Department of Business Administration

I-Shou University

Master Thesis

A Study of the Willingness to Apply the

Green Supply Chain Management in

Mining Enterprises

Advisor

: Ph.D. Joe Y.C.Yang

Co-Advisor

: Dr.Truong An Quoc

Graduate Student : Nguyen Hong Son

Acknowledgements

First and foremost, I would like to express my gratitude to Dr. Joe Y.C.Yang

and Dr.Truong An Quoc, my advisors for giving me the valuable knowledge

backgrounds, feedbacks and comments before and during the time of writing this Thesis.

I also would like to thank my family for their care and kindness that go beyond the Thesis as always. Thanks my classmate in IMBA program and partners for giving me good conditions, supports and comments for the thesis completion that would be a wonderful experience of my life. All of the mistakes in this thesis are solely my responsibility.

Abstract

This study aims to analyze the willingness to engage in green supply chain management (GSCM) in Vietnam’s mining industry (VMI) as the way to improve the environmental protection. The hypothesis was proposed to find the factor effect in GSCM includes: internal environment management, external environment with two sub factor (corporate with supplier and customer) and environmental regulation. Results show that there are positive relationship between the internal environment management and green supply chain management. Results also indicate that external environmental factor can predict the green supply chain management practice and there is the correlation between environmental regulation and green supply chain management practice. ANOVA result show that statistically significant differences, i.e., p < .0.05, exist among the three enterprise sectors in the implementation of one GSCM practices, namely JVEs. There are several factors that explain why the company is leaning towards green supply chain management.

Keywords: Green Supply Chain Management, Vietnam mining industry, of internal

Table Contents

Acknowledgements ... i

Abstract ... ii

List of Tables ... v

List of Figures ... vi

Chapter 1 INTRODUCTION ... 1

1.1 Background ... 11.2 Overview of Vietnam mining industry ... 3

1.3 The purpose of this Master of thesis is: ... 7

1.4 Research Questions ... 7

1.5 Research contribution ... 7

Chapter 2 LITERATURE REVIEW ... 8

2.1 Introduction ... 8

2.2 Traditional supply chain ... 8

2.3 Definition of Greening supply chains management ... 9

2.4 The factor effect on Greening supply chains management ... 10

2.5 The relationship between internal environmental management and greening supply chains management ... 11

2.6 The relationship between the external environment and Greening supply chains management ... 11

2.7 The relationship between Environmental regulation and Greening supply chains management ... 11

3.1 Research Design ... 13

3.2 Population and Sample Size ... 13

3.3 Questionnaire Design ... 13

3.4 Pilot Study ... 16

3.5 Data Collection ... 16

3.6 Data Analysis ... 16

Chapter 4 RESULT ANALYSIS ... 18

4.1 Respondents profile ... 18

4.2 Reliability analysis ... 20

4.3 Hypothesis testing ... 20

4.3.1 The relationship of internal environmental management and Green Supply Chain Management ... 20

4.3.2 The relationship of External environment and Green Supply Chain Management21 4.3.3 The relationship of environmental regulations and Green Supply Chain Management ... 22

4.3.4 Comparing the performance of GSCM among SOEs, PEs and JVEs ... 24

4.4 Discussion ... 27

Chapter 5 CONCLUSIONS AND SUGGESTIONS ... 29

5.1 Summary ... 29

5.2 Research Contribution ... 29

5.3 Managerial practice ... 30

References ... 32

List of Tables

Table 3.1 List of variables and items for GSCM practices in the VMI ... 14 Table 4.1 Respondent’s Profile ... 19 Table 4.3 The relationship of internal environmental management and Green Supply Chain Management ... 21 Table 4.5 the relationship of external environmental and Green Supply Chain Management 22 Table 4.6 the relationship of external environmental and Green Supply Chain Management 23 Table 4.7 ANOVA of performance of GSCM among SOEs, PEs and JVEs ... 24 Table 4.8 Tukey’s HSD of performance of GSCM among SOEs, PEs and JVEs ... 25 Table 4.9 Post Hoc Tests of performance of GSCM among SOEs, PEs and JVEs ... 26

List of Figures

Figure 2.1 illustrates the structure of the traditional supply chain. ... 8 Figure 2.2 Greening supply chains management (Sarkis, 2012) ... 9 Figure 2.3. Research Framework ... 12

Chapter 1 INTRODUCTION

1.1 Background

Vietnam mining industry (VMI) is entering a new phase of growth in both quantity and advanced technology applications, an important contribution to the cause of national renewal. However, mining activity has caused adverse environmental hazards and resource depletion, which have a negative impact on the health and safety of workers. As Dr Le Dang Doanh (2014) shows that the system of legal documents on environmental protection, including preparation providing, approving and implementation of projects to renovate and restore the environment after mining activities have been developed, but the rule of law still has many shortcomings, and it needs more modification.

With fast development of technology and increasing consumptions of natural resources, environmental protection has become a severe issue all over the world. Deterioration of land, exhaustion of energy and the green house effects are challenges that people have faced in recent decades. In order to slowdown the aggravation of the environment, sustainability is advocated. Considering this issue, developed countries took several measures, such as publishing certain laws and standards to control environmental impacts. However, in developing countries, sustainability is still a new topic. Policies and approaches that related with sustainability development are incomplete and development of sustainability is in a primary stage. Sustainability involves three components: environment, social and economic performance (Cater and Rogers, 2008).

The evident impact on the environment due to mining in Vietnam are: Distort geomorphology and landscape; occupy large areas of crops and trees to open mines and tailings dump; water and soil pollution around the mining area; changing cultural and social environment in both positive and negative ways. The mining process usually leaves the terrain types with a high potential of erosion, pollution of the environment, and causes humans, animals, and wildlife in a dangerous state.

According to statistics from the Ministry of Natural Resources and Environment1, from 2008 until now the Ministry and the provinces have approved 1,420 projects to renovate and restore the environment with total deposits over 1,360 billion. But in fact many organizations and individuals are concerned about the negative impact of mining. The reason is that there are no specific technical guidelines on renovation and restoration of the environment for each type of mining. Therefore, the implementation in accordance with Decision No. 18/2013 on the renovation and restoration of the environment and margin improvement and environmental rehabilitation of mining operations are facing more difficulties. Administrative procedures to withdraw funds that have invested collateral recovery complex environment, many businesses do not perform renovation and restoration of the environment as promised and did not get back the deposit.

On the other hand, many local authorities are not established by the Environmental Protection Fund, making it difficult for both deposits and state management agencies in monitoring collateral, environmental rehabilitation of the organization individuals engaged in minerals. Dr Le Dang Doanh (2014) address that also there are no specific guidelines on the size and type of organization and operation of the Fund for Environmental Protection in the local level. Therefore, the Fund for environmental protection activities in the province is inconsistent, inefficient and fails to promote the role supporting the protection of the local environment.

Almost of the projects which engage in renovation and restoration of the environment by district provincial evaluation and approval; low total deposits, lack of expenses, not enough to renovate, restore the environment after the project ends. The commitment to environmental protection and rehabilitation projects, environmental restoration not been evaluated and approved at the same time. The purpose of the margin improvement and environmental restoration is required of all mining projects must sign a minimum amount of money equal to the actual cost of

1 Ministry of Natural Resources and Environment (2015) World Vision supports to build

environmental protection models Retrieved from: http://www.monre.gov.vn/wps/portal/news/!ut/p/c5/

renovation and restoration of the environment, but there is no factors on inflation in total funding to implement. Thus giving rise to the risk of financial resources for the renovation and restoration of the environment after the end of mining. (Đàm Ngọc Hùng, 2014).

1.2 Overview of Vietnam mining industry

Mining industry Vietnam is formed from the late 19th century by the French initiative. In 1955, Vietnam started to manage, maintain and develop the base extraction and processing of minerals. So far, Vietnam has carried out baseline surveys, exploration and discovery of new mineral deposits on 5,000 points. In particular, a number of valuable minerals industry has been rated as the oil - gas (1.2 billion - 1.7 billion m3), coal (240 billion tons), iron (2 billion tons), copper (1 million tons of metal), titanium (600 million tons of heavy minerals), bauxite (10 billion tons), lead, zinc, tin, apatite (2 billion tons), rare (11 million tons) and mineral materials construction (52 billion m3) ( Le Dang Doanh, 2014, Nguyen Manh Quan, 2014) .

However, the vast continental shelf over 1 million km2, the exploration and exploitation of mineral resources in the sea is limited, mainly due to capacity issues and marine geological exploration investment. In the above minerals, except minerals such as oil, gas, coal, iron, titanium apatite were relatively basic exploration and sure; the remaining metallic minerals and non-ferrous metals including precious minerals exploration newly-level baseline survey (search). Before investing operators, enterprises must conduct additional exploration to limit risk ( Nguyen Manh Quan 2014).

Most of Vietnam's mineral reserves do not have large zones and distributed in scattered, and unfocused areas. Oil and gas reserves in Vietnam are not much. With the current speed of mining output, Vietnam's oil and gas resources will run out within the next three decades if there are no new reserves discovered. When the oil and gas in the mainland are exhausted, Vietnam will have to import coal from

abroad to ensure domestic demand. Fortunately, coal reserves in the Red River Delta according to calculations can be several hundred billion tons.

However, the extraction of coal from deep below the required technology is complex, there is currently no satisfactory solution for both underground mining, both protect rice fields. Without appropriate technology, the operators will greatly affect the environment and social security. Uranium and geothermal potential in Vietnam negligible. For other essential minerals such as gold or diamonds, Vietnam has very little or none. Some minerals such as bauxite Vietnam has many, rare earths, titanium ore, the world has more to ensure consumers hundreds of years and longer.

For a number of important minerals and has great potential, the Government has allocated to a number of state enterprises assumed a pivotal role in exploiting the model economy socialist orientation. Specifically, mining and processing of oil and gas delivery Vietnam Oil and Gas Corporation; mining and processing of coal and other minerals assigned to Coal-Mineral Vietnam (Vinacomin); mining and mineral processing chemicals (apatite) primarily assigned to Vietnam Chemical Corporation; mining and processing of iron ore mainly from Vietnam Steel Corporation and Vinacomin done; extraction and processing of building materials mainly assigned to the Corporation of Vietnam Cement and construction businesses, transportation performed (mineral industry of building materials by the Ministry of Construction Management).

In addition, there are many private enterprises and joint-stock company engaged mining and processing mineral mines in smaller localities. The total number of mining companies (including construction materials) so far about 2,500 now. Besides, there exist hundreds of thousands of grassroots illegal operators compete with each other.

Dr. Nguyen Khac Vinh2 - President of the Geological Association of Vietnam said, summarizing 13 years of implementation of the Law on Minerals (1996-2009) and the fact that extraction of mineral resources and mineral rampant held in many places was not only a great loss of resources but also adversely affect the infrastructure, severely degrade the system of roads, bridges, destroy habitats, many evils arise the local society where the mine.

Labor accidents in mining, particularly in underground mining and quarrying, occur frequently with a high casualty rate. This represents a low level of development and management very loosely in this field. In 13 years, the central level has issued 353 permits for mining and local levels to 3822 levels mining license. Many minerals such as copper, lead, zinc, antimony, coal or crude exported to foreign quota significant loss and depletion of mineral resources of the country.

Results of recent studies by experts Institute of Development Consultants and the Center for Human Nature also demonstrated that, although the Law on Minerals restrictions on mining exports crude product but most of the mining enterprises of Vietnam today want quick profits should only focus on mining and ore exports in the ore.

Therefore, the value and low efficiency, is not commensurate with the value of mineral resources, as well as causing a huge waste of resources because no significant advantage other mineral products come. Many small-scale mining operators only get the parts richest reserves, leaving the entire poor ore and associated minerals, leading to waste of resources due to the low level of mechanization of mining technology and backward.

More worryingly, the exploitation in the form of "eating away" and cause major losses in mineral processing. Reality resource loss in the extraction process was at a high level, especially in the mines and the mines managed by local authorities. For

2

Dr. Nguyen Khac Vinh - President of the Geological Association of Vietnam,

example, in gold mining, the recovery of gold ore processing (total return) is only about 30-40%, ie about half the emissions into the environment. A survey of research on mining loss and damage extent that the apatite mining la26-43%; Metal ore mining is 15-30%, construction materials is 15-20% ( Nguyen Manh Quan 2014).

Dr. Luu Duc Hai3, Faculty of Environment, University of Natural Sciences - VNU said that the current shortcomings in the processing of minerals in Vietnam are very few businesses are interested in the products and substances Waste can be recovered during mineral processing, wasting the resources of the country. In some cases, the value of solid waste, liquid removed from the ore processing line with economic value, underused.

In fact, the chromite ore in fixed tissue (Thanh Hoa), a large amount of clay minerals are excreted with the mineral composition is mainly nontronit the value used as the drilling fluid. The slow development of industrial processed into finished products with high added value is a major shortcoming led to last for a long time our country was "bleeding ore", production of crude ore, mainly to China. The most important thing is the lack of transparency about the exact reserves of mineral deposits of each point can be exploited to the full exploitation of the licensing process, creating asymmetric information in serious business relationship with the licensing authority. There have now suffered significant because geological data unreliable. Minerals Act 2010, although has been added, modified, but still no regulations on the valuation of minerals, petroleum pricing.

In summary, the mining industry of Vietnam exist many shortcomings. The issue of transparency and accountability should be enhanced to more effectively manage the mineral resources of the country. To do this, first of all, the government should assign a civil society organization independent building report on the status of mining and mineral management in Vietnam with recommendations for reform in a

3

proper route including the amendments and supplements Minerals Act, regulation by decentralization of mining licenses and mineral management ... In addition, the government must soon decide to join Transparency Initiative in the mining industry (EITI) and the full implementation of standards and regulations in the EITI.

1.3 The purpose of this Master of thesis is:

- Study of the Willingness to Apply the Green Supply Chain Management in mining enterprises

- Find out the factors affecting the performance model of green supply chain management (GSCM)

- Comparing the performance of GSCM between state own enterprises (SOEs) and private enterprises (PEs)

1.4 Research Questions

- What is internal environment management (IEM) related to mining industry in Vietnam?

- How external environment (EE) affect to Vietnam mining industry in applying the GSCM?

- How Vietnam mining industries deal with the environmental regulation (ER)?

1. 5 Research contribution

This study examines the practices of internal environment management (IEM), the external environment (EE), and environmental regulation (ER) as possible drivers in the VMI.

Chapter 2 LITERATURE REVIEW

2.1 Introduction

Since domestic techniques for mining industry cannot meet the international quality standard, and some related technologies are not available in Vietnam, it requires implementing a new method of supply chain management as GSCM.

In considering why firms use green supply chains, a series of studies argue that compliance with regulations is a major driver that contributes to the implementation of green supply chains (An et al, 2008).

2.2 Traditional supply chain

Competition in the global market is becoming increasingly fierce pressure to the home producers, forcing them to cut costs, improve product quality, together with the increased level of customer service (Tseng, M.L., 2010). The maker of manufacturing techniques applied just on time (JIT), total quality management (TQM) to improve quality, enhance production efficiency, and shorten delivery times. In a production environment with the use of fewer JIT inventory buffer for production scheduling, businesses began to notice the potential benefits and the importance of relationships strategy and cooperation of suppliers who and

customers. The concept of partnership or alliance increasingly the prominent as firms have to implement JIT and TQM (Melnyk et.al., 2009, Melnyk et.al., 2013).

Supply chain includes not only manufacturers and suppliers, but also companies transport, warehouse, retailer and its customers. For example, a supply chain starts with the mining enterprises materials from land such as iron ore, oil, wood and food - and sell them to businesses producing materials. These businesses, which acts as the order and after receipt of the request on specifications from the manufacturers of components, they will continue processing this material into suitable material (such as sheet steel, aluminum, copper, lumber and food checked). In turn, the manufacturer of components must meet orders and requests from their clients - manufacturers' end products. The output of this process is the detailed components or intermediaries (such as wire, fabric, printed circuits, the details you need ...).

2.3 Definition of Greening supply chains management

To address growing small and medium businesses do not grow or bankruptcy due to not finding solutions for sustainable development, require product innovation is seen as an important step for the business can survive and development.

Innovate "green" requires a combination of innovation development of new products (goods and services), production processes, organizational structures or marketing solutions to minimize the impact harmful to the environment by efficiently using natural resources. Not stopping there, the product innovation will help businesses proactively trends regulations. The regulations and standards become increasingly stringent (both aspects of resource use and control of business processes). By adopting innovative strategies, "green", companies will innovate by using the correct materials, technologies and processes of production and business efficiency and testing new solutions bring to their predecessors great advantages. Innovation strategy of "green" also brought positive effects on corporate reputation and provide an opportunity to influence new regulations in the future.

2.4 The factor effect on Greening supply chains

management

It was found that, in addition to activities related to environmental technologies such as wastewater treatment, dust filters, scrap recycling ... trends product innovation is also a common trend in the international market instructions. Choose to follow this trend will help enterprise customers, as well as wider export market, may even attract investment from foreign firms. With a model that helps effectively control operating costs, expansion opportunities both manufacturing and trading, it needed proper attention of domestic enterprises.

As for green public procurement (or green purchasing) Vachon and Klassen, (2007), find that it is a process whereby public authorities seek to purchase goods and services and work that minimize the environmental impact throughout the product lifecycle. This product when compared to goods, services and works together with the key functions usually shop. In terms of the current globalization, green supply chain management and green supply chain is considered to be a direct mechanism and effective to solve the environmental problems in the global value chain. By using purchasing power and consumer behavior of governments, big business and the community, green supply chain management is the market

mechanism to reduce pollution and increase energy efficiency as well as natural resources. When combined with the legal sanction of the national, regional and global, it can lead to a shift in the industry towards green (Sarkis, 2012).

2.5 The relationship between internal environmental

management and greening supply chains management

We offer our first hypothesis.

H1: Internal environmental management (IEM) has a significant impact on GSCM practice in the VMI.

2.6 The relationship between the external environment

and Greening supply chains management

Zhu et al. (2008) conclude that the success of eco-design requires internal, cross-functional cooperation within the company and external cooperation with other partners throughout the supply chain. According to the study by Vachon and Klassen (2007), it is better for corporations to establish long-term relationships with suppliers, which includes establishing requirements for product quality, following environmental regulations at the manufacturing level, having green packaging and distribution strategies and delivering high-quality products to customers. The discussion above leads to the second hypothesis.

H2: The external environment has a significant impact on the GSCM practices of the VMI.

2.7 The relationship between Environmental regulation

and Greening supply chains management

In considering why firms use green supply chains, a series of studies argue that compliance with regulations is a major driver that contributes to the implementation

of green supply chains (An et al, 2008). Zhu and Sarkis (2006) divide the regulatory environment into three levels: regional environmental regulations, central government environmental regulations, and international environmental regulation agreements. According to a study by Cater and Rogers (2008), sustainability involves three components: environmental, social and economic performance. Although governments aim to perform well in all areas, they pay the most attention to regulating environmental issues. To slow environmental degradation, sustainability is advocated. In considering this issue, developed countries took several measures, such as publishing certain laws and standards to control environmental impacts. However, in developing countries such as Vietnam, sustainability is still a new topic. Policies and approaches related to sustainability are incomplete, and the development of sustainability is at an early stage.

H3: Environmental regulation has a significant impact on the practice of GSCM in the VMI.

H4: There is difference between type of company in Willingness to apply GSCM.

Figure2.3. Research Framework Internal environmental management (IEM) External environmental (EE) Environmental regulation (ER) Willingness to apply GSCM in VMI H1 H2 H3 Type of enterprises H4

Chapter III: Research Methodology

3.1 Research Design

Based on literature discussed above, the technique for creation of attributes for this thesis is based on literature review, pilot sample, researcher’s judgment and experts. The structured questionnaire is employed. The communication approaches selected are both “survey via personal interview” and “self-administered survey”.

3.2 Population and Sample Size

For this study, we have chosen the form of interview as a method to collect data. Our goal is to collect 200 samples of survey questions from different units of Mining companies in the northern of Vietnam. This study uses a survey questionnaire to elicit perceptions/opinions about GSCM from managers in the VMI. The survey instrument includes questions seeking demographic information. The questionnaires were mailed to managers working in mining industry in northern of Vietnam using the spreadsheets tool of Google. The SPSS 20.0 software was used to analyze and verify the data gathered from the questionnaires.

This study is expected to give the new theory to the managers as well as the academic people. Also it is hoped that the result of research will help the manager and policy maker more understand about the footwear industry of Vietnam and GSCM concept to apply it in VMI.

3.3 Questionnaire Design

This study reviews scholars' literature based on the research and practice of GSCM, the appropriate measurement scales of Zhu et al (2008), Chen et al. (2011), and Diabat and Govindan (2011) and information gathered from expert interviews. The study of Zhu et al (2008) includes five categories applied to manufacturing industries. However, in the mining industry, the authors select and construct

environmental management” and the “external environment”. For the variable “environmental regulations”, this study uses the measurement scales of Zhu and Sarkis (2006) with two sub-factors as. This study also investigates the variables that affect the VMI’s willingness to engage in GSCM for these three categories. Table

3.1 1 shows the main factor and sub-factor impact on GSCM in the VMI.

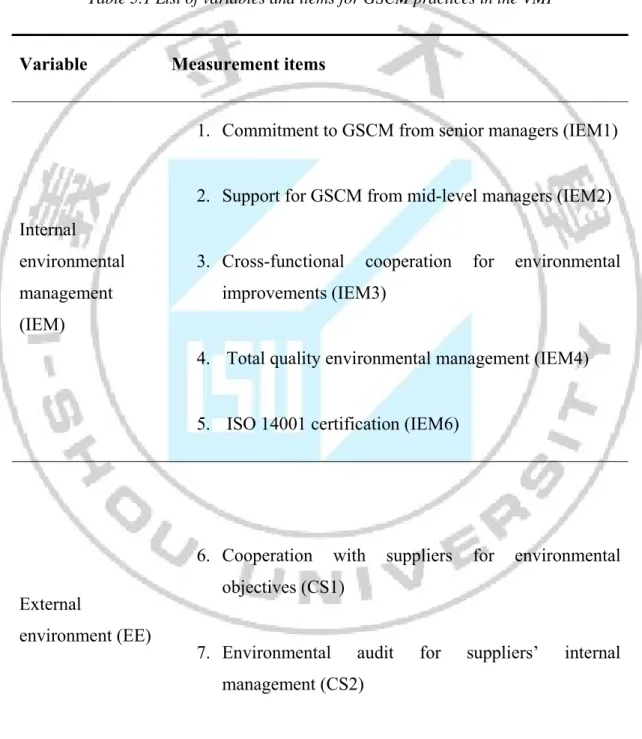

Table 3.1 List of variables and items for GSCM practices in the VMI

Variable Measurement items

Internal environmental management (IEM)

1. Commitment to GSCM from senior managers (IEM1)

2. Support for GSCM from mid-level managers (IEM2)

3. Cross-functional cooperation for environmental improvements (IEM3)

4. Total quality environmental management (IEM4)

5. ISO 14001 certification (IEM6)

External

environment (EE)

6. Cooperation with suppliers for environmental objectives (CS1)

7. Environmental audit for suppliers’ internal management (CS2)

9. Second-tier supplier environmentally friendly practice evaluation (CS4)

10. Commitment to customers for environmentally friendly practice evaluation (CC1)

11. Commitment to customers for cleaner production (CC2)

12. Commitment to customers for green packaging (CC3)

Environmental regulations (ER)

13. Regional environmental regulations (ER1)

14. Central governmental environmental regulations (ER2)

15. International environmental regulation agreement (ER3)

Willingness to apply GSCM by the VFI

16. Aware of the GSCM initiatives (GSCM1)

17. Willing to participate in the GSCM initiatives (GSCM2)

18. Expects environmental and economic benefits from the GSCM initiatives (GSCM3)

3.4 Pilot Study

The questionnaire was distributed firstly to 30 managers to check how they understand the questions. Afterward, questionnaire will be revised to be the final one and ready for collecting data.

3.5 Data Collection

The target population sample for this research is managers who are working for VMI. Therefore the questionnaire will be sent to leaders in VMI, the collected data will be analysis by SPSS software as the Analytical software to collate and verify the data.

3.6 Data Analysis

- Descriptive analysis

A method of described analysis is used to have a preliminary assessment of information on respondents, the average value of the components to do the analysis. b. Reliability analysis

Cronbach's alpha coefficient is a statistical test of strict level which variables (position ask) in an interrelated scales. Assess the reliability and value scales: The scales are rated reliability through Cronbach Alpha coefficients trust. Thereby, the observed variables correlate total variable small (<0.3) were excluded and the scale is accepted as Cronbach alpha coefficient reliability satisfactory (> = 0.7)

- Develop regression and correlation analysis

Applying regression to see the relationship between factors affecting employee satisfaction and level of impact of these factors. Testing the theoretical model: theoretical model for the study hypothesis was tested by means of multivariate regression significance level of 5%

- ANOVA

After the model has been processed, the performance analysis of ANOVA out to test whether or not the difference in applied GSCM between Comparing the performance of GSCM among state own enterprises (SOEs), private enterprises (PEs) and Joint venture enterprises (JVEs).

The data collection is reviewed to remove unusable questionnaires, coded and keyed into a database using an appropriate statistical method. The quantitative analysis is applied to evaluate the important degree of each attributes to employee motivation. Generally, the quantitative analysis is used to test hypotheses of this study using the following statistical techniques. Frequencies and percentages are employed to describe the respondent demographic.

Chapter 4 RESULT ANALYSIS

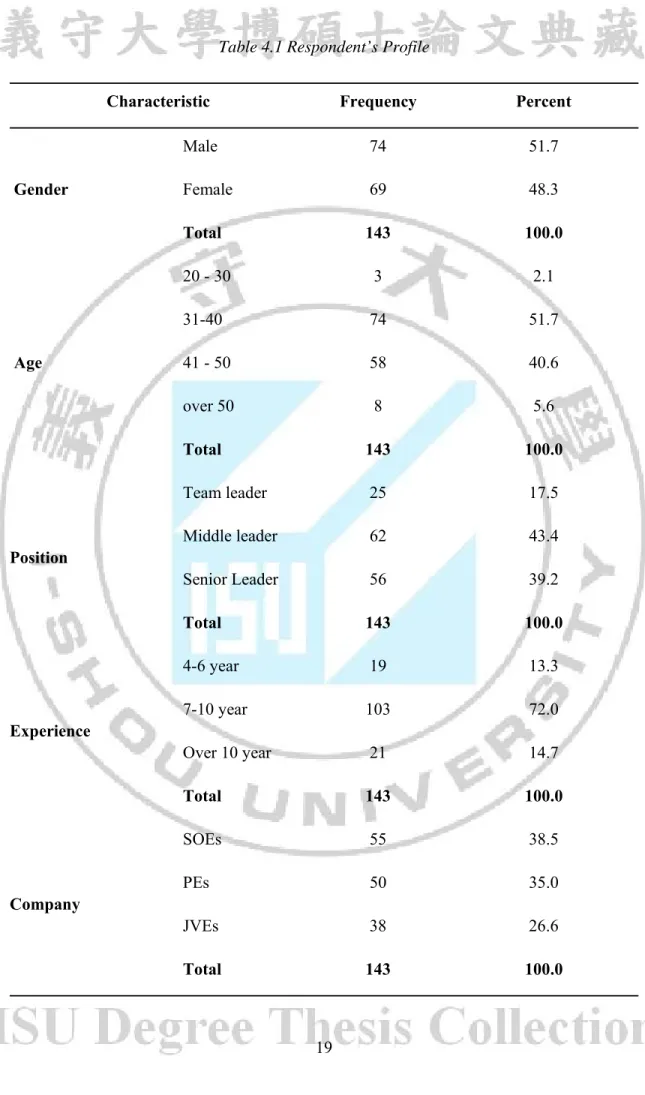

4.1 Respondents profile

The primary data was conducted on 200 samples by questionnaire. The questionnaires were mailed to managers working in mining industry in northern of Vietnam using the spreadsheets tool of Google. The SPSS 20.0 software was used to analyze and verify the data gathered from the questionnaires, and a total of 143 valid questionnaires were collected.

In term of respondent’s gender, results show 51.7% male and 48.3% female. Regarding to age, results show that respondents in 31 -40 years old account for 51.7%, followed by 41-50 years old for 40.6%. Relating to position, the result indicates that 43% of respondents work as middle managers, followed by 39% as senior leaders, and 18% as team leaders.

In terms of work experience, the results indicate that 72.0% of respondents have 7-10 years of working experience in mining industry, followed by 14.7% for over 10 years working experience, and 13.3% for 4-6 years. For types of mining company, there are 38.5% of respondents who work for state owned enterprises, followed by 35.0% in private enterprises and 26.6% in joint venture enterprises (Table 4.1).

Table 4.1 Respondent’s Profile

Characteristic Frequency Percent

Gender Male 74 51.7 Female 69 48.3 Total 143 100.0 Age 20 - 30 3 2.1 31-40 74 51.7 41 - 50 58 40.6 over 50 8 5.6 Total 143 100.0 Position Team leader 25 17.5 Middle leader 62 43.4 Senior Leader 56 39.2 Total 143 100.0 Experience 4-6 year 19 13.3 7-10 year 103 72.0 Over 10 year 21 14.7 Total 143 100.0 Company SOEs 55 38.5 PEs 50 35.0 JVEs 38 26.6 Total 143 100.0

4.2 Reliability analysis

From the result the Cronbach’s α were ranged from .898 to .759. Therefore, it demonstrates that all factors were accepted and reliable as recommended by Nunnally (1978) table 4.2

Variables Cronbach’s α

Internal environmental management .898

External environment (EE) .772

Environmental regulations (ER .808

Willingness to apply GSCM by the VFI .759

4.3 Hypothesis testing

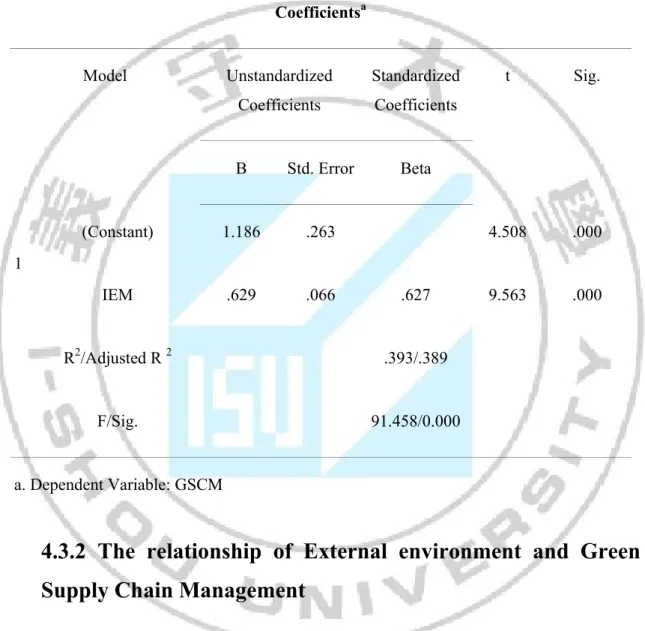

4.3.1 The relationship of internal environmental management

and Green Supply Chain Management

Results showed that there was a significant relationship between internal environmental management and green supply chain management with F = 91.458

at P= 0.00. Besides, the adjusted coefficient of determination (Adjusted R2) revealed that 38.9% of the variance in Green Supply Chain Management is explained by the regression model. The standardized coefficient beta (β) for internal environmental management factor is .627 (p <0.01) indicated significant (Table 4.5). It can be concluded that the hypothesis 1 is supported that “internal

environmental management factor has a significant impact on Green Supply Chain Management applied”

Table 4.3 The relationship of internal environmental management and Green Supply Chain Management

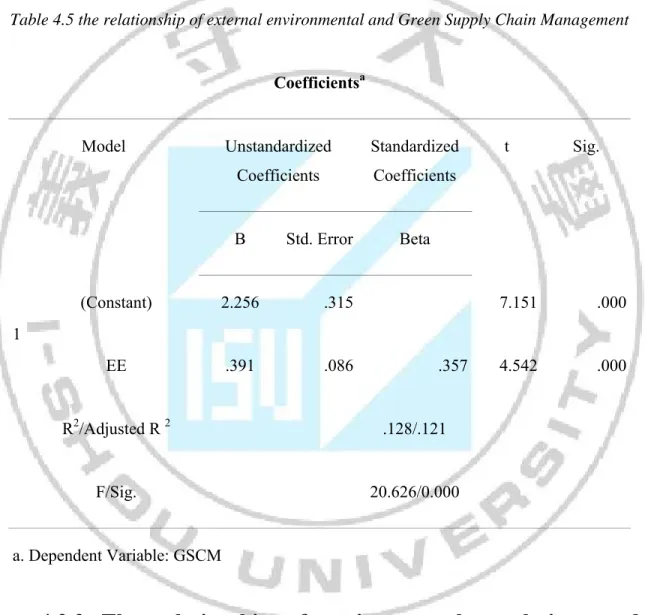

4.3.2 The relationship of External environment and Green

Supply Chain Management

For testing the relationship of total external environmental and Green Supply Chain Management (H2), the regression is taking the Green Supply Chain Management as dependent variable and external environmental factor as independent variable. The result is presented in Table 4.7. As the result, the F statistic of 20.626 is significant at P= 0.00, revealing that the model helps to explain some of the variation in Green Supply Chain Management. Besides, the

Coefficientsa Model Unstandardized Coefficients Standardized Coefficients t Sig. B Std. Error Beta 1 (Constant) 1.186 .263 4.508 .000 IEM .629 .066 .627 9.563 .000 R2/Adjusted R 2 .393/.389 F/Sig. 91.458/0.000 a. Dependent Variable: GSCM

adjusted coefficient of determination (Adjusted R2) revealed that 12.1% of the variance in Green Supply Chain Management is explained by the regression model. The standardized coefficient beta (β) for external environmental is .357 (p <0.01) indicated significant. It can be concluded that the hypothesis 1 is supported that “external environmental factor has a significant impact on Green Supply Chain Management applied” (Table 4.7).

Table 4.5 the relationship of external environmental and Green Supply Chain Management

4.3.3 The relationship of environmental regulations and

Green Supply Chain Management

For testing the relationship of environmental regulations and Green Supply Chain Management (H3), the regression is taking the Green Supply Chain Management

Coefficientsa Model Unstandardized Coefficients Standardized Coefficients t Sig. B Std. Error Beta 1 (Constant) 2.256 .315 7.151 .000 EE .391 .086 .357 4.542 .000 R2/Adjusted R 2 .128/.121 F/Sig. 20.626/0.000 a. Dependent Variable: GSCM

variable. The result is presented in Table 4.8. As the result, the F statistic of

62.035 is significant at P= 0.00, revealing that the model helps to explain some of the variation in Green Supply Chain Management. Besides, the adjusted coefficient of determination (Adjusted R2) revealed that 30.1% of the variance in Green Supply Chain Management is explained by the regression model. The standardized coefficient beta (β) for environmental regulations factor is .553 (p <0.01) indicated significant. It can be concluded that the hypothesis 1 is supported that “environmental regulations management factor has a significant impact on Green Supply Chain Management applied” (Table 4.8).

Table 4.6 the relationship of external environmental and Green Supply Chain Management

Coefficientsa Model Unstandardized Coefficients Standardized Coefficients t Sig. B Std. Error Beta 1 (Constant) 1.458 .284 5.128 .000 ER .572 .073 .553 7.876 .000 R2/Adjusted R2 .306/.301 F/Sig. 62.035/0.000 a. Dependent Variable: GSCM

4.3.4 Comparing the performance of GSCM among SOEs,

PEs and JVEs

For further testing the type of enterprises relate to GSCM Applied , ANOVA

method was used to test the different satisfaction level among age, and job of tourist who have been to Hanoi for travelling.

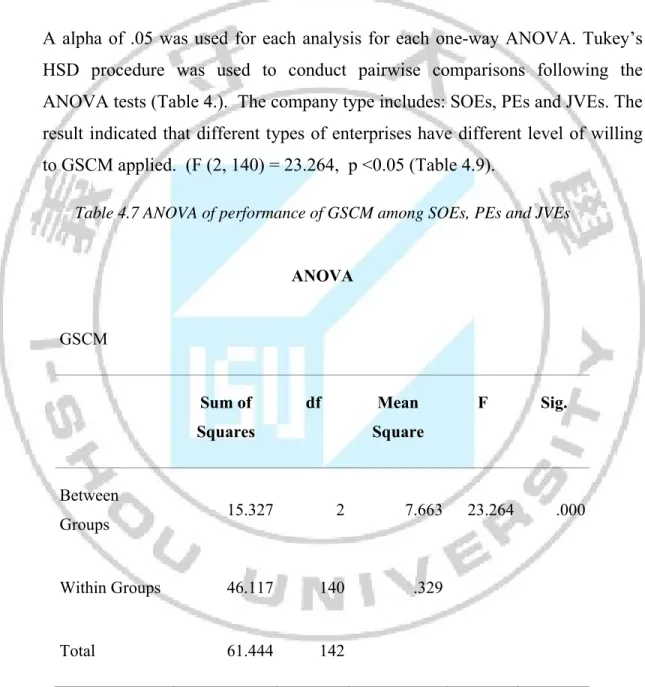

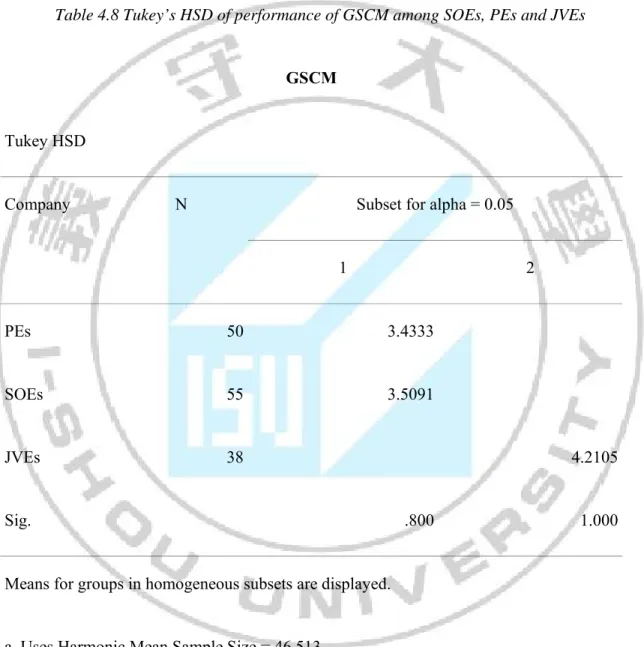

A alpha of .05 was used for each analysis for each one-way ANOVA. Tukey’s HSD procedure was used to conduct pairwise comparisons following the ANOVA tests (Table 4.). The company type includes: SOEs, PEs and JVEs. The result indicated that different types of enterprises have different level of willing to GSCM applied. (F (2, 140) = 23.264, p <0.05 (Table 4.9).

Table 4.7 ANOVA of performance of GSCM among SOEs, PEs and JVEs

ANOVA GSCM Sum of Squares df Mean Square F Sig. Between Groups 15.327 2 7.663 23.264 .000 Within Groups 46.117 140 .329 Total 61.444 142

Since there are different in performance of GSCM among SOEs, PEs and JVEs, Tukey’s HSD result is considered (table 4.10, 4.11 ). From the table 4.10, the

result indicates that joint venture enterprise have higher level of willing to GSCM applied (M = 4.2105) than other type of enterprise as PE (M =3.4333, MD =.77719) and SOEs (M= 3.5091, MD= .70144) in willing to GSCM applied level range around. Post Hoc Tests shows that there are no difference between SOEs and PEs in willing to GSCM applied (MD = .07576, P>0.05) (Table 4.10, Table 4.11).

Table 4.8 Tukey’s HSD of performance of GSCM among SOEs, PEs and JVEs

GSCM

Tukey HSD

Company N Subset for alpha = 0.05

1 2

PEs 50 3.4333

SOEs 55 3.5091

JVEs 38 4.2105

Sig. .800 1.000

Means for groups in homogeneous subsets are displayed.

a. Uses Harmonic Mean Sample Size = 46.513.

b. The group sizes are unequal. The harmonic mean of the group sizes is used. Type I error levels are not guaranteed.

Table 4.9 Post Hoc Tests of performance of GSCM among SOEs, PEs and JVEs Multiple Comparisons Dependent Variable: GSCM Tukey HSD (I) Company (J) Company Mean Difference (I-J) Std. Error Sig. SOEs PEs .07576 .11215 .778 JVEs -.70144* .12107 .000 PEs SOEs -.07576 .11215 .778 JVEs -.77719* .12352 .000 JVEs SOEs .70144* .12107 .000 PEs .77719* .12352 .000

4.4 Discussion

The hypothesis tested result shows the positive relationship between the internal environment management and green supply chain management. As the environment issue is going to important in all activities of business, sector and industry. That Boot all organization has to improve their knowledge and consideration in this green supply chain management. This result have a consistence with some other previous conclusion such So Analyzing, evaluating the conditions and factors affecting the environment, ecology, identification of technological solutions for environmental protection; Perform the job content of environmental technology part of the project. To create the project environmental impact assessment, project environmental rehabilitation and restoration. Implementation of the scientific research, technical management, training in the field of environmental technology, as required by the company has been implementing in the internal of company. The second hypothesis, the result shows the supported as external environmental factor can predict the green supply chain management practice. However, the sub-factors of customer corporate, the regression result shows the unsupported result. This issue have a little difference with some of the search when conclude that with the purpose of sustainable development the companies always advocated and committed to building relationships joint venture, association, cooperative long-term sustainable business with customers and partners in the country and international. And commitment to accompany customers and partners in the business is committed to being the most reliable place to put confidence of customers and partners ( Chien, 2007; Chen , 2011).

The third hypothesis result shows the correlation between environmental regulation and green supply chain management practice. As research of Ho (2010) shows that seriously implement the Law on Environmental Protection, in recent years the majority of the average open pit and large had concerns and fulfill our responsibility to protect our environment, environmental quality in each mine has improved. However, for each mineral, mining regions remain pressing problems of

environmental decline beyond the control of each mine, should be addressed in larger scale or with the alignment of the mines joint responsibility in the region. Particularly for small mines and most mines are indiscriminate exploitation phenomenon, not whether or not designed to cause damage leading to resources, serious environmental pollution and worsening regional landscape is still in love alert.

Lastly ANOVA is use to determine whether differences exist between the mean values of GSCM implementation, performance outcomes in each of the enterprises types. ANOVA result show that statistically significant differences, i.e., p < .0.05, exist among the three enterprise sectors in the implementation of one GSCM practices, namely JVEs. This result mean that the joint venture company have more concern and respect to environment issue and environmental regulation than domestic company include private and state owned enterprises. As discussed by Zhu et. al, ( 2006) in the research GSCM in china shows that developing country has started to emphasize its economic development, while at the same time increasing its awareness and action s on environmental protection while company come from developed countries have better awareness.

Chapter 5 CONCLUSIONS AND SUGGESTIONS

5.1 Summary

The purpose of this study aims to test the willingness to apply the green supply chain management in mining enterprises in Vietnam. The hypothesis was proposed to find the factor effect in GSCM includes: internal environment management, external environment with two sub factor (corporate with supplier and customer) and environmental regulation. The regression shows the positive relationship between the internal environment management and green supply chain management. The second hypothesis, the result shows the supported as external environmental factor can predict the green supply chain management practice and there is the correlation between environmental regulation and green supply chain management practice. ANOVA result show that statistically significant differences, i.e., p < .0.05, exist among the three enterprise sectors in the implementation of one GSCM practices, namely JVEs. There are several factors that explain why the company is leaning towards green supply chain management. One of them is more and more shareholders our commitment towards sustainable development. They include governments, retailers and other businesses; a broad umbrella covering not only the consumer segment (Ho, 2010; Chien, 2007; Chen , 2011.). There is a growing trend in Vietnam in the situation of Vietnam was a member of WTO and going to be the member of Trans-Pacific Strategic Economic Partnership Agreement (TPP).

5.2 Research Contribution

The study results are expected to be the subject of new contributions to basic research of economic science, especially in all sustainable development and supply chain network in mining industry, production and value chain: pattern shaped green supply chain management integrates a macro perspective and micro can be used as a framework to analyzes for research in the future of green supply chain, providing a

enacted to enforce road "green growth" in which the planning and construction of green supply chain in both the macro perspective and micro ..

This research result is contributing to improve the application GSCM of mining industry in Vietnam. This study provides current situation of the VMI. Moreover this study examines the practices of internal environment management (IEM), the external environment (EE), and environmental regulation (ER) as possible drivers in the VMI. Besides, this study also received consulting studies to share experiences related to the supply chain as well as practical examples of sustainable supply chains, green supply chain of mining industry in Vietnam in general, northern area in particular to suggest research directions and approaches to the subject. Delegates also added, comments the research methods in the need to expand the number and equitable distribution of the study subjects, disciplines, sectors and regions ... words can assess overall and complete supply chain management associated with green growth objectives.

5.3 Managerial practice

Conversion process and supply chain operations towards sustainability require enterprises to identify and analyze a number of barriers and challenges. The biggest challenge of sustainability in the supply chain is cost. Mining enterprises have to reduce the impact of business activities on the environment and increased financing costs for environment protection. Companies may run into conflicts over whether to pursue profit at any cost, or should be responsible to the environment but to sacrifice part of the profits. Another challenge that is dealing with the complexity increasing by sustainable development issues in the supply chain. That there exists a dilemma between social sustainability and environmental sustainability, where the improvements in access and infrastructure could increase mobility, but on the other hand also leads to failure Sustainable environmental degradation and growing logistics operations. Therefore, this research result can help enterprise face with the challenge of development of models and new perspectives of GSCM. This is

necessary to help individuals and enterprises to grasp and cope with the growing complexity of sustainable development by bringing.

Environmental friendliness is always a top priority of the business, but that goal will become impossible if company do not find a way to build a green supply chain. Be with the business partners of the company seek to minimize waste into the environment by the effective practical action, this is not only beneficial for company, but also can become an economic decision popular now.

Company should consider the current operations of the supplier of company. They did nothing to promote green supply chain. If suppliers do not want to perform the environmental change as company's expectations, the company should make a change for them. The company should answer the question such as: The partners of the company that are taking positive steps to reduce power usage by using window on the ceiling or use power-saving bulbs? The suppliers of the company are reducing, reusing and recycling their materials? Step by step look at what company is doing. There is actually not when company affect the suppliers so that they will apply green supply chain at high levels. Consider how company can reduce, reuse and recycle. Create a positive environment in company to promote green initiatives are all supported. Tackling an issue of reducing the packaging for both in-house and with suppliers that companies required for their products. Attracting the participation of employees to propose ideas can help company make a greener supply chain, be rewarded for these proposals. Learn how the joint venture companies have successfully implemented programs to encourage and reward their employees for ideas on green supply chain.

References

An H.K., Amano T., Utsumi H. and Matsui S., (2008), A framework for Green Supply Chain

Management complying with RoHS directive . Queen's University Belfast

Beamon, Benita M. (1999), Measuring Supply Chain Performance, International Journal of

Operations and Production Management, 19(3), 275-292.

Bowen, F.E., Cousins, P.D., Lamming, R.C. and Faruk, A.C. (2001), Horses for courses: explaining the gap between the theory and practice of green supply, Greener Management

International(autumn), 41-60.

Bryman, A. (2004) Social Research Methods (2nd edition). Oxford: Oxford University Press Carter C, Rogers DS (2008) A framework of sustainable supply chain management: moving toward new theory. International Journal of Physical Distribution & Logistics Management 38(5), 360-387

Chen, Y.H., Tseng, M.L. and Lin, R.J., (2011), “Evaluating the customer perceptions on inflight service quality,”African Journal of Business Management 5 (7), 2865-2873.

Chen, Y.H., Tseng, M.L., Lin, R.J., 2011. Evaluating the customer perceptions on in-flight service quality. African Journal of Business Management 5 (7), 2865- 2873.

Chien, M.K. and Shih, L.H., (2007), “An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances,”International Journal of Environment Science Technology,4 (3), 383- 394.

Creswell, J.W. (2003) Research Design: Qualitative, Quantitative, and Mixed Methods

Approaches (2nd edition). Thousand Oaks, CA: Sage.

Đàm Ngọc Hùng, (2014) SIGNIFICANCE OF ENVIRONMENTAL PROTECTION AND PRACTICAL ACTION Retrieved from: http://sovhttdl.bentre.gov.vn/nn-vi/pl-25/cm-108/nd/970

Diabat, A. and Govindan, K., (2011), “An analysis of the drivers affecting the implementation of green supply chain management Resource,”Conservation and Recycling 55 (6), 659-667. Friedman, A.L. and Miles, S. (2002), “SMEs and the environment: evaluating dissemination routes and handling levels,” Business Strategy and the Environment, 11, 324-41.

Ho Si Giao (2010), The environmental status of active surface mining - The burning issues,

Journal of Mining Industry, 1

Le Dang Doanh (2014) Industry mining in Vietnam inadequate, Policy Information QII / 2014 - The Center for People and Nature

Lin, R.-J., (2011), “Using fuzzy DEMATEL to evaluate the green supply chain management practices,” Journal of Cleaner Production, doi:10.1016/j.jclepro.2011.06.010

Linton, J.D., Klassen, R.and Jayaraman, V., (2007),“Sustainable supply chains: an introduction,”Journal of Operations Management 25 (6), 1075- 1082.

Melnyk, S. A., Lummus, R. R., Vokurka, R. J., Burns, L. J., & Sandor, J. (2009). Mapping the future of supply chain management: a Delphi study. International Journal of Production

Research, 47(16), 4629-4653.

Melnyk, S. A., Narasimhan, R., & DeCampos, H. A. (2013). Supply chain design: issues, challenges, frameworks and solutions. International Journal of Production Research, 52(7), 1887-1896.

Nguyen Manh Quan (2014), Orientations Vietnam mining, industry and trade newspapers, Retrieved from: http://hoachatlethuy.com/tin-chi-tiet-265.html

Nguyen T.T., (2010), “The effects of tourism supply chain on domestic tourists’ decision for resuming visits to Nhatrang city,” Journal of technology and science, Danang university, Vietnam

Rao P., (2004) “Greening production: a south-east Asian experience,”International Journal of

Operations and Production Management , 24, 289 -320.

Sarkis J., (2012) "A boundaries and flows perspective of green supply chain management,",Supply Chain Management: An International Journal, 17( 2), 202 – 216

Sarmiento, E., (2010), “Identifying improvement areas when implementing green initiatives using a multitier AHP approach,” An International Journal,17 (3), 452-463.

Shalishali, M.K., Ho, J.C., Tseng, T., and Ang, D.S., (2009).“Opportunities in green supply chain management,”The Costal business Journal . 8 (1), 18-31.

Sigala M., (2008),“A supply chain management approach for investigating the role of tour operators on sustainable tourism: the case of TUI,”Journal of Cleaner Production 16, 1589– 1599

Sundarakani, B., de Souza, R., Goh, M. (2010): “A Sustainable Green Supply Chain for

Globally Integrated Network”. Wang, L., Koh, S.C, (Eds.). Enterprise Networks and

Logistics for Agile Manufacturing, London, 191- 206.

Tseng, M.L., (2010). Using linguistic preferences and grey relational analysis to evaluate the environmental knowledge management capacity. Expert Systems with Applications 37 (1), 70 - 81.

Tseng, M.L., Divinagracia, L., Divinagracia, R., (2009). “Evaluating firm’s sustainable production indicators in uncertainty,”Computer and Industrial Engineering 57, 1393 - 1403. Vachon, S. and Klassen, R.D., (2008),“Environmental management and manufacturing performance: the role of collaboration in the supply chain”,International Journal of

Production Economics,111, 299 - 315.

Vachon, S., Klassen, R., (2007),“Extending green practices across the supply chain,”International Journal of Operations & Production Management 26 (7),795-821.

Walton, S.V., Handfield, R.B. and Melnyk, S.T. (1998), “The green supply chain: integrating suppliers into environmental management process,” International Journal of Purchasing and

Materials Management.

World Commission on Environment and Development. (1987). From One Earth to One World: An Overview. Oxford: Oxford University Press.

Zhu Q., Sarkis J. and Lai K.H (2008), “Confirmation of a measurement model for green supply chain management practices implementation,” International Journal of Production

Zhu, Q. and Sarkis, J. (2004), “Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises,” Journal of Operations Management, 22 (3), 265-89.

Zhu, Q. and Sarkis, J. (2006), “An inter-sectoral comparison of green supply chain management in China: drivers and practices,” Journal of Cleaner Production, 14, 472-86 Zhu, Q., Sarkis, J., Lai, K.H., (2007) “Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers,”Journal of Environmental

Management, 85, 179–189

Zhu, Q., Sarkis, J., Lai, K.H., (2008), “Green supply chain management implications for closing the loop”, Transportation Research , 44 (e), 1-18.

Appendix: Questionnaire (English Version)

Part A: Please read each item carefully and circle the appropriate number that indicates HOW MUCH YOU AGREE OR DISAGREE with each of the sections below: Statement Strongly DisagreeDisagree Neutral Agree

Strongly Agree

1 2 3 4 5

1. Commitment to GSCM from senior managers

(IEM1)

2. Support for GSCM from mid-level managers

(IEM2)

3. Cross-functional cooperation for

environmental improvements (IEM3)

4. Total quality environmental management

(IEM4)

I am a Vietnamese graduate student of International Master of Business of Administration program I-Shou University, Taiwan. My master thesis is about “A Study of the Willingness to Apply the Green Supply Chain Management in mining enterprises.” Please take about 10 to 15 minutes to answer all of the questions in my survey. The answers will only be used for academic purposes and will be strictly confidential. Thank you in advance for your time and help.

5. ISO 14001 certification (IEM6)

6. Cooperation with suppliers for environmental

objectives (CS1)

7. Environmental audit for suppliers’ internal

management (CS2)

8. Suppliers’ ISO14000 certification (CS3)

9. Second-tier supplier environmentally friendly practice evaluation (CS4)

10. Commitment to customers for

environmentally friendly practice evaluation (CC1)

11. Commitment to customers for cleaner

production (CC2)

12. Commitment to customers for green

packaging (CC3)

13. Regional environmental regulations (ER1)

14. Central governmental environmental

regulations (ER2)

15. International environmental regulation

16. Aware of the GSCM initiatives (GSCM1)

17. Willing to participate in the GSCM initiatives

(GSCM2)

18. Expects environmental and economic benefits

from the GSCM initiatives (GSCM3)

Part B: Demographic Information 1. Your Gender:

Male Female

2. Your age (years old):

20-30 year old 31-40 year old

41-50 year old over 50 years old

3. Your position

Team leader Middle leader Senior Leader

4. Your experience

4-6 year. 7-10 year

Over 10 year 5. Your Company

SOEs PEs JVEs