Effects of the Content of High Strength Polyethylene Terephthalate

Fiber and Kevlar Fiber on Properties of Geotextiles

Wen-Hao Hsing

1, Ching-Wen Lou

2, b, Ching-Wen Lin

3, Jin-Mao Chen

4and

Jia-Horng Lin

4, 5, 6, a1The Department of Textile Engineering, Chinese Culture University, Taipei 11114, Taiwan, R.O.C. 2Institute of Biomedical Engineering and Material Science, Central Taiwan University of Science

and Technology, Taichung 406, Taiwan, R.O.C.

3Department of Fashion Design, Asia University, Taichung 41354, Taiwan, R.O.C.

4Laboratory of Fiber Application and Manufacturing, Department of Fiber and Composite Materials,

Feng Chia University, Taichung City 407, Taiwan, R.O.C.

5School of Chinese Medicine, China Medical University, Taichung 40402, Taiwan, R.O.C. 6Department of Biotechnology, Asia University, Taichung 41354, Taiwan, R.O.C.

Corresponding email: ajhlin@fcu.edu.tw, bcwlou@ctust.edu.tw

Keywords: geotextile, high-strength polyethylene terephthalate (HPET) fiber, polyethylene

terephthalate (PET) fiber, Kevlar fiber, porosity, water permeability.

Abstract Geotextiles have been commonly used globally, making the control of material selection

to influence geotextiles’ properties an important research topic. This study aims to explore the effects of the ratio of high-strength polyethylene terephthalate (HPET) fiber to Kevlar fiber on hybrid geotextiles. At the first stage, HPET and polyethylene terephthalate (PET) fiber are combined to make HPET/PET hybrid geotextile and then tested for porosity and water permeability, determining the optimum HPET/PET ratio. At the second stage, with a content of 60 % PET fibers, HPET fibers and Kevlar fibers are mixed with various ratios to form Kevlar/HPET/PET hybrid geotextiles. The experimental results show that with an increase in the content of HPET fibers, the porosity and water permeability of the Kevlar/HPET/PET hybrid geotextile decrease.

Introduction

In ancient times, sandbags were often used for protection in coastal and hydraulic engineering. Geotextiles have gradually replaced sandbags to reinforce and protect groynes, dams, seawalls, revetments, dunes, and hillsides [1]. Geotexiles can protect soil from being scoured by erosion and provide them with reinforcement [2]. Nonwoven fabrics have good strength, erosion-resistance, fast production speed, low production cost and an eco-friendly processing procedure. As such, they currently are used as geotextiles. According to specific applications, nonwoven fabrics can be designed and made with various tensile strength, shear strength, porosity, water permeability, and bursting strength. As a result, many researchers actively explore geotextiles and geogrids [3-7]. This study aims to explore the effects of different fibers with varying finenesses and lengths on the porosity and water permeability of the resulting hybrid geotextiles.

Experimental Materials

Kevlar fiber (DuPont™ Company, U.S.A.) has a length of 55 mm. High strength polyethylene terephthalate (HPET, Chien Chen Textile., Ltd., Taiwan, R.O.C.) fiber has a length of 65 mm. Polyethylene terephthalate (PET, Far Eastern New Century Corporation.) fiber has a length of 51 mm

Procedure

Preparation of HPET/PET Hybrid Geotextile

HPET fibers and PET fibers are combined with various ratios, by opening, mixing, carding, lapping, and needle punching to form HPET/PET hybrid geotextile. The blending ratio of HPET to PET is 4:6, 5:5, 6:4, 7:3, 8:2, and 9:1.

Preparation of Kevlar/HPET/PET Hybrid Geotextile

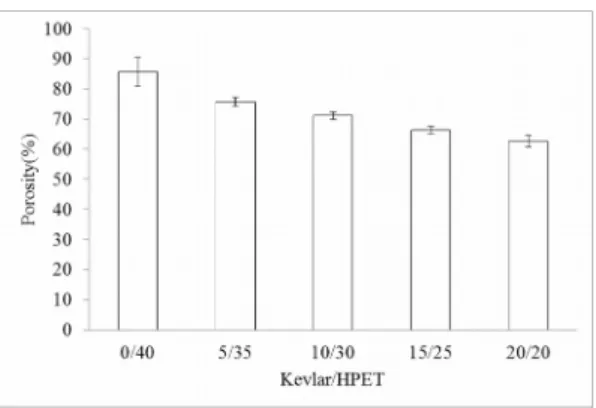

Kevlar fiber, HPET fibers, and PET fibers are combined by opening, mixing, carding, lapping, and needle-punching to form the Kevlar/HPET/PET hybrid geotextile. The PET fibers have a constant 60 % content. The ratios of Kevlar fibers to HPET fibers are 0/40, 5/35, 10/30, 15/25, 20/20. The porosity and water permeability of the resulting hybrid geotextiles are evaluated to determine the influence of variations in the Kevlar/HPET ratios on hybrid geotextiles.

Tests

Porosity

Samples are weighed by a microbalance procedure, and the true volume per 1 cm × 1 cm (Vm) was calculated based on equations of density and weight. The external volume per 1 cm × 1 cm (Vs) was also obtained by a vernier measurement. The porosity was expressed by the equation. Ten samples of each specification are tested in this matter.

Porosity (%) =[(Vs-Vm)/Vs] × 100 %...(1) Water Permeability

HPET/PET hybrid geotextiles and Kevlar/HPET/PET hybrid geotextiles are separately placed in a mold with a water inject hole on its upper end and a drainage hole on its lower end. Samples are laid flat, and 150 ml/s of water is poured into the mold for 10 seconds. A beaker is placed beneath the drainage hold to catch the water from the mold, and the amount of the water is recorded to calculate the water permeability. Ten samples of each specification are tested in this matter.

Results and Discussion

Porosity of HPET/PET and Kevlar/HPET /PET Hybrid Geotextile

Figure 1 shows that with a decrease in HPET fiber, the porosity of the HPET/PET hybrid nonwoven fabrics decreases. The fineness and length of HPET are greater than those of PET fibers. Therefore, the smaller the amount of HPET fibers is, the smaller the porosity and pore size become. High-porosity geotextiles have good filtration; therefore, at the next stage, the content of PET fibers is fixed as 60 % and only the ratio of Kevlar fibers to HPET fibers is varied. Figure 2 shows that with an increase in Kevlar fibers, the porosity of the Kevlar/HPET/PET hybrid geotextile decreases. The geotextile that contains a greater

amount of Kevlar fiber has a lower bulkiness because Kevlar fibers do not have crimpability. For this reason, the resulting hybrid nonwoven fabrics have a compact structure, in which the amount of pores decreases.

Figure 1. Porosity of the HPET/PET hybrid geotextiles containing 40, 50, 60, 70, 80, and 90 % of HPET fibers.

Figure 2 Porosity of the Kevlar/HPET/PET hybrid geotextiles made with a Kevlar/HPET ratio of 0/40, 5/35, 10/30, 15/25, or 20/20 %.

Water Permeability of the HPET/PET and Kevlar/HPET/PET Hybrid Geotextiles

Figure 3. Water permeability of the HPET/PET hybrid geotextiles containing 40, 50, 60, 70, 80, and 90 % of HPET fibers.

Figure 4. Water permeability of Kevlar/HPET/PET hybrid geotextiles made with a Kevlar/HPET ratio of 0/40, 5/35, 10/30, 15/25, or 20/20 %.

Figures 3 and 4 show that the water permeability of two types of hybrid geotextile has the same trend as the porosity as Figures 1 and 2. When the porosity is high, there are a greater amount and size of the pores of the hybrid geotextiles, resulting in a greater amount of water that permeates them, namely a greater water permeability. Geotextiles can be used widely and thus require various water permeabilities for various uses. Water resistant geotextiles require a minimum water permeability of 60 ml/s. The HPET/PET geotextiles containing 90 % of HPET fibers and the Kevlar/HPET/PET geotextiles containing 15 or 20 % of Kevlar fibers have a water permeability below this standard.

Conclusion

When containing 90 % of HPET fibers, the porosity and water permeability of the HPET/PET hybrid geotextile decrease by 16.4 % and 28.3 %. For Kevlar/HPET/PET hybrid geotextiles containing 20 % of Kevlar fibers, the porosity and water permeability decrease by 41.5 % and 33.7 %. Compared to the content of HPET fibers, the content of Kevlar fibers decreases the porosity and water permeability more significantly, proving that the fineness, length, and crimpability of the fibers have an influence on the properties of geotextiles.

Acknowledgements

This work would especially like to thank National Science Council of the Republic of China, Taiwan, for financially supporting this research under Contract NSC 100-2621-M-034-002 and NSC 101-2621-M-034-001.

Reference

[1] Fokke Saathoff, Hocine Oumeraci, Simon Restall, Australian and German experiences on the use of geotextile containers, Geotext. Geomembranes. 25 (2007) 251-263.

[2] S.M Haeri, R Noorzad, A.M Oskoorouchi, Effect of geotextile reinforcement on the mechanical behavior of sand, Geotext. Geomembranes. 18 (2000) 385-402.

[3] J.H. Lin, W.H. Hsing, Y.C. Chuang, T.T. Li, H.J. Tan and C.W. Lou, Optimization Process and Characteristic Evaluations of Pro-Environmental Recycled PET Composite Geotextiles, Advanced Materials Research, 627 (2013) 737-740.

[4] J.H. Lin, C.M. Lin, C.Y. Kuo, C.W. Lin, C.T. Hsieh and C.W. Lou, Manufacture Technology of Novel Reinforcing Composite Geotextile Made of Recycled Nonwoven Selvages, Advanced Materials Research, 123-125 (2010) 137-140.

[5] J.H. Lin, C.H. Huang, C.Y. Hsiao, K.C. Tai, J.M. Chen and C.W. Lou, Manufacturing Technique of High Modulus Complex Ply Yarn and Stiffening Geogrids. Advanced Materials Research, 332-334 (2011) 1101-1104.

[6] J.M. Chen, S.H. Chiang and J.H. Lin, Production and Applications of Geogrids with Functional Stainless Steel/PP Composite Yarns, Text. Res. J. 78 (2008) 1098-1109.