392 IEEE ELECTRON DEVICE LETTERS, VOL. EDL-5, NO. 10, OCTOBER 1 9 8 4

A Low-Power Programming

Technique for

Polysilicon Fuses

Abstract-A new programming technique for polysilicon resistor fuses using low input electrical power has been demonstrated. In contrast to the conventional technique which programs fuses in the air at atmospheric pressure, the new technique is to program fuses in a low-pressure gas ambient. Removal of the entire passivation layers over the fuses is not necessary thus avoiding the contamination problem.

E

I. INTRODUCTION

LECTRICALLY PROGRAMMABLE polysilicon-resistor fuses have been widely employed as memory elements in fusible-link PROM’s [ I ] , [2] and fuse elements for selection of redundant circuits in high-density memories [3] - [ 6 ] . Dif- ferent I-V switching modes of polysilicon resistors have been used [ 7 ] , [8]. The most popular one uses on-chip driver tran- sistors to blow open low-resistance polysilicon links. However, this technique requires large electrical power thus demanding large chip area for driver transistors. If the fuse is encapsulated with passivation layers such as phosphorus-silicate glass (PSG), the programming power is larger than without passivation layers [9]. Usually it is necessary to remove the passivation layers over the fuse to obtain lower programming power; how- ever, such openings can cause contaminations thus degrading the chip reliability [lo]

.

When programming power is designedtoo low, unexpected switching events may occur to nonpro- grammed fuses.

In this letter, a new programming technique for polysilicon- resistor fuses using low input electrical power has been demon- strated. In contrast to the conventional technique which pro- grams fuses in air at atmosphere pressure, the new technique is t o program fuses in a low-pressure gas ambient. This can save programming power and driver transistor area and increase

programming noise immunity, so that removal of the entire passivation layers over the fuses is not necessary, thus avoiding the contamination problem.

11. EXPERIMENTS

The fuses were fabricated in 0.35-pm-thick LPCVD poly- silicon films which were deposited over a 0.80-ym-thick ther-

Manuscript received June 13, 1984; revised July 18, 1984.

C. Y . Lu was at the Department of Electrical and Computer Engineering, North Carolina State University, Raleigh, NC 27695-7911 on leave from the Institute of Electronics, National Chiao-Tung University, Hsin-Chu, Taiwan, Republic of China. He is now with AT&T Bell Laboratories, Reading, PA 19604.

N. C.-C. Lu is with IBM Thomas J. Watson Research Center, Yorktown Heights, NY 10598.

C . 4 . Shih is with the Institute of Electronics, National Chiao-Tung University, Hsin-Chu, Taiwan, Republic of China

REMOVE PSG 8 OXIDE IN VACUUM

i

I

I I u/ I I14 18 22 26

PROGRAMMING CURRENT I T (mA)

Fig. 1 . Programming voltage and current of polysilicon resistor fuses at different conditions (CVD oxide layer thickness = 0.070 pm). Circles atmospheric pressure. Triangles (A, A ) and squares (B, i7)are data of

( 0 , 0) are data of programming voltage and current of group I in group I1 programmed at atmospheric pressure and low-pressure gas ambient (2 X torr.) respectively.

mal oxide layer on silicon substrates. The polysilicon films were heavily doped with phosphorus at an implant dose of

5 X 10l6 cm-2, then covered by either

0.070-

or 0.80-pm- thick CVD oxide films and 0.80-pm thick PSG layers, andannealed at 900’ for 30 min.

The wafers were divided into four groups: (I) having 0.07-pm CVD oxide and PSG layers over fuses; (11) having both 0.07-pm CVD oxide and PSG layers removed; (111) having 0.80-pm CVD oxide and PSG layers over fuses; and (IV) having

PSG layers was removed and a 0.80-pm CVD oxide layer was partially removed to approximately 0.40

pm.

The low-pressure gas ambient is air a t pressure of 2 to 3 X

IOw6

torr. The fuses were blown open in such an ambient and also at atmospheric pressure. A Tektronix 576 curve tracer was used for programming and observation.Programming power is defined as the product of the pro- gramming voltage and the programming current a t which the fuses were switched from a conductive state to an open state. The programming voltage versus current under different condi- tions is shown in Fig. 1. A figure of merit, power-saving ef-

L U e t al.: PROGRAMMING TECHNIQUE FOR POLYSILICON FUSES 3 9 3

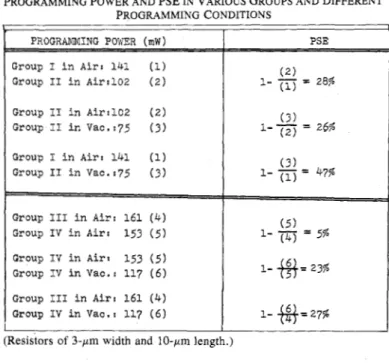

TABLE I conducted away, the central part of the resistor can be heated

PROGRAMMING POWER AND PSE IN VARIOUS GROUPS AND DIFFERENT up to a temperature higher than its melting point [ 1 1 ] such

PROGRAMMING CONDITIONS that the molten silicon can be swept

to generate a gap by the

PROGRAMMING POWER (mW) PSE applied electrical field [ 9 ] . If the power is fairly large, it is also

I reported in [3] that the fuse material can be evaporated to

~

Group I in Air: 141 (1)

Group I1 in Air:lO2 (2)

1

1- (1) (2) = 28%Group 11 in Air:102 (2)

Group 11 in Vac. :75 (3) I-- ( 3 ) (2)

-

-

26%(1)

-

47% Group I in Air: 141 (1)Group I1 in Vac.175 ( 3 ) 1-

-

(3)-

Group I11 in Air: 161 (4)Group IV in Air: 153 (5) Group IV in Air1 153 (5) Group IV in Vac.: 117 ( 6 ) (5) 1-

-

I (4) 5% 1- #= 23%Group I11 in Air: 161 (4)

Group IV in Vac.: 117 ( 6 ) 1-

#=

27%L

(Resistors of 3-pm width and 10-pm length.)

ficiency (PSE), is defined as

PSE = 1 - (programming power of group x in condition 1

)I

Removing both PSC and oxide layers over fuses in the air can save programming power by approximately 25 to 28 percent (PSE for group I1 samples t o group I samples) and an additional 26-percent power can be saved by programming fuses in the low-pressure gas ambient. Totally: by comparing the group I samples programmed in air to the group I1 samples in low- pressure air, PSE is as high as 47 percent. When the passivation layer is only partially removed (group IV samples), program- ming at atmosphere pressure does not save too much power(PSE for group IV samples to group I11 samples is less than 5

percent): however, programming group IV samples at low pres- sure air can save 20- to 23-percent power in comparison to programming at atmosphere (see Table I).

In summary, the most efficient way to save programming power is to remove entire passivation layers and to program fuse in low-pressure air. Retaining a thin CVD oxide film after removing PSG layer and programming in the low-pressure air can save a similar amount of power as the case of removing the

entire passivation layers, but programming at atmosphere, how- ever, the contamination problem can be eliminated. The other advantage of programming fuses at low-pressure air ambient is that fuses can be designed to have higher programming power at atmosphere thus reducing unexpected switching events after programming.

(programming power of group y in condition 2)

111. DISCUSSION

The physical mechanisms of polysilicon resistance switching are complicated and different switching patterns have been ob- served for various device configurations and programming con- ditions [ 7 ] , [ 8 ] . The physical mechanisms for saving program- ming power to blow open fuses in a low-pressure air are de- scribed here. When the electrical power is supplied into the re- sistor and the Joule heat is generated much faster than it is

form a gap.

Low-pressure gas ambient has notable effects on blowing a

fuse. First, reducing pressure over fuses lowers the boiling temperatures of polysilicon and oxide significantly, but

have minor effect on the melting point. At atmospheric

pressure, silicon has the boling point about 2878'C,

which decreases to 1230°C at 2 X l o F 6 torr [ 121

, [

131, Simi- lar behavior has been observed for silicon dioxide, which has the boiling point about 2230'C at atmospheric pressure and 1109'C a t 2 X torr [12] ~ [13]. Therefore, as the fuses are programmed in the low-pressure air: the boiling tempera- ture of polysilicon is much lower such that less electrical power is required to blow open the fuse, In addition, since the boiling temperature of silicon dioxide also decreases, less power is needed to evaporate the oxide passivation layer in contrast to the programming condition at atmosphere. It is interesting to note that when the passivation layer is only partially removed (group IV samples), programming at atmos- pheric pressure does not save too much power, however, pro- gramming group IV samples at low-pressure air can save 20- to 23-percent power in comparison to programming group IVsamples at atmosphere. Since the boiling points of both sili- con and silicon dioxide are higher than their melting points at atmospheric pressure and if the input power is not excessively large, the fuses are more likely blown open after the molten

filaments have been formed rather than when both silicon dioxide and silicon have to be evaporated. Therefore, a s long

a s the passivations over fuses are not completely removed, the programming power is not reduced very much because the effect of oxide is mechanical in that it impedes the movement of the molten silicon [ 9 ] . When the fuses are programmed in the low-pressure air, however, the boiling point is reduced drastically and. as a result, both silicon and silicon dioxide layers can be evaporated during programming. So, even the passivation layers are not completely removed, 20-23-percent PSE has been achieved. The thin oxide layer over polysilicon fuses avoids the contamination problems which would occur if the entire passivation layer were removed. Second, since the low-pressure air ambient is less thermal conductive than atmos- pheric pressure air ambient, Joule heat conducts away from

polysilicon slower in low-pressure air ambient. This can also re- sult in using lower power to blow open the fuse, however, the effect should be minor in comparison to the first effect. Be- cause the large difference in thermal conductivity among atmospheric pressure air (2.6 X l o w 4 W/K.cm), oxide (1.4 X l o p 2 W/K.cm), and silicon (1.5 WjK-cm), the major heatsink should be the oxide layer underneath the polysilicon film to the silicon bulk substrate.

In conclusion, a new low-pressure programming technique for polysilicon fuses has been demonstrated. In contrast to

the conventional technique, the new technique can save power and chip area? increase fuse noise immunity: and avoid the contamination problem.

394 IEEE ELECTRON DEVICE LETTERS, VOL. EDL-5, NO. 10, OCTOBER 1 9 8 4

ACKNOWLEDGMENT 161

The authors wish t o thankM.-K. Lee and K.-Z. Chang of ERSO,

Industrial Technology Research Institute of Republic of China, V I

for sample preparation and N.-T Liang of Academia Sinica at Taipei for technical assistance. C.-Y. Lu would like to thank Dr. A. Reisman and Prof.

N.

A. Masnari for their encouragement. [81REFERENCES [91

R. C . Smith, S. J. Rosenberg, and C. R . Barrett, “Reliability studies of polysilicon fusible link PROM’s,” in 14th Annual Proc. [lo]

Reliability Phys., 1976, pp. 193-197.

R. K . Wallace, “A 35-11s 16 K PROM,” in IEEE ZSSCC Tech. [ l l ] Dig., 1980, pp. 148-149.

R . J. Smith, “Redundancy-the new device technology for circuits of 80’”’’ in IEDM Tech. Dig., 1982, pp. 608-611. [ W K . Kokkonen er a l . , “Redundancy techniques for fast static

RAM’S,” in ZEEE ISSCC Tech. Dig., 1981, pp. 80-81.

T. Mano et ai., “A 256 K RAM fabricated with rnoly- bedum-polysilicon technology,” in IEEEISSCC Tech. Dig., 1980, [I31

pp. 234-235.

S. S. Eaton, D. Wooten, W. Slemmer, and J. Bardy, “A 100-ns 64 K

DRAM using redundancy techniques,” in ZEEE ISSCC Tech. Dig., C. Y . Lu, N. C. C. Lu, C. C. Shih, M. K. Lee, and C . S. Wang, “On resistance switching in polycrystalline-silicon resistors,” in Proc.

Eletrochem. Soc. Meet., (San Francisco, CA), 1983, Extended Abs.

no. 404, pp. 627-628.

C. . Y . Lu, N. C. C. Lu, and C. C. Shih, “Resistance switching characteristics in polycrystalline-silicon film resistors,” submitted to

.I.

Electrochem. SOC., 1984.D. W. Gerve, “Programming mechanism of polysilicon resistor fuses,” IEEE Trans. Electron Devices, vol. ED-29, pp. 719-724,

1982.

D . L. Crook and W . K . Meyer, “Redundancy reliability,” in 19th Annual Proc. Reliability Phys., 1981, pp. 1-5.

D. H. Pontusi, W. B. Smith, and P. P. Bundenstein, “Filamentation in silicon-on-sapphire homogeneous thin film,” J . Appl. Phys., vol.

G. E. C. Kaye and T. H . Laby, Table of Physical and Chemical Constants. London: Longman Press, 1973.

R. C. Weast, CRC Handbook of Chemistry & Physics, 64th ed.

Boca Raton. FL: CRC Press, 1984.

R. E. Honig, “Vapor pressure data for the solid and liquid element,”

R C A Rev., vol. 23: pp. 567-582, 1962. 1981, pp. 84-85.