IEEETRANSACTIONSON INDUSTRIALELECTRONICS,VOL.IE-29, NO. 4, NOVEMBER 1982

Design

and

Implementation

of

a

Fully Digital

DC

Servo

System Based

on a

Single-Chip

Microcomputer

PEI-CHONG TANG, SHUI-SHONG LU, AND YUNG-CHUN WU

Abstract-A single-chip microcomputer is used to design a fully

digital dc servo system to replace the conventional analog circuits.

Thismicrocomputer performsthreemain tasks: thefiringcontrol ofa

three-phase full-wavethyristordual converter; thecompensationfor thenonlinearandloading effectin theconverter; andcompensations ofposition loop and rate loop. With nocurrentfeedback and min-imum components, this dc servo system provides fast transient re-sponseandhigh reliability.

I.INTRODUCTION

M ICROPROCESSOR applications in the industrial control are increasing rapidly in recentyears. For the

thyristor-driven dc servo systems, several

microprocessor-based

designs have beenimplementedtoreplace

the conventionalanalog

anddiscrete digital circuits

[1

]-[3]

. Ohmae eta!.[1

] used abit-slice microprocessor system to

design

aspeed

regulation

sys-tem by adual-mode currentloop-control

method. Chan etal.[2]

-[3] used an 8-bit microprocessor system to control thespeed and position of a dc motor

by

a different currentloop-controlled method. In the case of

thyristor-driven

dc servo systems, the criticalproblem

is to find an easy way to compensate the nonlinear andloading

effect ofthyristor

con-verter. From this point of view, the methodsproposed

by OhmaeandChanetal. areunsatisfactory.

Recently, Tang, Lu, and Wu

[4]

proposed a cascadenon-linear compensation scheme to compensate the nonlinear and

loading

effect of thyristor converter. In this scheme, no currentloops wererequired and simple computing algorithmswere used. Thus, the microprocessor-based controller design

was simplified in both hardware and software. In

addition,

it was shown that this compensated thyristor-driven dc servo system could be regarded as a quasi-linear system. Thus, the

control-loop design was simplified. In another paper,

Tang,

Lu, and Wu[5]

introduced a microprocessor-based firing scheme to provide maximumfiring

range with minimumfiring delay. This scheme used minimum components and no ad-justment was required. In this paper, asingle-chip microcom-puter isused toimplement a fast-response thyristor-driven dc servo system based on these two schemes. This circuit usesfullydigital components with minimum hardware.

II.HARDWARE DESCRIPTION

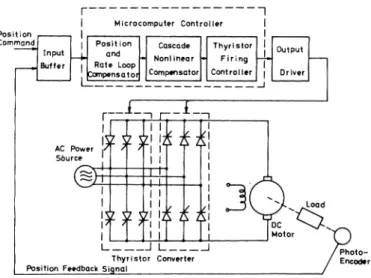

The schematic diagram of the dc servo system based on a

single-chip microcomputer is shown in Fig. 1. The three-phase

full-wave thyristordual converter is composed oftwelvesilicon

Manuscriptreceived April 21, 1981; revised March 9, 1982. P. C. Tang is with the Institute of Electronics Engineering, National

ChiaoTung University,Hsinchu, Taiwan, Republic of China.

S.S.Luis with theDepartment of Mechanical Engienering, National TaiwanUniversity,Taipei, Taiwan, Republic of China.

Y. C.Wu is with the Department of Control Engineering, National

ChiaoTung University, Hsinchu,Taiwan,Republicof China.

ji I, I; ~ > Load

II

j otorL..._W L___

Thyristor Converter itionFeedbackSignal

Fig. 1. Block diagram of the position servo system.

controlled rectifiers(SCR's). This converterisused to drive a

separately excited dc motor in a four-quadrant operation. The motor field is maintained constant. One incremental

photoencoderis coupled to themotor shaft as the only feed-back transducer. Two-phase outputs of the photoencoder are used to generatethe position and the derived-speedfeedback. Uponreceiving the pulse-train-like command, this control cir-cuit will control both speed and position of the thyristor-driven dc motor. The block diagram of this fully digital

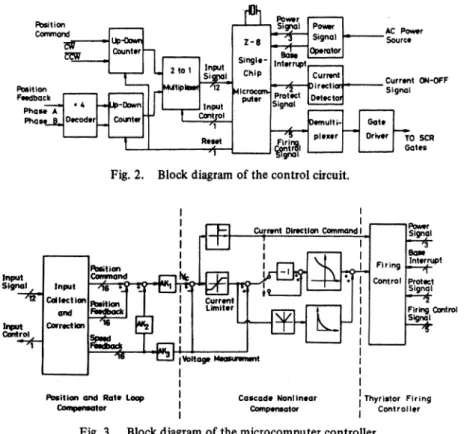

circuitisshowninFig.2 anddescribedbelow. A. Input Buffer

Input buffer functions as the interface among command,

photoencoder, and the single-chip microcomputer. For the purpose oftracking-system applications, command inputs are two pulse-train signals. One is the clockwise command and the other is thecounterclockwise command. By using three

divide-by-sixteen up-down counters, the position command is

obtainedby integrating these pulse-train signals.

Outputs of the incremental photoencoder are two-phase

pulse-train signals. The phase difference between them is

about

900.

After the multiply-by-four decoder, thesetwo-phase signals are decoded to clockwise and counterclockwise signals. Then, the position feedback is obtained by using the 12-bit up-down counter similar to the one used for position command. A microcomputer-controlled 12-bit two-to-one

multiplexer is used to read in the digitized position command and feedback. This multiplexeris desired in order to decrease thenumber ofmicrocomputerI/O required.

B.MicrocomputerController

The microcomputer used is

Zilog

Z8single-chip

micro-computer. The Z8 microcomputer introduces a new level of0278-0046/82/1100-0295$00.75 © 1982 IEEE

IEEETRANSACTIONS ONINDUSTRIALELECTRONICS, VOL. IE-29, NO. 4, NOVEMBER 1982

Fig.2. Blockdiagramofthecontrol circuit.

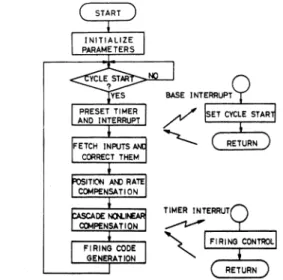

Position and Rate Loop cascade Nonlinear IThyristor Firing

Compwetor I Compensator I Controller

Fig.3. Blockdiagramofthemicrocomputercontroller.

sophistication

ofsingle-chip

architecture with 2Kbytes

ofinternal

ROM,

124bytes

ofon-chip

RAM,

twoprogrammable

8-bittimers, and 32 bitsofprogrammable

I/O.

The block

diagram

of themicrocomputer controller

isillustrated in

Fig.

3. Thefunctions

performed by

themicro-computer will be detailed in the next section. Becausemost

complex

works are executedby

microcomputer

software,thehardwaresarejustbuffersanddrivers. C

Output

DriverThe output driver functions as the interface between

the

thyristor

dual converter and thesingle-chip

microcom-puter. The design of the output driverisbased onthe workby

Tang,

Lu, and Wu[5].

Thethree-phase

ac sourcesignals,

digitized

by

using the powersignal

operator, are sent to themicrocomputer for

firing

control. In each600,

ofac source, the base interrupt signalis generated at each zerocrossing

of the three-phase ac source. This signal is used tosynchronize

themicrocomputer andacsource.The current direction detector is used to detect the

bi-direction current ON-OFF signals. These ON-OFF

signals

are sent tothemicrocomputer

forcrossoverdamage

protectionofthyristordual converter.

The

demultiplexer

andthegatedriverareusedtodistributethe SCR

firing

signals to each gate of chosen SCR's. These SCRfiring

signalsare generatedby

themicrocomputer under the control of afiring

controlsoftware.III.SOFTWAREDESCRIPTION

Most functions of the servo controller are performed by the microcomputer software. As shown in Fig. 3, there are

three main tasks in the microccomputer software

which

in-cludes position and

rate-loop

compensation,cascade nonlinearcompensation,andthyristor

firing

control.A.Position and

Rate-Loop

Compensation

The

position

and rate-loop compensator compares theposition

command and feedback, then generates avoltage

command VC as its output. The first important job is to

obtain the correct position, command, and feedback. Be-cause the

length

ofhardware counterisonly 12bits, theover-flow of counter

happens

frequently. To correct theoverflow errorofthe counter,the foLlowing

code correctiontechnique

isused.

Due to the

frequency

response ofthephotoencoder,

it is assumedthat theinput signal frequency

is less than 700kHz.

In one

period

of360-Hzsamplingtime,themaximumnumberintegrated by

thecounterisless than 2047 pulses,which can be handledby

an 11-bit counter. Thus, the remaining bit in the 12-bitcounterisusedtocheck theoverflow of 11-bit data,and the software counter can then be constructed by

inte-grating

these overflows. In thisway,

the 16-bit position com-mand and feedback are constructed by combining the 4-bit softwarecounterandthe12-bithardwarecounter.By differentiating

the position feedback, the speed feed-back is obtained for rate-loop compensation. Due to the linearrelationship

between themotorspeed and the inducedEMF,

the speed signal canbe usedasthevoltage measurementby

multiplying a gain constantAK3. The other twoparam-eters, AK1 and

AK2,

are used to construct a proportionalcontrollerwith innerrate

loop.

B. CascadeNonlinearCompensation

The cascade nonlinear compensation is based on the design

by Tang,

Lu,

and Wu [4]. Using the difference between the voltage command and voltage measurement as a new param-eter, the firing-angle command is obtained by searching twotables. One isusedtogetthefiring angle underthe continuous current mode and the otheris used tomodify thisfiringangle 296

TANG et al.: DESIGNANDIMPLEMENTATIONOFSERVO-SYSTEMBASEDON A MICROCOMPUTER

External

Torque Cowmrand

Input

Fig.5. Linear modelofthepositionservo.

Fig. 4. Flow chart of themicrocomputercontroller. underthe discontinuouscurrent mode. In addition to the com-pensation ofnonlinear and loadingeffect in thethyristordual converter, the difference between the voltage command and voltage measurement canbe limited toasafe regionsothatit

functions as a current limiter. The sign of this voltage

dif-ference is also used asthecurrent direction command forthe

thyristor dual converter. Thus, the cascade nonliner compen-sation software computes the thyristorfiring angle and

direc-tion commands used for thethyristor firingcontrol.

C Thyristor FiringControl

This controller is based on the design by Tang, Lu, and

Wu [5]. The flowchart is shown in Fig. 4. The control cycle has a period of about 2.7 ms and is synchronized with the

ac source. At the start ofeach control cycle,the firing-angle

command calculated in last control cycle is used to set the delay time of thetimer, then the microcomputer proceedsto

calculate the next firing angle command. When the timer

counts down to zero, a signal is generated to interrupt the main process, and the SCR firing signals are sentto fire the chosenSCR's.

IV. SERVO SYSTEM DESIGN

The overall system is a nonlinear, sampled-data control

system. The sampling rate is 360 Hz and the maximum de-lay time including computing time and firing delay is two

sampling periods, about 5.5 ms. The exact analysis of the overall system is difficult, but the approximate solution is simple [4]. Because the system time constantis muchgreater

than the sampling periodanddue to thelinearizationeffect of the cascade nonlinear compensation, the overall system can

be approximated to a linear and continuous control system.

Thus, most of the design methods based on the linear and

continuous control theory can be applied to this micro-computer-based dcservosystem.

One ofthe simplest methods usedis aproportionalcontrol

with inner rate loop, as shown in Fig. 5. The step-by-step

design from inner loop to outer loop is chosen tosolve this problem. In the experiment, the motor used is a 0.5-kW

permanent magnet dc motor (90 V, 15 A, 3000 rpm). The only feedback transducer is a photoencoder with 2000 ppr.

With a 200-V peak-to-peak ac source and the parameters

AKl,

AK2,

andAK3 set at0.039,5.45,and0.98,respectively,theopen-loop gainis

43.3/s.

V.EXPERIMENTALRESULTS ANDDISCUSSIONS

Theopen-loopstep response of the uncompensatedthyristor

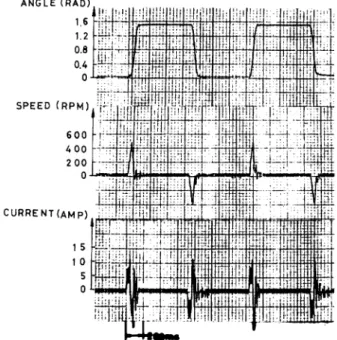

dual converter is shown in Fig. 6(a). Because of the semi-conductor characteristics of SCR's, no decelerating torque is applied to the motor during the transcience from high speed to low speed. The settling times in each transcience of ac-celeration and deac-celeration areapproximately 220 ms and 660 ms, respectively. With the use of the cascade nonlinear com-pensator, the transient response is improved in both tran-sience of acceleration and deceleration. The settling time of compensated thyristor dual converter is about 160 ms for both acceleration and deceleration, as shown in Fig. 6(b). In the experiments, the current limiter in the cascade nonlinear compensator is set at about 5 A to show its effect. As is evident from Fig. 6(b), both theacceleration anddeceleration are limited by this current limiter. If theopen-loopcommand change is so small that the current limit does not occur, asin the case ofFig. 6(c), the transient response are very fast and the same for both acceleration and deceleration. The settling time inthis case is about 40 ms.

As can be seen fromFig. 6, thebenefitofthecascade non-linear compensation is obvious. With the use of the cascade nonlinear compensation, the step responses of the rate loop and the position loop are showninFigs. 7and8, respectively. The settling time of the rate-loop response andthe

position-loop response are about 80 ms undertheconditionofcurrent limiting. The transient responses are the same in both direc-tions. Because only a simple proportional controller is used

for the rate loop,there is some steady-state error in the

rate-loop

response,asshowninFig.7.For atype-1 controlsystem,

nosteady-state error exists in the response of position loop if there is no external torque.

The memory used in this system is about 1.4K bytes and

the maximum computing time in one control cycle is about 1.5 ms, as shown in Table I. In most servo control systems, some complex controllers are usually used to achieve the

higher performance, such as a lead-lag compensator, a PID controller, or a second-order compensator. The on-line

cap-ability in the microcomputer used in this system is so small that a morecomplexcompensator can also beimplemented.In

addition, the fully digital organization and microcomputer software control make it easy to link this system with other microcomputer systems. Thus, this system can be part of a computer network for adaptive control, automatic testing, automatic design, or other processes for industrial application needs.

IEEETRANSACTIONSONINDUSTRIAL ELECTRONICS, VOL. IE-29, NO. 4, NOVEMBER 1982 ANGLE(RAl 1. 1. 0. 0. SPEED (RPM 60 4 01 2 0 CURRENT(AMF D1) .6 .8 4 0

4,

I

t

-t'. t 44.-

t_..."L.--I';.. L;:1.,

-KL[

''_

II,

. 0oOr 1[1htli-; -L Jg8__ _ . I|XI § - .: 41 !,!,1 |s |lti !,,-I-...t*I t ) 1 5 10 S 0I I

II

,E .-I

Fig. 8. Step responseofposition loop;positioncommand from 0 rad

to1.57 rad.

TABLE I

LIST OF MEMORYANDTIME USED (b) 1200 800 400 0k I. .{t' 'It, Ut!["t K r lfl 1t-jt'!: (c)

Fig. 6. Stepresponseofthecompensatedthyristordualconverter with dc motor. (a) Without cascade nonlinearcompensator; firing-angle command from 1000 to 60°. (b) With cascade nonlinear

compen-sator; voltage command from 6 V to 70 V. (c)With cascade

non-linearcompensator;voltage commandfrom12Vto24 V.

Fig. 7. Step response of rate loop; rate command from 180 rpmto

1400rpm.

memory used(kbytes) time used(ms)

position and rate compensation 0.41 1.05

cascode nonlinear compensot ion 0.52 0.1

(including tables)

thyristor firing control 0.2 0.4

(including tables)

initialization program 0 27

total 1.4 1.55

z8 provided 2.0

sampling period 2.77

reserved for futureuse 0.6 1.22

VI.CONCLUSION

The quasi-linearization effect of a compensated thyristor

dual converter based on the principle of cascade nonlinear

compensation proposed by Tang, Lu, and Wu is confirmed by the experiment. Also, the equivalent effect of current

limitingispossiblethrough software control without usingany

currentfeedback.

With minimum hardware and good performance, this single-chip microcomputerdesignissuitable forafast-response

high-power dcservosystem forindustrialcontrol.

REFERENCES

[ ] T. Ohmaeetal.,"Amicroprocessor-controlled fast-responsespeed

regulator with dual-mode current loop for DCM drives," IEEE

Trans.Ind.Appi., vol. IA-16, pp. 388-394, May 1980.

[2] Y. T. Chanetal.,"AMicroprocessor-based currentcontrollerfor

SCR-DC motor drivers," IEEE Trans. Ind. Electron. Contr.

In-strum., vol. IECI-27, pp. 169-176, Aug. 1980.

[3] J. B. Plantetal., "Microprocessorcontrolofpositionorspeedof

an SCR-DC motor drive:' IEEE Trans. Ind. Electron. Contr.

Instrum., vol. IECI-27, pp. 228-234,Aug. 1980.

[4] P. C. Tang et al., "A cascade nonlinear compensation of the

thyristor dualconverterfor DCmotordrives," tobe published. [5] P. C. Tangetal., "Microprocessor-based design ofafiring circuit

forathree-phase full-wave thyristor dualconverter," IEEETrans.

Ind. Electron., vol. IE-29, pp. 67-73, Feb. 1982.

SPEED(RPM) SPEED (a) CURRENT F'7 I...I ,,.

JItL-V2

t .I..., ,Wn

SPEED(RPM) CURRENT(AMP)I5

101

'-iF

L.:;

.'" F I.,I'.-..-..]1. 1. 1 1::. .. 4 I Its. !., .. -LL-.1 ., kw"-,._.. ...S --! _ _,X .,..z I .i 298tii-i"II.;--

!-I '. Li .1