Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Journal of the Chinese Institute of Engineers

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/tcie20

Evaporation of water film in an enclosure filled with a porous medium

Wu‐Shung Fu a & Wen‐Wang Ke aa

Department of Mechanical Engineering , National Chiao Tung University , 1001 Ta Hsueh Road, Hsinchu, 30050, Taiwan, Republic of China

Published online: 03 Mar 2011.

To cite this article: Wu‐Shung Fu & Wen‐Wang Ke (1999) Evaporation of water film in an enclosure filled with a porous medium, Journal of the Chinese

Institute of Engineers, 22:3, 325-339, DOI: 10.1080/02533839.1999.9670470

To link to this article: http://dx.doi.org/10.1080/02533839.1999.9670470

PLEASE SCROLL DOWN FOR ARTICLE

Taylor & Francis makes every effort to ensure the accuracy of all the information (the “Content”) contained in the publications on our platform. However, Taylor & Francis, our agents, and our licensors make no representations or warranties whatsoever as to the accuracy, completeness, or suitability for any purpose of the Content. Any opinions and views expressed in this publication are the opinions and views of the authors, and are not the views of or endorsed by Taylor & Francis. The accuracy of the Content should not be relied upon and should be independently verified with primary sources of information. Taylor and Francis shall not be liable for any losses, actions, claims, proceedings, demands, costs, expenses, damages, and other liabilities whatsoever or howsoever caused arising directly or indirectly in connection with, in relation to or arising out of the use of the Content.

This article may be used for research, teaching, and private study purposes. Any substantial or systematic reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any form to anyone is expressly forbidden. Terms & Conditions of access and use can be found at http://www.tandfonline.com/page/terms-and-conditions

EJ061199900325

Journal of the Chinese Institute of Engineers, Vol. 22, No. 3, pp. 325-339 (1999)EVAPORATION OF WATER FILM IN AN ENCLOSURE FILLED

WITH A POROUS MEDIUM

Wu-Shung Fu* and Wen-Wang Ke Department of Mechanical Engineering

National Chiao Tung University

1001 Ta Hsueh Road, Hsinchu, 30050, Taiwan Republic of China

Key Words: evaporation, porous medium, latent heat, sensible heat.

ABSTRACT

A double diffusive natural convection in an enclosure filled with a porous medium is investigated numerically. To enhance the heat transfer rate of a heat wall, the heat wall is wetted with a thin water film, then sensible and latent heat transfer occur simultaneously. The Darcy-Brinkman-Forchheimer model is used and the factors of heat flux, porosity and diameter of bead are taken into consideration. The SIMPLEC method with iterative processes is adopted to solve the gov-erning equations. The results show that the effect of evaporation on the heat transfer rate is apparent, and the latent heat transfer plays an important role in the high Darcy-Rayleigh number situations. The av-eraged Nusselt number Nu is approximately 2.5 when Ra*<4. In the range of 4<Ra*<4469, the relationship of the averaged Nusselt number with the Darcy-Rayleigh number is linear in logarithmic scale.

I. INTRODUCTION

Double diffusive natural convection in a porous medium has many important applications in energy-related engineering problems, such as moisture mi-gration in fibrous insulation, diffusion of pollutants in saturated soil, and flow in the wick of a heat pipe. Although numerous investigations have studied the problem of double diffusive natural convection in a porous medium numerically and experimentally, due to the complexity of temperature and flow fields in the porous medium, the subject has continued to be a focus of research in the last decade.

Trevisan and Bejan (1985) investigated the ef-fects of heat and mass transfer on natural convection in a porous medium by numerical simulations and scale analysis. The results of the scale analysis were in agreement with those produced by the discrete

numerical experiments, and sorted out many effects which influence overall heat and mass transfer results of numerical experiments. Lai and Kulacki (1991) studied a vertical plate embedded in a saturated po-rous medium and utilized a similar method to solve governing equations derived from Darcy's law and Boussinesq approximation. The results showed that the effect of the Lewis number on the concentration convection field was more pronounced than that of the temperature and flow fields. Hsiao et al. (1992) conducted a numerical investigation of natural con-vection of a heated horizontal cylinder in an enclo-sure filled with a porous medium. The results pointed out that the effect of thermal dispersion on the natu-ral convection was small from ranging from low to moderate Rayleigh numbers, and the numerical solu-tions were in better agreement with the experimental data. Alavyoon (1993) also used a numerical method

*Correspondence addressee

•5/3

to study unsteady and steady convection in a fluid-saturated vertical and homogenous porous medium. The results indicated that as the Lewis number was larger than 1, there existed a minimum aspect ratio below which the concentration field in the core re-gion was rather uniform and above which it was lin-early stratified in the vertical direction. Alavyoon et

al. (1994) subsequently studied the above subject with

opposite and horizontal gradients of heat and solute conditions. The results revealed that under a certain domain the convection oscillated and outside this domain the convection approached a steady state. Nithiarasu et al. (1997) studied a generalized non-Darian porous medium model with constant and vari-able porosities for natural convective flow. The re-sults indicated the wall Nusselt number was signifi-cantly affected by the combination of Rayleigh number, Darcy number and porosity in the non-Darcy flow regime, and the model was able to predict the channeling effect. Murray and Chen (1989) carried out an experimental study to examine double-diffu-sive convection in a porous medium, and the results showed that as the temperature difference was reduced from supercritical to subcritical values, the heat flux curve established a hysteresis loop. Lauriat and Prasad (1989) investigated non-Darcian effects on natural convection in a vertical porous enclosure, and the results showed that the effect of Prandtl number on Nussult number was not straight forward and depended on the flow regime and other parameters.

Because of the difficulties associated with the theoretical determination of effective thermal conductivity for the corresponding porous medium situation, a number of experimental studies investi-gating the effective thermal conductivity were conducted. Singh et al. (1973) conducted experimen-tal studies of the effective thermal conductivity of liq-uid saturated sintered fiber metal wicks, and a new correlation for predicting the effective thermal con-ductivity was proposed. Koh and Fortini (1973) performed experimental studies for prediction of thermal conductivity and electrical resistivity of po-rous materials including 304L stainless steel powders and OFHC sintered spherical powders. The results showed that the thermal conductivity and electrical resistivity could be related to the solid material properties and porosity of the porous matrix, re-gardless of the matrix structure. Hadley (1986) presented both experimental measurements and a theoretical model for the thermal conductivity of a consolidated mixture of a two-metal powder. The predictions showed good agreement with published two-phase data from a wide variety of sources. Shonnard and Whitaker (1989) conducted an experi-mental study to determine the effective thermal

conductivity for a point-contact porous medium, and the results verified the functional dependence of

(kjkf) predicted by Batchelor and O'Brien. Besides,

the experimental data and the theory of Batchelor and O'Brien were in good agreement with the experimen-tal results of Swift. Prasad et al. (1989) conducted an experimental study to evaluate a correlation for stag-nant thermal conductivity of liquid-saturated porous beds of spheres. The results showed that a mixing rule based on the volume fraction could not be used to predict stagnant thermal conductivity unless the thermal conductivity ratio was almost unity.

Differing with the above literature, Renken and Aboye (1993) analyzed film conductivity condensa-tion within inclined thin porous-layer coated surfaces. The dependence of the average heat transfer coeffi-cient on the surface subcooling, the gravity field and the thin porous-layer coating characteristics were documented.

Based on the above research, the temperature and concentration boundary conditions on the surfaces are almost always designated as respective constants. However, for some situations, such as the enhance-ment of a heat surface wetted with liquid, and evapo-ration of sweat on skin, etc, the temperature and concentration boundary conditions induced by evapo-ration of liquid on the heat surface can no longer be regarded as constants in advance, and mutual conju-gation often results. The heat transfer mechanism of the above situations becomes complicated and is hard to investigate.

The purpose of this paper is to numerically in-vestigate double diffusive natural convection phe-nomena of an enclosure filled with a porous medium. The channeling effect, constant porosity and Darcy-Brinkman-Forchheimer model of the porous medium are taken into consideration. To reduce the tempera-ture on the heat wall, the heat wall is wetted with a thin water film. Due to the occurrence of latent and sensible heat transfer on the left wall, the boundary conditions of temperature and concentration of the heat wall are no longer designated as the known val-ues in advance, and the above boundary conditions are then conjugated. The SIMPLEC numerical method is adopted to solve the governing equations and iterative computing processes are indispensable in obtaining temperatures, concentrations and veloci-ties on the heat surface and in the enclosure. The results indicate that the effect of the evaporation on the reduction of temperature of the heat wall is re-markable and the latent heat transfer plays an impor-tant role in the heat transfer mechanism under high Darcy number situations. The relationship of aver-aged Nusselt number with Darcy-Rayleigh numbers is almost linear in logarithmic scale for high Darcy-Rayleigh numbers and the averaged Nusselt number

W.S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 327

is approximately 2.5 for low Darcy-Rayleigh numbers.

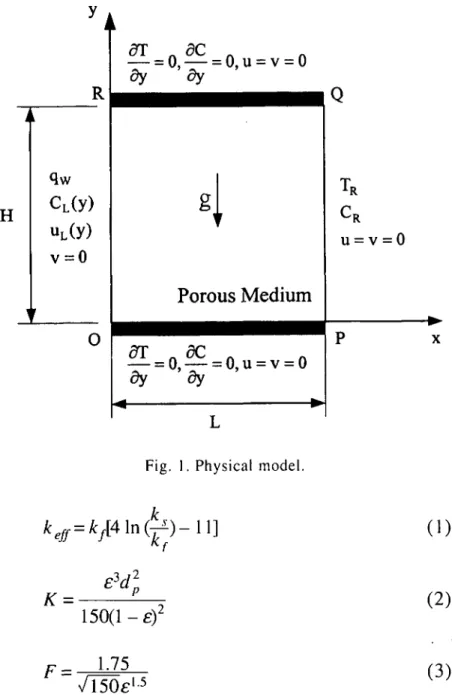

II. PHYSICAL MODEL

A physical model of a two-dimensional rectengular enclosure filled with a porous medium is shown in Fig. 1. The width and length of the enclo-sure are labeled H and L, respectively. The gravity is downward and two horizontal walls of the enclo-sure are adiabatic. The left wall is subject to a uni-form heat flux qw and the relatively low temperature,

concentration, and relative humidity conditions of the right wall are designated as TR, CR and <pR,

respectively, and are constant. In order to enhance the heat transfer rate of the left wall, the left wall surface is wetted with a water film. The thickness of the a water film is assumed to be extremely thin and stationary such that water does not penetrate into the region of the porous medium. The water film is evaporated by the heat flux imposed on the left wall and the condition of relative humidity of the left wall surface is saturated. Consequently, the sensible and latent heat transfers of natural convection occur in the enclosure simultaneously, and the temperature,

TL(y) and concentration, CL(y) on the left wall are no

longer regarded as constant in advance and conjugate mutually. The working fluid in the enclosure becomes an air-moist fluid.

To facilitate the analysis, the following assump-tions are made .

(i) The porous medium is made of non-deformable pure copper spherical beads (&s=386 Wm~loC~')

which are not chemically reactive with the fluid, (ii) The flow in the enclosure is laminar, steady and two-dimensional. Corresponding to the thermal and concentration boundary conditions selected, condensation phenomenon does not occur in the enclosure.

(iii)The effects of Soret and Dufour induced by mass transfer are neglected, and Boussinesq approxi-mation is held.

(iv)Except for the left wall region, the properties of the porous medium are constant and based on the temperature of the right wall. The properties on the left wall are based on the temperature of the left wall under a saturated condition (Kato and Mihara, 1977).

(v) The form of the effective thermal conductivity keff

defined in Eq. (1) has been proposed in (Shonnand and Whitaker, 1989). The calculations of the air-moist fluid properties are shown in the the Ap-pendix (Kato and Mihara, 1977). The porosity e is constant and the permeability K and inertia fac-tor F (Uafai, 1984) are defined in Eqs. (2) and (3), respectively.

Fig. 1. Physical model.

keff=kf[4\n(-^)-[\) K = 150(1 -ef _ 1.75 (1) (2) (3) Based on the above assumptions and with the following characteristic scales of H, TR, qw, vR, and keff, the governing equations adopted in (Hsiao et cd.,

1992), geometry dimensions and boundary conditions are normalized as follows. The Darcy-Brinkman-Forchheimer model is used in the momentum equations. Continuity equation (4) X-momentum equation l

a F aF

JDa

Y-momentum equation U 'Da eU (5) F U 'Da Gr t0e+GrcW£ (6)Energy equation / ]v±L 4. I / — UdX + VdY~Pi Concentration equation , ydW _ 1 (d2W (7) (8) where y y — x v — u — —vn P — q H ' gf3c{C-CR)Hl (9) aR DP pCp U = Boundary conditions On OP (top wall)

U=0, V=0, i j | = 0 ,

(10) On PQ (right wall) UR=0, VR=0, 6R=0, WR=0 On QR (bottom wall) (11) M), V=0, | | = 0, = 0 (12) On RO ( left wall )v

L=o, e

L=e

L(Y), w

L=w

L(Y)

The other important values of evaporation mass flow rate mL(y), evaporation velocity uL(y), sensible

heat flux qs(y) and latent heat flux g^(jjare calculated

by the following equations, respectively

PLDL dC x=0 (14) —Ar 2 ' PL (\-CL(y))dx ,= 0 DL (CE(Xl,y)-CL(y)) (l-CL(y)) K ,

= -kejf(TE(Xl,y)-TL(y))

(15) (16) (17) .x = 0 (CE(xvy)-CL(y)) d-CL(y)) —AY 2 ' (18)

III. NUMERICAL METHOD

The SIMPLEC algorithm (Van Doormaal and Raithby, 1984) with TDMA solver (Patankas, 1980). is used to solve the governing Eqs. (3)-(8) of the flow, temperature and concentration fields. Eqs. (3)-(8) are first discretized into algebraic equations by using the control volume method (Patankar, 1980) with the power-law scheme. The under-relaxation factors for the velocity, temperature, and concentration fields range from 0.1-0.5 for all the fields. The conserva-tion residues (Van Doormaal and Raithby, 1984) of the equations of momentum, energy, concentration and continuity and the relative errors of all variables are used to examine the convergence criteria which are defined as follows:

n Re sidue of O equation c.v.

\

o=u, v, e, w

max max < 1 0 , <3>=U, V, P, d, W (19) (20)To reduce computation time, staggered mesh is used, and the finer meshes are set near the solid wall regions. The meshes are then expanded outward from the boundary wall with a scale of 1.03. The accuracy of a similar numerical method is validated in Fu et

al. (1996, 1997). A comparison of the results, which

indicate double diffusive natural convection in a po-rous cavity with aspect ratio A=l and Darcy number D«=10"7 using the Darcy-Brinkman formulation of

Goyeau et al. (1996), with the present method in shown in Table 1. The deviations between these two

1/1/. S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 329

Table 1. A comparison of the results of Goyeau et al. [21] with the present study.

Ra 50 100 200 Le 1 10 100 1 10 20 50 100 1 10 20 50 100 Nu (Goyeau et al.) 1.98 1.98 1.98 3.11 3.11 3.11 3.11 3.11 4.96 4.96 4.96 4.96 4.96 Nu (present study) 1.9984 1.9984 1.9984 3.1558 3.1558 3.1558 3.1558 3.1558 5.0911 5.0911 5.0911 5.0911 5.0911 Error (%) 0.92 0.92 0.92 1.45 1.45 1.45 1.45 1.45 2.58 2.58 2.58 2.58 2.58 Sh (Goyeau et al.) 1.98 8.79 27.97 3.11 13.25 18.89 29.72 41.53 4.96 19.86 28.17 44.00 61.09 Sh (present study) 1.9984 8.9514 28.754 3.1558 13.660 19.558 30.619 42.358 5.0911 20.615 29.083 44.658 60.327 Error (%) 0.92 1.8 2.73 1.45 3.00 3.42 2.94 1.95 2.58 3.66 3.12 1.47 1.26

methods are less than 4%.

The following steps provide a brief outline of the computing processes and numerical results based on the given data of TR=293K, PR=\.0\3 bar and

Wl + 1 111 + I

(i) Under given heat flux qw and boundary

condi-tions on the right wall, the pseudo values of T", C", u" and v" in the enclosure, including the left wall, are initially selected (n=0). Subsequently, calculate the corresponding properties of the air-moist fluid on the left wall including v'[,

PlCplDlandh^.

(ii) Based on the above conditions, utilize the SIMPLEC method to solve Eqs. (5) and (6) and obtain the values of u"E+l(x,y) and v"E+l(x,y) in

the enclosure, without including the values on the left wall.

(iii) Based on the values of u"E+{(x,y) and v£+l (x,y), the SIMPLEC method is successively

uti-lized to solve Eqs. (7) and (8) to gain the new values of T"E+](xhy) and C"E+\x\,y) in the

en-closure except the values on the left wall.

(iv) Substitute C'[(y) and C"E+\xhy) into Eq. (14)

to calculate the evaporation mass flow rate

m'[(y) on the left wall, and use Eq. (18) to

ob-tain q'\ sequentially. If q"f is smaller than qw,

continue the computing procedures, otherwise try a new value of TL(y)and return to Step (ii).

(v) Subtract q'\ from qw in Eq.(16) to obtain q".

Use qns in Eq. (17) to calculate T"L+](y) on the

left wall.

(vi) Using the saturated condition on the left wall and the calculated value of T"L+\y), the new

values of C"L+\y), v'[+\y), p'l + ](y), Cnp+](y), \, s ...., >» + \,y) a r e c aic uia te d . Th Dn + \L

n + I

fi

"L (y) and hnf*x{y) are calculated. Then

(vii)

C"L+l(y) and C£+l(x,,)0 in Eq. (14), and the

evaporation velocity u'[+[(y), induced by the

evaporation mass flow rate mnL+i(y), is

calcu-lated from Eq. (15).

Calculate the values oiqn( + [{y) from Eq. (18),

then subtract q"( + \y) from qw in Eq. (16) and

obtain q" + l(y).

(viii) Compare the values of qn + x(y) and q"{y)

ob-tained from Steps (7) and (5), respectively. If the difference between q" + l(y) and q"(y) and

the convergence criteria of TE(x,y), CE(x,y), uE(x,y) and vE(x,y) do not satisfy the criteria of

Eqs. (21) and (19)~(20), respectively, then use the corrected values of T"L+ ' (y), C"L+i (y), u'[ + (y) and the corresponding properties T"E+i

C n +

£ W of air-moist fluid to iterate the computing procedure from Step (2), until the above conditions are satisfied.

•\-3

(21)

IV. RESULTS AND DISCUSSIONS

m'[+ (y) can be calculated by the utilization of

The dimensionless parameters of four Rayleigh numbers, three porosities and three diameters of spherical beads tabulated in Table 2 are adopted in this paper. H, L, T/?=293K, fo=30%, Pr=0.02583

and 5c=0.5425 are fixed in the following situations. The ranges of Ra' and Da are from 0.02725 to 4469.041 and from 2.963xlO"8 to 1.215xlO"3,

respectively.

The grid test for computation is based on the situation of #a=9.197xlO5, D/?=5xl0"3 and £=0.4.

The results of the test are listed in Table 3, and

Table 2. Values of Ra, e and Dp adopted in the study. Ra Dp 9.197xlO5 1.839X106 2.758xlO6 3.678X106 0.4 0.7 0.9 0.005 0.025 0.05

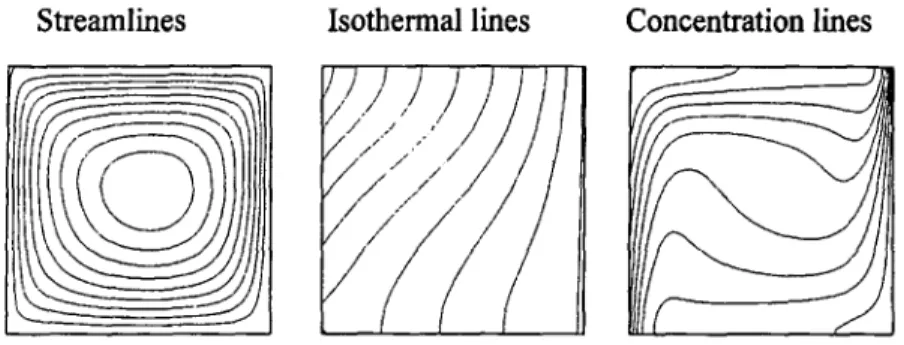

Streamlines Isothermal lines Concentration lines

( a ) Ra = 9.197 x 105, e = 0.7, Dp = 0.025 and Da = 1.588 x 10"5

Table 3. Grid tests for 7?a=9.197xlO5, £=0.4, and

Dp=0.005 A.vi,A.Vl'Ayl Xi -1) Grids (NxxNv) Nu 0.025 0.025 0.015 0.015 0.015 0.01 0.01 0.0075 0.0075 0.0075 0.0075 0.005 0.0025 0.0025 1.03 1.01 1.005 1.03 1.01 1.03 1.001 1.05 1.03 1.01 1.005 1.03 1.05 1.03 32x32 36x36 38x38 46x46 58x58 62x62 98x98 60x60 74x74 102x102 116x116 94x94 98x98 132x132 0.99562 0.99578 0.99570 0.99650 0.9951 0.9959 0.9955 0.9956 0.9967 0.9955 0.9955 0.9961 0.9961 0.9969

the grids of 74x74 are selected for the following calculation processes with Ax^A)^ =0.0075 and the ratio of AJC,-+I/AX/=1.03, which are symmetric to

cen-tral lines of the computing domain.

The distributions of streamlines, isothermal lines and constant concentration lines are illustrated in Fig. 2. In Figs. 2(a) and (b), as Ra becomes larger, the convection is more dominant, the isothermal lines be-come more skewed and the distributions of concen-tration lines are dense near the two vertical walls of Fig. 2(b).

In Figs. 2(c) and (d), the larger the porosity is, the stronger the convection becomes, therefore, the isothermal and concentration lines of Fig. 2(d) are more curved than these shown in Fig. 2(c). For the same reason, the larger the diameter of the spherical bead, the more dominant the convection, and the distributions of the isothermal and concentration lines of Fig. 2(f) are more skewed than these of Fig. 2(e).

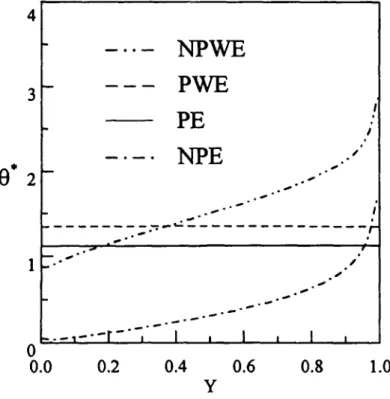

The distributions of modified dimension tem-perature 0* on the left wall under different physical situations are illustrated in Fig. 3. The situations shown in Figs. 3(a) and 3(b) are the two limiting cases

l 6 o -( b) Ra = 3.678 x 106, e = 0.7, Dp = 0.025 and Da = 1.588 x 10-5 ( c ) Ra = 1.839 x 106, e = 0.4, Dp = 0.05 and Da = 2.963 x 10' ( d ) Ra = 1.839 X 1 06, E = 0.9, Dp = 0.05 and Da = 1.215x10-3 ( e ) Ra = 1.839 x 106, e = 0.7, Dp = 0.005and Da = 6.353 x 10- 7 ( f ) Ra = 1.839xl06,e = 0.7,]

Fig. 2. The distributions of streamlines, isothermal lines and con-stant concentration lines under different Rayleigh num-bers Ra, porosities £ and diameters of beads Dp.

IV. S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 331

0 2

0.0 0.2 0.4 0.6 0.8 1.0

conductivity ratio (~) in upper region of the left

kf

wall, is more remarkable than that of the NPE situation. The highest temperature of the PE situa-tion in upper region of the left wall is lower than that of the NPE case, and the distribution of temperature is more even than that of the NPE case.

The effects of Rayleigh number Ra, porosity e and diameter of bead Dp on the local Nusselt Nu(Y) and Sherwood numbers Sh(Y) on the left wall are il-lustrated in Figs. 4(a), 4(b) and 4(c), respectively. The definitions of Nu(Y) and Sh(Y) are expressed in the following equations.

Nu(Y) = ^ ^ = Nu S(Y) + Nu e(Y)

keff

(a) Ra=9.197xlO-\ e=0A Dp=0.005 and Da=2.963xl(H (22)

0 0.0 1 1 1 1 ' 1

NPWE

PWE

PE

NPE

1 i 1 1 / y m * m ^m ^ ^ • * ™ .*• ^ * ^ ^ i 0.2 0.4 0.6 Y 0.8 1.0(b) Ra=3.678xlO6. e=0.9, Dp=0.05 and Da= 1.215x10-'

Fig. 3. The distributions of modified dimensional temperature 6° on the left wall under four different physical situations.

where ht(y) = (TL(y)-TR)

dx

(23) x=o where hc(y) = m L(\-CL(y)) pL(CL(y)-CR)In general, as Ra, e and Dp become larger, evaporation, mainly induced by convection, becomes more dominant. Therefore, the local Nusselt and Sherwood numbers on the left wall are larger under the larger Ra, £ and Dp situations.

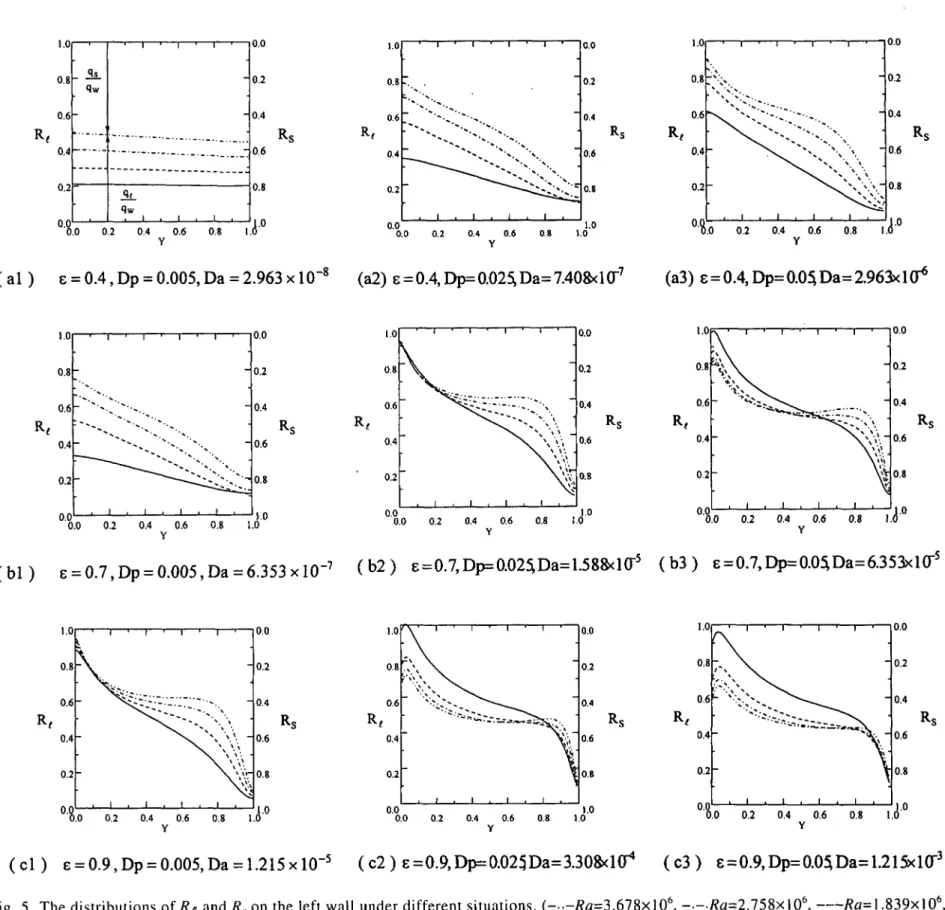

In Fig. 5, the values of Re and qs indicate the

ratios of latent heat flux qp and sensible heat flux qs

to the total heat flux qw, respectively, and these

val-ues are defined in the following equations.

(24)

of convection capability under the lowest and high-est Ra", respectively. Generally, the effect of the evaporation on heat transfer is remarkable, and then the temperatures distributed on the left wall de-scend efficiently. The flow resistance in the porous medium situation (PE) is greater than that in the non-porous medium situation (NPE), therefore convection in the NPE situation is more active than that in the PE situation. As a result, for most regions of the left wall, the temperatures of the NPE situation are lower than those of the PE situation. However, the convec-tion effect is weak in the upper region of the left wall (the upper left corner). The occurrence of conduc-tion in the PE situaconduc-tion, with a larger thermal

The value of the ratio R means the contribution of above individual heat flux to the total heat flux. As the values of Ra, e and Dp become smaller, the resistance to fluid flow becomes serious, which si-multaneously results in weak convection and little evaporation. The value of Re is thus smaller under

the smaller Ra, e and Dp cases as shown in Figs. 5 (al), 5(a2) and 5(a3). Oppositely, as the values of

Ra, e and Dp become larger, based on the reason

men-tioned above, evaporation becomes dominant and the values of R? are larger as shown in Figs. 5(b2), 5(c2) and 5(c3). In Fig. 5(c2), the value of Re is

even larger than 1 at F=0.03 which means the evaporation of film absorbs heat not only from the total heat flux qw on the left wall but also from the

Nu(Y)

5.0 4.0 3.0 2.0 1.0 \ ' I ' I I , I 0.0 I • I Sh(Y) 10.0 8.0 6.0 4.0 2.0 1 \ V \ \ " \ \ _ * — -, 1 1 Ra Ra Ra 1 1 • I * = 3.678xlO6 -= 2.758xlO6" = 1.839xlO6_ = 9.197xlO5 • _ X " . 0.0 0.2 0.4 0.6 0.8 1.0 Y 0.0 0.0 0.2 0.4 0.6 0.8 1.0 Y ( a ) E = 0 . 4 , D p = 0.05and Da = 2.963x10' Nu(Y) 10.0 8.0 6.0 4.0 2.0 1 ' 1 \ ~* \ \ *\ " s, * N -' • I . I 1 " in. ^ * %. _ i 1 • 1 — _ -1 Sh(Y) 25.0 20.0 15.0 10.0 5.0 i ' I • i T \ — • — • — 8; \ s

- \ 8 \ \ ^. •— N >» N N» V " ^ 1 • 1 , 1 i 1 r I= 0.9 '

= 0.7 "

= 0.4

-* x N 0.0 0.0 0.2 0.4 Y 0.6 0.8 1.0 0.0 0.0 0.2 0.4 Y 0.6 0.8 1.0 ( b ) Ra = 1.839 xlO6 and Dp = 0.025 10.0Nu(Y)

0.0 0.2 0.4 0.6 0.8 1.0 30.0 20.0 Sh(Y) 10.0 i • r Dp = 0.05 Dp = 0.025 Dp = 0.005 -0.0 0.2 0.4 0.6 0.8 1.0 ( c ) Ra = 3.678xl06ande = 0.7Fig. 4. The distributions of local Nusselt and Sherwood numbers on the left wall.

fluid in the enclosure. As Dp or e increases, Da also increases, which leads to greater permeability of the porous medium and an increase in latent heat transfer. Based on the above results, the latent heat flux plays an important role in the heat transfer mechanism under a high Darcy number. Besides, the

distribution of the ratio Rf in the low Rayleigh

num-ber region is larger than that in the high Rayleigh number region under Da>10~5.

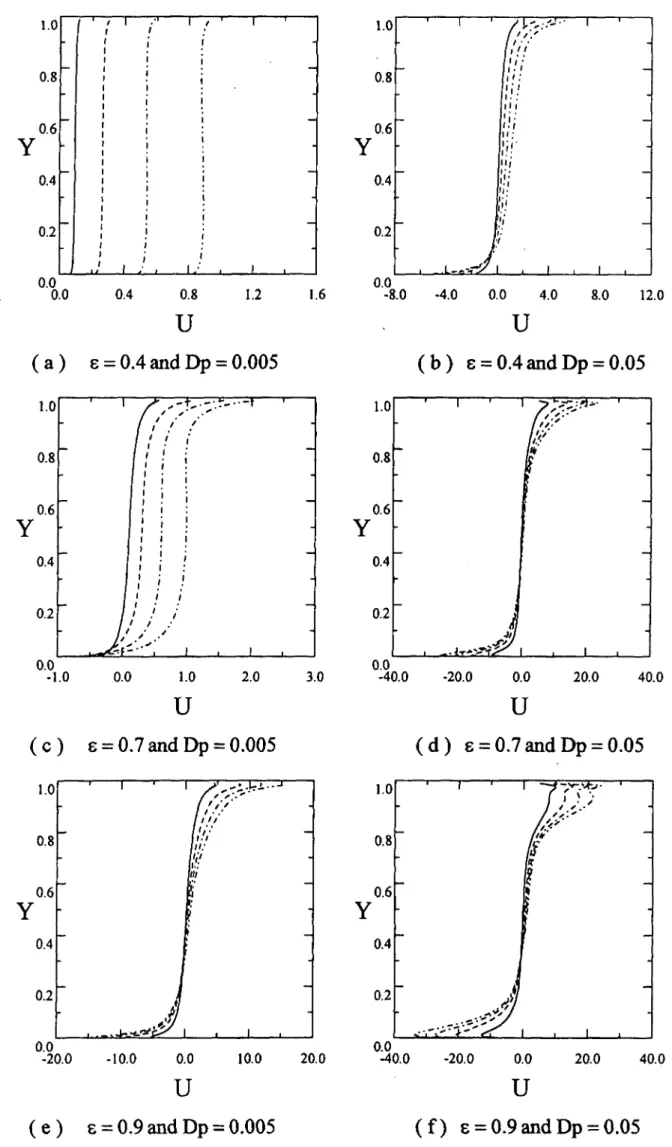

The distributions of velocity V along the y-axis at X=0.0075 are very close to the left wall are shown in Fig. 6. The evaporation of the water film on

W.S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 333 1.0 0.8 0.6 0.4 0.2 - Si. I . I . I 0.0 0.2 0.4 0.6 0.8 0.0 0.2 0.4 0.6 0.8 1 Y

<J°

1.0 0.8 0.6 0.4 0.2°%

"*. \

\

-0 1 \ 1 , 0.2

K

i 0.4 ^ \ i 0.6 1 \ \ \ \ i 0.8 -V \ ~ 1 0.0 0.2 - 0.4 0.6 0.8( a l ) e = 0.4,Dp = 0.005,Da = 2.963xl(T8 (a2) e=0.4, Dp= 0.025, Da=7.40&<l(r7 (a3) e = 0.4,Dp= 0.05,Da= 2.963x1(1*

R,

0.0 0.2 0.4 0.6 0.8 1.0

0

0.0 0.2 0.4 0.6 0.8 1.0

( b l ) e = 0.7, Dp = 0.005, Da = 6.353 ( b 2 ) 6=0.7,Dp=0.025,Da=1.58&<l(r5 ( b 3 ) e = 0.7, Dp= 0.05, Da= 6.3 53xlOTs

0.2 0.4 0.6 0.8 1.0

( c l ) e = 0.9,Dp = 0.005,Da = 1.215xlO"5 ( c 2 ) 8=0.9,Dp=0.025,Da=3.30&ia4 ( c 3 ) e=0.9,Dp= 0.05,Da= 1.215xl(T3

Fig. 5. The distributions of R( and /?, on the left wall under different situations. (—-Ra=3.678x106, — -fla=2.758x106, fla=1.839xlO6,

—Ra=9.197x10s)

the left wall is taken into consideration, and the direction of the evaporation velocity uL(y) is to the

right. Under the strong convection cases shown in Figs. 6(d), 6(e) and 6(f) mentioned earlier, the main velocity of the fluid flow in the enclosure is clock-wise and overcomes the evaporation velocity, and the direction of the resultant velocity is to the left in the lower region of the Y axis. Oppositely, when £=0.4 and Dp=5xl0~\ the convection effect is minute, and the evaporation velocity is relatively more re-markable than that of the fluid flow in the enclosure. Consequently, in this situation, the direction of the velocity U is to the right in the lower region of the K-axis. In the upper region of the K-axis, the direction of the main velocity of the fluid flow and the evaporation velocity are the same and to

the right. Naturally, the direction of the velocity

U is to the right in the upper region of the F-axis,

and the channeling effect is observed in some situations.

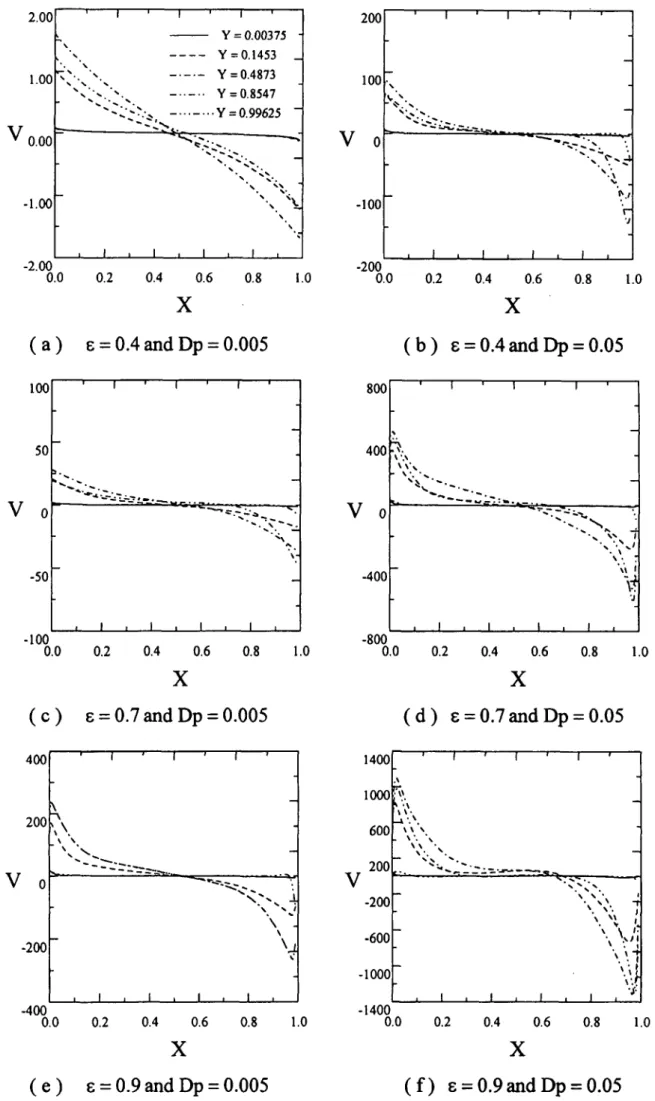

The distributions of velocity V along the X-axis at different positions at both vertical walls are illustrated in Fig. 7. The channeling effect is ob-served in some situations of Figs. 7(b), (d), (e) and (f) where the convection is strong. Due to the occur-rence of evaporation on the left wall, the channeling effect on the right wall is more apparent than that on the left wall. For the same reason, as £=0.4 and 0.7, and D/?=5xl0~3, the convection, and there is little

evi-dence of the channeling effect on the both walls. Figure 8 shows the relationship of Darcy-Rayleigh number Ra* with the averaged Nusselt

1.0 0.8 0.6 0.4 0.2 • • / i ." i i ' i ' i • ! i ; : 0.0 0.0 0.4 0.8 1.2 1.6

U

( a ) e = 0.4 and Dp = 0.005 -1.0 0.0 1.0 2.0 ( c ) e = 0.7 and Dp = 0.005 1.0 0.8 0.6 0.4 0.2-J

/ /. '/• I'-ll.1; / " •r

\

-I . I , 0.0 -20.0 -10.0 0.0

U

10.0 20.0 1.0 0.8 0.6 0.4 0.2 1 • / j . . - , ; / - • • • / ' / / •1

;.'; I!.1/ ' • ' • ' ;; '•i?/

/

, ..L.,«r!/ \ , i i • -— i i i 0.0 8 -8.0 -4.0 0.0 4.0 8.0 12.0u

( b ) e = 0.4 and Dp = 0.05 o.o -40.0 -20.0 0.0 20.0 40.0U

( d ) e = 0.7 and Dp = 0.05 o.o -40.0 -20.0 0.0 20.0 40.0U

( e ) E = 0.9 and Dp = 0.005 ( f ) 6 = 0.9 and Dp = 0.05Fig. 6. The distributions of velocity U along the /-axis at ^=0.0075 under different situations. (-.-/?a=3.678xlO6, — .Ra=2.758x106,

/?a=1.839xl06,—Ra=9.197x105)

number Nu, which is defined in Eq. (25) and expressed in Eqs. (26) and (27). Under the smaller

Ra* regions, the averaged Nusselt number Nu is

al-most independent of the Darcy-Rayleigh number and

its value is approximately 2.5. Beyond the above region, the relationship of Nu with Ra* is almost lin-ear based on the logarithmic coordinates. The equations of these two parts are shown in Eqs. (26)

W.S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 335 2.00 1.00 V 0.00 -1.00 V Y Y Y Y ' = 0.00375 = 0.1453 = 0.4873 = 0.8547 = 0.99625 I I I . I I -2.00 0.0 0.2 0.4 0.6 0.8 X ( a ) E = 0.4 and Dp = 0.005 1.0 -100 0.0 0.2 0.4 0.6 0.8 1.0 X ( c ) e = 0.7 and Dp = 0.005 V 400 200 0 -200 \ ^\

\v

i i i ' i I . I , -• \ . \ V 1 -400 0.0 0.2 0.4 0.6 X 0.8 1.0 200 100 V 0 -100 -200 \ "O • , • ^ ^ -i i 1 I 1 i , -^ - i r j 0.0 0.2 0.4 0.6 0.8 1.0 X ( b ) e = 0.4 and Dp = 0.05 800 400 V 0 -400 -800 • \ -• >\ 1 1 1 1 1 1 1 -\'\ 1 "yj V. J 0.0 0.2 0.4 0.6 0.8 1.0 X ( d ) e = 0.7 and Dp = 0.05 V 1400 1000 600 200 -200 -600 -1000 • I ' % - w \ -• -1 1 • - . ^ - ,w^ 1 , 1 . 1 -\ v • 1 • \ \ ' x. v '\ V'!

\ \ ~*

\ . i I , •<• -1400 0.0 0.2 0.4 0.6 X 0.8 1.0 ( e ) e = 0.9 and Dp = 0.005 ( f ) z = 0.9 and Dp = 0.05Fig. 7. The distributions of velocity V along the X-axis at different heights of K-axis under situation of /?a=3.678x!06 situation.

and (27)

Jo

Nu = Nu(Y)dY

Nu=2.5±0.5 for Ra<4

(25)

(26)

Nu = 1.9463fla*°202 for 4</?a*<4469

V. CONCLUSIONS

(27)

A double diffusive natural convection in an enclosure filled with a porous medium under an

12 10 8 6 4

Nu

i i mill -. -• • M M Nil —i i mini—rTTTirm—i i mmr i >• Present results ~ - Eq.(26) / r?nf97\ /• E,q\ LI ) s i i i n u l l i 1 1 I I I I I I i i i m i l l i IIIIIII 1 1 IIIIII / -i t m -i l -i -i -i -i n n 1 0 0.1 1 10 100 1000 10000 Ra*Fig. 8. The relationship of averaged Nusselt number Nu and Darcy-Rayleigh number Ra°.

evaporation situation was investigated numerically. The effects of Rayleigh number Ra, porosity e and diameter of beads Dp on heat transfer were examined with the D-B-F model. The results are summarized as follows:

(i) The effect of evaporation on the reduction of tem-perature of the heated wall is remarkable, espe-cially in the upper corner.

(ii) The latent heat flux plays an important role in the heat transfer mechanism for high Darcy numbers. The distribution of the ratio R( in the

lower Ra region is larger than that in the high Ra region as £>a>10~5.

(iii) The relationship of averaged Nusselt number Nu with Darcy-Rayleigh number Ra" is almost lin-ear in logarithmic scale when 4<Ra "<4469-, and

Nu is approximately 2.5 when Ra*<4.

NOMENCLATURE

C Mass or concentration fraction Cp Specific heat of fluid (kJkg"1 "C"1)

dp Porous bead diameter (m)

D Binary diffusion coefficient ( m V ) Da Darcy number

Dp Dimensionless porous bead diameter,

(dp/H)

F Inertial factor; Forchheimer factor

g Gravitational acceleration (ms~2)

Grc Grashof number for mass diffusion, [gfic

Gr,

K

hfs ht H Kff K L rh Nu Nu P P Pr Qw Ra Sc Sh T u U v Vw

x,y X, Y PE PWE NPE NPWEGrashof number for thermal diffusion,

[(gprqwH4)/(keffV2R)]

Mass transfer coefficient along vertical wall Vaporization enthalpy (Jkg"1)

Thermal heat transfer coefficient along ver-tical wall (WnT2 °C-')

Dimensional width of porous enclosure (m) Effective thermal conductivity of porous medium (War1 "C"1)

Thermal conductivity of fluid (Wm"1 °C~') Thermal conductivity of solid phase in po-rous medium (Wm"1 °C~')

Permeability (m2)

Dimensional length of porous enclosure (m) Evaporation mass flow rate (Kgm"2s~') Local Nusselt number along vertical wall Mean Nusselt number

Dimensional pressure (Nm~2) Dimensionless pressure Prandtl number

Heat flux (WnT2)

Rayleigh number, [Gr, Pr=(gP,qwH4)/

Darcy-Rayleigh number, [RaDa =

(gPiqwH2K)/(keffvRaR)]

Ratio of latent heat flux in left wall to total heat flux in the left wall

Ratio of sensible heat flux in left wall to total heat flux in the left wall

Schmidt number, (~)

Local Sherwood number along vertical wall Temperature (°C)

Dimensional velocity in x direction (ms"1) Dimensionless velocity in X direction Dimensional velocity in y direction (ms"1) Dimensionless velocity in Y direction Dimensionless concentraction

Dimensional Cartesian coordinate (m) Dimensionless Cartesian coordinate, (=x/H,

=ylH)

Porous medium with evaporation situation in enclosure

Porous medium without evaporation situa-tion in enclosure

Non-porous medium with evaporation situ-ation in enclosure

Non-porous medium without evaporation situation in enclosure

Greek symbols

a

Pc

Thermal diffusivity (m2s ')

Coefficient of volumetric expansion with temperature (°C~')

Coefficient of volumetric expansion with mass fraction

W.S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 337 V 9

e*

Porosity (m3m 3) Viscosity (kgrrr's"1) Kinematic viscosity ( m V ) Dimensionless temperatureModified dimension temperature (6/keff)

Fluid density (kgm 3) Relative humidity 0 ¥ Computation variable Dimensionless stream Superscripts n — —>

The nth iteration index Mean value Velocity vector Subscripts C.V.

eff

Ef

i I L P R s S W Control volume Effective value Enclosure Fluid phase Index Latent heat Left wall Porous medium Right wall Solid phase Sensible heat Solid wall OTHERI I Magnitude of velocity vector

ACKNOWLEDGMENT

The support of this work by the National Sci-ence Council, Taiwan, R.O.C. under contract NSC86-2212-E-009-042 is gratefully acknowledged. The au-thors also appreciate the instructive suggestions from Dr. Huang.

REFERENCES

1. Alavyoon, F., 1993, "On Natural Convection in Vertical Porous Enclosures Due to Prescribed Fluxes of Heat and Mass at the Vertical Boundaries," International Journal of Heat and

Mass Transfer, Vol. 36, pp. 2479-2498.

2. Alavyoon, F., Masuda, Y. and Kimura, S., 1994, "On Natural Convection in Vertical Porous Enclosures Due to Opposing Fluxes of Heat and Mass Prescribed at the Vertical Walls,"

Interna-tional Journal of Heat and Mass Transfer, Vol.

37, pp. 195-206.

3. Fu, W.S., Huang, H.C. and Liou, W.Y., 1996, "Thermal Enhancement in Laminar Channel Flow with a Porous Block," International Journal of

Heat and Mass Transfer, Vol. 39, pp. 2165-2175.

4. Fu, W.S. and Huang, H.C., 1997, "Thermal Per-formances of Different Shapes of Porous Blocks under an Impinging Jet," International Journal

of Heat and Mass Transfer, Vol. 40, pp.

2261-2272.

5. Fujii, T., Kato, Y. and Mihara, K, 1977, "Expres-sion of Transport and Thermodynamic Properties of Air, Steam and Water," Sei San Ka Gaku Kenkyu Jo, Report no. 66, Kyu Shu Dai Gaku, Kyu Shu, Japan.

6. Goyeau, B., Songbe, J.P. and Gobin, D., 1996, "Numerical Study of Double-diffusive Natural Convection in a Porous Cavity Using the Darcy-Brinkman Formulation," International Journal

of Heat and Mass Transfer, Vol. 39, pp.

1363-1378.

7. Hadley, G.R., 1986, "Thermal Conductivity of Packed Metal Powders," International Journal

of Heat and Mass Transfer, Vol. 29, pp.

909-920.

8. Hsiao, S.W., Cheng, P. and Chen, C.K., 1992, "Non-uniform Porosity and Thermal Dispersion Effects on Natural Convection About a Heated Horizontal Cylinder in an Enclosed Porous Medium," International Journal of Heat and

Mass Transfer, Vol. 35, pp. 3407-3418.

9. Kon, J.C.Y. and Fortini, A., 1973, "Prediction of Thermal Conductivity and Electrical Resistivity of Porous Metallic Materials," International

Jour-nal of Heat and Mass Transfer, Vol. 16, pp.

2013-2022.

10. Lai, F.C. and Kulacki, F.A., 1991, "Coupled Heat and Mass Transfer by Natural Convection from Vertical Surfaces in Porous Media," International

Journal of Heat and Mass Transfer, Vol. 34, pp.

1189-1194.

11. Lauriat, G. and Prasad, V., 1989, "Non-Darcian Effects on Natural Convection in a Vertical Porous Enclosure," International Journal of

Heat and Mass Transfer, Vol. 32, pp.

2135-2148.

12. Murray, B.T. and Chen, C.F., 1989, "Double-dif-fusive Convection in a Porous Medium," Journal

of Fluid Mechanics, Vol. 201, pp. 147-166.

13. N i t h i a r a s u , P., S e e t h a r a m u , K.N. and Sundararajan, T., 1997, "Natural Convective Heat Transfer in a Fluid Saturated Variable Porosity Medium," International Journal of Heat and

Mass Transfer, Vol. 40, pp. 3955-3967.

14. Patankar, S.V., 1980, "Numerical Heat Transfer and Fluid Flows," Hemisphere, Washington

D.C.

15. Prasad, V., Kladias, N., Bandyopadhaya, A. and Tian, Q., 1989, "Evaluation of Correlations for Stagnant Thermal Conductivity of Liquid-satu-rated Porous Beds of Spheres," International

Journal of Heat and Mass Transfer, Vol. 32, pp.

1793-1789.

16. Renken, K.J. and Aboye, M., 1993, "Analysis of Film Condensation Within Inclined Thin Porous-layer Coated Surfaces," International Journal of

Heat and Fluid Flow, Vol. 14, pp. 48-53.

17. Shonnard, D.R. and Whitaker, S., 1989, "The Effective Thermal Conductivity for Point Con-tact Porous Medium: an Experimental Study,"

In-ternational Journal of Heat and Mass Transfer,

Vol. 23, pp. 503-512.

18. Singh, B.S., Dybbs, A. and Lyman, F.A., 1973, "Experimental Study of the Effective Thermal Conductivity of Liquid Saturated Sintered Fiber Metal Wicks," International Journal of Heat and

Mass Transfer, Vol. 16, pp. 145-155.

19. Trevisan, O.V. and Bejan, A., 1985, "Natural Convection with Combined Heat and Mass Trans-fer Buoyancy Effects in a Porous Medium,"

In-ternational Journal of Heat and Mass Transfer,

Vol. 28, pp. 1597-1611.

20. Vafai, K., 1984, "Convection Flow and Heat Transfer in Variable Porosity Media," Journal of

Fluid Mechanics, Vol. 147, pp. 233-259.

21. Van Doormaal, J.P. and Raithby, G.D., 1984, "Enhancements of the SIMPLE Method for Pre-dicting Incompressible Fluid Flow," Numerical

Heat Transfer, Vol. 7, pp. 147-163.

APPENDIX

Thermophysical properties of air, steam and

air-moist mixture, in T[K], T[°C] and P[bar]. (i) Air ,1.5 .1.6 (kgm-3) (kgm-'s"1) (kgnr'K-1) - i or3) x ] O3 CPfl=(l+2.5xl0-10r)xl0 (ii) Steam

f)

0 8](f) (kgm-

3)

- 6 AW=(8.02+0.04/)xl0 ^,m=(1.87+1.65xl0-¥/7+5.7xl0-'¥')xl0-2 (kgm-'K-1) CPt,m=1.863xl03+1.65xl0-V5+1.2xl0-'¥5 (Jkg-'K"1) stm'(iii) Air-moist mixture 1 + co Pm = [0.455(<w + 0.622)1] x 10- 2 1+0.352(1+0.888 stm Vstm 1+0.1727(1 + 1.1259 (kgm-J) (kgm-'s-1) 1 +0.4018\ 1+0.837

ft

(1 Vstm (1 . 115.: 1 T . 559.' ' T " stm l+0.15556\ 1 + 1.195 r^stm ( H(n

559.7 x T } 115.5x T } (kgm-'K-1)W.S. Fu and W.W. Ke: Evaporation of Water Film in An Enclosure Filled with A Porous Medium 339 stm A,,=8.O7xlO-6r1833 (iv) Others (Jkg-'K"1) (mV)

The evaporation latent heat from the liquid phase to vapor phase for water saturation

hfg=A\ 86.8x(597.3-0.5590

The saturation pressure of the vapor phase for water

L o gi n( ^ ) = -[3.1323 + 3.116xl(T6

Humidity ratio

co = P -P

tot sat

Mass fraction of air-moist mixture

C = 0)

1 + CO

Discussions of this paper may appear in the discus-sion section of a future issue. All discusdiscus-sions should be submitted to the Editor-in-Chief.

Manuscript Received: Oct. 17, 1998 Revision Received: Jan. 29, 1999 and Accepted: Feb. 04, 1999

71=1 zlc

\$.1iii.BM SIMPLEC S5|5^Darcy-Brinkman-Forchheimer model #)W$1?

B*MM ' &M Darcy-Rayleigh W ' WWkW&®&WI§L#}W&fa& °

^Darcy-Rayleigh tfc/K5£ 4 ' ^i^Nusselt WLffiU 2.5 ; ^E Darcy-^Darcy-Rayleigh WJYifc 4 %} 4469 ZF$ ' ¥ ^ Nusselt iffn Darcy-Rayleigh %L&MWL£M}#MM&Mtifr °

![Table 1. A comparison of the results of Goyeau et al. [21] with the present study.](https://thumb-ap.123doks.com/thumbv2/9libinfo/7618074.131164/6.1128.79.1032.180.570/table-comparison-results-goyeau-et-al-present-study.webp)