Calculation of PID controller parameters by using a fuzzy neural

network

Ching-Hung Lee,

a,*

Ching-Cheng Teng

b,†aDepartment of Electrical Engineering, Yuan Ze University, 135 Yuan Tung Rd., Chung-Li, Taoyuan 320, Taiwan, Republic of China bDepartment of Electrical and Control Engineering, National Chiao Tung University, Hsinchu 300, Taiwan, Republic of China

共Received 21 December 2001; accepted 13 July 2002兲

Abstract

In this paper, we use the fuzzy neural network共FNN兲 to develop a formula for designing the proportional-integral-derivative共PID兲 controller. This PID controller satisfies the criteria of minimum integrated absolute error 共IAE兲 and maximum of sensitivity ( Ms). The FNN system is used to identify the relationship between plant model and controller

parameters based on IAE and Ms. To derive the tuning rule, the dominant pole assignment method is applied to

simplify our optimization processes. Therefore, the FNN system is used to automatically tune the PID controller for different system parameters so that neither theoretical methods nor numerical methods need be used. Moreover, the FNN-based formula can modify the controller to meet our specification when the system model changes. A simulation result for applying to the motor position control problem is given to demonstrate the effectiveness of our approach. © 2003 ISA—The Instrumentation, Systems, and Automation Society.

Keywords: PID controller; Dominant pole assignment; Fuzzy neural network

1. Introduction

The proportional-integral-derivative 共PID兲 con-trollers are still widely used in process industries even though control theory has been developed significantly since they were first used decades ago. There are many well-known PI and PID tun-ing formulas for stable processes that are suitable for autotuning and adaptive control关1–9兴. Astrom and Hagglund, in 1984, first proposed a tuning method for PID controllers based on phase and amplitude specifications 关3兴. Then, Ho et al. pre-sented a tuning method for stable and unstable processes 关5–9兴. In Refs. 关10,11兴, the author

pro-posed a tuning method based on the integrated er-ror共IE兲 and maximum of sensitivity( Ms) for spe-cial model. However, this method cannot be applied to high-order process. In this paper, we modify the ideas of关10,11兴 and use the fuzzy neu-ral network system 共FNN兲 to develop an FNN-based tuning formula of PID controller for general processes.

To accomplish the specified performance, fuzzy controllers were proposed including a nonlinear fuzzy PI controller with proportional gain关12兴 and nonlinear fuzzy PID controller关13,14兴. These non-linear controllers are not easy to implement be-cause of the nonlinearity. In our previous papers 关4,15兴, we presented a tuning method that uses fuzzy neural network 共FNN兲 systems to tune the PID controller parameters efficiently. This ap-proach enjoys the advantage of functionally map-ping the FNN, and gives better performance than

*Corresponding author. Tel.: ⫹886-3-4638800, ext. 427; fax: ⫹886-3-4639355. E-mail address: chlee@saturn.yzu.edu.tw

†Tel.: 5712121, ext. 54345; fax: ⫹886-3-5715998. E-mail address: ccteng@cn.nctu.edu.tw

TRANSACTIONS

ISA Transactions 42共2003兲 391–400

the result of关5–9兴. Indeed, the proposed method is valid for the general system and guaranteed the stability of the closed-loop system 关15兴. As the previous results, The FNN is capable of universal approximation with high mapping accuracy 关15– 19兴 and offers the following benefits: 共1兲 the abil-ity to learn from experience and adaptabilabil-ity,共2兲 a simple learning algorithm, and 共3兲 a high degree of robustness and fault tolerance. Here, we will use the FNN to automatically tune the PID con-troller parameters for a different model.

In this paper, we use the FNN to develop a for-mula for designing the PID controller. This PID controller satisfies the criterions IAE andMs.The FNN system will be used to identify the relation-ship between the plant model and controller pa-rameters. To derive the tuning rule, the dominant pole assignment method is applied to simplify our optimization processes. Therefore, the FNN sys-tem is used to automatically tune the PID control-ler for different system parameters. The FNN-based formula can modify the controller to meet our specification when the system model changes 共parameters or plant order varies兲. Simulation re-sults are given to demonstrate the effectiveness of our approach.

The arrangement of this paper is as follows. In Section 2, we briefly introduce problem formula-tion, dominant pole assignment method, and the FNN structure. Section 3 presents the proposed tuning formula using the FNN. Section 4 gives the simulation result. Finally, conclusions are summa-rized in Section 5.

2. Preliminaries

2.1. Problem formulation

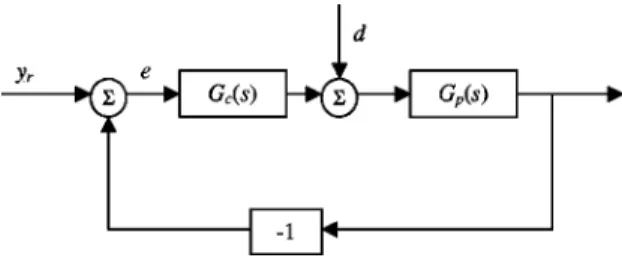

Consider the feedback control system, shown in Fig. 1, that composes a process and a controller,

whered denotes the external disturbance. Assume that the process is modeled by an nth-order pro-cess with time delay

Gp共s兲⫽ bmsm⫹bm⫺1sm⫺1⫹¯⫹b1s⫹b0 sn⫹a n⫺1sn⫺1⫹¯⫹a1s⫹a0 e⫺Ls. 共1兲 Here, we assume n⬎m. Here we assume process 共1兲 is stable, i.e., all poles of Eq. 共1兲 have a nega-tive real part. For the PID controller, the transfer function is given by

GC共s兲⫽k⫹ki

s ⫹kds, 共2兲 and the implementation is

u共t兲⫽ke共t兲⫹ki

冕

e共t兲dt⫹kdde共t兲 dt , wheree⫽yr⫺y, u, yr, andy are the control sig-nal, the set point, and plant output, respectively.Thus, 1⫹Gc共s兲Gp共s兲 ⫽1⫹共ki⫹sk⫹kds 2兲共b msm⫹bm⫺1sm⫺1⫹¯⫹b0兲 s共sn⫹a n⫺1sn⫺1⫹¯⫹a0兲 e⫺Ls. 共3兲 Herein, we adapt the second-order Pade´ approxi-mation to replace the time-delay element, i.e.,

e⫺Ls⫽a共s兲 b共s兲⫽ 1⫺Ls 2 ⫹ 共Ls兲2 12 1⫹Ls 2 ⫹ 共Ls兲2 12 . 共4兲

Therefore, the characteristic polynomial is ob-tained as follows: ⌬共s兲⫽共bmsm⫹¯⫹b1s⫹b0兲共ki⫹sk⫹kds2兲 ⫻

冉

1⫺Ls 2 ⫹ 共Ls兲2 12冊

⫹s共sn⫹¯⫹a 1s⫹a0兲 ⫻冉

1⫹Ls 2 ⫹ 共Ls兲2 12冊

. 共5兲It is clear that there aren⫹3 poles in Eq.共5兲. For system to be stable, we should properly design the controller parameters (k,ki,kd) such that all roots

of Eq.共5兲 lie on the left half of the complex plane. The purpose of this paper is to propose a method that designs the PID controller satisfying stabiliza-tion and performance index for different models. That is, when the plant model is changed, then the PID controller varies to be a proper one by the FNN system at the same time.

For system performance and robustness require-ment, let us introduce the integrated absolute error

共IAE兲 and maximum sensitivity Ms 关2兴. The IAE

is defined as

IAE⫽

冕

0 ⬁

兩e共t兲兩dt. 共6兲

The criterion IAE is in many cases a natural choice, at least for control of quality variables. The robust specifications usually include gain margin, phase margin, and sensitivity. Herein, a robustness measure for stability, the maximum sensitivity Ms, is adopted. Let Ms be defined as

Ms⫽ max 0⭐w⬍⬁

冏

1

1⫹Gp共jw兲GC共jw兲

冏

. 共7兲 The typical values for the maximum value of the sensitivity function are in the range of 1.3 to 2关2兴. These two specifications are adopted to select the proper parameters that results robustness and good static-state response.2.2. Dominant pole assignment method

Herein, the dominant pole assignment method 关2兴 is introduced by choosing controller

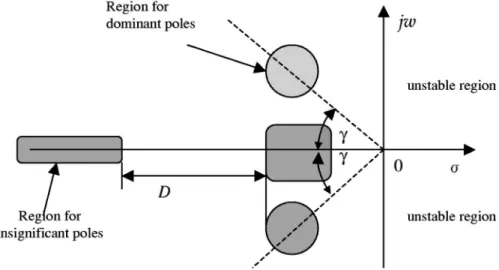

param-eters (k,ki,kd) based on the above specifications for the poles placement. In practical use, these tems are usually approximated by lower-order sys-tems based on transient response 关20兴. Therefore, in design, we can use the dominant poles to con-trol the dynamic performance of the system. As in Ref.关20兴, for design purposes, such as in the pole-placement design, the dominant poles and the in-significant poles, as selected by the designer, should most likely be located in the shaded re-gions in Fig. 2. According to this method, for dif-ferent models, the time responses of the closed-loop systems with the same dominant poles will have similar results. The remaining question is to choose proper dominant poles. In this paper, the dominant poles are set based on the IAE and Ms criteria.

In the following, we briefly introduce the rela-tion of dominant poles and PID controller param-eters. Note that there are three tuning parameters

(k,ki,kd) andn⫹3roots in Eq.共5兲. Therefore, we can assign three poles of the closed-loop system. Thus, the other poles are obtained relatively. As-sume the desired poles are

P1,2⫽w0共⫺0⫾ j

冑

1⫺0 2兲⫽w0ej(⫺␥),

共8兲 P3⫽⫺␣0w0,

where cos␥⫽0. For simplicity, we introduce the quantitiesa(w0), b(w0), and(w0) defined by

GP共w0ej(⫺r)兲⫽a共w

0兲ej(w0),

共9兲 GP共⫺␣0w0兲⫽⫺b共w0兲.

The condition that P1, P2, and P3 are roots of Eq.共5兲 is given as follows 关2兴:

冋

b ⫺b␣0w0

⫺␣0w0b ⫺a cos a cos共⫹␥兲

w0 w0a cos共⫺␥兲 ⫺a sin a sin共⫹␥兲

w0 w0a sin共⫺␥兲

册

⫻冋

k ki kd册

⫽冋

1 1 0册

. 共10兲 Thus, k⫽⫺␣0 2b sin共␥⫹兲⫹b sin共␥⫺兲⫹␣ 0a sin2␥ ab共␣02⫺2␣0cos␥⫹1兲sin␥ , 共11a兲 ki⫽⫺␣0w0a sin␥⫹b关sin共␥⫺兲⫹␣0sin兴ab共␣02⫺2␣0cos␥⫹1兲sin␥

,

共11b兲 kd⫽⫺␣0a sin␥⫹b关␣0sin共␥⫹兲⫺sin兴

w0ab共␣02⫺2␣0cos␥⫹1兲sin␥ .

共11c兲 By the definition of the dominant poles, we have to check the system’s stability and the other poles are far from the dominant pole. Therefore, we use the superposition principle to select (0,w0,␣0)

and then design the PID controller by IAE and Ms.

Remark 1. As in the above discussion, the process is of order n with time delay L such that the closed-loop system has n⫹3 poles. If the consid-ered plant is of lower order without time delay, for example, first order or second order, the domain-pole properties is not obvious. Therefore, in this case, we set the dominant poles to be P1 andP2.

In Section 4, a motor position control is used as an example to explain this case.

2.3. Fuzzy neural network

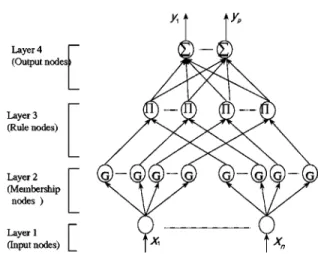

The FNN is one kind of fuzzy inference system 关15–19兴. Herein, the FNN system is a static case of the recurrent fuzzy neural network 共RFNN兲 关18兴. A schematic diagram of the four-layered

FNN is shown in Fig. 3. The simplified fuzzy rea-soning is briefly described as follows.

Given the training input data xk, k⫽1,2,...,n

and the desired output yp, p⫽1,2,...,m, the ith control rule has the following form:

Ri: I f x1 is A1 i

and ¯xn is An i

then y1 is w1i and ¯ym is wmi ,

wherei is a rule number, theAqi’sare membership functions of the antecedent part, andwpi’sare real numbers of the consequent part. When the inputs are given, the truth value i of the premise of the ith rule is calculated by

i⫽A1 i共 x1兲A2 i共 x2兲¯An i共 xn兲. 共12兲 Among the commonly used defuzzification strate-gies, the simplified fuzzy reasoning yields a supe-rior result. The output where yp of the fuzzy rea-soning can be derived from the following equation:

yp⫽

兺

iwpii, p⫽1,2,...,m, 共13兲 where i is the truth value of the premise of the ith rule. The FNN system has total four layers.

Nodes in the first layer are input nodes repre-senting input linguistic variables. Layer two has membership nodes. Here, the Gaussian function is used as the membership function. Each member-ship node is responsible for mapping an input lin-guistic variable into a possibility distribution for that variable. The rule nodes reside in layer three. The last layer contains the output variable nodes.

More details about FNNs, convergent theorems, and the learning algorithm can be found in Refs. 关15–19兴. Also, the FNN used here has been shown to be a universal approximator. That is, for any given real function h: Rn→Rp, continuous on a compact set K傺Rn, and arbitrary ⬎0,there ex-ists a FNN system F(x,W), such that 储F(x,W)

⫺h(x)储⬍ for everyx inK.

As in the previous discussion, the FNN system is used to find the mapping of the plant model and controller parameters. Therefore, the FNN system used is with n⫹m⫹2 inputs and three outputs, i.e., input variables (an⫺1,...,a0,bm,...,b0,L)

and output variables(k,ki,kd). Details will be de-scribed in the following section.

3. Tuning method for PID controller

Our proposed method can be described in two stages. The design goal of the first stage is to se-lect(k,ki,kd) for a process such that IAE is mini-mized under the constraint thatMs is between 1.3 and 2.0. The second stage is to get training pattern and train the FNN system for developing the pa-rameter tuning formulas.

3.1. Controller design method

Here, our purpose is to design the PID controller to satisfy the IAE and Ms criteria. As previously discussed, it is clear that the PID controller param-eter(k,ki,kd) is obtained by using Eq.共11兲 if the dominant poles of Eq.共5兲,P1 – 3, are chosen. From the discussion of Ref.关21兴, the transient response properties are guaranteed by dominant pole as-signment. Also, the characteristics of the closed-loop systems having the dominant poles P1 – 3 are similar. Therefore, we can predesign for a plant with three polesP1 – 3satisfying our specifications. Then, ranges as shown in Fig. 2 are chosen for the considered plant to find the optimal results.

In practice, the industrial processes are usually modeled as a first-order plus time delay plant, e.g., G(s)⫽关Kp/(1⫹as)兴e⫺sL.Therefore, for clarity, we here choose this system to predesign the domi-nant pole locations (0* ,w0* ,␣0*) that satisfy our

requirement, i.e., IAE and Ms criteria.

For convenience, the design procedure is de-scribed as follows:

Procedure 1.

Step 1. Consider the open-loop response of plant Gb共s兲⫽ k

s3⫹a2s2⫹a1s⫹a0

e⫺sL,

and set the poles of Gb(s) as the dominant poles

(0* ,w0* ,␣0*).

Step 2. Randomly choose poles 关Datal ⫽(0

l,w 0 l,␣

0

l), l⫽1,...,N] from the desired ranges as shown in the shaded region of Fig. 2, i.e.,

⍀⫽

兵

共0,w0,␣0兲兩w0*ej(⫺␥*)⫹Rp1,2ej ⭐w0ej(⫺␥)⭐w0*ej(⫺␥ *)⫹R p1,2ej, ␣0*w0*⫺Rp3⭐␣0w0⭐␣0*w0*⫹Rp3, Rp 1,2⬎0, Rp3⬎0, 0⭐⬍2其

. 共14兲Step 3. Using Eq.共11兲, we have the corresponding PID controller parameters Cl⫽(kl,kil,kdl).

Step 4. Choose the proper parameters Cl ⫽(kl,k

i l,k

d

l) that satisfy the dominant pole prop-erty and system stability for each control Cl ⫽(kl,k

i l

,kdl).

Step 5. Calculate the corresponding IAE and Ms.

Step 6. If l⬍N, go to Step 1.

Step 7. Choose the pair satisfying Cl*

⫽minlIAE(kl,ki l,k d l), 1.3⭐M s(kl,ki l,k d l)⭐2.0. Remark 2. In Step 2, we select three poles (the dominant poles), and the other n poles (P4,..., Pn⫹3) are set simultaneously. Therefore, for system stability, we must prove these poles lie on the left-half plane. Besides, in Step 4, we should also guarantee the dominant pole proper-ties. That is, these insignificant poles(P4,...,Pn⫹3) should be far from the dominant poles(P1,...,P3). In this paper, the distance D is set to be 5w0max(␣0,0); see Fig. 2.

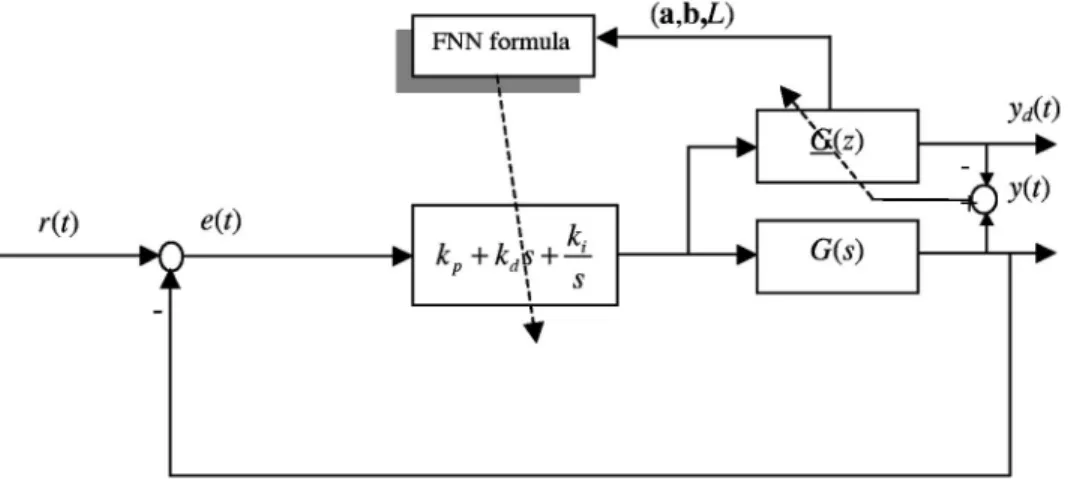

3.2. FNN-based PID tuning formulas

Herein, our goal is to develop a tuning formula for general plant, (k,ki,kd)⫽ f (a,b,L), where a ⫽(an⫺1,...,a0),b⫽(bm,...,b0). That is, this

for-mula can automatically tune the PID controller so that neither theoretical methods nor numerical methods need to be used. In this paper, we first obtain the PID controller for given processes using

Procedure 1. These processes are randomly chosen from a known range, i.e., ai⫽(aគi,a¯i), bi ⫽(bគi,b¯i),andL⫽(Lគ,L¯).This is called the varia-tion of plant parameters. We then train the FNN system to identify the mapping of process model and controllers. Fig. 4 summarizes our approach. Because our objective is controller parameters and FNN’s inputs are plant parameters, we must create the training data to train the FNN. For the con-trolled plant, using Procedure 1, we have the cor-responding PID controller. Subsequently, train the FNN to develop the PID controller tuning for-mula.

Remark 3. In practice, the typical industrial pro-cesses are usually modeled as follows (see [2,21]): Two-parameter model: G1共s兲⫽ K 1⫹sT. Three-parameter model: G2共s兲⫽ K 1⫹sTe⫺sL. Four-parameter model: G3共s兲⫽ K 共1⫹sT1兲共1⫹sT2兲e⫺sL.

For generalizing and applying our approach to these test plants, we presented our approach for general systems in this manuscript. Consequently, the number of FNN input is less or equal to 4. From the previous literature [15–19], it is known that the FNN system is capable of universal ap-proximation with high mapping accuracy and of-fers the ability to learn from experience, adapt-ability, and a high degree of robustness and fault tolerance. Moreover, our approach is applicable for high-order system by previous discussion.

Remark 4. From the previous discussion, after developing and training the FNN system, we can conclude that the FNN system automatically de-signs the PID controller for system model so that neither theoretical methods nor numerical meth-ods need be used. Moreover, the FNN-based for-mula is able to modify the PID controller accord-ing to the system model variation.

3.3. Training of the FNN system

Considering the single-output case for clarity, our goal is to minimize the error function

E共k兲⫽1

2关yP共k兲⫺yˆ共k兲兴

2⫽1

2e

2共k兲, 共15兲 where yP and yˆ denote the desired output

(k,ki,kd) and estimated output(kˆ,kˆi,kˆd), respec-tively. Then, the gradient of the above error func-tion is E ⌰ ⫽e共k兲 e共k兲 ⌰ ⫽⫺e共k兲 yˆ共k兲 ⌰ , 共16兲

where⌰⫽关m,,w兴 represents the weighting vec-tor of the FNN,mis the mean共center of member-ship function兲, is the standard deviation 共width of the membership function兲, andw is the linking weight between layers 3 and 4. By using the gen-eral backpropagation algorithm, we can describe the update law for the linear system as

⌰共k⫹1兲⫽⌰共k兲⫹⌬⌰共k兲 ⫽⌰共k兲⫹

⌰冉

⫺E共k兲 ⌰冊

⫽⌰共k兲⫹

⌰e共k兲冉

⫺yˆ共k兲 ⌰冊

. 共17兲 Therefore, we have the update laws for the FNN:mi j共k⫹1兲⫽mi j共k兲⫹

me共k兲yˆ共k兲 m , 共18a兲 i j共k⫹1兲⫽i j共k兲⫹

e共k兲 yˆ共k兲 , 共18b兲 wi j共k⫹1兲⫽wi j共k兲⫹

we共k兲 yˆ共k兲 w , 共18c兲 Fig. 4. Training architecture of the FNN-based PID tuningwhere

m,

, and

w are the learning rates form 共mean兲,共STD兲, andw 共weight兲, respectively.

The convergence of the FNN system’s parameters is guaranteed by Refs. 关15–19兴. Details can be found in Refs. 关15–17兴.

3.4. On-line tuning of the FNN formula

After training the FNN system, the FNN-based PID formula is available for system control prob-lem. The control architecture is shown in Fig. 5, where the identification block is to obtain the sys-tem’s parameter variation. For system identifica-tion, we first digitize the continuous-time system to a discrete-time system by a small sampling time Ts. Details for system identification can be found in Ref.关22兴. Consequently, the least squares algo-rithm is used to identify the system parameters. In Section 4, a simulation for applying to a motor position control system is shown to illustrate the effectiveness of this scheme.

4. Simulation results

Our approach is applied to an example to illus-trate the effectiveness and robustness. As the de-scription in 关2,21兴, in practice, the typical indus-trial processes are usually modeled as a first- or second-order with time-delay system. Conse-quently, a third-order with time-delay plant is adopted in the following examples. The plant is

G共s兲⫽ Kpe

⫺sL

a3s3⫹a

2s2⫹a1s⫹a0

. 共19兲

Herein, plant 共19兲 can be reduced to a second or first order if a3⫽0, a2⫽0, or a3⫽0, a2⫽0, a1 ⫽0.We choose the range(aគ3,a¯3),(aគ2,a¯2) of

pa-rameters(a3,a2) that contains the zeros. Then the

FNN-PID formulas can be used for the system with order less or equal to three. In the following the range is chosen as

a3苸关0,1兴, a2苸共⫺1,10兲, a1苸共0,100兲,

a0苸共0.01,100兲, KP苸共0.01,100兲, and L苸关0,2兴.

After eliminating the dissatisfying data, there are 2188 training data left finally. The training error is

2.1⫻10⫺4.

Example 1. For the plant G共s兲⫽ 20e

⫺2s

共s2⫹2.4s⫹4兲共s⫹5兲,

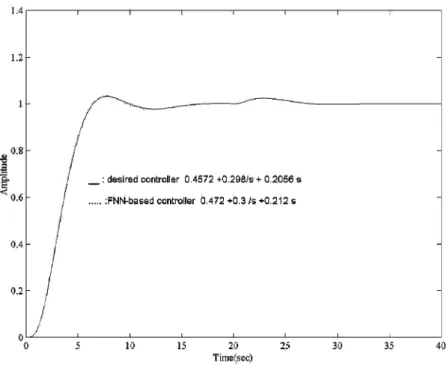

We assume the plant parameters are exactly known. The developed formula is then tested for the above plant. The step point and load distur-bance response in Fig. 6 demonstrates the effec-tiveness of our approach. The disturbance with magnitude 1 is given at time 20 to 20.1 s. The example shows that the FNN has provided a good mapping result for the system parameter and PID controller.

Example 2. Consider the DC motor position con-trol system in Fig. 7, where the motor is assumed to have the transfer function

Gm共s兲⫽ K

s共Js⫹b兲共Ls⫹R兲

⫽LJs3⫹共bL⫹JRK 兲s2⫹bRs. Here the parameters of the dc motor will vary when the system load changes. Therefore, the on-line control scheme is applied to solve the position control problem. Obviously, the system is without a time-delay term, and the closed-loop system has four poles. Therefore, we choose two dominant poles with a complex conjugate pair. Here, to sim-plify our computation, the PI controller was cho-sen.

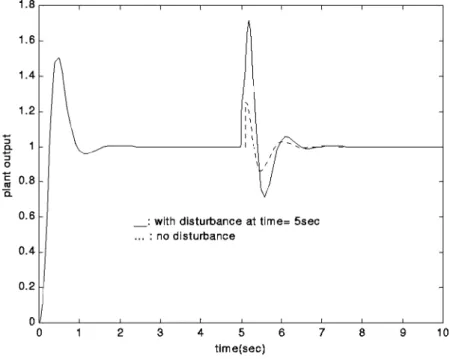

In this example, we assume the plant loading changes at time 5 s, where the plant is described as follows:

Nominal plant:

15

0.005s3⫹0.1s2⫹1.305s.

Plant with loading variant:

18

0.0032s3⫹0.072s2⫹1.28s.

The identification plant:

18

0.0031s3⫹0.077s2⫹1.25s.

The FNN-based formulas for the two plants are

(0.39s⫹1.82)/s and (0.45s⫹1.41)/s , respec-Fig. 6. Simulation result of the test plant G(s)⫽ 20e⫺2s/(s2⫹2.4s⫹4)(s⫹5) .

tively. The parameter variation of the process is identified by the least squares method at time 5 to 5.1 s, i.e., the controller changes at time 5.1 s. Herein, in identification, 11 input-output pairs are chosen to estimate the model. To demonstrate the robustness of our approach, an impulse input dis-turbance with magnitude 2 is given at time 5 to 5.1 s. Fig. 8 gives the simulation result. The simula-tion result demonstrates the effectiveness of our approach.

According to the above example, it is indicated that the proposed FNN-based formula and archi-tecture can estimate the parameters of the motor to adjust the self-tuning PI controller control param-eters.

5. Conclusions

We have presented an efficient practical method to design the PID controller. This PID controller is based on the criteria of the minimum absolute in-tegrated error 共IAE兲 and maximum of sensitivity

( Ms). The FNN system was used to identify the relationship between the plant model and control-ler parameters based on IAE and Ms. To derive the tuning rule, the dominant pole assignment method is applied to simplify our optimization processes. The FNN system automatically designs

the PID controller for the system model so that neither theoretical methods nor numerical methods need be used. Moreover, the FNN-based formula is able to modify the PID controller according to the system model variation. Simulation results have demonstrated the effectiveness of our ap-proach.

Acknowledgments

The authors would like to thank the anonymous referees for their constructive comments and sug-gestions. This work was supported by the National Science Council, Taiwan, R.O.C., under Contract No. NSC-90-2213-E-155-027.

References

关1兴 Astrom, K. J., Hagglund, T., Hang, C. C., and Ho, W. K., Automatic tuning and adaptation for PID controllers—A survey. IFAC J. Control Eng. Practice

1, 699–714共1993兲.

关2兴 Astrom, K. J. and Hagglund, T., PID Controllers: Theory, Design, and Tuning. ISA, Research Triangle Park, NC, 1995.

关3兴 Astrom, K. J. and Hagglund, T., Automatic tuning of simple regulators with specifications on phase and am-plitude margins. Automatica 20, 645– 651共1984兲. 关4兴 Chu, S. Y. and Teng, C. C., Tuning of PID controllers

based on gain and phase margin specifications using fuzzy neural network. Fuzzy Sets Syst. 101, 21–30 共1999兲.

关5兴 Ho, W. K., Hang, C. C., and Zhou, J. H., Performance and gain and phase margins of well-known PI tuning formulas. IEEE Trans. Control Syst. Technol. 3, 245– 248共1995兲.

关6兴 Ho, W. K., Gan, O. P., Tay, E. B., and Ang, E. L., Performance and gain and phase margins of well-known PID tuning formulas. IEEE Trans. Control Syst. Technol. 4, 473– 477共1996兲.

关7兴 Ho, W. K., Hang, C. C., and Cao, L. S., Tuning of PID controllers based on gain and phase margin specifica-tion. Automatica 31, 497–502共1995兲.

关8兴 Ho, W. K., Hang, C. C., and Zhou, J., Self-tuning PID control of A plant with under-damped response with specifications on gain and phase margins. IEEE Trans. Control Syst. Technol. 5, 446 – 452共1997兲.

关9兴 Ho, W. K. and Xu, W., PID tuning for unstable pro-cesses based on gain and phase-margin specifications. IEE Proc.: Control Theory Appl. 145, 392–396 共1998兲.

关10兴 Shen, J. C., New tuning method for PID control of a plant with under-damped response. Asian J. Control 2, 31– 41共2000兲.

关11兴 Shen, J. C., Fuzzy neural-networks for tuning PID controller for plants with underdamped responses. IEEE Trans. Fuzzy Syst. 9, 333–342共2001兲. 关12兴 Xu, J. X., Liu, C., and Hang, C. C., Tuning of fuzzy PI

controllers based on gain/phase margin specifications and ITAE index. ISA Trans. 35, 79–91共1996兲. 关13兴 Rodrige, M. A., Seco, A., Ferrer, J., Penya-roja, J. M.,

and Valverde, J. L., Nonlinear control of an activated sludge aeration process: Use of fuzzy techniques for tuning PID controllers. ISA Trans. 38, 231–241 共1999兲.

关14兴 Shafiei, Z. and Shenton, A. T., Tuning of PID-type controllers for stable and unstable systems with time delay. Automatica 30, 1609–1615共1994兲.

关15兴 Lee, C. H. and Teng, C. C., Tuning of PID controllers for stable and unstable processes based on gain and phase margin specifications: A fuzzy neural approach. Int. J. Fuzzy Sys. 3, 346 –355共2001兲.

关16兴 Chen, Y. C. and Teng, C. C., A model reference control structure using a fuzzy neural Network. Fuzzy Sets Syst. 73, 291–312共1995兲.

关17兴 Chen, Y. C. and Teng, C. C., Fuzzy neural network systems in model reference control Systems. In Neural Network Systems, Technique and Applications, edited

by C. T. Leondes, Academic Press, San Diego, 1998, Vol. 6, pp. 285–313.

关18兴 Lee, C. H. and Teng, C. C., Identification and control of nonlinear dynamic systems using recurrent fuzzy neural networks. IEEE Trans. Fuzzy Syst. 8, 349–366 共2000兲.

关19兴 Lee, C. H. and Teng, C. C., Fine tuning of membership function for fuzzy neural systems. Asian J. Control 3, 216 –225共2001兲.

关20兴 Kuo, B. C., Automatic Control Systems, 6th ed. Pren-tice Hall, New York, 1993.

关21兴 Isermann, R., Digital Control Systems. Springer Ver-lag, Berlin, 1981.

关22兴 Hsia, T. C., System Identification: Least-Squares Methods. Heath, New York, 1977.

Ching-Hung Lee was born in Taiwan, R.O.C., in 1969. He received B.S. and M.S. degrees in Control Engineering from the National Chiao Tung Uni-versity, Hsinchu, Taiwan, R.O.C., in 1992 and 1994, re-spectively, and the Ph.D. de-gree in Electrical and Control Engineering from the National Chiao Tung University, in 2000. He is currently an Assis-tant Professor of the Depart-ment of Electrical Engineering at Yuan Ze University. His main research interests are fuzzy neural systems, fuzzy logic control, neural network, signal processing, non-linear control systems, and robotics control.

Ching-Cheng Teng was born in Taiwan, R.O.C., in 1938. He received a B.S. degree in Elec-trical Engineering from the National Cheng Kung Univer-sity, Taiwan, in 1961. During 1991–1998, he was the Chair-man of the Department of Electrical and Control Engi-neering, National Chiao Tung University. He is currently a Professor of the Department of Electrical and Control Engi-neering at National Chiao Tung University. His research interests includeH⬁ optimal control, signal processing, and fuzzy neural systems.