Microstructure and magnetic properties of the

„

FePt

…

100ÀxCr

xthin films

P. C. Kuo

Institute of Materials Science and Engineering, National Taiwan University, Taipei 107, Taiwan Y. D. Yaoa)

Institute of Physics, Academia Sinica, Taipei 115, Taiwan C. M. Kuo and H. C. Wu

Institute of Materials Science and Engineering, National Taiwan University, Taipei 107, Taiwan

The (FePt)100⫺xCrxalloy thin films with x⫽0 – 16 at. % were fabricated on natural-oxidized Si共111兲 substrate by dc magnetron sputtering. The as-deposited films were annealed between 300 and 750 °C in order to transform the soft magnetic fcc␥-FePt phase to the hard magnetic fct␥1-FePt phase. The addition of Cr in the FePt thin films will reduce its saturation magnetization and coercivity, however, it could inhibit the grain growth during annealing of the samples. The optimum condition for high-density magnetic recording purpose of the (FePt)100⫺xCrxalloy films was found with x⫽5 at. %, annealing at 650 °C for 15 min, and ice water quench cooling. According to the transmission electron microscopy study, the average grain size in the annealed (FePt)100⫺xCrxalloy thin films decrease from 60 to 5 nm with increasing x from 0 to 16. © 2000 American Institute of

Physics. 关S0021-8979共00兲52408-6兴

I. INTRODUCTION

In recent years, the FePt thin films have received signifi-cant attention owing to their potential applications in mag-netic and magneto-optic recording.1–4In the thin film record-ing media, high coercivity and small grain size are required for high-density longitudinal magnetic recording. The or-dered equiatomic FePt phase with tetragonal L10 structure has very high magnetocrystalline anisotropy constant (Ku

⬃7⫻107ergs/cm3兲, high coercivity, good corrosion resis-tance, and large energy products (BH)max.5–8It suits for the application in magnetic recording media and various micro-magnetic devices. Previous investigations have shown that the magnetic properties of the FePt films are sensitive to process parameters.9,10 In this work, the effects of annealing temperature and doping concentration of Cr on the magnetic properties and grain size of the FePt thin film were investi-gated.

II. EXPERIMENT

The (FePt)100⫺xCrx alloy thin films with x

⫽0 – 16 at. % were fabricated on natural-oxidized Si共111兲

substrate by dc magnetron sputtering. A mosaic target con-sisting of high purity iron disk 共99.99%兲 overlaid with high purity platinum pieces共99.99%兲 was used. Two separated dc magnetron guns were used for Co sputtering FePt and Cr, respectively. The deposition rate is about 0.6 Å/s. The base pressure in the vacuum system was under 5⫻10⫺7Torr, and after the high purity argon gas共99.9995%兲 was introduced, the sputter pressure of 5 mTorr was used in this study. The (Fe50Pt50)100⫺xCrxfilm thickness was fixed at 10 nm in order to examine the possibility of applying these films in high-density magnetic recording media. The as-deposited film was sealed in a quartz capsule and then postannealed in vacuum

at a temperature between 300 and 750 °C. The annealing time was 15 min, and the film was quenched in ice water after annealing.

The magnetic properties of the film at room temperature were measured with a superconducting quantum interface device 共SQUID兲. Microstructure of the film was character-ized by x-ray diffractometer. The average grain size of the film was measured by the transmission electron microscopy

共TEM兲 bright-field image. Composition and homogeneity of

the film were determined by energy disperse spectrum

共EDS兲.

III. RESULTS AND DISCUSSION

The structure and magnetic properties of the pure FePt films have been reported before.9,10In this investigation, the influence of Cr addition on the structure and magnetic prop-erties of the FePt thin films is reported. The addition of Cr in the FePt thin films from 0 to 16 at. % reduces its saturation magnetization roughly from 700 to 400 emu/cm3, and its coercivity roughly from 10 to 4 kOe. From the x-ray diffrac-tion pattern studied, we find that all as-deposited (FePt)100⫺xCrxalloy thin films with x⫽0 – 16 at. % are poly-crystalline fcc ␥-phase structure. The␥-FePt phase is mag-netically soft in bulk form, however, due to the contribution of large internal stresses introduced by sputtering process, it has higher coercivity in the thin film form than in the bulk form. These internal stresses may produce some microcracks in the as-deposited FePt film for thicker films 共e.g., 200 nm兲.1,9 However, we found that these microcracks disap-peared for the 10 nm film. It indicates that the internal stress of the film was decreased as film thickness decreased.

For annealed films, small amount of FeCr phase was observed for all the doped films; and the fct␥1-FePt phase is dominated for samples with annealing temperature roughly above 500 °C. As an example, Fig. 1 shows the x-ray diffrac-a兲Electronic mail: phyao@gate.sinica.edu.tw

JOURNAL OF APPLIED PHYSICS VOLUME 87, NUMBER 9 1 MAY 2000

6146

0021-8979/2000/87(9)/6146/3/$17.00 © 2000 American Institute of Physics

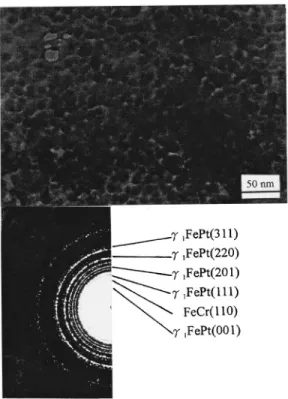

tion patterns of the (FePt兲88Cr12 thin films with 共a兲 as-deposited and共b兲 to 共f兲 annealed between 300 and 650 °C for 15 min. It is clear that the fcc␥-FePt phase is dominated in the as-deposited films and the fct ␥1-FePt phase increases with increasing the annealing temperature. For the two films annealed at the highest temperatures, there are a few uniden-tified lines in the x-ray spectra. It may be due to the reaction of the films with their substrates during high temperature annealing. Figure 2 is a typical TEM bright-field image and diffraction pattern of a (Fe50Pt50兲95Cr5 film annealed at 650 °C for 15 min. It shows that the average grain size is roughly 12 nm. The fcc␥-FePt, fct␥1-FePt, and FeCr phases

were observed, however, from our experimental data, it was not sufficient to clarify the extent of Cr in the FePt phase.

From the observations of TEM images, Fig. 3 shows the variation of the average grain size as a function of annealing temperature (Tan) for the pure FePt and (Fe50Pt50兲95Cr5 films. The average grain size of all the unannealed films are about the same共⬃5 nm兲. After annealing, the average grain size of the 共FePt兲95Cr5film grows slower than that of a pure FePt film. At Tan⫽650 °C, the average grain size of a pure FePt film is 60 nm, and it is only about 12 nm for a (FePt兲95Cr5film. From the TEM bright-field image and co-ercivity studies, we found that the effect of Cr addition is not only reducing the film’s magnetic hardening but also limiting the grain growth of the magnetic FePt phase during anneal-ing. Figure 4 shows the average grain size as a function of Cr concentration for the (FePt)100⫺xCrx films annealed at 650 °C for 15 min. The average grain size decreases very fast for films containing a few percent共⬍5 at. %兲 of Cr. For films containing Cr between 5 and 16 at. %, they decrease slowly from 12 to 5 nm.

FIG. 1. X-ray diffraction patterns of the共FePt兲88Cr12alloy thin films with

共a兲 as-deposited, and annealed at 共b兲 300, 共c兲 400, 共d兲 500, 共e兲 600, and 共f兲

650 °C for 15 min.

FIG. 2. TEM bright-field images and diffraction patterns of the共FePt兲95Cr5 film annealed at 650 °C for 15 min.

FIG. 3. Average grain size as a function of annealing temperature for the pure FePt and共FePt兲95Cr5films.

FIG. 4. Average grain size as a function of the Cr concentration for the (FePt)100⫺xCrxfilms.

6147

J. Appl. Phys., Vol. 87, No. 9, 1 May 2000 Kuoet al.

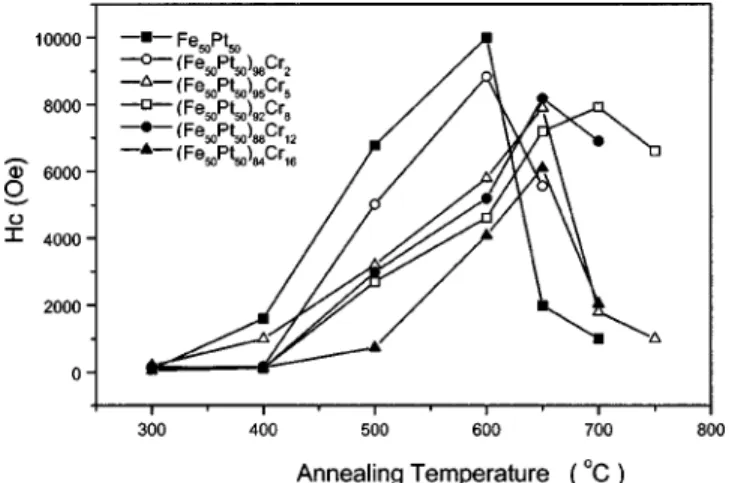

Figure 5 shows the coercivity of the (Fe50Pt50)100⫺xCrx alloy thin films as a function of annealing temperatures. In general, for films annealing between 600 and 650 °C, the saturation magnetization is between 400 and 700 emu/cm3, and the coercivity between 4 and 10 kOe can been achieved. The coercivity increases monotonously with the annealing temperature before reaching its maximum value. This is due to the gradual transform of the fcc ␥-FePt phase to the fct

␥1-FePt phase. After reaching its maximum value, the coer-civity drops rapidly with increasing Tan. This is due to the chemical reaction of the thin film with Si substrate.

In conclusion, we have observed that the addition of Cr in the FePt thin films will reduce its saturation magnetization and coercivity, however, it could inhibit the grain growth during annealing of the samples. The optimum condition for high-density magnetic recording purpose of the (FePt)100⫺xCrx alloy films was found with x⫽5 at. %, an-nealing at 650 °C for 15 min, and ice water quench cooling. According to the TEM study, the average grain size in the annealed (FePt)100⫺xCrxalloy thin films decrease from 60 to 5 nm with increasing x from 0 to 16.

1S. W. Yung, Y. H. Chang, T. J. Lin, and M. H. Hung, J. Magn. Magn. Mater. 116, 411共1992兲.

2

S. Mitani, K. Takanashi, M. Sano, H. Fujimori, A. Osawa, and H. Naka-jima, J. Magn. Magn. Mater. 148, 163共1995兲.

3N. Li and B. M. Lairson, IEEE Trans. Magn. 35, 1077共1999兲. 4T. Suzuki, N. Honda, and K. Ouchi, J. Appl. Phys. 85, 4301共1999兲. 5

K. Watanabe and H. Masumoto, Trans. Jpn. Inst. Met. 24, 627共1983兲. 6

M. Watanabe, T. Nakayama, K. Watanabe, and K. Kiraga, IEEE Trans. Magn. 8, 875共1993兲.

7B. Zhang and W. A. Soffa, Scr. Metall. Mater. 30, 683共1994兲. 8M. Watanabe, T. Nakayama, K. Watanabe, T. Hirayama, and A.

Tono-mura, Mater. Trans., JIM 37, 489共1996兲.

9C. M. Kuo, P. C. Kuo, and H. C. Wu, J. Appl. Phys. 85, 2264共1999兲. 10C. M. Kuo, P. C. Kuo, H. C. Wu, Y. D. Yao, and C. H. Lin, J. Appl. Phys.

85, 4886共1999兲.

FIG. 5. Coercivity as a function of annealing temperature for the (FePt)100⫺xCrxalloy thin films with x⫽0, 2, 5, 8, 12, and 16 at. %.

6148 J. Appl. Phys., Vol. 87, No. 9, 1 May 2000 Kuoet al.