Y. Y. Hsieh

T. F. Lin

Department of Mechanical Engineering, National Chaio Tung University, Hsinchu, Taiwan, R.O.C.

Evaporation Heat Transfer and

Pressure Drop of Refrigerant

R-410A Flow in a Vertical Plate

Heat Exchanger

Experiments are carried out here to measure the evaporation heat transfer coefficient hr

and associated frictional pressure drop∆Pfin a vertical plate heat exchanger for

refrig-erant R-410A. The heat exchanger consists of two vertical counterflow channels which are formed by three plates whose surface corrugations have a sine shape and a chevron angle of 60 deg. Upflow boiling of refrigerant R-410A receives heat from the hot downflow of water. In the experiments, the mean vapor quality in the refrigerant channel is varied from 0.10 to 0.80, the mass flux from 50 to 100 kg/m2s, and the imposed heat flux from 10 to 20 kW/m2 for the system pressure fixed at 1.08 and 1.25 MPa. The measured data

indicate that both hrand∆Princrease with the refrigerant mass flux except at low vapor

quality. In addition, raising the imposed heat flux is found to significantly improve hrfor

the entire range of the mean vapor quality. However, the corresponding friction factor ft p

is insensitive to the imposed heat flux and refrigerant pressure. Based on the present data, empirical correlations are provided for hr and ft p, for R-410A in the plate heat

ex-changer. 关DOI: 10.1115/1.1518498兴

Keywords: Boiling, Evaporation, Heat Transfer, Heat Exchangers

1 Introduction

Over the past decades the HCFC共hydrochlorofluorocarbon兲 re-frigerant R-22 has been used as the working fluid in many refrig-eration and air-conditioning systems. But it will be phased out in a short period of time共before 2020兲 since the chlorine it contains has an ozone depletion potential共ODP兲 of 0.055 and compara-tively high global warming potential共GWP兲 of 1500 based on the time horizons of 100 years 关1,2兴. As a result, the search for a replacement for R-22 has been intensified in recent years. Owing to the fact that there are no single-component hydrofluorocarbons

共HFCs兲 that have thermodynamic properties close to those of

R-22, binary or ternary refrigerant mixtures have been introduced. The technical committee for the Alternative Refrigerants Evalua-tion Program共AREP兲 has proposed an updated list of the potential alternatives to R-22关2兴. Some of the alternatives on the AREP’s list are R-410A, R-410B, R-407C and R-507. Currently, R-134a is extensively used in many systems. A number of investigations have been reported in the literature dealing with the phase change heat transfer of R-134a in ducts of various geometries. However, the two-phase boiling and condensation heat transfer characteris-tics for R-410A, R-410B, and R-407C have not been studied ex-tensively. It should be mentioned here that refrigerant R-410A is a mixture of R-32 and R-125共50 percent by mass兲 which exhibits azetropic behavior with a temperature glide of about 0.1°C.

A number of studies have been reported in the open literature on the R-22 evaporation heat transfer in various enhanced ducts such as microfin tubes关3,4兴, internally-fin tubes 关5兴, and axially grooved tubes关6兴. The measured data were compared with other common refrigerants. Recently, Sami and Poirier关7兴 compared the evaporation and condensation heat transfer data inside an en-hanced tubing for several refrigerant blends proposed as substi-tutes for R-22, including R-410A, R-410B, R-507 and the quan-ternary mixture R-32/125/143a/134a. They showed that the two

phase heat transfer coefficient and pressure drops all increased with the refrigerant mass flux. In a continuing study 关8兴 they showed that in a double fluted tube for the refrigerant Reynolds number higher than 4.2⫻106, R-410A had better evaporation heat transfer than R-507. Wang et al.关9兴 compared the measured data for R-22 and R-410A flowing in a horizontal smooth tube and indicated that the heat transfer coefficients for R-410A were 10–20 percent higher than those for R-22 and the pressure drop of R-410A was about 30– 40 percent lower than that of R-22. This outcome was attributed to the higher latent heat of vaporization, thermal conductivity and specific heat, and lower liquid viscosity for R-410A. In a similar study Ebisu and Torikoshi关10兴 indicated that the evaporation heat transfer coefficient of R-410A was 20 percent higher than that of R-22 up to the vapor quality of 0.4, while the heat transfer coefficients for both R-410A and R-22 became almost the same at the quality of 0.6. Furthermore, the pressure drop for R-410A was about 30 percent lower than that of R-22 during evaporation. The quantitative differences in the pres-sure drops between R-410A and R-22 were mainly attributed to the lower vapor density for R-410A. Wijaya and Spatz 关11兴 reached a similar conclusion.

Plate heat exchangers 共PHEs兲 have been widely used in food processing, chemical reaction processes and many other industrial applications due to their high effectiveness, compactness, flexibil-ity, and cost competitiveness. Furthermore, they have been intro-duced to the refrigeration and air conditioning systems as evapo-rators or condensers. Recently, a number of investigations on PHEs were reported in the open literature. Unfortunately, these studies were mainly focused on the single-phase liquid-to-liquid heat transfer 关12–15兴. In view of this scarcity in the two-phase heat transfer data for PHEs, Yan and Lin关16兴 recently investigated the evaporation of R-134a in a vertical plate heat exchanger. They showed that that evaporation heat transfer for R-134a flowing in the PHE was much higher than that in circular tubes, particularly in high vapor quality convection dominated regime. Both the evaporation heat transfer coefficient and pressure drop increased

Contributed by the Heat Transfer Division for publication in the JOURNAL OF

HEATTRANSFER. Manuscript received by the Heat Transfer Division April 24, 2001; revision received July 25, 2002. Associate Editor: M. K. Jensen.

with the refrigerant mass flux and vapor quality. Moreover, the rise in the heat transfer coefficient with the quality was larger than that in the pressure drop.

The above literature review clearly reveals that although R-410A is one of the most possible substitutes for R-22, the two-phase heat transfer data for R-410A are still scarce especially for PHEs. To complement our previous study on the two-phase heat transfer in the PHE关16兴, the evaporation heat transfer of R-410A in a vertical PHE is investigated in this study.

2 Experimental Apparatus and Procedures

The experiment apparatus established previously to explore the R-134a evaporation in a PHE关16兴 is used here to investigate the evaporation heat transfer and associated frictional pressure drop of R-410A in a vertical PHE. It includes a refrigerant loop, two water loops共one for preheater and the other for the test section兲, and a cold water-glycol loop. R-410A is circulated in the refrigerant loop. In order to control various test conditions of R-410A in the test section, we need to control the temperature and flow rate in the other three loops. The detailed description of the apparatus is available from our earlier study关16兴. The refrigerant flow rate is measured by an accurate mass flux meter manufactured by Mir-comotion共Type UL-D-IS兲 with a reading accuracy of ⫾1 percent. Here only the test section employed in the experiment is described in some detail.

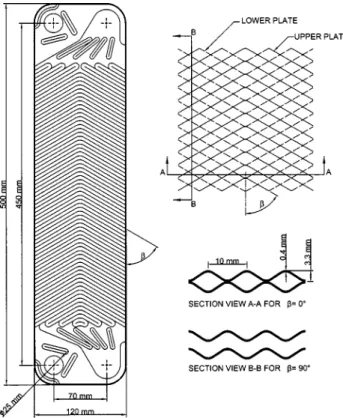

Three commercial SS-316 plates manufactured by the Kaori Heat Treatment Co. Ltd., Taiwan, form the plate heat exchanger

共test section兲. The plate surfaces are pressed to become grooved

with a corrugated sinusoidal shape and 60 deg of chevron angle. The detailed configuration of the PHE can be seen in Fig. 1. The corrugated grooves on the right and left outer plates have a V shape but those in the middle plate have a contrary V shape on both sides. This arrangement allows the flow stream to be divided into two different flow directions along the plates. Thus, the flow moves mainly along the grooves in each plate. Due to the contrary V shapes between two neighbor plates the flow streams near the two plates cross each other in each channel. This cross flow

re-sults in significant flow unsteadiness and randomness. In the PHE the upflow of R-410A in one channel is heated by the downflow of the hot water in the other channel. The heat transfer rate in the test section is calculated by measuring the total water temperature drop in the water channel and the water flow rate.

In each test the system pressure at the test section is first main-tained at a specified level. Then, the vapor quality of R-410A at the test section inlet is kept at the desired value by adjusting the temperature and flow rate of the hot water loop for the preheater. Next, the heat transfer rate between the counterflow channels in the test section can be varied by changing the water temperature and flowrate in the water loop for the tests section. Meanwhile, the R-410A mass flow rate in the test section is maintained at a desired value.

In the test any changes of the system variables will lead to fluctuations in the temperature and pressure of the refrigerant flow. It takes about 20–100 minutes for the system to reach a statistically stable state at which variations of the time-average inlet and outlet temperatures are both less than⫾0.2°C, and the variations of the pressure and imposed heat flux are within 1 per-cent and 4 perper-cent, respectively. Then the data acquisition unit is initiated to scan all the data channels for ten times in 50 sec. The mean value of the data for each channel is used to calculate the evaporation heat transfer coefficient and the associated frictional pressure drop. Additionally, the flow rate of water in the test sec-tion should be high enough to have turbulent flow in the water side so that the associated single-phase heat transfer in it is high enough for balancing the evaporation heat transfer in the refriger-ant side.

Before examining the R-410A evaporation heat transfer charac-teristics, a preliminary test for single-phase water-to-water con-vective heat transfer in the vertical PHE is performed. The Wil-son’s method关17兴 is adopted to calculate the relation between the single-phase heat transfer coefficient and the flow rate from these data. The result obtained can then be used to analyze the data acquired from the evaporation heat transfer experiments.

The uncertainties of the experimental results are analyzed by the procedures proposed by Kline and McClintock 关18兴. This analysis indicates that the uncertainties for the data of the imposed heat flux q, mass flux G, pressure P, pressure drop⌬P, average vapor quality Xmsingle phase heat transfer coefficient hw, evapo-ration heat transfer coefficient hr, and friction factor ft p are re-spectively⫾6.5 percent, ⫾2 percent, ⫾1 percent, ⫾1.5 percent,

⫾8 percent, ⫾11 percent, ⫾14.5 percent, and ⫾16.5 percent.

3 Data Reduction

The data reduction analysis detailed in our earlier study for R-134a evaporation关16兴 is also used here to deduce the R-410A evaporation heat transfer coefficient and associated frictional pres-sure drop from the meapres-sured raw data. Specifically, the data from the single-phase water-to-water heat transfer tests are analyzed by the modified Wilson plot关17兴. The single phase convection heat transfer coefficient in a PHE, suggested by Shah and Focke关12兴, can be expressed empirically as

hw⫽C•

冉

k Dh冊

•Re n•Pr1/3•冉

wall冊

0.14 (1) Here the constants C and n can be determined from the Wilson plot.To evaluate the evaporation heat transfer coefficient of the re-frigerant flow, the total heat transfer rate Qwbetween the counter flows in the PHE is calculated first from the hot water side. Then, the refrigerant vapor quality at the test section inlet is evaluated from the energy balance for the preheater. The change in the re-frigerant vapor quality in the test section is then deduced from the total heat transfer rate to the refrigerant in the test section,

⌬X⫽ Qw

Wr•if g

(2)

Fig. 1 Schematic diagram of the plate

The determination of the overall heat transfer coefficient for the evaporation of refrigerant R-410A in the PHE is based on the heat transfer between the counter-flow channels and is expressed as

U⫽ Qw

A•LMTD (3)

The log-mean temperature difference共LMTD兲 is determined from the inlet and exit temperatures in the two channels. According to the thermal resistances for heat transfer across the channel, the evaporation heat transfer coefficient in the flow of R-410A is evaluated from the equation

冉

1 hr冊

⫽冉

1 U冊

⫺冉

1 hw冊

⫺R wall•A (4)where hw is calculated from the single-phase water-to-water heat transfer test.

In order to obtain the friction factor associated with the R-410A evaporation in the refrigerant channel in the vertical PHE, the frictional pressure drop⌬Pf is calculated by subtracting the ac-celeration pressure drop, the pressure losses at the test section inlet and exit manifolds and ports, and the elevation pressure rise from the measured total pressure drop in the refrigerant channel. The acceleration pressure drop and elevation pressure rise are es-timated by the homogeneous model for two phase gas-liquid flow

关19兴. The pressure drop in the inlet and outlet manifolds and ports

was empirically suggested by Shah and Focke关12兴. Based on the above estimation, the acceleration pressure drop and the pressure losses at the test section inlet and exit manifolds and ports are found to be rather small. In fact, the summation of these two pressure losses ranges from 1 percent to 3 percent of the total pressure drop. The pressure drop due to the elevation difference between the inlet and outlet ports of the PHE is smaller than 1 percent of the total pressure drop. According to the definition

ft p⫽⫺

⌬Pf•Dh 2G2•v

m•L

(5) the friction factor for the evaporation of R-410A in the PHE is obtained

4 Results and Discussion

The single phase water-to-water convection heat transfer coef-ficient for the present vertical plate heat exchanger deduced from the modified Wilson plot can be correlated as

hw⫽0.2092•

冉

K1 Dh冊

•Re 0.78•Pr1/3•冉

m wall冊

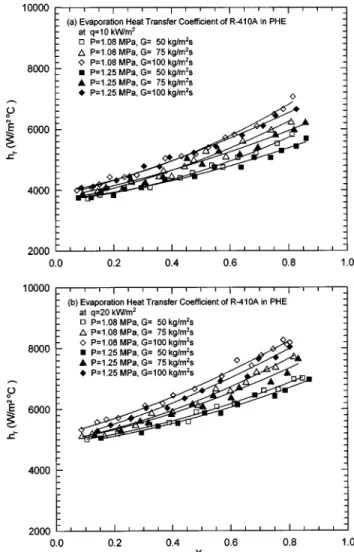

0.14 (6) with the regression accuracy of 0.997. Here the viscositiesmand wallare, respectively, based on the average bulk water and wall temperatures estimated by averaging the measured inlet and outlet temperatures in the hot and cold sides. The present single-phase heat transfer data well agree with Eq.共18兲 in the study of Muley and Manglik关13兴, as is clear from Fig. 2.Effects of the refrigerant mass flux, imposed heat flux and sys-tem pressure on the evaporation heat transfer of R-410A in the vertical PHE are illustrated in Fig. 3 by presenting the changes of the R-410A evaporation heat transfer coefficient with the refriger-ant vapor quality at the imposed heat fluxes q⫽10 and 20 kw/m2 for refrigerant mass fluxes G⫽50 to 100 kg/m2s, system pressures

P⫽1.08 and 1.25 MPa (Tsat⫽10°C and 15°C兲. In these plots Xm denotes the mean R-410A vapor quality in the PHE. The total change in the vapor quality⌬X in the test section for the present study ranges from 0.126 and 0.337. The data in Fig. 3 clearly indicate that a given heat flux, mass flux and system pressure the evaporation heat transfer coefficient increases noticeably with the mean vapor quality of the refrigerant in the PHE. For example, at

G⫽75 kg/m2s, P⫽1.08 MPa, and q⫽10 kW/m2the evapora-tion heat transfer coefficient at Xm of 0.8 is about 60 percent

higher than that at 0.1共Fig. 3共a兲兲.This significant increase of hr with Xm obviously results from the fact that in the high vapor quality regime, intense evaporation at the liquid-vapor interface diminishes the thickness of the liquid film on the plate surface to a noticeable degree. This, in turn, reduces the resistance of heat transfer from the channel surface to the refrigerant. Furthermore, the data also show that a rise in the refrigerant mass flux always produces an evident increase in the evaporation heat transfer co-efficient except at the low vapor quality regime. In fact, at low vapor quality (Xm⬍.20) the evaporation heat transfer coefficient is insensitive to the refrigerant mass flux. This can be ascribed to the fact that the interfacial evaporation of the liquid film on the plate is largely suppressed at low vapor quality. Moreover, the evaporation heat transfer coefficient for the higher mass flux rises more quickly with the vapor quality than that for the lower mass flux. This larger increase in hrwith Xmat a higher G is considered to result from the more intense turbulence in the flow for a higher

G. Similar results were noted for other system pressures. The

results in Fig. 3 further show that the evaporation heat transfer coefficient increases significantly with the imposed heat flux for both pressures. For example, at G⫽75 cg/m2s and P⫽1.08 MPa the quality-average evaporation heat transfer coefficients at 20 kW/m2is about 32 percent higher than that at 10 KW/m2. This large increase in the evaporation heat transfer coefficient is as-cribed to the higher wall superheat and thinner liquid film on the plate surface for a higher imposed heat flux. It is also noted that the evaporation heat transfer is slightly better at the lower pressure for a higher vapor quality (Xm⬎0.6). At the low vapor quality for

Xm⬍0.5 the effects of the pressure on the evaporation heat trans-fer is insignificant except for q⫽20 kW/m2 and G ⫽100 kg/m2s 共Fig. 3共b兲兲. This is attributed to the fact that the density of the R-410A vapor is lower at a lower saturated pres-sure, which causes the vapor flow to move in a higher speed and hence the higher evaporation heat transfer coefficient.

We also compare the present data for the R-410A evaporation heat transfer in the PHE with those for R-134A in the same PHE

Fig. 2 Comparison of the present single-phase water convec-tion heat transfer data with the correlaconvec-tion from Muley and Man-glik†13‡

reported by Yan and Lin 关16兴 and with those for R-410A in a horizontal smooth pipe collected by Ebisu and Torikoshi 关10兴. This comparison indicates that the R-410A evaporation heat trans-fer coefficient is higher than that for R-134a in the PHE to a noticeable degree except at high vapor quality for Xm⬎0.75. More specifically, at high Xm the R-134a evaporation is more effective. These opposite trends in different vapor quality ranges are attributed mainly to the different thermal conductivities of the two refrigerants for the liquid and vapor phases. Specifically, the liquid thermal conductivity for R-410A is higher than that for R-134a by about 20 percent. However, the vapor thermal conduc-tivity for R-410A is lower than that for R-134a. Hence, at lower quality the evaporation heat transfer coefficient for R-410A is higher than that for R-134a. The results suggest that the evapora-tion heat transfer in the PHE is dominated by the heat transfer associated with the liquid film evaporation. The comparison also shows that for R-410A the evaporation heat transfer coefficient in the PHE is substantially higher than that in a horizontal smooth tube.

The friction factor, defined in Eq. 共5兲, associated with the R-410A evaporation in the PHE obtained in the present study are presented in Fig. 4. The results indicate that the friction factor significantly decreases with the increase in the refrigerant mass flux. For example, at P⫽1.08 MPa, G⫽100 kg/m2s, and q ⫽10 kW/m2, the quality-average fraction factor is respectively about 50 percent and 30 percent lower than those for G⫽50 and

75 kg/m2s 共Fig. 4共a兲兲. Besides, the friction factor decreases sig-nificantly with the increase in the mean vapor quality at low vapor quality (Xm⬍0.4). At high vapor quality for Xm⬍0.5, the effect of the vapor quality on the friction factor is insignificant. It is of interest to note that the friction factor is not affected to a notice-able degree by the imposed heat flux and refrigerant pressure. We also note that for Xm⬎0.5 the frictional pressure drop of R-410A evaporation in the PHE is substantially lower than that for R-134a in the same PHE, but is much higher than in a smooth horizontal pipe for all Xm. The lower frictional pressure drop for R-410A evaporation can be attributed to the fact that the densities and viscosities of R-410A vapor and liquid are lower than those of R-134a.

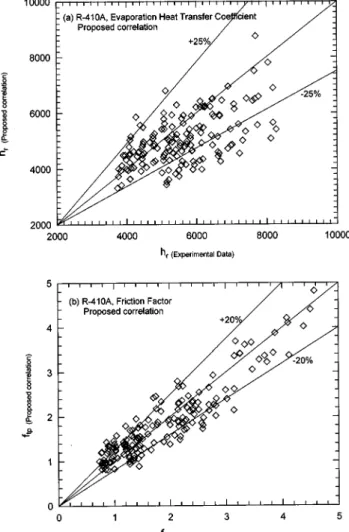

Correlation equations for the heat transfer coefficient and fric-tion factor associated with the R-410A evaporafric-tion in the vertical PHE are important for thermal design of evaporators in various air conditioning and refrigeration systems. Based on the present data, an empirical correlation for the evaporation heat transfer coeffi-cient is proposed by considering the convective and nucleate boil-ing contributions关20兴. It is expressed as

hr⫽E•h1⫹S•hpool, for 2000⬍Re⬍12,000

and 0.0002⬍Bo⬍0.0020 (7)

Here h1and hpoolare respectively given by the Dittus-Boelter Eq. 关21兴 and Cooper 关22兴 as

Fig. 3 Variations of evaporation heat transfer coefficient with mean vapor quality for various system pressures and refriger-ant mass fluxes at„a…qÄ10 kWÕm2and„b…qÄ20 kWÕm2

Fig. 4 Variations of friction factor with mean vapor quality for various system pressures and refrigerant mass fluxes at„a…q Ä10 kWÕm2and„b…qÄ20 kWÕm2

h1⫽0.023•Re1 0.8•Pr0.4•共k 1/Dh兲 (8) hpool⫽55•Pr 0.12•共⫺log 10Pr兲-0.55•M⫺0.5•q0.67 (9) Besides, E and S respectively represent the enhancement and sup-pression factors, which are dependent on the boiling number Bo, the Martnelli parameter Xttand liquid Reynolds number Re1. The expressions for E and S are

E⫽1⫹24,000•Bo1.16⫹1.37

冉

1 Xtt冊

0.86 (10) S⫽共1⫹1.15⫻10⫺6•E2•Re1 1.17兲⫺1 (11) The friction factor is correlated asft p⫽23,820•Reeq⫺1.12, for 2000⬍Re⬍12,000 and 0.0002⬍Bo⬍0.0020 (12) where Reeqis the equivalent Reynolds number and is defined as

Reeq⫽ Geq•Dh 1 (13) in which Geq⫽G

冋

共1⫺Xm兲⫹Xm•冉

1 g冊

1/2册

(14)Here Geqis an equivalent mass flux which is a function of the R-410A mass flux, mean vapor quality and densities at the satu-rated conditions. Figure 5 shows that more than 74 percent of the present experimental data for hrfall within⫾25 percent of Eq. 共7兲, and the average deviation between the present data for ft pand the proposed correlation is about 18 percent.

5 Concluding Remarks

Experiments have been carried out here to investigate the evaporation heat transfer and the associated frictional pressure drop for the ozone friendly refrigerant R-410A in a vertical plate heat exchanger. The effects of the refrigerant mass flux, imposed heat flux, system pressure and vapor quality of R-410A on the evaporation heat transfer coefficient and friction factor were ex-amined in detail. A summary of the major findings is given in the following.

1. The evaporation heat transfer coefficient and frictional pres-sure drop normally increases with the refrigerant mass flux and vapor quality. It is also noted that the evaporation heat transfer coefficient is only slightly affected by the refrigerant mass flux at low vapor quality. Furthermore, the increase of the frictional pressure drop with the vapor quality is more evident than the rise of the heat transfer.

2. A rise in the imposed heat flux results in a significant in-crease in the evaporation heat transfer coefficient. Neverthe-less the influences of the imposed heat flux and system pres-sure on the friction factor are rather slight.

3. Empirical correlation for the R-410A evaporation heat trans-fer coefficient and friction factor in the PHE were provided to facilitate the design in various thermal systems.

Acknowledgments

The financial support of this study by the engineering division of National Science Council of Taiwan, R.O.C. through the con-tract NSC 85-2221-E-009-06 is greatly appreciated

Nomenclature

A ⫽ heat transfer area of the plate, m2

Bo ⫽ boiling number, Bo⫽ q/G•if g, dimensionless

cp ⫽ specific heat, J/kg°C

Dh ⫽ hydraulic diameter, Dh⫽2b,m

E, S ⫽ enhancement and suppression factors ft p ⫽ two-phase friction factor

G ⫽ refrigerant mass flux, kg/m2s

Geq ⫽ equivalent all liquid mass flux in Eqs. 共13, 14兲

h ⫽ heat transfer coefficient, W/m2°C

if g ⫽ enthalpy of evaporation, J/kg

k ⫽ conductivity, W/m°C

L ⫽ plate length from center of inlet port to center of

exit port, m

LMTD ⫽ log mean temperature difference, °C

M ⫽ molecular weight

Nu ⫽ Nusselt number, Nu⫽ hw•Dh/k1, dimensionless

P ⫽ pressure, Pa

Pr ⫽ Prandtl number, Pr⫽•cp/k, dimensionless

Qw ⫽ total heat transfer rate, W

q ⫽ imposed heat flux, W/m2

Rwall ⫽ thermal resistance of the wall

Re ⫽ Reynolds number, Re⫽ G•Dh/, dimensionless Reeq ⫽ equivalent all liquid Reynolds number in Eqs. 共12,

13兲

U ⫽ overall heat transfer coefficient, W/m2°C

vm ⫽ specific volume of the vapor-liquid mixture, m3/kg

W ⫽ mass flow rate, kg/s Xm ⫽ mean vapor quality

Xtt ⫽ Martinelli parameter, dimensionless

Fig. 5 Comparison of the proposed correlations with the present data for „a… the heat transfer coefficient and „b… the friction factor

Greek Symbols

⌬Pf ⫽ frictional pressure drop

⌬X ⫽ total quality change in the exchanger  ⫽ chevron angle ⫽ viscosity, Ns/m2 ⫽ density, kg/m3 Subscripts g ⫽ vapor phase l ⫽ liquid phase

m ⫽ mean value for the two-phase mixture in the

ex-changer pool ⫽ pool boiling

r ⫽ reduced, refrigerant w ⫽ water

wall ⫽ wall/fluid near the wall

References

关1兴 Newman, P. A., 1988, ‘‘Preserving Earth’s Stratosphere,’’ Mech. Eng. 共Am.

Soc. Mech. Eng.兲, 120, pp. 88–91.

关2兴 Gopalnarayanan, S., 1998, ⬘‘Choosing the Right Refigerant,’’ Mech. Eng. 共Am.

Soc. Mech. Eng.兲, 120, pp. 92–95.

关3兴 Chamra, L. M., and Webb, R. L., 1996, ‘‘Advanced Micro-Fin Tubes for

Evaporation,’’ Int. J. Heat Mass Transf., 39, pp. 1827–1838.

关4兴 Schlager, L. M., Pate, M. B., and Bergles, A. E., 1990, ‘‘Evaporation and

condensation Heat Transfer and Pressure Drop in Horizontal 12.7-mm Micro-fin Tubes With Refrigerant 22,’’ ASME J Heat Transfer, , 112, pp. 1041–1047.

关5兴 Kubanek, G. R., and Miletti, D. L., 1979, ‘‘Evaporative Heat Transfer and

Pressure Drop Performance of Internally-Finned Tubes With Refrigerant 22,’’ ASME J. Heat Transfer, , 101, pp. 447– 452.

关6兴 Liu, X., 1997, ‘‘Condensing and Evaporating Heat Transfer and Pressure Drop

Characteristics of HFC-134a and HCFC-22,’’ ASME J. Heat Transfer, , 119, pp. 158 –163.

关7兴 Sami, S. M., and Poirier, B., 1997, ‘‘Comparative Study of Heat Transfer

Characteristics of New Alternatives to R-22,’’ ASHRAE Trans., 103, pp. 824 – 829.

关8兴 Sami, S. M., and Poirier, B., 1998, ‘‘Two Phase Flow Heat Transfer of Binary

Mixtures Inside Enhanced Surface Tubing,’’ Int. Commun. Heat Mass Trans-fer, 25, pp. 763–773.

关9兴 Wang, C. C., Yu, J. G., Lin, S. P., and Lu, D. C., 1998, ‘‘An Experimental

Study of Convective Boiling of Refrigerant R-22 and R-410A,’’ ASHRAE Trans., 104, pp. 1144 –1150.

关10兴 Ebisu, T., and Torikoshi, K., 1998, ‘‘Heat Transfer Characteristics and

Corre-lations for R-410A Flowing Inside a Horizontal Smooth Tube,’’ ASHRAE Trans., 104, pp. 556 –561.

关11兴 Wijaya, H., and Spatz, M. W., 1995, ‘‘Two-Phase Flow Heat Transfer and

Pressure Drop Characteristics of R-22 and R-32/R125,’’ ASHRAE Trans., 101, pp. 1020–1027.

关12兴 Shah, R. K., and Focke, W. W., 1988, ‘‘Plate Heat Exchangers and their Design

Theory,’’ Heat Transfer Equipment Design, R. K. Shah, E. C. Subbarao, and Mashelkar, R. A., eds. Hemisphere, Washington, pp. 227–254.

关13兴 Muley, A., and Manglik, R. M., 1999, ‘‘Experimental Study of Turbulent Flow

Heat Transfer and Pressure Drop in a Plate Heat Exchanger With Chevron Plates,’’ ASME J. Heat Transfer, , 121, pp. 110–117.

关14兴 Muley, A., Manglik, R. M., and Metwally, H. M., 1999, ‘‘Enhanced Heat

Transfer Characteristics of Viscous Liquid Flows in a Chevron Plate Heat Exchanger,’’ ASME J. Heat Transfer, , 121, pp. 1011–1017.

关15兴 Thonon, B., Vidil, R., and Marvillet, C., 1995, ‘‘Recent Research and

Devel-opments in Plate Heat Exchangers,’’ J. of Enhanced Heat Transfers, 2, pp. 149–155.

关16兴 Yan, Y. Y., and Lin, T. F., 1999, ‘‘Evaporation Heat Transfer and Pressure Drop

of Refrigerant R-134a in a Plate Heat Exchanger,’’ ASME J. Heat Transfer, ,

121, pp. 118 –127.

关17兴 Wilson, E. E., 1915, ‘‘A Basic for Traditional Design of Heat Transfer

Appa-ratus,’’ Trans. ASME, 37, pp. 47–70.

关18兴 Kline, S. J., and McClintock, F. A., 1953, ‘‘Describing Uncertainties in

Single-Sample Experiments,’’ Mech. Eng.共Am. Soc. Mech. Eng.兲, 75, pp. 3–12.

关19兴 Collier, J. G., 1981, Convective Boiling and Condensation, 2nd ed.,

McGraw-Hill, New York, pp. 26 – 69.

关20兴 Gungor, K. E., and Winterton, R. H. S., 1986, ‘‘A General Correlation for Flow

Boiling in Tubes and Annuli,’’ Int. J. Heat Mass Transf., 29, pp. 351–358.

关21兴 Incropera, F. P., and Dewitt, D. P., 1981, Fundamentals of Heat Transfer, John

Wiley & Sons, New York, p. 406.

关22兴 Cooper, M. G., 1984, ‘‘Saturation Nucleate Pool Boiling: A Simple

Correla-tion,’’ 1st U.K. National Conference on the Heat Transfer, 2, pp. 785–793.