ORIGINAL ARTICLE

An analysis of the formability of aluminum/copper clad

metals with different thicknesses by the finite

element method and experiment

Huang-Chi Tseng&Chinghua Hung&Chin-Chuan Huang

Received: 26 December 2008 / Accepted: 11 November 2009 / Published online: 2 December 2009 # Springer-Verlag London Limited 2009

Abstract In this research, the possibility of applying forming limit diagrams to the formability and fracture prediction of clad metal sheets is examined. The forming limits of clad metal sheets with different thickness combinations (e.g., A1050 1.0, 1.5, 2.0 mm/C1100 1.0 mm) are investigated via forming limits test (punch stretching tests). The true stress–strain curves of Al/Cu clad metal sheets are obtained through tensile tests. Using the experimental forming limit diagrams and the stress– strain curves, the fracture prediction of clad metal sheets are simulated by finite element analysis. Moreover, deep drawing tests are carried out to compare the experimental with the numerical results. These results can verify the accuracy of finite element model. Finally, significant differences in formability are found, and comparisons of the fracture prediction of clad metals with different initial thickness ratios are analyzed both numerically and experimentally.

Keywords Finite element method . Clad metal . Forming limit . Deep drawing test

1 Introduction

In this research, the clad metals are considered multilayer sheets that possess various properties. Generally, with different material combinations, clad metals can have advantageous characteristics such as good thermal conduc-tivity, anti-corrosion properties, wear resistance, surface quality, and so forth. Therefore, they can be used in many applications, for instance, in electronics, the maritime industry, and the automobile industry. Clad metals not only preserve the original properties of the base metals but also give additional characteristics during the product develop-ment. In recent years, clad metals have become a good solution for products with multi-functional requirements [1]. For good surface quality of the product, Ti/Al or SUS/ Al clad metals have been adopted to form 3C product housing [2]. SUS/steel/SUS clad metals can be used in knife products where the SUS layer exhibits good corrosion resistance and the steel core layer provides good strength and toughness (http://www.mirdc.org.tw/FileDownLoad/ EpaperFile/2/61/MPNEWS9804_2_61/mirdc.htm). The Al/ Cu clad metal studied in this research can be applied to thermal conductivity products, such as a heat exchanger plate or a temperature switch.

In general, clad metals can be made by several processes, for instance, explosive bonding, adhesive bonding, or cold/ hot roll bonding. In the cold roll-bonding process, clad metals are bonded together by interface diffusion, while the thickness is reduced. The cold roll-bonding process has many advantages, especially accurate dimension control and straight bonding layers. However, because the clad metals are produced at room temperature, the residual stress generated in the rolling process cannot be released by the conventional annealing process because the melting temper-atures of the individual layer sheets are often different from

H.-C. Tseng

:

C. HungDepartment of Mechanical Engineering, National Chiao Tung University,

Hsinchu 30050, Taiwan, Republic of China C.-C. Huang

Metal Industries Research & Development Centre, Kaohsiung, Taiwan, Republic of China

C. Hung (*)

EE452, National Chiao Tung University, 1001 University Road,

Hsinchu, Taiwan 300, Republic of China e-mail: chhung@mail.nctu.edu.tw DOI 10.1007/s00170-009-2446-4

each other. Therefore, the effect of residual stress on the secondary formability of the clad metal sheet is significant.

Today, some studies estimate the bonding performance of clad metals with a long holding time, high diffusion temperature, and complicated equipment. Mahendran [3] developed diffusion bonding windows for the effective joining of AZ318B magnesium and commercial grade copper alloys. Nowicke et al. [4] considered that the unwanted strain localization of clad metal sheets can be delayed significantly with the use of a small roll radius.

There have been some studies on the performance of diffusion bonding, the evolution of textures, and the effect of rolling process parameters concerning the production of clad metal sheets at high temperature [5–8], but there have been few studies done on the formability and diffusing performance of clad metals produced at room temperature [9–12]. In general, most of the research on deep drawing tests has analyzed the formability of a single material during the forming process [13], but there have been few studies done on the formability of clad metal sheets made by cold roll-bonding process.

During the forming process, sheet metals can deform only to a certain level, which is dependent mainly on the combination of the ratio of the major and minor strains before necking occurs. Keeler [14] first introduced the forming limit diagram (FLD). The FLD is widely applied for predicting the fracture of sheet metals during the deformation process [15,16]. In this research, in order to understand the formability of clad metals with different thickness combinations, the punch stretching test (forming limit test), the deep drawing test, and associated finite element analysis were carried out. The specimens of Al/Cu clad metal sheets were obtained through a cold roll-bonding process. Second, the mechanical properties of clad metal sheets with different initial thicknesses were measured by tensile tests. Then, the punch stretching test was carried out to determine the forming limit data of Al/Cu clad metal sheets with different initial thickness ratios. After that, deep

drawing tests of clad metal sheets using a square punch were carried out. The deep drawing tests were also simulated with ABAQUS to validate the possibility and accuracy of using finite element (FE) models. During this verification process, fracture initiations during the deep drawing of the clad metal sheets were carefully inspected.

2 Cold rolling process and mechanical property test 2.1 Experimental procedure for roll bonding

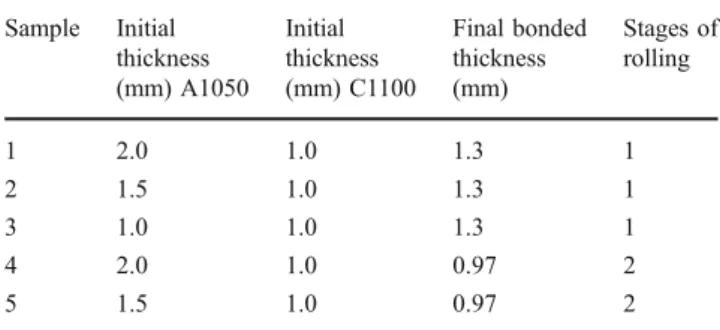

Specimens of Al/Cu clad metal sheets were prepared in the following manner. The base materials were aluminum sheets with thicknesses of 2.0, 1.5, and 1.0 mm and copper sheets 1.0 mm thick. The two-ply clad metal sheets were arranged as illustrated in Fig. 1a. Before the roll-bonding process, all contact surfaces of the base materials were cleaned to remove impurities such as oxides, grease, and vapor in order to enhance the bonding performance of the Al/Cu clad metal sheets. The rolls were set to a small roll-gap opening, resulting in a nominal deformation. However, the final thickness of the clad metal sheet was always larger than the initial roll-gap opening, which is attributed to elastic recovery of the blank. Table 1 shows the list of thickness combinations of the clad metal sheets. All Al/Cu

Fig. 1 a Schematic representation of the roll bonding of two-ply clad metal sheet; b rolling mill

Table 1 Different thickness combinations of clad metal sheets Sample Initial thickness (mm) A1050 Initial thickness (mm) C1100 Final bonded thickness (mm) Stages of rolling 1 2.0 1.0 1.3 1 2 1.5 1.0 1.3 1 3 1.0 1.0 1.3 1 4 2.0 1.0 0.97 2 5 1.5 1.0 0.97 2

clad metal sheets were made by the cold rolling process through diffusion bonding, as shown in Fig.1b.

2.2 Tensile test of clad metal sheets

In order to measure the mechanical properties of the Al/ Cu clad metal sheets, tensile tests were carried out on a MTS-810 tensile machine. In this research, all specimens

of Al/Cu clad metal sheets were produced at room temperature, and thus, the residual stress of two base materials cannot be released by conventional annealing process. After the roll-bonding process, the specimens were very thin, and it was difficult to obtain the flow rule of each of the two materials. Based on the iso-strain deformation behaviors of Al/Cu clad metal sheets, these sheets were considered to be equivalent to a single material in the FE simulation. Therefore, the fracture of Al/Cu clad metal sheets was predicted according to the forming limit data of the equivalent single material.

Figure 2 shows the true stress–strain curves obtained for the Al/Cu clad metal sheets with three different initial thickness combinations (Al 2.0 mm/Cu 1.0 mm, Al 1.5 mm/Cu 1.0 mm, and Al 1.0 mm/Cu 1.0 mm) and two different bonded thicknesses (0.97 and 1.3 mm).

Fig. 2 True stress–strain curves of the clad metal sheets

sheet

Sandwich

a

b

Blank

Fig. 3 a Tooling dimension; b 50-ton universal material test machine

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 -0.2 0 0.2 0.4 0.6 Minor strain (%) Major strain (%) Al 2.0mm Cu 1.0mm bonded 1.3mm Al 1.5mm Cu 1.0mm bonded 1.3mm Al 1.0mm Cu 1.0mm bonded 1.3mm

b

a

Fig. 4 FLDs of the clad metal sheets for different initial thickness ratios 0 0.2 0.4 0.6 0.8 1 1.2 -0.2 0 0.2 0.4 0.6 0.8 Minor strain (%) Major strain (%) Al 2.0mm Cu 1.0mm bonded 1.3mm Al 1.5mm Cu 1.0mm bonded 1.3mm Al 1.0mm Cu 1.0mm bonded 1.3mm Al 1.5mm Cu 1.0mm

These tensile properties were used in the following FE simulations.

2.3 Punch stretching test (forming limit test)

The punch stretching tests were carried out to evaluate the forming limit of the Al/Cu clad metal sheets. In the forming limit diagram, the major and minor strains at a critical site are plotted at the onset of visible, localized necking in a deformed sheet, and the locus of the strain combinations that will produce failures in an actual forming operation can be drawn. The major axes of the ellipses are parallel to the direction of the greater elongation. If the area of the original circle before deformation is less than the area of the ellipse after deformation, the thickness of the sheet has changed at the point because the volume remains constant during deformation. Experimental methods were used to construct the diagram. First, the clad metal sheets were clamped at their edges and stretched by a 50-mm diameter hemispherical punch, as shown in Fig. 3. Specimens 100 mm long and of various widths from 10 to 100 mm were prepared to cover various stretch modes. Talcum powder was used for lubrication; the blank holding force was set to 160 KN. The aluminum side of the Al/Cu clad metal sheets was in contact with the punch. Before these tests, the surfaces of the copper side of the Al/Cu clad metal sheets were etched with circular meshes so that the major and minor strains could be measured after the stretching test.

2.4 FLD results

2.4.1 Different initial thickness combinations (Al 2.0, 1.5, and 1.0 mm/Cu 1.0 mm)

The fractured conditions of the Al 1.5 mm/Cu 1.0 mm clad metal after the punch stretching test are shown in Fig. 4a. The FLDs of different thickness ratios are shown in Fig.4b. The trend of the forming limit curve of Al 2.0 mm/Cu 1.0 mm is obviously higher than those in other cases and thus indicates better formability during the forming test. On the other hand, the clad metal sheet of Al 1.0 mm/Cu 1.0 mm has a lower ductility limit. According to this result, the initial thickness ratio (related to the reduction ratio because the final thickness is the same) influences the trend of the FLDs of the clad metal sheets; this is due to the work-hardening effects during the roll-bonding process. Therefore, the higher reduction ratio of the material is a significant factor for raising the forming limit of the clad metal sheets in the secondary forming process.

2.4.2 Single metal sheet (Al 1.5 mm and Cu 1.0 mm) The comparison of the formability between the clad metal sheets and single metal sheets (Al 1.5 mm and Cu 1.0 mm) is shown in Fig.5. The fracture points of the single metal sheets are mostly located above the forming limit curves of the clad metal sheets, revealing the better formability of the single metal sheets than the clad metal sheets.

Fig. 6 Tooling and blank geometry of the deep drawing test

Combination material (bonded thickness) Specimen diameter

70mm 80mm 90mm

Holding force (result)

Al 2.0 mm/Cu 1.0 mm (0.97 mm) 5 KN(OK) 50 KN(FT) 5 KN(FT) Al 1.5 mm/Cu 1.0 mm (0.97 mm) 50 KN(FT) 15 KN(FS)

20 KN(FT) 5 KN(FT)

Al 1.0 mm/Cu 1.0 mm (1.3 mm) 15 KN(OK) 15 KN(FT) 10 KN(FT) Table 2 Type of facture

conditions of clad metal sheets with different thickness combinations of holding force and specimen diameter (OK, FT—fracture on top, FS—fracture on side)

3 Deep drawing tests

Deep drawing tests were carried out on the Al/Cu clad metal sheets with a 50-ton universal material test machine to evaluate the drawing depth and fracture conditions directly. A square punch with an associated die set was used for the deep drawing test, as shown in Fig.6. By changing the blank holding force and the blank dimensions, the drawing depth of the blank can be measured. In order to compare the forming variation for different bonded thicknesses, the clad metal sheets were rolled to 0.97 and 1.3 mm in thickness. Circular specimens with various diameters (70, 80, and 90 mm) were used. To reduce the effect of friction of the punch, talcum powder was also used between the punch and the blank. The blank holding force was set to 5, 10, 15, 20, and 50 kN, respectively. The same as the above punch stretching tests, the aluminum side of clad metal was considered to be the contact surface. Table 2 lists the fracture conditions for the different combinations. Compar-ing the experimental results of 80-mm specimen with those of the 90-mm specimen, the fracture mostly occurs near the punch corners at the early stage of deep drawing. The experimental result for Al 1.0/Cu 1.0 mm (bonded thickness 1.3 mm) points out that reducing the blank dimensions is helpful for forming with a low ductility limit when the holding force is fixed. In the next section, the fracture prediction of these experimental results is validated using previous forming limit data in FE simulations.

4 Numerical simulation of deep drawing test 4.1 Finite element model

In this section, the fracture prediction of Al/Cu clad metal sheets using finite element simulations will be analyzed and verified with deep drawing tests. The deep drawing test was modeled using ABAQUS/CAE. For the numerical simula-tion of the deep drawing test, ABAQUS/Explicit was used

to simulate large deformation behavior of the clad metal sheet. In this case, a 1/4 symmetric model was used; the Al/ Cu clad metal sheet was considered as an equivalent isotropic single layer material, with material properties previously determined from tensile tests and used to simulate the actual flow rule of the Al/Cu clad metal sheet with the residual stress effect considered. The blank was meshed with quadrilateral shell elements, while the die, punch, and holder plate were considered to be discrete rigid bodies. A finite element model was constructed as shown in Fig.7.

For boundary conditions, the punch was specified to move in the z direction, and a holding force was applied on the blank through the holder. Three contact pairs (punch– blank, holder–blank, and blank–die) were defined in this study. The Coulomb coefficient of friction was set to 0.1 for all of contact surfaces.

4.2 Damage initiation criterion

For fracture prediction, the damage initiation option was used in the deep drawing forming simulation. The damage initiation criterion associated with the FLD is given by the condition ωFLD=1, where the variable is a function of the current deformation state and is defined as the ratio of the current major principal strain,εmajor, to the major limit strain on the Front view

Front

Fig. 7 The finite element model (1/4 symmetry) Major strain B A Minor strain FLC

FLD evaluated at the current values of the minor principal strain,εminor. For the deformation state given by point A in Fig.8, the damage initiation criterion is evaluated as follows: wFLD¼

"A major "B

major

The parameters for the forming limit of the clad metal sheets were determined from the forming limit tests as discussed above.

5 Results and discussion

The deformation conditions and sheet fracture are shown in Fig. 9a. For the clad metal sheet with Al 1.5 mm/Cu Al2.0mm/Cu1.0mm 0.97mm

Al1.5mm/Cu1.0mm 0.97mm

a

Al1.5mm/Cu1.0mm 0.97mm F=15KN,D=80mm 23.5mm

b

Fig. 9 a Deformation conditions of blank with different initial thickness. b Maximum drawing depth of 23.5 mm (Al 1.5 mm/Cu 1.0 mm)

Al1.0mm/Cu1.0mm 1.3mm D=90mm10KN

Fracture

Fig. 10 Experimental verification of deep drawing (d =90 mm)

Al1.0mm/Cu1.0mm 1.3mm D=80mm15KN

F

Fracture

Fig. 11 Experimental verification of deep drawing (d=80 mm)

Al1.0mm/Cu1.0mm 1.3mm D=70mm15KN

1.0 mm (blank dimension=80 mm), Fig.9breveals that the maximum drawing depth was 23.5 mm when the holding force was set to 15 kN. It was observed that the fracture occurs on the side wall of the blank. When the holding force was increased, the metal flow of the clad metal sheet was constrained by larger frictional forces, with the result that the blocked metal flow caused fracture at the top corner of the blank for other fracture cases.

In this study, the applicability of FLDs on the fracture of clad metal sheets was verified. Al 1.0 mm/Cu 1.0 mm blanks with a thickness of 1.3 mm and three diameters (70, 80, and 90 mm) were used in the finite element analysis, and the simulation results were compared to those of the experiments. From the results shown in Figs.10, 11, and 12, we can examine the fracture of clad metal sheets. When the blank dimension was 90 mm, the simulation of deep drawing indicated that the possible fracture site is at the corner of the blank where the higher holding area effect causes too much resistance for drawing. This fracture is caused by the near biaxial tensile mode. In FLD, the strain distribution is located on a minor strain of positive value. The experimental results verified this prediction.

When the blank dimension was 80 mm, the experimental fracture was at the corner. This fracture was caused by the biaxial tensile mode. The strain distribution was located on a positive minor strain in the FLD. In the simulation result, the strain distribution at the corner and side wall of the blank approached the high fracture criterion value. There-fore, the predicted fracture site of the blank was similar to the experimental result.

When the blank dimension was 70 mm and the holding force was set to 15 kN, the blank was drawn without fracture. From the simulation result, the forming limit factor is 0.573, and the strain distribution is located on a safe zone.

6 Conclusion

In this research, the secondary formability and fracture prediction of Al/Cu clad metal sheets with different initial thickness ratios were analyzed. From the results of punch stretching tests, the formability of single materials was shown to be better than that of clad metal sheets. It is expected that the formability of clad metal sheets is affected by the residual stress during the cold rolling process. Given the different ductility of two base materials, higher plastic deformation occurred in the aluminum during the roll-bonding process. Therefore, in this research, reduction ratio of the material was a significant factor for the formability of the clad metal sheets when the bonded thickness was the same. As for the fracture predictions in Al/Cu clad metal sheets, the use of forming limit diagrams with finite

element model has been verified by this research. The thickness distribution, the fracture prediction, and the deformation behavior of Al/Cu clad metal sheets were accurately predicted using the FLD criterion option in ABAQUS.

Finally, the formability of clad metal sheets can be manipulated by changing the process parameters such as the holding force and the blank diameter in deep drawing tests. In these tests, the maximum drawing depth of 23.5 mm for clad metal sheets (Al 1.5 mm/Cu 1.0 mm) was obtained when the blank diameter was 80 mm and the holding force was 15 kN.

Acknowledgments The authors would like to thank Metal Indus-tries Research & Development Centre (MIRDC) for its support of this research project as well as Dr. Chiang for his assistance in fabricating the clad metal sheet. The authors especially thank Professor Chen from National Taiwan University (NTU) and Professor Huang from National Taiwan University of Science and Technology (NTUST) for their assistance and helpful discussions.

References

1. Jung CG, Seung DY, Yang DY, Na SJ (2009) Development of a continuous fabrication system for a metallic sandwich plate with a three-dimensional truss core. Int J Adv Manuf Technol 45:352–361. doi:10.1007/s00170-009-1964-4

2. Tseng HC, Wu ZC, Hung C, Lee MH, Huang CC (2009) Investigation of optimum process parameters on the sheet hydro-forming of titanium/aluminum clad metal for battery housing. 4th International Conference on Tube Hydroforming, September 6–9, Kaohsiung, Taiwan

3. Mahendran G, Balasubramanian V, Senthilvelan T (2009) Devel-oping diffusion bonding windows for joining AZ31B magnesium and copper alloys. Int J Adv Manuf Technol 42:689–695. doi:10.1007/s00170-008-1645-8

4. Nowicke JrF Zavaliangos A, Rogers HC (2006) The effect of roll and clad sheet geometry on the necking instability during rolling of clad sheet metals. Int J Mech Sci 48:868–877. doi:10.1016/j. ijmecsci.2006.01.021

5. Özdemir N, Bilgin B (2009) Interfacial properties of diffusion bonded Ti-6Al-4V to AISI 304 stainless steel by inserting a Cu interlayer. Int J Adv Manuf Technol 35:814–820. doi:10.1007/ s00170-008-1493-6

6. Masahashi N, Komatsu K, Kimura G, Watanabe S, Hanada S (2006) Fabrication of iron aluminum alloy/steel laminate by clad rolling. Metall Mater Trans A 37A:1665–1673. doi:10.1007/ s11661-006-0108-9

7. Kim JK, Huh MY, Lee JC (2004) Evolution of strain states and textures during roll-cladding in STS/Al/STS sheets. J Mater Sci 39:5371–5374. doi:10.1023/B:JMSC.0000039247.10346.5d

8. Kang HG, Kim JK, Huh MY, Engler O (2007) A combined texture and FEM study of strain states during roll-cladding of five-ply stainless steel/aluminum composites. Mat Sci Eng A 452– 453:347–358. doi:10.1016/j.msea.2006.10.130

9. Tseng HC, Hung C (2009) The finite element analysis on diffusion bonding of Al/Cu clad metal in cold rolling process. Int 26th National Conference on Mechanical Engineering CSME, November 20–21, Tainan, Taiwan (accepted)

10. Kim KJ, Kim D, Choi SH, Chung K, Shin KS, Barlat F, Oh KH, Youn JR (2003) Formability of AA5182/polypropylene/AA5182

sandwich sheets. J Mater Process Technol 139:1–7. doi:10.1016/ S0924-0136(03)00173-0

11. Takuda H, Mori K, Fujimoto H, Hatta N (1996) Prediction of forming limit in deep drawing of Fe/Al laminated composite sheets using ductile fracture criterion. J Mater Process Technol 60:291–296. doi:10.1016/0924-0136(96)02344-8

12. Yoshida F, Hino R (1997) Forming limit of stainless steel-clad aluminium sheets under plane stress condition. J Mater Process Technol 63:66–71

13. Park DH, Yarlagadda PKDV (2008) Effects of punch load for elliptical deep drawing product of automotive parts. Int J Adv Manuf Technol 35:814–820. doi:10.1007/s00170-006-0758-1

14. Keeler SP (1965) Determination of forming limits in automotive stamping. Sheet Met Ind 42:683–691

15. Goodwin GM (1968) Application of strain analysis on sheet metal forming problems in the press shop. SAE Paper No. 680093 16. Cockcroft MG, Latham DJ (1966) Ductility and workability of