Journal of Mechanics

http://journals.cambridge.org/JOMAdditional services for

Journal of Mechanics:

Email alerts: Click hereSubscriptions: Click here Commercial reprints: Click here Terms of use : Click here

Endochronic Simulation on the Effect of Curvature Rate at the Preloading

Stage on the Subsequent Creep or Relaxation of Thin-Walled Tubes Under

Pure Bending

K.-H. Chang and C.-Y. Hung

Journal of Mechanics / Volume 27 / Issue 04 / December 2011, pp 511 - 519 DOI: 10.1017/jmech.2011.54, Published online: 07 December 2011

Link to this article: http://journals.cambridge.org/abstract_S1727719111001055

How to cite this article:

K.-H. Chang and C.-Y. Hung (2011). Endochronic Simulation on the Effect of Curvature Rate at the Preloading Stage on the Subsequent Creep or Relaxation of Thin-Walled Tubes Under Pure Bending. Journal of Mechanics, 27, pp 511-519

doi:10.1017/jmech.2011.54

Request Permissions : Click here

Journal of Mechanics, Vol. 27, No. 4, December 2011 511

ENDOCHRONIC SIMULATION ON THE EFFECT OF CURVATURE-

RATE AT THE PRELOADING STAGE ON THE SUBSEQUENT CREEP OR

RELAXATION OF THIN-WALLED TUBES UNDER PURE BENDING

K.-H. Chang *

Department of Mold and Die Engineering National Kaohsiung University of Applied Sciences

Kaohsiung, Taiwan 80778, R.O.C. C.-Y. Hung **

Department of Mechanical Engineering R.O.C. Military Academy Kaohsiung, Taiwan 83059, R.O.C.

ABSTRACT

In this paper, the first-order ordinary differential constitutive equations of endochronic theory were combined with the principle of virtual work for simulating the response of creep (moment is kept constant for a period of time) or relaxation (curvature is kept constant for a period of time) of thin-walled tubes subjected to pure bending with different curvature-rates at the preloading stage. A group of Fourier se-ries was used to describe the circumferential displacements of the tube. Thus, a system of nonlinear al-gebraic equations was determined. This system of equations can be solved by numerical method. Ex-perimental data tested by Pan and Fan [1] were compared with the theoretical simulations in this study. It is shown that the theoretical formulations effectively simulate the experimental data.

Keywords: Endochronic theory, Thin-walled tubes, Pure bending, Curvature-rate, Creep, Relaxation.

1. INTRODUCTION

It has been shown that bending of circular tubes leads to the ovalization of the tube cross-section (change of the outside diameter / original outside di-ameter, D/D). Increase bending may cause a gradual growth in ovalization. The increasing ovalization pro-gressively reduces in the bending rigidity of the tube. The tube will buckle when a critical magnitude of ovalization is reached.

Kyriakides and his co-workers designed and con-structed a tube cyclic bending machine and conducted a series of experimental and theoretical investigations. Kyriakides and Shaw [2] examined the response and stability of elastoplastic pipes under monotonic bending and external pressure. Shaw and Kyriakides [3] in-vestigated the inelastic behavior of 6061-T6 aluminum and 1018 steel tubes subjected to cyclic bending. Kyriakides and Shaw [4] extended the analysis of 6061- T6 aluminum and 1018 steel tubes to the stability con-ditions under cyclic bending. Corona and Kyriakides [5] examined the stability of 304 stainless steel tubes subjected to combined bending and external pressure. Corona and Kyriakides [6] studied the degradation and

buckling of 6061-T6 aluminum and 1020 carbon steel tubes under cyclic bending and external pressure. Corona and Vaze [7] studied the response, buckling and collapse of long, thin-walled seamless steel square tubes under bending. Vaze and Corona [8] experi-mentally investigated the elastic-plastic degradation and collapse of steel tubes with square cross-sections under cyclic bending. Corona and Kyriakides [9] looked into the collapse of 304 stainless steel tubes subjected to external pressure and bending. Corona et al. [10] conducted a set of bending experiments on aluminum alloy tubes to explore the effects of yield anisotropy on buckling. Kyriakides et al. [11] examined the plastic bending of steel tubes with a diameter-to-thickness ratio of 18.8 displaying Lüders bands.

Pan and his co-workers also constructed a similar bending machine with a newly invented measurement apparatus, which was designed and set up by Pan et al. [12], to study various kinds of tubes under different cyclic bending conditions. Pan and Her [13] investi-gated the response and stability of 304 stainless steel tubes subjected to cyclic bending with different curva-ture-rates. Lee et al. [14] studied the influence of di-ameter-to- thickness ratio on the response and stability of circular tubes subjected to cyclic bending. Lee et al. * Assistant Professor, corresponding author ** Assistant Professor

DOI : 10.1017/jmech.2011.54

512 Journal of Mechanics, Vol. 27, No. 4, December 2011

[15] experimentally examined the effect of the diame-ter-to- thickness ratio and curvaturate on the re-sponse and stability of circular tubes subjected to cyclic bending. Chang et al. [16] studied the mean moment effect on circular thin-walled tubes under cyclic bend-ing. Chang and Pan [17] studied the buckling life estimation of circular tubes under cyclic bending.

In addition, Elchalakani et al. [18] experimentally investigated on the cyclic inelastic behavior of cold- formed circular hollow section (CHS) with Do / t ratios ranging from 20 to 40 using a variable amplitude load-ing history. Elchalakani and Zhao [19] tested the cy-clic inelastic flexural behavior of concrete-filled tubular (CFT) beams, which were made of cold-formed circular hollow sections filled with normal concrete, using a variable amplitude loading history.

Fan and Pan [1] experimentally investigated the re-sponse of the effect of different curvature-rates at the preloading stage on the subsequent creep or relaxation of thin-walled tubes under pure bending. According to their experimental result at the preloading stage, the tube exhibits hardening for higher curvature-rates. However, the ovalization of the tube’s cross-section also increases for higher curvature-rates. Next, at the subsequent creep stage, a higher curvature-rate at the preloading stage leads to a rapidly increased tube cur-vature and ovalization. The tube buckles at this stage. In addition, at the subsequent relaxation stage, a higher curvature-rate at the preloading stage leads to rapid decrease of the moment. However, the amount of ovalization does not change at this stage. Therefore, the tube does not buckle. Until now, the theoretical simulation of the aforementioned response and collapse has not been proposed.

In this study, the first-order ordinary differential constitutive equations of the endochronic theory pro-posed by Pan and Chern [20] were combined with the principle of virtual work for simulating the aforemen-tioned response. In addition, the rate-sensitivity func-tion of the intrinsic time scale proposed by Pan and Chern [20] and the scaling function of the intrinsic time scale proposed by Pan et al. [21] were used. Experi-mental data tested by Pan and Fan [1] were compared with the theoretical simulation in this study. It is shown that the proposed theory can properly simulate the experimental findings.

2. THEORETICAL FORMULATION In this section, the response of the 304 stainless steel tubes subjected to creep or relaxation with different curvature-rates at preloading stage tested by Pan and Fan [1] is analyzed. The kinematics of the tube cross section, the constitutive model and the principle of vir-tual work are discussed separately.

2.1 Kinematics

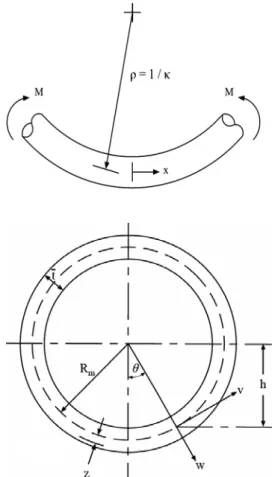

A circular tube subjected to cyclic bending is con-sidered in this study. Figure 1 shows the problem geometry, in which Rm is the mean radius, and t is the

Fig. 1 Problem geometry of circular tube subjected to pure bending

wall thickness. Based on the axial, circumferential, and radial coordinates x, and r, the displacements of a point on the tube’s mid-surface are denoted as u, v and w, respectively.

The kinematic relations required must be general enough to accommodate ovalization of the cross-section. Such a set of relations has been developed by Gellin [22] and used successfully by Kyriakides and Shaw [2]. Briefly, it is assumed that the plane sections perpen-dicular to the tube mid-surfaces before and during de-formation. The strains are assumed to remain small but finite rotations about both axes of bending are al-lowed. The axial strain is expressed as (Kyriakides and Shaw [2], Shaw and Kyriakides [3], Kyriakides and Shaw [4]):

0

x x h

(1)

and

( m ) cos sin cos

h R w v Z (2)

where 0 x

is the axial strain of the cylinder’s axis, h is distance between the point and the horizontal plane passing through the center of the cross-section, is the tube curvature and Z is the distance between the point and the midpoint surface. The circumferential strain is

0 h

518 Journal of Mechanics, Vol. 27, No. 4, December 2011

Fig. 9 Experimental and theoretical results of ovali-zation (D/D) vs. time (t) for 304 stainless steel tube of the entire loading (preloading and subsequent relaxation) under pure bending

NOMENCLATURES b material parameter

C material parameter Ci material constants D original outside diameter

e

deviatoric strain tensor

p e

deviatoric plastic strain tensor

(eeq op) reference equivalent deviatoric plastic strain-rate

(eeqp) relative equivalent deviatoric plastic strain-rate.

f() material hardening function g scaling function

h distance between the point and the horizontal plane

K bulk modulus

k temperature and rate-sensitivity function ks rate-sensitivity parameter

M tube bending moment m material parameter Rm mean radius

s

deviatoric stress tensor t Newtonian time t wall thickness V volume of the material u displacement in x-direction v displacement in -direction w displacement in r-direction

Z distance between the point and the midpoint surface

z intrinsic time scale i material constants material parameter

D change of the outside diameter W virtual work of the external loads

strain tensor

circumferential strain

0 x

axial strain of the cylinder’s axis kk trace of strain tensors

tube curvature o elastic shear modulus (z) kernel function

stress tensor

kk trace of stress tensors intrinsic time measure

REFERENCES

1. Pan, W. F. and Fan, C. H., “An Experimental Study on the Effect of Curvature-Rate at Preloading Stage on Subsequent Creep or Relaxation of Thin-Walled Tubes under Pure Bending,” JSME International Journal, Series A, 41, pp. 525531 (1998).

2. Kyriakides, S. and Shaw, P. K., “Response and Stability of Elastoplastic Circular Pipes under Combined Bending and External Pressure,” Inter-national Journal of Solids and Structures, 18, pp. 957973 (1982).

3. Shaw, P. K. and Kyriakides, S., “Inelastic Analysis of Thin-Walled Tubes under Cyclic Bending,” In-ternational Journal of Solids and Structures, 21, pp. 10731110 (1985).

4. Kyriakides, S. and Shaw, P. K., “Inelastic Buckling of Tubes under Cyclic Loads,” Journal of Pressure Vessel and Technology, ASME, 109, pp. 169178 (1987).

5. Corona, E. and Kyriakides, S., “On the Collapse of Inelastic Tubes under Combined Bending and Pressure,” International Journal of Solids and Structures, 24, pp. 505535 (1988).

6. Corona, E. and Kyriakides, S., “An Experimental Investigation of the Degradation and Buckling of Circular Tubes under Cyclic Bending and External Pressure,” Thin-Walled Structures, 12, pp. 229263 (1991).

7. Corona, E. and Vaze, S., “Buckling of Elas-tic-Plastic Square Tubes under Bending,” Interna-tional Journal of Mechanical Sciences, 38, pp. 753775 (1996).

8. Vaze, S. and Corona, E., “Degradation and Col-lapse of Square Tubes under Cyclic Bending,” Thin-Walled Structures, 31, pp. 325341 (1998). 9. Corona, E. and Kyriakides, S., “Asymmetric

Col-lapse Modes of Pipes under Combined Bending and Pressure,” International Journal of Solids and Structures, 24, pp. 505535 (2000).

10. Corona, E., Lee, L. H. and Kyriakides, S., “Yield Anisotropic Effects on Buckling of Circular Tubes under Bending,” International Journal of Solids and Structures, 43, pp. 70997118 (2006).

11. Kyriakides, S., Ok, A. and Corona, E., “Localiza-tion and Propaga“Localiza-tion of Curvature under Pure Bending in Steel Tubes with Lüders Bands,”

In-Journal of Mechanics, Vol. 27, No. 4, December 2011 519 ternational Journal of Solids and Structures, 45, pp.

30743087 (2006).

12. Pan, W. F., Wang, T. R. and Hsu, C. M., “A Cur-vature-Ovalization Measurement Apparatus for Circular Tubes under Cyclic Bending,” Experi-mental Mechanics, 38, pp. 99102 (1998).

13. Pan, W. F. and Her, Y. S., “Viscoplastic Collapse of Thin-Walled Tubes under Cyclic Bending,” Journal of Engineering Materials and Technology, ASME, 120, pp. 287290 (1998).

14. Lee, K. L., Pan, W. F. and Kuo, J. N., “The Influ-ence of the Diameter-to-Thickness Ratio on the Stability of Circular Tubes under Cyclic Bending,” International Journal of Solids and Structures, 38, pp. 24012413 (2001).

15. Lee, K. L., Pan, W. F. and Hsu, C. M., “Experi-mental and Theoretical Evaluations of the Effect between Diameter-to-Thickness Ratio and Curva-ture-Rate on the Stability of Circular Tubes under Cyclic Bending,” JSME International Journal, Se-ries A, 47, pp. 212222 (2004).

16. Chang, K. H., Pan, W. F. and Lee, K. L., “Mean Moment Effect of Thin-Walled Tubes under Cyclic Bending,” Structural Engineering and Mechanics – an International Journal, 28, pp. 495514 (2008). 17. Chang, K. H. and Pan, W. F., “Buckling Life

Esti-mation of Circular Tubes under Cyclic Bending,” International Journal of Solids and Structures, 46, pp. 254270 (2009).

18. Elchalakani, M., Zhao, X. L. and Grzebieta, R. H., “Variable Amplitude Cyclic Pure Bending Tests to Determine Fully Ductile Section Slenderness Lim-its for Cold-Formed CHS,” Engineering Structures, 28, pp. 12231235 (2006).

19. Elchalakani, M. and Zhao, X. L., “Concrete-Filled Cold-Formed Circular Steel Tubes Subjected to Variable Amplitude Cyclic Pure Bending,” Engi-neering Structures, 30, pp. 287299 (2008).

20. Pan, W. F. and Chern, C. H., “Endochronic De-scription for Viscoplastic Behavior of Materials under Multiaxial Loading,” International Journal of Solids and Structures, 34, pp. 21312159 (1997).

21. Pan, W. F., Chiang, W. J. and Wang, C. K., “En-dochronic Analysis for Rate- Dependent Elasto- Plastic Deformation,” International Journal of Sol-ids and Structures, 36, pp. 32153237 (1999). 22. Gellin, S., “The Plastic Buckling of Long

Cylin-drical Shells under Pure Bending,” International Journal of Solids and Structures, 16, pp. 397407(1980).

23. Valanis, K. C., “Fundamental Consequence of a New Intrinsic Time Measure- Plasticity as a Limit of the Endochronic Theory,” Achieve Mechanics, 32, pp. 171191 (1980).

24. Valanis, K. C., “On the Foundations of the Endo-chronic Theory of Plasticity,” Achieve Mechanics, 27, pp. 857872 (1975).

25. Lee, C. F., “Recent Finite Element Applications of the Incremental Endochronic Plasticity,” Interna-tional Journal of Plasticity, 11, pp. 843865 (1995).

26. Murakami, H. and Read, H. E., “A Second-Order Numerical Scheme for Integrating the Endochronic Plasticity Equations,” Computers and Structures, 31, pp. 663672 (1989).

27. Lee, C. F., Lee, Z. H. and Ou, S. H., “The Endo-chronic Viscoplasticity for Sn/3.9Ag/0.6Cu Solder under Low Strain Rate Fatigue Loading Coupled with Thermal Cycling,” Journal of Mechanics, 25, pp. 261270 (2009).

28. Valanis, K. C. and Fan, J., “Endochronic Analysis of Cyclic Elastoplastic Strain Fields in a Notched Plate,” Journal of Applied Mechanics, 50, pp. 787794 (1983).

(Manuscript received June 3, 2010, accepted for publication December 14, 2010.)