainty and higher internal uncertainty. Firm 3 and firm 4 are in the contrary. Our case study shows that the low integrated web-based EP system drives better performance in suppliers like firm 1 and firm 2, which is consistent with our propositions. Nevertheless, firm 3 and firm 4 show sufficient capability and willingness to reduce their uncertainties and improve performance eventually. Though a simple basic EP system can not live up to expected benefits in complex and dynamic environment, a powerful highly integrated EP system can not fit all suppliers neither. Firms may prefer to maintain a unique EP system due to cost consideration and other concerns. However, we argue that companies should align their EP with different suppliers just like they provide several versions of their products for different customers to get maximum profits. Fit between business environment and technology can produce win-win situation and best profits to both buyer and sellers.

6. Conclusion

Through the empirically case study, we find the firms’ external and internal factors can affect the performance of EP. That is, EP usage in the form of low-integrated system may lead to greater performance under lower environment, partnership, or process uncertainty, and lives up to more benefit under lower knowledge skills. We also observe that lack of fit between procurement practices and EP system produces extra burdens and costs to companies. Such costs are reflected in the performance of both buyer side and supplier side. Therefore, companies should align their EP with different trading partners to get maximum efficiency and benefits. The IT context of this case study focuses on low-integrated systems which are the most popular means of e-commerce transaction in Taiwan manufacturing industry and leaves highly-integrated EP an unsettled subject. In the future we can design more quantifiable measures to further validate the result derived from the case study.

7. References

1. Bensaou, M., and Venkatraman, N. "Configurations of interorganizational relationship: A comparison between U.S. and Japanese automakers," Management Science (41:9), 1995, pp. 1471-1492.

2. Chen, H., Themistocleous, M., and Chiu, K.H. "Approaches to supply chain integration followed by SMEs: An exploratory case study," The 10th Americas Conference on Information Systems

(AMCIS2005), New York, NY, 2004, pp. 2610-2620.

3. De Boer, L., Harink, J., and Heijboer, G. "A conceptual model for assessing the impact of electronic procurement," European Journal of Purchasing & Supply Management (8) 2002, pp. 25-33

4. Duncan, R.B. "Characteristics of organizational environments and perceived environmental uncertainty," Administrative Science Quarterly (17:3), 1972, pp. 313-327.

5. Favre, D. and Brooks, J. “E-sourcing: procurement’s leading edge,” ASCET (4), 2002, pp. 74-76. 6. Gebauer, J., and Segev, A. "Assessing internet-based procurement to support the virtual enterprise,"

CALS Expo International and 21st Century Commerce: Global Business Solutions for the New Millennium, Long Beach, CA, 1998

7. Grant, R.M. "Prospering in dynamically-competitive environment: Organizational capability as knowledge integration," Organizational Science (7:4), 1996, pp. 375-387.

8. Gribbins, M.L., Subramaniam, C., and Shaw, M.J. "The impact of process and technology factors on user's assessment of the fit of e-procurement with the procurement process," The 3rd Workshop on

E-Business (WeB2004), Washington, DC, 2004.

9. James I. Cash, J., and Konsynski, B.R. "IS redraws competitive boundaries," Harvard Business

Review, 1985, pp. 134-142.

10. Kalakota, R., and Robinson, M. E-Business: Roadmap for Success Addison-Wesley, MA, 1999 11. Luftman, J., and Brier, T. "Achieving and sustaining business-IT alignment," California Management

Review (42:1), 1999, pp. 109-122.

12. Mata, F.J., Fuerst, W.L., and Barney, J.B. "Information technology and sustained competitive advantage: A resource-based analysis," MIS Quarterly (19:4), 1995, pp. 487-505.

13. Mukhopadhyay, T., and Kekre, S. "Strategic and operational benefits of electronic integration in B2B procurement processes," Management Science (48:10), 2002, pp. 1301-1313.

14. Premkumar, G., Ramamurthy, K., and Saunders, C.S. "Information processing view of organizations: An exploratory examination of fit in the context of interorganizational relationships," Journal of

Management Information Systems (22:1), 2005, pp. 257-294.

15. Subramaniam, C., and Shaw, M.J. "A study of the value and impact of B2B e-commerce: The case of web-based procurement," International Journal of Electronic Commerce (6:4), 2002, pp. 19-40. 16. Yu, S., Mukhopadhyay, T., and Slaughter, S. "Organizational capabilities and the assimilation of

electronic procurement in service industries," The 24th International Conference on Information