E L S E V I E R Materials Science and Enga

Role of grain size

leering A225 (1997) 135-I44

on the stress

aluminum

M A T E R I A L S SCIEHCE & E N G I N E E R I N GA

corrosion cracking of 7475

alloys

T.C. Tsai

Institute of Materials Science and EngineerA b s t r a c t

Receiv(

T.H. Chuang *

ng, National Taiwan UHiversity, Taipei, Taiwan, ROC

d 22 August 1996

The effect of grain size upon the stress corrosion cracI:ing of 7475 Al-alloy plates has been investigated. Grain refinement resulted in a more homogeneous slip mode and a smaller size of grain boundary precipitates (GBPs) to influence the stress corrosion cracking (SCC) resistance• The more homogeneous slip mode is always beneficial for improving the SCC resistance. However, ff the GBPs size was smaller than a critical preclpltate size for nucleating hydrogen bubbles, the improvement of SCC resistance due to grain refinement, resulting from a more hdmogeneous slip mode, could not be obtained. The correlation of SCC susceptibility and hydrogen embrittlement susceptibility has been evaluated. The SCC susceptibility of the 7475 alurninum alloys is mainly controlled by hydrogen induced cracking mechanism. © 1997 Elsewer Science S.A.

Keywords: Grain refinement; Grain boundary precipitates; Stress

1. I n t r o d u c t i o n

High strength A I - Z n - M g - C u (7xxx series) aJu- minuln alloys are widely used in airframe construction However, this series of alloys are suscepuble to stress

I corrosion cracking (SCC) to limit their usefulness, par-_ ticularly when they are aged to the near peak strength of T6 temper [1,2]. Their susceptibility to SCC can be eliminated by overaging to a T7 type temper but with a

i concomitant loss of about 10-15% in strength• A hdat i treatment known as retrogression and reaging (RRA) has been developed to g~ve SCC resistance eqmvalent to

• I

that of T73 temper together wlth T6 strength levels [3,4]• This treatment has been applied to material in the T6 condition and consists of reheating the material for a short time in the temperature range of 200-260iC (retrogression treatment), followed by reaging using the same conditions as in the original T6 aging process• An optimum condition for the SCC testing is to retrogress

• o " • I

the materials at 220 C for 5 mm, followed by reagmg. It has produced the best SCC results [5,6]. I

Burleigh [2] summarized three main mechanisms for SCC in aluminum alloys. They are anodic dissolutidn,

* Corresponding author. Tel.: + 886 02 3630231; fax: + 886 02 3934562.

corrosion cracking; Hydrogen embrittlement

hydrogen induced cracking (HIC) and passive film rup- ture. He also indicated that anodic dissolution is gener- ally favored in the 2xxx series aluminum alloys while H I C is favored in the 7xxx series• It is well known that the hydrogen embrittlement (HE) is the most severe for underaged tempers, intermediate for peak strength tem- pers and minimal for overaged tempers [7,8]. The R R A tempered condition could effectively improve the SCC resistance of 7xxx series alloys in the T6 temper• It is suggested that the R R A tempered condition can provide a larger size of grain boundary precipitates (GBPs) to nucleate the hydrogen bubble, then reduce the hydrogen concentration in the grain boundary and improve the HE resistance [4,6].

Grain refinement can be made by thermo-mechanical treatment for 7xxx series aluminum alloys, and fre- quently results in beneficial effects for mechanical prop- erties [9-11]. Wanhill and Gestel [9] have even summarized the results of grain refinement on stress corrosion tests. They found that thermo-mechanical treatment is always advantageous to the SCC resis- tance, but sometimes grain refinement has no profit on improving the SCC resistance. Fine grain microstruc- ture in high strength aluminum alloys, such as 7475 aluminum alloy, has been commercialized and applied in air frame constructions by using a superplastic form-

0921-5093/97/$17.00 © 1997 Elsevier Science S.A. All rights reserved.

136 T.C. Tsai, T.H. Chuang/Materials Science and Engbwering A225 (1997) 135-144 Table 1

Chemical Compositions (wt.%) of the 7475 aluminum alloys

Alloy Zn Mg Cu Cr Fe Si Mn Ti A1

7475S 5.80 2.24 1.53 0.19 0.08 0.02 0.01 0.02 BaI.

7475L 5.96 2.18 1.54 0.21 0.09 0.02 0,01 0.01 Bal.

Table 2

Intercept grain sizes of the 7475 aluminum alloys

A l l o y Longitudinal direction (gm) Long transverse direction (gm) Short transverse direction (gin)

7475S 12.5 12.1 9.2

7475L 110.8 93.6 16.6

ing process [12,t3]. Shin et al. [14] found that a maxi- m u m ductility of approximately 2000% could be ob- tained when the tensile specimens of the fine-grained 7475 alloy were tested at 530°C and at an initial strain rate of 2.8 × 1 0 - s s - 1. However, a superplastic 7475 alloy was found to suffer from atmospheric SCC if it was treated in T4 and T6 tempered conditions [15]. It indicated that a superplastically formed workpiece of superplastic 7475 aluminum alloy is necessary to p a y attention to the property o f SCC susceptibility. There- fore, a detailed understanding of the effect of grain size on SCC resistance needs to be achieved.

The microstructural characteristics of 7xxx series alu- m i n u m alloys are well known to have a strong effect on SCC susceptibility. The m a j o r microstructural features have been discussed concerning the influence of SCC to be the precipitate free zone (PFZ), the matrix precipi- tate structure and the G B P structure [16-18]. The purpose of this investigation is to evaluate the relation- ship between SCC susceptibility and H E susceptibility, and use the hydrogen induced cracking mechanism to analyze the influence of grain size upon the SCC sus- ceptibility.

2. Experimental procedures

2.I. M a t e r i a l s and heat treatmentsThe material used in this study was a commercial superplastic 7475 aluminum alloy (7475S) in T4 tem- pered condition. The nominal chemical composition is listed in Table 1, This material, supplied as a 2 m m thick plate, possessed an average grain size o f about 10 g m as shown in Table 2. All the heat treatment proce- dures including the T4, T6, R R A and T73 conditions are described in Table 3.

A commercial, non-superplastic and 2 m m thickness 7475 (7475L) aluminum alloy plate with average grain size o f about 100 gm was also used in this investigation.

The chemical composition of 7475L atloy is also shown in Table 1. The SCC resistance of this 7475L alloy was used to c o m p a r e with that of the fine grained 7475S alloy in the T6 and T73 tempered conditions. It is helpful for analyzing clearly the influences of grain size and microstructure upon the SCC susceptibility. 2.2. M e c h a n i c a l and stress corrosion testing

Tensile specimens with longitudinal direction for each heat treatment condition were used to measure mechanical properties and aqueous SCC resistances. Rectangular tensile specimens with a gauge length of 25 m m and a width of 6 m m were used. Tensile tests were performed at a strain rate of i 0 - ~ s - t in air to obtain 0.2% offset yield strength, tensile strength and elonga- tion. The SCC tests were assessed by using slow strain rate tests (SSRT) [19]. The S S R T have the advantage that they will p r o m o t e SCC in systems that in static tests either do not crack or take a particularly long time to show evidence of failure. The specimens o f SSRT were tested at a strain rate of 4 x 10 - ~ s - t in air and in 3.5% NaCI + 0.3% H202 solution, respectively. The SCC susceptibility for each heat treatment could be evaluated by means of comparing the elongation loss between the elongation o f testing in air and testing in stress corrosion solution.

Table 3

Heat treatment procedures for alloy investigated Temper Condition Aging treatment

T4 u Underaged As naturally aged to stable T6 ~ Near peakaged 24 h/120°C

RRA ~ Peakaged T6 aged + 5 min/220°C + WQ + T6 T73 a Overaged 6 h/i07°C+24 h/163°C

a Solution treated at 515°C For 1.5 h+water quenched (WQ). b As received for superplastic 7475 aluminum alloy.

T.C. Tsai, T.H. Chuang /Materials iScience and Engineering A225 (1997) 135-i44

I

I

137

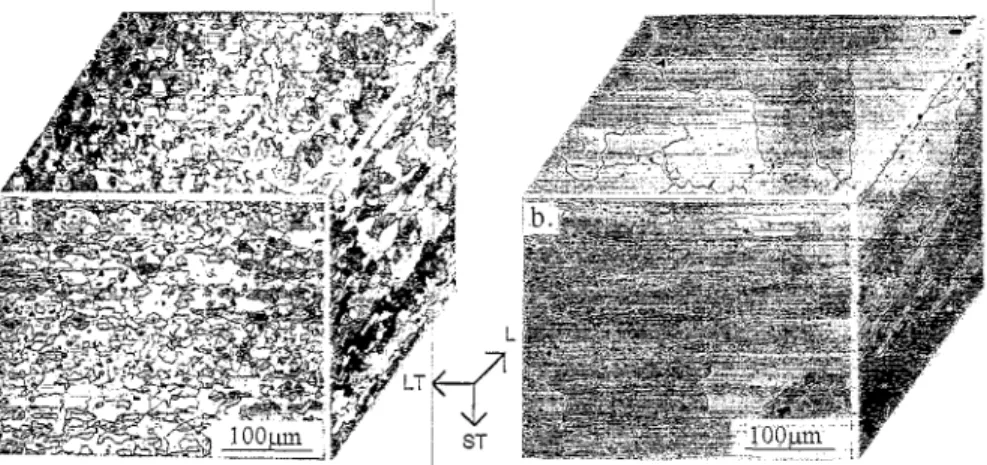

Fig. 1. Three dimensional micrographs showing grain structures of the as-received (a) 7475S and (b) 7475L aluminum alloy plates. !

Table 4 [

MechanicaI properties of tensile test for various tempered conditions ~

Temper Ultimate strength (MPa) Yield strength (MPa) EIongation (%)

7475S-T4 569.1 7475S-T6 592.9 7475I_-T6 551.8 7475S-RRA 572.3 7475S-T73 500.4 7475L-T73 481.6

Tensile test at a strain rate of ~= I0 -3 s -~ in air.

2.3. Hydrogen embrittlement testing

461•5 20•0 511.0 16.I 448.5 15.5 514.5 9.6 356.6 13.1 348.6 10.2 2•4• Microstructure observation For proving the relationship of SCC and HE for dl

heat treatment conditions, both hydrogen-charged a i d uncharged tensile specimens for each tempered condi- tion were used to obtain HE resistances. Tensile tests I

were performed in air at an initial strain rate of 3.3 ix 10-4 s-1. At least three charged specimens for e@h heat treatment condition were prepared by using strain- ing electrod test (SET) method described previously [7]. In this test, specimens were preloaded to approximately 70% of the yield strength, exposed to the cathodic charNng in an electrolyte of HC1, pH i under a con- stant potential of - 1500 mV (measured versus a stun-, dard calomel electrode, SCE), and then strained at I a slow strain rate of 4 x l0 -6 s-1. Straining was contin- i

ued for varying times chosen to correspond to a total I

plastic strain of about 2%. Following this straining

• • [

period, the solution was removed, the specimen rinsed and dried, and then pulled to fracture in air at the

4 I

hi~her strain rate of 3 3 x 10- s - The HE suscepti-

• ~ . . I

bxhty for each tempered condltlon could be evaluated by means of comparing the elongation loss between the elongation of uncharged and charged specimens.

Optical microscopy (OM) and transmission electron microscopy (TEM) were utilized to observe the mi- crostructural change• Samples for OM were chemically etched in Keller's Reagent, and thin foils were prepared by twin jet electropolishing in a HNO3: methanol = 2:1 solution cooled to - 25°C, using a potential of ~ 12 V. TEM quantitative data for the width of the PFZ, the GBP population and size, and the size of the matrix precipitates were characterized by a JEOL 100CXII TEM operating at 100 KV. The PFZ width, the GBP size and the number of GBPs per unit area, were determined by using the methods described previously [20]. Slip behavior was investigated using prestrained tensile specimens which were slowly strained to a plastic strain of 4%. Thin foils were made from these speci- mens and observed in the TEM. Under the same two- beam conditions, the foils were tilted until the slip bands were visible and normal to an operating ~ 111) g vector [18,20]. Fractography of all failed SCC and HE specimens was conducted with a PHILIPS SEM515 scanning electron microscope (SEM) operating at 20 KV.

I38 T.C. Tsai, T.H. Chuang /' Materials Science and Engineering A225 (I997) i35-144 600.00 500.00- 400.00 - "-~ 3 0 0 . 0 0 - %1 200.00 t00.00 "Testing solution : 1 3.5 %NaCI+0,3 %H2021 - -

I

/

1.00 2,00 3.00 4.00 Displacement (ram)->

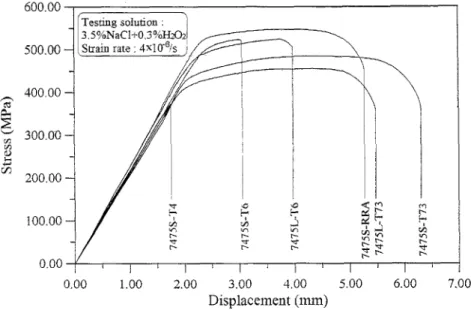

0.00 0.00 7.00 IP- p. .a d~ I ' I 5.00 6.00Fig. 2. Stress-displacement curves o f the slow strain rate tests for various tempers of the 7475 aluminum alloys. Table 5

Results o f slow strain rate test for various tempered conditions ~

Temper El.~m (%) El,~c c (%) FE~I R (J) FE~,cc (J) El.sc c loss b (%) FE.sc c loss c (%)

7475S-T4 7,8 2.2 20.6 4.0 71,8 80.6 7475S-T6 17.6 6.7 41,5 11.7 61.9 7I .8 7475L-T6 16.2 8.5 39.5 15.6 47.5 60.5 7475S-RRA 10,4 9.6 29.6 26.1 7.7 11.8 7475S-T73 14.2 13.7 28.9 27.2 3.5 5.9 7475L-T73 11.2 10.6 25.0 23,4 5,4 6,4

Tensile test at at a strain rate o f k = 4 x t 0 - 6 s - ~ .

b El.scc l o s s = 1-(El.scc/E1.AmO, where E1.A~s:=elongation of specimens, testing in air. El.sc c =eiongation of specimens, testing in 3.5% N a C I + 0.3% H z Q solution.

° F E s c c loss = 1 - ( F E s c c / F E A m ), where FEA~ R = fracture energy o f specimens, testing in air. F E s c c = fracture energy o f specimens, testing in 3.5% N a C I + 0.3% H20 z solution.

3. R e s u l t s

3. I. Mechanical properties

Three dimensional optical micrographs of the as-re- ceived 7475S and 7475L alloys are shown in Fig. I. The difference of grain size between the 7475S and 7475L

Table 6

Results o f straining electrode test for various tempered conditions ~

Temper El.~noh~g~ a (%) E l . ~ r ~ a (%) EI.He loss b (%)

7475S-T4 16.5 4.3 73.9 7475S-T6 17.1 10.2 40.4 7475L-T6 16.0 ! 2.1 24.4 7475S-RRA 10.2 9.5 6,9 7475S-T73 I3.9 13.5 2.9 7475L-T73 10.8 10.2 5,6

a Tensile test at a strain rate of ~ = 3 . 3 x 10 - a s -a in air.

b E1,HI~ IOSS = 1--(El.charged/El.uncharged), where El. Ltn~h~fg~d= elonga-

tion of uncharged specimens, El.d~a,ge, l = elongation o f charged speci-

naens.

alloys is indicated in Table 2, it shows that the grain shape of the 7475L alloy possesses more anisotropy than that of the 7475S alloy. Any obvious microstruc- rural difference could not be found for the other heat treatment conditions.

The mechanical properties of the tensile test are shown in Table 4. The yield strength of the 7475S alloy was evidently increased from T4, through T6 to RRA tempered, and decreased from R R A to T73 tempered condition. However, the elongation revealed the oppo- site relationship of the yield strength. An aging se- quence is revealed fi'om T40 through T6 and RRA tempered, to T73 tempered condition, and the aging treatment condition for each heat treatment is indicated in Table 3. The yield strength and elongation of the 7475S alloy were larger than that of the 7475L alloy, as observed fi'om a comparison of the 7475S and 7475L aluminum alloys in the T6 and T73 tempers. The higher values of mechanical properties for all various tempers of 7475S alloy, as demonstrated in Table 4, are a result of grain refinement [9].

T.C. Tsai, T.Iz[. Chuang / Materials Science and Engineering A225 (1997) 135-144

Table 7 I

Characteristics of microstructures for various heat treatment conditions ~

I

139

Temper P F Z width (nm) GBPs ] Matrix PPTs

Size (nm) No. (per ~[n 2) Size (nm) Type

Slip behavior Spacing (nm) Type 7475S-T4 7 3.9 7475S-T6 27 17.9 7475L-T6 29 25.3 7475S-RRA 35 32.8 7475S-T73 47 48.7 7475L-T73 260 52.2 1400 2.6 410 5.2 320 5.0 235 9.0 I35 12.4 i30 14.6 GP zones + rl'+ ~l 84 Planar GP zones + t f + r/ 71 Planar GP zones + ~l' + r/ 335 Planar J/' + r/ 55 Planar r/' + ~l < 40 Wavy ;7' + II < 60 Wavy

Data indicate the average values.

3.2. Stress corrosion and hydrogen embrittlement susceptibility

The typical stress-displacement curves of the SCC testing specimens for all heat treatments are indicated in Fig. 2. Generally, if the value of displacement ,!is larger, it means that the SCC resistance of the alloy iis better [21]. The fracture energy, which is the area I beneath the stress-displacement curve, was also used ~o

i

evaluate the SCC behavior for each heat treatment [22]. The aqueous SCC results in a reduction of the fracture energy compared with reference values determined m. i n

air. The elongation losses and fracture energy losses for

i

all tempered conditions are given in Table 5. From Fig. 2 and Table 5, the following points should be noted. (;1) The values of displacement were in proportion to the values of elongation loss and fracture energy loss for All

• . ]

tempered conditions• These proportional relatlonshlps proved that the relative SCC susceptibility for all h@t treatments could be directly obtained by comparing the values of displacement of each heat treatment• (2) The

m

SCC resistances for 7475S aluminum alloy increased, as the aging degree increased. The 7475S-T4 and 7475S- T73 tempered condition possessed the largest and the !

smallest SCC susceptibilities, respectively. The 7475S- R R A alloy could effectively improve the aqueous SCC resistance of 7475S-T6 alloy and did not sacrifice me- chanical strength. (3) The SCC susceptibility of the 7475S-T6 was larger than that of the 7475L-T6, arid conversely, the SCC resistance of 7475S-T73 is bet!er than that of the 7475L-T73. I I

The results of SET for all heat treatment conditions I are shown in Table 6. The elongation loss following the

I

SET for 7475S altLrninum alloy was also found ito increase with increasing the degree of aging. The HE susceptibility also showed the same tendency as did the

• I

SCC susceptibility, as observed from a comparison iof the 7475S and 7475L aluminum alloys in the T6 and T73.

3.3. Microstructztra[ characterization

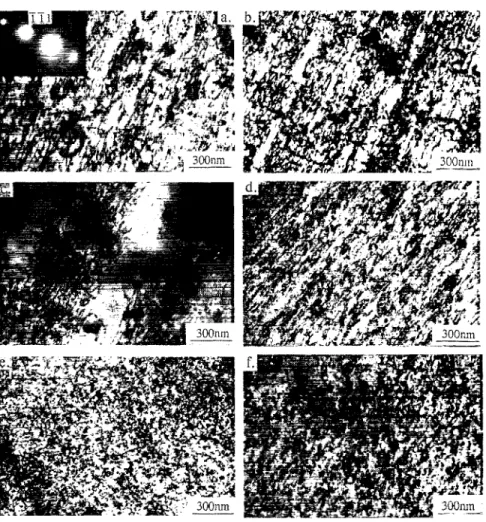

The data of microstructural characteristics of all heat treatment procedures are summarized in Table 7. Typi- cal PFZ widths, grain boundary ~/precipitates and slip behaviors for the 7475S and 7475L aluminum alloys under various tempered conditions are shown in Figs. 3-5, respectively. Only high-angle GBP sizes and distri- butions were characterized by calculating average pre- cipitate diameters and numbers per unit area [18,20]. More than 100 GBPs in five different grain boundary areas were measured for each heat treatment condition to obtain the data of precipitate diameters and numbers per unit area. The sizes and types of matrix precipitates were directly derived from bright field micrographs. The slip behaviors were obtained under the same dif- fraction conditions and magnifications. The average values of PFZ width, matrix precipitates and GBPs were increased by increasing the aging degree for the 7475S aluminum alloy, but it is converse for numbers per unit area and slip band spacings. The 7475S-T4 alloy showed the largest slip band spacing for the 74'75S aluminum alloy, and the spacing decreased with the increasing degree of aging. This phenomenon is pre- sumably due to the increase of matrix precipitate size, and the associated change from GP zones to semicoher- ent ~l and incoherent t/ precipitates [7,18].

The comparison of the 7475S with 7475L aluminum alloys in T6 tempered condition did not reveal any obvious differences on both the PFZ widths and the sizes of matrix precipitates. Both the 7475S-T73 and 7475L-T73 alloys had also similar sizes of matrix pre- cipitates and GBPs. However, the size of GBPs of 7475L-T6 was larger than that of the 7475S-T6 alloy. The 7475L-T6 and 7475L-T73 alloy possessed wider slip band spacings than the 7475S-T6 and 7475S-T73 alloy, respectively, as indicated by the comparison of Fig. 5(b) with (c) and that of Fig. 5(e) with (f). It means that grain refinement can effectively reduce the coarse- ness of the slip band and increase the homogeneity of the slip character. The types of matrix slip are also shown in Fig. 5 to transfer from the planar slip type

140 T.C. Tsai, T.H. Chuang / Materials Science and Ettghwering A225 (I997) 135-144

Fig. 3. TEM micrographs showing the precipitate free zone width of the various tempers, (a) 7475S-T4; (b) 7475S-T6; (c) 7475L-T6; (d) 7475S-RRA; (e) 7475S-T73; (f) 7475L-T73.

before overaging (T73) treatment to the wavy slip type after overaging tempered conditions have been reached.

4. Discussion

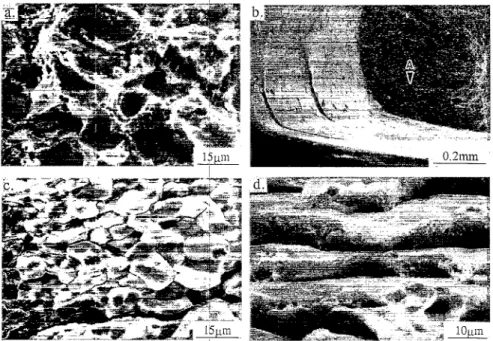

The results of SSRT and SET for all tempered condi- tions indicate that the hydrogen embrittlement resis- tances were in proportion to the SCC resistance for all tempered conditions. It directly proves that the HIC plays a main role to control the SCC susceptibility of 7475 aluminum alloys. The fracture surface of a un- charged 7475S-T6 specimen was mainly ductile trans- granular nature, as illustrated in Fig. 6(a). The fractographys of a charged 7475S-T6 specimen exhib- ited some isolated secondary cracks and equiaxed inter- granular fracture surfaces, as shown in Fig. 6(b) and (c), respectivity. Fig, 6(d) shows a typical fractography of a charged 7475L-T6 specimen, which appears as a pancake-shaped intergranular fracture surface.

Gruhl [11] indicated that grain refinement can lead to the reduction of planar slip and a more homogeneous

slip mode. The homogeneous slip mode can effectively reduce intercwstalline fracture and SCC susceptibility. Therefore, it is reasonable to assume that the SCC resistance of 7475S-T73 alloy is better than 7475L-T73 alloy. The 7475L-T6 alloy is shown from a comparison of Fig. 5(b) with Fig. (c) to possess wider slip band spacings than the 7475S-T6 alloy. Therefore, the SCC susceptibility of 7475L-T6 tempered alloy could be inferred from the above discussions to be larger than that of 7475S-T6 tempered alloy. However, the SCC resistance of 7475L-T6 alloy is shown in Table 5 to be really better than that of 7475S-T6 alloy. It means that the decrease of the SCC susceptibility which is at- tributed to the reduction of the slip band spacing by means of grain refinement can not be obtained in 7475S-T6 alloy.

Increasing the matrix precipitate size can generally improve the SCC resistance of high strength aluminum alloys [18], because it can result in the reduction of planar slip and a more homogeneous stip mode. The homogeneous slip mode can effectively reduce hydro- gen transported to the grain boundaries to induce

T.C. Tsai, T.H. Chuang / Materials Science and Engineering A225 (I95)7) 135-144 [ 4 1

I

Fig. 4. TEM micrographs showing the grain boundary precipitates 7475S-RRA; (e) 7475S-T73; (f) 7475L-T73. I

I !

cracking by means of mobile dislocations [7]. Therefo}e, it is reasonable to assume that the SCC resistance for alloy could be improved by increasing <he the 7475S

degree of aging. On the other hand, an increasing size of GBPs has been proposed to explain the higher SCC resistance in the 7xxx series aluminum alloys [4]. The larger ~l precipitates in the grain boundary can act i as trapping sites for atomic hydrogen to nucleate hydro-

.I

gen bubbles, thereby reducing hydrogen concentration below a critical value to retard hydrogen embrittlem~nt_ and improve the SCC resistance [4,6,23]. Christodoulou and Flower [23] found that a critical precipitate size of approximately 20 nm for GBPs is required for nucle- ation of hydrogen bubble. The average size of GBPs I in 7475S-T6 alloy is indicated in Table 7 to be smaUer than 20 nm, and conversely, the 7475L-T6 alloy p o s -

• I

sesses a larger average size of GBPs of approximately 25 nm. Therefore, the 7475L-T6 alloy possesses a

• .1

higher fraction of GBPs which are larger than a critical precipitate size required to form hydrogen bubbles tl~an the 7475S-T6 alloy does. These results demonstrate that the SCC susceptibility of 7475S-T6 alloy would be

of the various tempers. (a) 7475S-T4; (b) 7475S-T6; (c) 7475L-T6; (d)

larger than that of the 7475L-T6 alloy. Moreover, it seems that the PFZ width has no obvious effect on SCC susceptibility because the 7475S-T6 and the 7475L-T6 tempered alloys possess the similar width of PFZ, as shown in Table 7.

The size of GBPs in 7475S-T4 alloy should be smaller than a critical size necessary for nucleating hydrogen bubbles. The 7475S-T4 alloy exhibits long dislocation lines and planar slip bands, as shown in Fig. 5(a), which can transport atomic hydrogen over a longer distance and concentrate hydrogen at the intersection of dislocation and grain boundary [18]. It results in an easier to reach critical atomic hydrogen concentration which is necessary to embrittle grain boundaries [23]. Therefore, The wider slip band spacing and the smaller size of GBPs are considered to be the two most impor- tant factors leading to the serious SCC susceptibility of 7475S-T4 alloy.

The larger average GBPs size of about 33 nm in the 7475S-RRA treatment can effectively trap the atomic hydrogen in bubbles nucleated at GBPs inhibiting the hydrogen embrittlement. On the other hand, the 7475S-

142 T.C. Tsai, T.H. Chua~g, Materials Science cmd D~gmeer#tg A225 (1997) 135- t44

ie~,

og_t Y

,.. ; 2,

?e ~,"

Fig. 5. T E M micrographs showing the deformation structure after 4% plastic strain for the various tempers. (a) 7475S-T4; (b) 7475S-T6; (c) 7475L-T6; (d) 7475S-RRA; (e) 7475S-T73; (f) 7475k-T73. [1 t2] matrix zone axis and g = (1 l 1) lbr all micrographs,

R R A alloy possesses more homogeneous slip type than the 7475S-T6 alloy, as indicated by a comparison of Fig. 5(b) with (d). It is due to a larger average matrix precipitate size and a higher fraction of ~l' (or ~7) matrix precipitates of the 7475S-RRA. Therefore, the 7475S- R R A alloy could effectively improve the SCC resistance of 7475S-T6 alloy, which can be concluded that R R A temper can produce larger sizes of both the matrix precipitates and GBPs than T6 tempered condition.

Another significant effect produced by grain refine- merit is superplasticity [14,24]. A high strength alu- minum alloy (like as 7475S alloy) presents fine grain size of about 10 ~.tm, which is the fundamental condi- tion fox" the superplasticity [24]. Staley [25] stated that the fine grain structure also contains a smaller size o f GBPs. Therefore, the fine grain structure means that it easily results in undersized GBPs which are smaller than a critical precipitate size necessary for nucleating hydrogen bubbles. It reveals that a fine-grained alu- minum alloy with unsuitable tempers or microstructural conditions would cause severe SCC damage, as ob-

rained by the 7475S-T4 and 7475S-T6 alloys in this study. The elongation of the 7475S-T4 alloy, tested at a fast strain rate of 10 - 3 s - ~ in air, is about of 20%. The higher values of elongation for 7475S-T4 alloy, as demonstrated in Table 4, are a result of grain refine- ment. However, the elongation of the 7475S-T4 alloy, tested at a slow strain rate of 4 × 10 -~' s -1 in air, is only about 8% as shown in Table 5. These results indicate that the 7475S-T4 alloy presents a severe atmo- spheric SCC susceptibility. The typical fl'acture surface of the SSRT specimen, tested in air, for the 7475S-T4 alloy appear as the obvious secondary cracks and inter- granular fracture surfaces, as shown in Fig. 7(a) and (b). The above fl'actography could not be found in any other tempered condition. A further conclusion can be inferred from the above result, if the size o f GBPs is smaller than a critical precipitate size necessary for nucleating hydrogen bubbles, then the hydrogen em- britttement will become serious, and an improvement of the SCC resistance due to grain refinement can not be obtained.

T.C. Tsai, T.H. Chuang / Materials Science and Engi~zeering A225 (i997) i 3 5 - i 4 4 143

I cr

Fia. 6. Scanning electron fractographs of typical failed specimens. (a) Trans~ranular fracture of uncharged 7475S-T6 specimen; (b) and (c) are some isolated secondary cracks and eqmaxed mtergranular fracture surfaces of hydrogen-charged 7475S-T6 specimen, respectively; (d) pancake- shaped intergranular fracture surfaces of hydrogen-charged 7475L-T6 specimen.

5. Conclusions

(1) The same tendency between the hydrogen embrit- tlement susceptibility and the SCC susceptibility for ~11 heat treatment conditions indicated that the mechanism of HIC plays a main role to control the SCC suscepti- bility of the 7475 aluminum alloys. I

(2) A clear relationship has been found between the

/

Fig. 7. Scanning electron fractographs of SSRT specimen for 7475S- T4 alloy, tested in air. (a) Some intergranular fracture zones sho!wn

on fracture surfaces; (b) higher magnification of area A in (a).

grain refinement and the effect of microstructure on SCC susceptibility. Grain refinement presents a more homogeneous slip mode and a smaller size of GBPs. The more homogeneous slip mode is the major factor to reduce the SCC susceptibility. However, the SCC resistance can not be improved by means of grain refinement, if the GBPs size of the superplastic 7475 aluminum alloy is smaller than a critical precipitate size which is required for hydrogen bubble nucleation.

(3) GBPs size which is smaller than a critical precip- itate size for nucleating hydrogen bubbles and a planar slip behavior cause the serious SCC susceptibility for the 7475S-T4 alloy. The R R A treatment could effec- tively improve the SCC resistance of T6 temper for superplastic 7475 aluminum alloy because R R A temper could produce larger sizes of both the matrix precipi- tates and GBPs than T6 tempered condition could.

(4) Fine grain size of the 7475 alloy does not only insure its superplastic characteristic, it also acts detri- mentally as the main cause of inducing SCC. For preventing such a material failure from occurring, a suitable post heat treatment, such as R R A tempered treatment, should be employed to insure the application of this advanced superplastic alloy.

Acknowledgements

The authors are grateful to the support of National Science Council of the Republic of China under con- tract No. NSC 82-0405-E002-099.

144 T.C. Tsai, T.H. Chuang / Materials Science and Engineering A225 (i997) 135-144

References

[1] M.O, Speidel, MetalL Trans., 6A (I975) 631. [2] T.D. Burleigh, Corrosion, 47 (t991) 89. [3] B,M. Cina, U.S. Patent 3856584, Dec. 24, 1974,

[4] J.K. Park and A.J. Ardell, Merall. Trans., 15A (1984) 1531. [5] M.U. Islam and W. Wallace, Met. Technol., I0 (I983) 386, [6] K. Rajan, W. Wallace and J,C. Beddoes, J. Mater. Sci., i7

(1982) 2817.

[7] J. Albrecht, I.M. Bernstein and A.W. Thompson, MetalI. Trans.,

13,4 (1982) 811.

[8] D,A. Hardwick, A.W. Thompson and I.M. Bernstein, Metall.

Trans,, 14A (1983) 25t7.

[9] R.J.H. WanhiI1 and G.F.J.A. van Ges'~d, Aluminium, 54 (1978) 573.

[10] J.A. Wert, N.E. Paton, C.HH. Hamilton and M.W. Mahoney,

MetalL Trans., I2A (I981) 1267. [11] W. Gruhl, Ahoninium, 54 (1978) 323.

[12] C,H. Hamilton and N.E. Paton (eds.), &¢perplasticity and Super-

plastic Forming, TMS, Warrendale, PA, USA, 1989.

[13] B. Baudelet, Mater. Sei. Eng., ,4 t37 (1991) 41.

[14] D.H. Shin. K.S. Kim, D.W. Kum and S.W, Nam, Metal].

Trans., 21A (1990) 2729.

[15] T.C. Tsai and T.H. Chuang, MetatL Trans., 27A (1996) 2617. [16] P.N. Adler, R. Deiasi and G. Geschwind, Metall. Trans., 3

(1972) 319I.

[17] P.K. Poulose, J.E. Morrai and A.J. Mcevily, Metall. Trans., 5 (1974) 1393.

[18] D, Nguyen, A.W. Thompson and I.M. Bernstein, Acta Metall.,

35 (1987) 2417.

[I9] R.N. Parkins, F. Mazza, J.J. Royuela and J.C. Scully, Br.

Corros. J., 7 (1972) 154.

[20] G.M. Ludtka and D.E. Laughlin, MetalL Trans., i9-,4 (1981) 2083.

[21] S. Ohsaki and T, Takahashi, J. Jpn Inst. Light Met., 35 (1985) 261.

[22] R. Braun, Mater. Sei. Eng., .,tt90 (I995) 143.

[23] L. Christodoulou and H.M. Flower, Acta MemlL, 28 (1980) 481. [24] C.H. Hamilton and N.E. Paton (eds.), Superplastici O' and Super-

plastic Forming, TMS, Warrendale, PA, USA, 1989. [25] J.T. Staley, A S T M STP 605, 1976, p. 71.