亞 東 技 術 學 院

The relative characteristics between absorption-desorption curves and

dyeing affinities of pre-treated Lyocell fiber

Yi-Jun Pan

*, Chien-Kuo Yen

*Abstract

Lyocell fibers can obtain improving dyeability but damaging mechanical properties after been pre-treated by CT, ET, CET and ECT methods. It was found that the sorption characteristic of the pre-treated fibers can be used as a confident examining tool for reflecting the changes of their fine structures. In general, although each treatment condition was keeping the same, changing the processing sequences would build up substantial different modifications on the fibre fine structures and dyeing behaviours as well. The hydrolysis actions by cellulase at different caustic treatment stages (in ET, CET and ECT methods) would be quite variable. Similarly, the hydration power at enzymatic treatment and different caustic treatment stages (in CT, CET and ECT methods) would also be significant changed too. Therefore, when Lyocell fibres have been pre-treated by caustic and enzyme solution alone or sequentially, their moisture regain and dyeing characteristics would be altered to different extents.

Keywords:Lyocell, enzymatic pre-treatment, caustic

pre-treatment, absorption-desorption 、 dyeing affinities

Introduction

Lyocell is the newest generation man-made cellulosic fibre made by a special extrusion process from directly dissolved wood pulp consisting in highly oriented molecular chains along the length of the fibre axis. For obtaining high quality dyeing of Lyocell fibres, a detailed analysis of the pre-treatment process is very important [1,2].

Caustic treatments are important for processing cellulosic fibres, in improving physical and dyeing properties [3-5]. Enzymatic treatments by cellulase enzymes are known to be useful for cellulosic fibre finishing, especially in Lyocell defibrillation. Both treatments, either alone or changing sequence, enzymatic before or after caustic treatments, should have significant influences on morphologies and dyeing characteristics of Lyocell fibres [6-9]. Understanding how caustic and enzymatic affects the morphologies as well as the dyeing affinities and the moisture absorption-desorption of pre-treated Lyocell fibres would help in selecting preparation and finishing methods and also in optimizing Lyocell dyeing and finishing performance.

Most of the previous publish papers have involved using fabrics. During the fabric formation process, either by weaving or by knitting, each yarn is subjected to lots of uneven tensions in the various operations. For reducing extra unexpected

experimental errors and knowing more useful information about Lyocell, resulting data from experiments using yarn samples for pre-treatment and dyeing processes should have the advantage over fabric types. Therefore, all the samples and experiments applied in this study are the yarn type.

It is clear from previous references that some work has been done to study the effects of enzymatic or caustic pre-treatments on the dyeing properties of Lyocell fibres using direct dyes [10-12], but seldom, if any, using reactive dyes. However, reactive dyes are widely used in the textile industry, especially in high quality cellulosic fabrics. Suitable evaluation of the dyeing affinities and the moisture absorption-desorption can provide useful information about the changes of processing condition and fibre fine structure. Therefore, the above characteristics of moisture and reactive dyes before alkali fixation on the caustic and enzymatic pre-treated Lyocell yarns should be very important to determine.

Materials and Equipments Materials

1. Lyocell yarn: Ne 16 (Tencel, supplied by

Sanyueh Textile CO. Ltd. Taiwan)

2. Reactive dyes (supplied by Chung Fu Dyestuffs

CO. Ltd. Taiwan, which were not purified prior to use. ):

C.I. Reactive Blue 19: (MW-503, chrom.-VS), coded as B19

C.I. Reactive Black 5: (MW-1015, VS-chrom.-VS), coded as B5

C.I. Reactive Blue 222: (MW-1357, chrom.-MCT-VS), coded as B222

3. Cellulase enzyme(CELLUSOFT PLUS L,

Continental CO. Ltd., Taiwan)

4. Sodium hydroxide

Equipment

1. Dyeing machine (Magnetic- Levitated Vortex

dyeing machine, HJ-8762t, Hang Jie Xing Ye CO. Ltd., Taiwan)

2. UV/VIS Spectrophotometer (Hitachi U-3010,

Wavelength range: 190 to 900 nm, Double Beam Double Monochromator )

3. Balance (Precisa XB 220)

4. Oven (Cherng Huei ST-60A, 25 – 250 oC)

5. Temperature & Humidity Tester Oven

(Justice Testing Instruments Co. Ltd., 5 – 95 oC,

RH%: 20%- 95%)

6. pH meter (Suntex SP-701)

Experimental Procedure

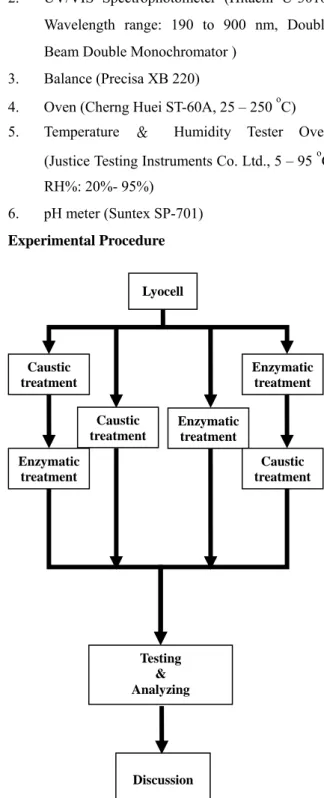

Fig. 1 Experiment procedure

Lyocell Testing & Analyzing Discussion Enzymatic treatment Caustic treatment Caustic treatment Enzymatic treatment Enzymatic treatment Caustic treatment

The experimental procedure in this research is illustrated in Fig.1. Four pre-treatment methods were applied before dyeing, i) caustic soda (Caustic), ii) cellulase enzyme (Enzymatic), iii) caustic pre-treatment before enzymatic (Caustic -> Enzymatic), and iv) enzymatic pre-treatment before caustic (Enzymatic->Caustic). In the case of the enzymatic treatments only, before or after the caustic in the experiments, all the enzymatic treatments were carried out in the same way.

In this research, the various treatments are all coded as follows:

Code Pre-treatment method

CT Caustic treatment only

ET Enzymatic treatment only

CET Caustic treatment followed by enzymatic treatment

ECT Enzymatic treatment followed by caustic treatment

For the samples treated with enzyme only (ET), no caustic soda treatment was applied, so the influence of caustic soda concentration could not be determined.

Pre-treatment Procedure Caustic treatment

1.1 gram of Lyocell yarn was rolled around a bobbin. Caustic treatment was carried out by immersing the sample bobbin in a stainless steel pot with different concentration of sodium hydroxide solution at a bath

ratio of 100:1 at 5 oC for 5 min. The caustic

concentrations in the bath were 5, 10, 15, 20, 25 g NaOH/100 ml respectively. When the treatment

period was over, the yarns were dipped in 80 oC

water for 10 min, then neutralized in deionized water with a bath containing 0.1% aqueous acetic acid at 25

o

C for 10 min, and followed by rinsing with 25 oC

deionized water for 10 min again to make sure the rinsed water had a neutral pH. The yarns were then

air-dried at 40 oC oven for 24 h. To obtain greater

accuracy in experimental data, each treatment was repeated three times.

Enzymatic treatment

Enzymatic treatment of the Lyocell yarns in this research is using a commercial product of liquid acidic cellulase from Novozymes (CELLUSOFT PLUS L). 1.1 gram of each sample was weighted and rolled around a bobbin, then put into a flask containing 10% owf cellulase and pH 5.0 buffer solution (acetic acid with sodium acetate), and shaken

at 55 oC for 90 min. The enzyme was deactivated by

heating the treatment solution to 85 oC for 15 min,

and followed by thoroughly rinsing in running water for 10 min, after which it was air-dried at 40◦C for 24 h. Each treatment was also repeated three times.

Dyeing procedure

All exhaustion dyeing was carried out using a Magnetic- Levitated Vortex dyeing machine. One gram of pre-treated or untreated Lyocell yarn wound around a bobbin was dyed in a stainless steel pots (150 ml) at a liquor ratio of 1: 90 with sodium chloride (50 g/L). Each dye was applied at six depths: 0.25%, 0.5%, 1%, 2%, 3%, 5% o.w.f (on weight of fibre) respectively. For more accurate in dyeing results, each same treatment was split up three samples at same procedure from which average value could be calculated. At the end of the dyeing process, the samples were removed from the dye pots and rinsed in deionized water for 10 min, and then the samples were soaped at a liquor ratio of 1: 100 at 85

o

C for 15 min. Finally the yarn was rinsed with cold

water for 10 min and air dried at 40 oC for 24 h.

Testing

Moisture sorption measurements

Approximately 1 g of Lyocell yarn was placed in a constant temperature and humidity oven. The

atmosphere in the oven was first kept at 20 oC and then the relative humidity (RH) was raised step-wise from 25%, 45%, 60%, and 80% to 95% to measure the moisture absorption ability of the treated or untreated yarns. After the oven reached 95% RH for 2 hours, the relative humidity was decreased step-wise from 95%, 80%, 60%, 45% to 25% but keeping

temperature at 20 oC. In this way the desorption trend

and hysteresis isotherms were measured. Moisture regain at a given humidity was calculated from the average of three individual samples of same conditioned yarn. The following equation (1) was used for the calculation:

MR% = [(WC – WD) /WD]*100% (1) where,

WC , fibre weight at given humidity WD , fibre weight of dried fibre

Dye exhaustion

Exhaustion in a dyeing experiment is used to evaluate the characteristics of physical dye absorption on the fibre. The extent of dye exhaustion and the amount of

dye adsorbed on the fibre Df was calculated by

equation (2) and (3),

%Exhaustion= ([Di] –[Ds]) / [Di] × 100 (2)

where [Di]: the concentration (mole/L) of dye in

solution applied at dyeing start

[Ds]: the concentration (mole/L) of dye in solution

remained at dyeing end

Df = ([Di] –[Ds]) × V/ M (3)

Df: the concentration (mole/Kg) of dye absorbed on

the fibre at dyeing equilibrium

V: the volume of the dyeing solution (L), and M is the weight of dry fibre (Kg) used in the dyeing The absorbance values of the [D]- before dyeing, before and after the fixation of the dyeing, were measured from the spectrophotometry and their corresponding dye concentrations can be determine by using the calibration curve, respectively. Reactive

dyes are applied by chemical reaction at alkali condition, and are irreversible which makes it difficult to remove the dye from the fibre. This affects the dyeing equilibrium established during the adsorption of dyes onto fibres. Therefore, it is only possible to study the substantivity ratio of reactive dye from the dyebath before the alkali fixation procedure on those which are reversible.

Results and Discussion

Analysis of the moisture sorption

Evaluating the characteristics of moisture absorption and desorption can be useful for comparing the extent and the difference of less ordered regions and functional groups between modified cellulosic fibrous materials. For fibres having the same chemical composition but different fine structures, the amount of absorbed water molecules at a given humidity are proportional to the amount of non-crystalline regions present [13,14].

The results show that moisture absorption values are higher for ET, CT and ECT pre-treated yarns. But for yarns pre-treated by the CET method the moisture values do not change much and display a lesser trend at higher caustic soda concentration.

After the enzymatic pre-treatment, some of the entangled cellulose chains in the amorphous regions were cleaved into short segments by cellulase enzyme degradations. These actions helped the entangled molecular chains in these areas to become more loosened and more stretchable when subjected to the follow-up caustic treatment. Therefore, the amorphous regions became more regular and tight than those in fibres given by caustic treatment only. That is the reason attributes to the moisture regains for yarns subjected to the ECT pre-treatment are less than that for the CT yarns.

The caustic pre-treatments could provide an accelerating action on enzymatic degradation because they made the cellulosic structure more accessible to the cellulase molecules. The caustic pre-treatments caused Lyocell fibres to possess higher swelling ability in the following enzymatic treatment procedure. They not only enabled the following hydrolysis actions to become easier and more drastic, but also let the molecular chains be subjected to higher stretch forces. Then the arrangement of molecular chains became more regular and accompanied with the decrease of the accessible functional groups inside the fine structure too. Consequently there was a block effect by the CET pre-treatment for absorbing more water molecules and gave a decrease in water absorption ability for the treated yarns.

Fig.2 and Fig.3 are the moisture sorption isotherm curves for the untreated yarns and the yarns pre-treated (10% caustic soda) by the four different pre-treated methods. According to the hysteresis theory suggested by Urquhart and Hermans [15], fibres with more hydrogen bonds in the non-crystalline regions possessed fewer available hydroxyl groups that would provide mechanical restraint and reduced moisture absorption. As humidity increased, the hydrogen bonds tended to be broken and replaced by water absorption on the hydroxyl groups, so the moisture absorption would be increased but the mechanical properties would be poor.

In Fig.2 and Fig.3, it can be seen that the moisture absorption and desorption curves for different pre-treated fibres at different relative humidity are significantly different. These differences also give evidence that although treatment conditions were the same, changing the processing sequences

would build up substantial different modifications in the fibre fine structure. As compared with untreated yarns, most of the moisture sorption abilities for pre-treated Lyocell become higher, especially for the CT and ECT pre-treated yarns. But yarns given the CET pre-treatment show a decreasing trend than untreated Lyocell yarns.

0 5 10 15 20 25 0 15 30 45 60 75 90 Relative humidity Mo istu re Re ga in ( % ) Untreated absorption Untreated desorption Enzymatic -absorption Enzymatic -desorption Caustic -absorption Caustic -desorption

Fig.2 Sorption comparisons for untreated, enzymatic and caustic pre-treated yarns at different RH% and 10% caustic pre-treated concentration conditions 0 5 10 15 20 25 0 15 30 45 60 75 90 Relative humidity Mo ist ure Re gai n (% ) Untreated absorption Untreated desorption Enzymatic->Caustic absorption Enzymatic->Caustic desorption Caustic->Enzymatic absorption Caustic->Enzymatic

Fig.3 Sorption comparisons for different pre-treated yarns at different RH% and 10% caustic concentration pre-treated condition

The mechanism, by which water molecules become attached to the hydroxyl groups of the molecular chains at the different relative humidity can be divided into two types, directly attached (hydrated) water and indirectly attached (bound) water [13,14]. The directly attached water are the first

water molecules absorbed directly onto the hydrophilic groups of the cellulose molecules and are firmly fixed, fitting closely to the fibre structure. The indirectly attached water molecules are more loosely held and easy evaporated. At typical absorption curve of moisture regain plotted against relative humidity usually gives a sigmoidal shape. The absorption curve shows a rapidly increasing regain at lower humidity, representing absorption of directly attached water molecules, then follows a linear saturated portion and a more rapid rise at high humidity, corresponding to the indirect absorption of water molecules.

Because most of the saturated conditions appear between 45% RH to 65% RH, the absorption values between 45% RH to 60% RH could be simply represented as an indication of the directly attached water contents in this experiment. The absorption value difference between 95% RH and 80% or 60% or 45% RH could also be expressed as the degree of the indirectly attached water.

The comparisons of the water content of directly and indirectly absorbed water for yarns given the different pre-treatments are listed in Table 1 and 2. Similarly, the amount of desorption value difference between 95% RH and 80% RH or 60% RH can be used as an indication of the ability of the indirectly attached water in the pre-treated fibre to escape from the fibre structure in the desorption processes, as given in Table 3. If this value is small, it implies that the entrance of the voids or free spaces are too narrow, water molecules may get in easily but come out with difficulty in the desorption processes. Fibres with this kind of fine structure would be unable to absorb molecules with large size which could be blocked from entering the voids or free spaces.

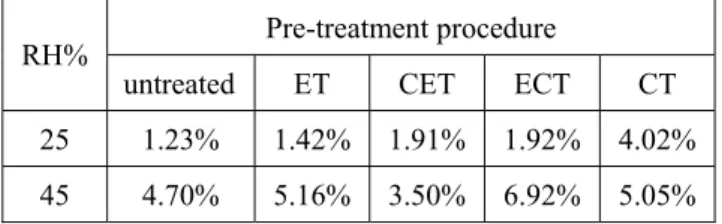

Table 1 Content of directly attached water by different pre-treatments at 10% caustic pre-treated concentration

Pre-treatment procedure RH%

untreated ET CET ECT CT

25 1.23% 1.42% 1.91% 1.92% 4.02%

45 4.70% 5.16% 3.50% 6.92% 5.05%

Table 2 Content of indirectly attached water by different pre-treatments at 10% caustic pre-treated concentration

Pre-treatment procedure RH%

untreated ET CET ECT CT

45↑ 13.19% 16.18% 13.80% 15.97% 19.57%

60↑ 11.25% 14.46% 14.33% 14.59% 16.99%

45↑: means indirectly absorbed water from 45 % RH to 95% RH 60↑: means indirectly absorbed water from 60 % RH to 95% RH

Table3 Content of indirectly desorbed water by different pre-treatments at 10% caustic pre-treated concentration

RH% untreated ET CET ECT CT

60↓ 10.94% 12.84% 11.68% 12.78% 15.45%

80↓ 5.83% 7.79% 6.90% 9.58% 10.81%

60↓: means indirectly desorbed water from 95% RH to 60% RH 80↓: means indirectly desorbed water from 95 % RH to 80% RH

Table 1 to Table 3 show the differences of attached water for all the pre-treated fibres at 10% caustic pre-treated concentration condition. The results indicate that most of the amount of directly and indirectly attached water for fibres by the ET, CT and ECT pre-treatments is higher than the untreated fibre. The CT pre-treatment gave fibres with more space for water to get through, highly increasing the absorption of more indirectly attached water. Cellulase pre-treatment effectively hydrolyzed the fibre surfaces and amorphous regions by cleaving the β 1-4 glucosidic bonds of cellulosic chains which were the advantage in increase the absorption abilities of indirectly attached water. Fibres given the ECT pre-treatment had the highest content of directly

attached water at 45% RH and had the moderate content of indirectly attached water. The absorption of indirectly absorbed water could be improved by CET pre-treatment, but the amount of indirectly desorbed water was the least as compared with other pre-treatments, which means CET pre-treatment could increase the accessible functional groups but could not create more and larger voids for the Lyocell fibres.

Fig.6.7 compares the hysteresis difference of different pre-treatment yarns at different relative humidity and at 10% caustic concentration. The results indicate that yarns given the CET pre-treatment had the characteristic to hold more indirectly attached water at higher RH conditions in spite of CET pre-treated yarns adsorbing less water than those of the other pre-treated methods. It implies that, the entrance of the voids or free spaces were narrow in the fine structure of the yarns pre-treated by CET, water molecules were not easily escaped during the earlier desorption processes. While at lower RH% condition, Lyocell given the ECT pre-treatment had the highest hysteresis value, which gave suggestion that the increasing accessible group helped absorbing more direct attached water.

Substantivity behaviour of the pre-treated Lyocell fibres

The primary exhaustion, as mention previously in equation (2), is used to evaluate the characteristics of the physical dye adsorption for the different pre-treated Lyocell yarns dyed with three different types of reactive dye before the alkali fixation

procedures at 70oC and pre-treated by various NaOH

concentrations.

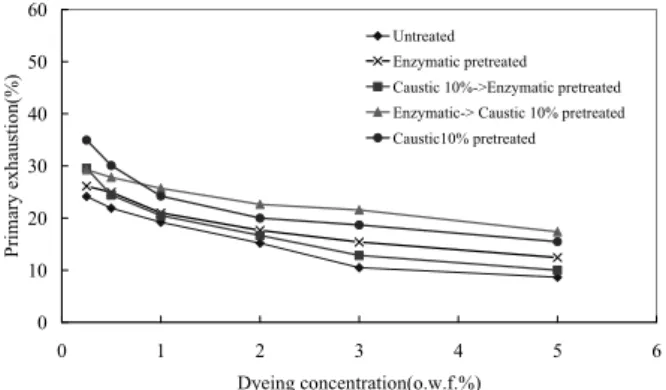

Fig. 4 to Fig. 6 indicate the comparisons of the effects of the ET, CT, ECT and CET pre-treatments on the primary exhaustion of the three reactive dyes,

before the alkali fixation procedures of the dyeing process. All the pre-treatments have the advantage of increasing the substantivity tendency between the dye B19 and the pre-treated Lyocell fibre (Fig. 4), and the order of increasing exhaustion is ECT > CT > ET > CET > untreated yarn, at higher dye concentration.

0 10 20 30 40 50 60 0 1 2 3 4 5 6 Dyeing concentration(o.w.f.%) Pr ima ry ex hau st ion (% ) Untreated Enzymatic pretreated Caustic 10%->Enzymatic pretreated Enzymatic-> Caustic 10% pretreated Caustic10% pretreated

Fig.4 Comparisons of primary exhaustion of dye B19 on the Lyocell given the different pre-treatments at different dyeing concentration (before fixation)

For dye B5 (Fig.5), primary exhaustion values were improved for the ET, CT and ECT pre-treated yarns than those for untreated yarn, especially for the CT pre-treated yarn. But for pre-treatment by the CET method, the primary exhaustion value was not improved at the higher dye and caustic pre-treatment concentration, as also shown in Fig.7.11 previously. For dyeing with the large molecular size dye B222 (Fig.6), the CT, ECT and CET pre-treatment methods were also useful for increasing the primary exhaustion. The increasing amounts for all the ranges of the caustic pre-treatment concentration became narrow by the CET and ECT pre-treated methods. By the ET pre-treatment, it did not improve the primary exhaustion a lot at higher dye concentration for dyeing with dye B222.

0 10 20 30 40 50 60 0 1 2 3 4 5 6 Dyeing concentration(o.w.f.%) Pri m ary exhaust ion(%) Untreated Enzymatic pretreated Caustic 10%->Enzymatic pretreated Enzymatic-> Caustic 10% pretreated Caustic 10% pretreated

Fig.5 Comparisons of primary exhaustion of dye B5 on the Lyocell given the different pre-treatments at different dyeing concentration (before fixation) 0 10 20 30 40 50 60 0 1 2 3 4 5 6 Dyeing concentration(o.w.f.%) Pr im ary ex haus tion (%) Untreated Enzymatic pretreated Caustic 10%->Enzymatic pretreated Enzymatic-> Caustic 10% pretreated Caustic10% pretreated

Fig.6 Comparisons of primary exhaustion of dye B222 on the Lyocell given the different pre-treatments at different dyeing concentration (before fixation)

Conclusion

The influence of the pre-treatment methods, CT, ET, CET and ECT, on the mechanical, sorption and dyeability of Lyocell fibres have been investigated. The pre-treatments could improve their dyeability but damaged their mechanical properties. The sorption and dyeing characteristics were examined to reflect the physical differences among each pre-treatment. It was found that although the conditions of each treatment were the same, changing the processing sequences will build up substantially different modifications on the fibre fine structure and its dyeing behaviours as well. The hydrolysis actions by cellulase at different caustic treatment stages (in ET,

CET and ECT methods) were quite variable. Similarly, the hydration power at enzymatic treatment and different caustic treatment processes (in CT, CET and ECT methods) showed significant differences too. Therefore, when Lyocell fibres have been pre-treated by caustic and enzyme solution alone or sequentially, its structural and dyeing characteristics will be altered to different extents. In general, the higher values of moisture regain and dyeing substantivity, were mostly obtained at 10% or 15% caustic soda concentration for all the pre-treatment methods with each of the three dyes used in the study.

1. In the CT process, hydrated alkali ions can effectively penetrate the fibre crystalline regions and create more irregular regions causing the orientation in the pre-treated fibres to reduce and inducing the fibre crystallinity and fibre strength to decrease. Besides, the swelling of Lyocell fibres exhibit a certain drawability which further increases the orientation of the amorphous chains and give recrystallization action in the subsequent treatments.

2. For ET pre-treated Lyocell fibre, the cellulase hydrolysis action mainly increases the amount of accessible functional groups in the amorphous regions and pore volumes on the fibre surface, which allows more dye molecules to be attracted. 3. The caustic pre-treatment of the CET method

causes Lyocell fibres to possess higher swelling ability, which not only enables the following enzyme hydrolysis actions to become easier and more drastic, but also allows the molecular chains to be subjected to higher stretch forces during the time-consuming post enzymatic treatment stage. 4. The enzymatic pre-treatment in the ECT method

increases the surface accessible groups and allows some of the entangled cellulose to cleave into short

segments which helps the entangled molecular chains in the amorphous areas to become more loosened and more stretchable when subjected to the follow-up caustic treatment.

5. Comparing the experimental results of these two methods (CET with ECT) shows that the mechanical and adsorption properties for yarns pre-treated by the CET method were different from those by the ECT method. Due to the characteristics of lower dyeability and sorption ability but higher tensile modulus for the CET pre-treated Lyocell yarns, it gave evidnce that the degree of the rearrangement of molecular chains should be more regular for Lyocell yarn given the CET pre-treatment.

Reference

1. Lenz, J. Schurz, E. Wrentschur, Properties and structure of solvent-spun and viscose-type fibres in the swollen state, Colloid Polym. Sci., 271, p460-268 (1993)

2. R. N. Ibbett, Y. L. Hsieh, Effect of fiber swelling on the structure of Lyocell fabrics, Text. Res. J., 71(2), 164-173 (2001)

3. W. Zhang, S. Okubayashi, T. Bechtold, Fibrillation tendency of cellulosic fibers- Part3. Effects of pretreatment of Lyocell fiber with alkalis, Carbohydrate Polymers, 59, p173–179 (2005)

4. W. Zhang, S. Okubayashi, T. Bechtold, Fibrillation tendency of cellulosic fibers- Part 4. Effects of alkali pretreatment of various cellulosic fibers, Carbohydrate Polymers, 61, p427–433 (2005)

5. W. Zhang, S. Okubayashi, W. Badura, T. Bechtold, Fibrillation tendency of cellulosic fibers. VII. Combined effects of treatments with an alkali,

crosslinking agent, and reactive dye, J. Appl. Polym. Sci., 100, p1176–1183 (2006)]

6. A Cavaco-Paulo, L. Almeida, Cellulase hydrolysis of cotton cellulose: The effects of mechanical action, enzyme concentration and dyed Substrates, Biocatalysis, 10, p353-360 (1994).

7. A Cavaco-Paulo, L. Almeida, Cellulase activities and finishing effects, Text. Chem. Color, 28(6), p28-32 (1996)R. Mori, T. Haga, T. Takagishi, Reactive dye dyeability of cellulose fibers with cellulase treatment, J. Appl. Polym. Sci., 59, p1263-1269 (1996)

8. R. Mori, T. Haga, T. Takagishi, Changes in Dyeability and Morphology of Cotton Fiber Subjected to Cellulase Treatment, J. Appl. Polym. Sci., 65, p155-164 (1997)

9. G. Buschle-Diller, S. H. Zeronian, Enzymatic and acid hydrolysis of cotton cellulose after slack and tension mercerization, Text. Chem. Color., 26(4), p17-24 (1994)

10. S. H. Bae, H. Motomura, Z. Morita, Adsorption behavior of reactive dyes on cellulose, Dyes and Pigments, 34(1), p37-55 (1997)

11. S. H. Bae, H. Motomura, Z. Morita, Diffusion/ adsorption behavior of reactive dyes in cellulose, Dyes and Pigments, 34(4), p321-340 (1997) 12. S. H. Bae, H. Motomura, Z. Morita, Effect of

anionic groups in cellulose on the adsorption of reactive dyes on, Dyes and Pigments, 36(1), p61-77 (1998)

13. A. Kongdee, T. Bechtold, E. Burtscher, M. Scheinecker, The influence of wet/dry treatment on pore structure-the correlation of pore parameters, water retention and moisture regain values, Carbohydrate Polym., 57, p39–44 (2004) 14. W. E. Morton, J. W. S. Hearle, in “Physical

of moisture sorption, The Textile Institute, Heinemann: London, p223 (1975)

15. W. E. Morton, J. W. S. Hearle, in “Physical Properties of Textile fibres”, Chapter 12 Theories

of moisture sorption, The Textile Institute, Heinemann: London, p223 (1975)