行政院國家科學委員會專題研究計畫成果報告

糯性米穀粉擠出物之黏彈性質

The viscoelastic pr oper ties of extr udates made fr om waxy r ice flour

計畫編號:NSC 88-2214-E-002-004

執行期限:87 年 8 月 1 日至 88 年 7 月 31 日

主持人:葉安義 教授 國立台灣大學 食品科技研究所

一、中文摘要 本研究探討擠壓溫度與進料水分對糯 米穀粉擠出物黏彈性質的影響,低進料水 分(45%)使擠出物具較高的 G’,於 80oC 之擠壓溫度時呈現最高值,於實驗條件 下,提高比機械能(SME)則,G’隨著增加, 但 tanδ則減少。於高進料水分(50、55%) 下,提高擠壓溫度可增加糊化度,但擠出 物的 G’值變化不大。水溶性指數隨 tanδ之 提高而增加,本報告也討論擠出物黏彈性 質與其物性的相關性。 關鍵詞:黏彈性質、動態測試、比機械能 Abstr actThe effects of extrusion temperature and water content on viscoelastic properties of waxy rice extrudates have been studied. Low water content resulted in highest G’ among three water contents (45, 50, 55%). There existed a maximum G’ at the extrusion

temperature of 80oC. The increase in specific

mechanical energy (SME) resulted in the

increase in G’ and G’’, but decrease in tanδ.

At high water content (50, 55%), raising extrusion temperature increased the degree of starch gelatinization, but did not affect

significantly G’. High tanδ was associated

with high water solubility index. The relationships between viscoelastic properties and texture analysis were also discussed. Keywor ds: Viscoelastic Properties, Dynamic

Test, Specific Mechanical Energy 二、緣由與目的 米食製品為東方人主食之一,為因應 市場之變化與需求,開發多樣化的米食產 品、改善其加工製程實為推廣米食並使之 邁向全球市場的有效途徑。米麻糬為中國傳 統米製甜點,其香 Q 可口馳名中外,然傳 統製程費時且耗工,成本較高,故市場競 爭力薄弱。 食品擠壓技術乃是利用熱、剪力及壓 力等作用,達到蒸煮、塑化及成型之現代 食品科技,具有產能高、多樣化、省時省 力之優點,如運用於米麻糬之生產,將有助 於製程之連續化與自動化,並提升該產業 之技術。 擠壓機之操作條件如溫度、水分、螺 軸轉速等與澱粉糊化、熔融及裂解有關, 也是影響擠出物流變性質的重要因素[1] ; Mackey 與 Ofoli 則認為玉米澱粉經雙軸擠 壓機處理後之黏度,主要受溫度與水分之 影響,與蒸煮時間無關,但其使用溫度大 於 75℃,水分為 0.476g/gdb[2] 。另外擠壓 操作輸入能量與物料之變化關連極大,比 機械能增加所導致之澱粉分子裂解較為嚴 重,造成水溶性增加、酵素敏感性上昇[3] 、 內生性黏度下降[4] 。 糯米穀粉中的枝鏈澱粉是其澱粉之主 要成份,經蒸煮、揉捻產生特定之黏彈性, 具良好口感,為米麻糬 Q 度來源,但 Q 度量 化分析困難,故多仍以黏彈性為指標。本 研究之目的即在利用食品流變學的方法, 探討擠壓溫度與進料水分對擠出物黏彈性 與質地分析之影響,以確認單軸擠壓機生 產米麻糬之適用性,並建立產品分析模式。 三、材料與方法 本研究之原料為台中糯 70 號米(彰化 溪州 87 年第 I 期稻作)經磨粉過篩(100 mesh)之糯米穀粉。使用國產單軸擠壓機進 行實驗,穀粉預調濕至水分為 40%,進料

時再以泵送水調整至 45、50、55%, 進料 速率(包括水分)8 kg/hr,螺軸轉速 80 rpm,擠壓溫度為 75、80、85、90、95 ℃, 圓形模口之直徑為 10 mm,線上以扭力計 測定扭力後換算比機械能。產品擠出後立 刻以真空包裝袋承裝密封以防水分散失, 於室溫下放置 12 小時平衡後,進行動態測 試 (dynamic test), 並 進 行 質 地 剖 面 分 析 (Texture Profile Analysis,TPA)、糊化度、 容積密度、水溶性指數、色澤(L、a、b)等 測試。 四、結果與討論 1. 擠出物之黏彈性質 動態測試可以測得擠出物之貯存模數 (Storage modulus,G’)、耗損模數(loss modulus,G”)、複數黏度(complex,η*) 及損耗正切(tanδ)等。結果顯示,增加水 分使 G’值降低,當水分為 45%時,於 80 ℃ 有一最高 G’值。但水分增為 55%時,於 80 ℃時,G’值反為最低 (圖一)。G”及η*隨溫 度、水分變化趨勢與 G’相似。當 G’值最高 時,tanδ為最低值(圖二),顯示進料水 分為 45%、擠壓溫度為 80 ℃時,擠出物 中固相比例最高。於相同溫度下,55%的 水分使擠出物的 tanδ最高,亦即固相比例 最低。將原料粉調整水分含量後直接進行 溫度掃瞄(圖三),加熱前,水分為 45%者 即具最高的 G’值,為水分 50、55%者之 10 倍以上,顯示濃度的重要性;加熱後,水 分為 45%者之 G’值隨溫度上昇而下降,與 高水分者之 G’值的差異性減少。澱粉凝膠 之貯存模數與濃度成指數關係[6],濃度高 時,膨潤顆粒的體積分率及固有的形變力 可能是影響流變性質之關鍵[7]。 SME 隨溫度升高而降低,以 45%水分 最為顯著,而 50∼55%由於水分的潤滑作 用,故 SME 數值較小,與溫度之相關性較 不顯著。以 SME 對 G’、G”及η*做圖(圖 四),發現呈指數相關(R2 ≒0.92);SME 與 tanδ也有顯著的相關性(R2 ≒0.87)(圖 五 ) 。 tan δ 數 值 小 , 代 表 系 統 較 傾 向 Solid,因此產生的 SME 也較高,此數據似 乎與體積分率的論點[6 9] 相符。 2. 產品特性與質地 隨擠壓溫度與進料水分的上昇,糊化 度(DG)增加(表一),但當溫度高於 85℃, 進料水分對糊化度無影響。此可能由於 TCW70 在 50 ∼ 55 % 水 分 的 糊 化 溫 度 為 77 81℃,45%水分之糊化溫度約為 87℃, 高於 85℃時,物料均已達到糊化溫度,故 糊化度無差異。產品容積密度(BD)隨擠壓 溫度上昇而略微增加,但隨水分增加而降 低,澱粉顆粒之比重大於 1,因此水分增加 有降低容積密度之作用。隨溫度增加,L、 a 值降低,b 值增加,顯示原料受熱後之色 澤往暗黃色變化,水分增加有提高亮度的 趨勢。 水溶性指數(WSI)隨進料水分之增加 而提高,與黏彈性質有關,當 WSI<15%時, WSI 與 tanδ呈線性正相關 (圖六),其回 歸係數 (R2 )為 0.96;WSI>15%時,tanδ雖 隨著水溶性指數之增加而提高,但趨勢較 平緩(R2 ≒0.59),顯示 WSI 的提高使擠出 物傾向 Liquid。 經由 TPA 的分析(表二),提高水分使 Elasticity 與 cohesiveness 有增加的趨 勢 , 但 降 低 hardness, viscosity, gumminss, brittleness。隨擠壓溫度之上 昇 , hardness, gumminss, chewiness, brittleness 均呈增加的趨勢。數據經整理 後發現,若假設一個新的物性測定值,Q value。令:

Q = Hardness ×Elasticity / Viscosity 發現 45%水分擠出物的 Q value 隨擠壓溫 度提高而增加(圖七),其相關性(R2 ≒ 0.998)很好。但擠壓溫度對 50、55%之擠 出物 Q value 的影響不顯著,與擠壓溫度 對 G’值的影響類似(圖一),顯見黏彈性 質確實與質地有關。 五、計畫成果自評 本計畫之完成有助於瞭解糯米穀粉經 擠壓蒸煮後黏彈性質的變化,擠出物黏彈 性質之測定與系統分析模式的建立,有助

於工業界設定操作條件與品質管制要點的 設定;惟黏彈性與質地分析結果如能與消 費者的感官品評相結合,更可發揮本研究 成果的效用。

五、參考文獻

[1] Lai, L. S. and Kokini, J. L. 1991. Physicochemical changes and rheological properties of starch during extrusion. Biotechnol. Prog. 7:251-266.

[2] Mackey, K. L. and Ofoli, R. Y. 1990. Rheological modeling of corn starch doughs at low to intermediate moisture. [3] J.Food Sci. 55:417-423.

[4] Meuser, F. and van Lengerich, B. 1984. Possibilities of quality optimization of industrially extruded flat breads. p180-184 in Thermal Processing and Quality of Foods. Zeuthen, P., Cheftel, J.-C., Eriksson, C., Jul, M., Leniger, H., Linko, P., Varela, G. and Vos, G. (eds.) Elsevier Applied Science Publ., London. [5] Della Valle, G., Taydeb, J. and Melcion,

J. P. 1987. Relationship of extrusion variables with pressure and temperature during twin-screw extrusion cooking of starch. J. Food Eng. 6:423-444.

[6] Biliaderis, C. G. and Juliano, B. O. 1993. Thermal and medhanical properties of concentrated rice starch gels of varying composition. Food Chem. 48:243-250. [7] Evans, I. D. and Lips, A. 1992.

Visco-elasticity of gelatinized starch dis-persions. J. Texture Stud. 23:69-86. [8] Ellis, H. S., Ring, S. G. and Whittam, M.

A. 1989. A comparison of the viscous behavior of wheat and maize starch pastes. J. Cereal Sci. 10:33-44.

[9] Doublier, J. L., Lamas, G. and Le Meur, M. 1987. A rheological investigation of cereal starch pastes and gels. Effect of pasting procedures. Carbohydr. Polym. 7:251-275. 六、圖表 圖一、擠壓溫度與水分對貯存模數之影響 圖二、擠壓溫度與水分對耗損正切之影響 圖三、台中糯 70 於不同水分時之動態測試溫 度掃瞄圖(應變 0.2%,頻率 1Hz) Moisture Content 1000 10000 100000 70 75 80 85 90 95 100 Extrusion Temperature (℃) G' (Pa) 45% 50% 55% Moisture Content 0.3 0.4 0.5 0.6 0.7 0.8 70 75 80 85 90 95 100 Extrusion Temperature (℃) tanδ 45% 50% 55% Moisture Content 100 1000 10000 100000 0 20 40 60 80 100 120 Temperature (℃) G' (Pa) 45% 50% 55%

圖四、比機械能與擠出物貯存模數、耗損 模數、複數黏度之相關性

圖五、比機械能與擠出物耗損正切之相關性

圖六、水溶性指數與耗損正切之相關性

Q value = Hardness ×Elasticity / Viscosity 圖七、擠壓溫度與水分對 Q 值的影響

表一、進料水分與擠壓溫度對擠出物 特性之影響

表二、進料水分與擠壓溫度對質地剖面 分析(TPA)數值之影響

Moisture Temp. SME BD DG WSI

Content (℃) (kJ/kg) (g/cm3) (%) (%) 75 18.36 1.175 67 11.7 74.23 -1.21 9.62 80 16.57 1.169 85 9.9 72.59 -1.64 9.97 45% 85 13.53 1.183 96 13.1 70.48 -1.80 10.49 90 10.82 1.200 94 14.3 68.46 -2.01 10.44 95 12.64 1.210 100 23.7 67.16 -2.24 10.64 75 7.54 1.160 77 31.6 78.88 -0.61 9.18 80 8.52 1.157 94 34.5 76.51 -0.66 9.43 50% 85 7.56 1.158 94 28.8 74.32 -0.92 9.43 90 7.56 1.161 96 32.1 73.04 -1.27 9.91 95 6.51 1.169 100 31.7 72.50 -1.36 10.12 75 4.74 1.093 89 39.6 79.98 -1.74 8.92 80 3.66 1.129 96 41.2 75.51 -2.69 9.75 55% 85 2.24 1.134 94 46.1 72.17 -3.23 10.10 90 2.14 1.135 97 38.6 72.62 -2.92 10.57 95 1.93 1.143 100 41.3 72.29 -3.02 10.60 SME : Specific Mechanical Energy L : Lightness

BD : Bulk Density a : (+) Redness or (-)Greenness DG : Degree of Gelatinization b : (+)Yellowness or (-)Blueness WSI : Water Solubility Index

L a b

Extrudate Properties

Moisture Temp. Elasti- Hard- Visco- Adhesion Cohesive- Gummi- Chewi-

Brittle-Content (℃) city ness (g) sity (g) (erg) ness ness (g) ness (g) ness (g)

75 0.9455 339.0 125.3 193.7 0.7660 265.6 251.6 459.7 80 0.9401 568.5 157.0 241.7 0.7330 423.4 399.2 726.6 45% 85 0.9572 364.0 80.6 124.3 0.8534 311.3 298.3 437.9 90 0.9380 520.5 79.2 110.6 0.7502 384.4 361.8 607.0 95 0.9623 444.5 55.6 76.2 0.8489 361.3 345.0 500.1 75 1.3695 98.7 50.5 166.9 1.0488 104.9 141.9 149.4 80 1.2522 130.7 53.2 216.4 0.9619 125.4 157.4 185.7 50% 85 1.3278 145.0 59.6 229.3 0.9399 134.2 173.3 203.7 90 1.1841 151.1 62.9 251.7 0.9465 140.1 162.3 215.3 95 1.1346 176.4 64.8 227.6 0.9068 158.9 179.1 242.1 75 1.3943 47.2 23.4 86.4 1.0110 49.4 68.3 70.6 80 1.1545 65.4 31.8 131.1 0.9412 63.4 73.1 98.8 55% 85 1.3262 61.4 30.5 126.2 0.9919 61.5 83.2 91.5 90 1.1372 86.1 38.5 157.9 0.8944 75.2 85.1 124.0 95 1.2565 77.9 37.9 166.8 0.9618 72.3 90.1 110.0 y = 1010.8e0.1726x R2 = 0.926 y = 746.71e0.1395x R2 = 0.929 y = 187.62e0.1648x R2 = 0.927 100 1000 10000 100000 0 5 10 15 20

Specific Mechanical Energy (kJ/kg)

G' , G" (Pa) & η* (Pa•s)

G' G" η* y = -0.001x2 + 0.0033x + 0.6447 R2 = 0.8745 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0 5 10 15 20

Specific Mechanical Energy (kJ/kg)

tanδ y = 0.0462x - 0.1214 R2 = 0.958 y = 0.0032x + 0.511 R2 = 0.591 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 10 20 30 40 50

Water Solubility Index (%)

tanδ WSI < 15% WSI > 15% Moisture Content y = 2.0801e0.0042x R2 = 0.2005 y = 3.1016e-0.0021x R2 = 0.0673 y = 0.0273e0.0603x R2 = 0.998 0 1 2 3 4 5 6 7 8 9 10 70 75 80 85 90 95 100 Extrusion Temperature (℃) Q value 45% 50% 55%

附件一

出席 1999 食品科技會議及食品展 報告

葉安義教授

國立臺灣大學食品科技研究所

一、參加會議經過

食 品 科 技 會 議 及 食 品 展 是 由 食 品 科 技 學 會 (Institute of Food

Technologists)主辦, 每年舉辦一次, 參加本次會議者超過兩萬餘人,

來自世界各地, 包括美國、英國、法國、澳大利亞、日本、南韓、及

我中華民國等40 餘國, 是歷年來參加人數最多的一次, 顯見本會議

之受重視,芝加哥市長(Mr. Richard M. Daley)則以公開信表示歡迎之

意。 於大會中發表的論文達 1500 餘篇, 70%來自美國的大學、研

究機構與企業, 其次是墨西哥與加拿大,少數來自亞洲地區, 其中

以南韓最多 (如下表), 為我中華民國之1.5倍, 顯見我國雖居第二

位, 但仍需努力。

亞洲地區國家發表論文篇數之統計

國

別

發 表 論 文 篇 數

南

韓

35

中 華 民 國

23

中國大陸(包括香港)

11

日

本

5

澳

門

5

泰

國

3

參展的廠商共有 878 家, 租用2575個攤位,大多為歐美地區的

公司, 來自亞洲的公司較少, 很可惜,我國的食品公司未參展, 展

示其產品於調味之功能性,日本、 香港、 與中國大陸均有一家以上

的公司參展,尤其是中國大陸,由添加物協會與出口協會組團參展,

顯見其推廣產品的用心,值得我國企業界參考。 參展廠商除展出其最

佳產品外, 有些還以歌唱、贈品、佳餚等招徠參觀者,使人感受到市

場之競爭性。

本會期的第一天(7月24日)晚上為開幕式, 由食品科技學會理事長

(Dr. Bruce R. Stillings)主持, 並邀請全國餐廳協會總裁兼執行長 (Mr.

Herman Cain) 致 詞 , 其 演 講 主 題 是 ”二 十 一 世 紀 前 瞻 性 的 領 導

(Visionary Leadership for the 21

thCentury)”。 討論領導者所應具有的

特質,稱之為DEF,D是領導者認知工作者需要激勵,E是代表創業是

具有風險性的,F是凝聚力量解決問題的核心,並認為領導者需做ROI

三件基本且重要的事情,R是去除工作者自我激勵的障礙,O是獲得正

確且為所需的結果,I是鼓舞工作者的士氣。同時指出,偉大的領導者

是天生俱來,但好的領導者是可以訓練出。這三種特質與該作的事亦

可用於家庭生活,尤其是父親如何帶領家庭往前走,故值得大家深思。

本次大會除安排技術性的研討會與海報組外(兩者分別進行), 並

特地安排三個熱門話題, 討論消費心態、法規與科技之變遷及其對食

品工業之影響。 技術性的研討會與海報組的主題包括食品工程、微生

物、營養、 加工技術、生物技術、 化學、衛生與健康、 品管與相關

法律、 包裝、 教育、 產品開發等多項。 三個熱門話題則均由具有

實務經驗者主講,與會者提出問題共同討論, 第一個熱門話題是“保

健食品”,由Kellogg公司副總裁(Mr. Guy Johnson)與St. Catherine大學

Dr. J. Miller Jones共同主持,討論保健食品應具有之法律地位,目前美

國法律禁止食品標示療效,換言之,食品不能稱為藥品,鑑於保健食

品的市場一直成長中,雖然美國食品藥物管理局(FDA)以保護消費者的

立場(Mr. I. R. Heller),未放寬法規,但許多藥草類的產品,如人參、

蒜頭、銀杏等,由於數據之缺乏(Mr. M. Rotblatt),無法獲准標示,但

消費者仍食用,於保護消費者之外,另一件事為消費者有知的權利,

兩者之間如何取得平衡,是保健食品相關法規最重要的課題。

第二個熱門話題是“政策、政治、情緒對食品工業的影響”, 以食

品法規之制訂為主要議題,McCormick 公司Mr. R.T. Lawrence認為消

費者的需求是制訂法規的原動力,全球統一的法規將增加使消費者對

產品的瞭解,故有必要訂定單一法規;尤其是有關安全、衛生,與消

費者的健康息息相關,法規制訂時,應特別重視(Dr. C.S. Dewaal);政

治角力不應犧牲消費者的健康,因此立法機構應以科學數據為主要依

據(Dr. K.D. Johnston),美國國會將是制訂食品法規的主要機構,成員

間已有共識,立法的出發點將是有利於消費者、業界、與執法者,所

以各個團體間的溝通與共識是立法的基本要件。第三個熱門話題是“創

作或抄襲為企業創造利潤?”,Mr. R.D.C. Macnair以半導體的晶片為

例,說明創作之表現與其對人類生活的影響,進而以馬鈴薯片為例,

說明技術性創作的需要性與消費者對產品的喜愛度,所以技術性創作

與新產品的開發是食品公司所不可或缺,對一個技術人員而言,確實

瞭解自己的獨特發明,並有毅力克服困難,將發明轉變成市場中的產

品,才能符合創作的定義(Dr. T. Abraham),但技術性創作不一定為企

業增加利潤,這是生產成本與市場需求的平衡,有時反而以非創作性

的產品有較高的利潤,創作與抄襲是相互矛盾的,故企業經營者需於

兩者取得平衡,以獲得最大利潤(Mr. P. Mccormick),欲進行創作,工

作人員必須發揮想像力,不可劃地自限,方能有所突破(Ms. A.

Moser-Wellman),企業經營者需提供研究人員的原動力,並以教育或資源的

提供鼓舞士氣(Dr. D.L. Braun),才能成功地開發新產品。

技術性的討論共有79場研討會及37場海報組,分別探討不同的主

題,本人依探討之主題性質加以分類,可歸納為食品化學、食品微生

物、食品加工、食品工程、包裝、產品開發、各類產品、生物技術、

品質管制、法規與教育、 營養與市場等十一項。

(1) 食品化學:涵蓋之子題包括香料化學、油脂、乳化液、碳水化合物、

以及品評技術等,香料化學研討會著重肌肉食品(muscle food)香味

的產生,分別從脂肪衍生物與蛋白質及其分解物探討香味物質產

生的機制,並討論各種食品香味物質(包括揮發性與非揮發性成分)

之萃取與鑑定方法, 及加工過程對產品香味之影響;乳化液研討

會則討論各種乳化液之基本特性,如穩定度、流變性質、微粒結

構、以及光性質等,並比較各種分析方法;碳水化合物之討論以

澱粉與膠類物質的分子結構與其對膠體性質的影響,以及澱粉與

膠類物質間的相互作用,利用該性質,可作為產品開發的參考,

並討論碳水化合物在未來市場中,將扮演重要角色; 脂肪則著重

於分析與萃取方法的探討, 並討論於加工與 儲存時, 油脂產生

之氧化機制;品評是產品開發與市場調查不可或缺的工具, 除探

討添加物對產品質地的影響外, 廣泛地討論如何利用統計方法與

電腦, 進行數據分析, 使結果能確實區分消費者對產品的喜好

性。

(2) 食品微生物: 涵蓋之子題包括微生物的傳染途徑、加工程序對微生

物的影響、壓力對微生物的影響、李斯特菌等,由於人類生活習

慣與大環境的改變,使微生物的傳染途徑亦發生變化,同時發現

新微生物,因此快速且準確的分析方法是必須的,方能快速偵測

被污染的食品;由於高壓加工方法保有產品質地與風味,是良好

的加工程序,故許多學者探討其對微生物的影響,尤其是病原菌

的生存狀況;環境對微生物產生影響,使其具有抗惡劣環境(如

高溫、高壓)等之能力,稱之為壓力衍生之微生物,於加工過程

中,應避免此效應的發生;李斯特菌是一種病原菌,有賴全球之

共同努力,方能將之排除於食品之外,故國際間應有此共識,制

訂共通的法則並教育消費者,使食品免於李斯特菌的威脅。

(3) 食品加工: 由於消費者對加工食品的方便性, 新鮮度, 與天然性的

需求性日殷迫切, 所以過度加工, 防腐劑與人工添加物之使用,

或過度包裝等之產品均會逐漸消失, 故衍生最少加工方法的觀

念, 包括熱與非熱加工:非熱加工則是利用電場產生電流,進行

加工;高壓法處理,可達到滅菌之效果,同時保存固有風味,但

加工程序之費用則較其它方法高;或添加CO

2以延長乳品的保存

期;熱加工則以如何使食品之受熱均勻,縮短加工時間為主要討

論方向。相關法律與成本是開發新加工方法的兩大考量,消費者

對產品的接受性更是新加工方法能否生存的關鍵。

(4) 食品工程: 涵蓋之子題包括流變學、擠壓技術、質傳、熱傳、數學

模式、殺菌工程、食品之性質與加工、製程之研發、與食品物化

等。流變學以產品之黏彈性與玻璃轉換現象為主題,利用所得資

訊,預測產品之質地、保存期等;擠壓技術的討論主題包括流變

學之應用、硬體設計(以螺紋組成為主)、滯流時間之測定、與

數學模式之研究,本人過去十年有關擠壓之研究包含上述之主

題,顯示擬定之研究方向正確;質傳以討論水分與脂質於加工過

程(如乾燥、油炸)中,在食品中的移動現象及其對產品品質的

影響;熱傳以探討於油炸、微波、歐姆式加熱中,熱對食品結構

與組成的影響;數學模式則以各種加工方法與製程之模擬為主,

並就其於製程之商業化所扮演的角色加以討論;殺菌工程以電阻

是加熱為主要工具,探討液體食品之連續性滅菌方法及製程之模

擬;食品之性質與加工則討論各類食品於加工過程中,結構、滲

透性、黏度等各種理化特性的改變;製程研發的主要目的是將產

品商業化,工作者應瞭解市場趨勢,並需考量投資成本與勞力成

本之平衡、產率、原料品質及供應穩定性、市場需要及特性、產

品整合性、產品之附加價值等,方能有效地開發製程;食品物化

以水分之影響為議題,探討水分對產品的保存性、流變性質、塑

化作用、微生物生長等之影響,將物化理論應用於食品加工,本

人發表之論文”米擠出物之玻璃轉換溫度與其膨發溫度之相關性”

屬於此類論文,有多位與會者表達其興趣,尤其是Kellogg公司的

研發人員與本人就結果討論20餘分鐘。與食品工程相關之研討會

共有16場次,佔大會所有研討會之14%,顯見食品工程之受到重

視,台大食科所一直推動食品工程教育,顯見教育方向之擬定是

正確的。

(5) 包裝:涵蓋改氣包裝與包裝材料兩子題,改氣包裝針對蔬菜、水果

進行研究,以延長產品之儲存期限為主要目的;包裝材料則以可

食用包裝材料之開發為主軸,以蛋白質、澱粉為主要材料,探討

如何改變材質,使開發成功的包裝材料符合產品的需求。

(6) 產品開發:涵蓋之子題包括低卡油脂產品之分析與其營養價值、不

同市場之產品開發、具保健功能成分之產品的開發與技術等。低

卡油脂產品主要討論產品中代用油脂,如olestra、salatrim等的分

析與鑑定,其相關法律亦為討論重點; Dr. Bailey 以開拓日本市

場的經驗與大家分享,討論如何將產品的口味地方化,以拓展全

球市場,Dr. Pommer 提出不同訴求的新產品,液體蛋白質,說明

新產品開發成功的例子;新產品之開發與技術涵蓋的範圍較廣,

包括添加物如可得蘭膠(curdlan)、纖維素、天然澱粉、纖維等之應

用,以及甜味料之開發,Dr. G. R. Huber 以擠壓產品為例,討論

澱粉對產品的質地、香味、穩定度、玻璃轉換現象等之影響,並

有專題討論如何開發具保健功能成分之新產品,基本概念是將已

被認知的保健成分分離、純化、保存,以及如何應用於新產品,

目前應用最多的產品是飲料,乃因加工無問題,但產品的標示則

是一大課題;技術顧問可從不同角度,如策略性產品規畫、建立

產品計畫功能的組織架構、市場潛力之鑑定、觀念之篩選與測試、

人力資源之規畫,產品測試、產品最佳化、量化生產、商業化、

生產線之再調整、生產線之擴充、以及問題之解決等方面協助業

者;產品開發的首要步驟是確認市場的需求,理出所有可能的想

法與觀念,由具有相關知識的工作者共同篩選,即可進行試驗與

開發工作,以證實觀念之正確性,如市場反應良好,利用公司現

有設備或以代工方式進行量化生產;業務用產品具極大之潛力,

該類產品之開發與消費商品相較,其特點是消費者嘗試新產品之

意願較高、銷售管道已建立、包裝線可明顯縮短、開發成本較低,

最大的不同點是產品之生產除了需符合公司生產線之配備與消費

者之需求外,尚需與客戶(如餐廳)之設備配合,產品存活空間

才能擴大。

(7) 各纇產品:涵蓋海產、無菌包裝、肉品、乳品、冷藏及冷凍、柑橘

類、蔬果、飲料等。海產品之開發需先瞭解其原有產品之特性及

製 程 , 會 中 就 以 開 發 成 功 的 產 品 , 如 調 味 海 鮮 (marinated

seafood) 、魚漿麵糰(surimi pasta) 、海鮮點心等提出討論,主題

涵蓋製程之改進、添加物之使用、酵素利用、蛋白質加工特性、

產品之品質管制等;含顆粒產品是無菌包裝產品開發之重點,歐

姆式加熱與高壓滅菌法是討論重點,由於商業化可能性已提高,

該產品將有極高之成長率;肉品之開發以低脂產品為重點,主要

方法為使用添加物,如蒟蒻、大豆分離蛋白、穀物澱粉等,並討

論加工過程、肉品成分、與脂質氧化對產品之影響;乳品研討會

著重於新加工方法之應用,如高壓處理對牛乳安全性之影響,與

乳品(如乳酪)之流變性質,以及乳漿蛋白(whey protein)與酪蛋

白(casein)的功能性及其對產品質地之影響;冷藏及冷凍食品的穩

定品質與合理價格是該類產品能持續成長的關鍵,由於消費者意

識之改變,天然且具健康性之農產品已為主要原料,Dr. H. L.

Cooperhous 認為冷藏調理食品將成為市場主流,而為第三代產

品,取代第二代的冷凍食品與第一代的罐頭食品,因其可取代一

般家庭之餐食,成為家庭餐食取代品(home meal replacement),主

要問題是產品的保存期限,需保持新鮮且可口,故需與銷售商結

合,進行HACCP之品質管制,以確保產品之安全性;柑橘類產品

之討論重點為香味之鑑定及滅菌方法之探討,以提高產品之保存

期限,佛羅里達大學Dr. R. Bazemore 提出以電子鼻(electronic nose)

進行香味之分析與鑑定,成效良好,故可成為有效之工具;蔬果

產品之討論以如何使消費者食用更多蔬果,並從中獲得維生素及

蔬果之加工,期能使產品的保存期限加長,且維持原有之質地與

風味,並討論加工過程中香味之變化,以瞭解製程對品質之影響;

非澄清飲料是飲料研討會之主要產品對象,乳化液之安定性、外

觀、口感等是討論主題。

(8) 生物技術:涵蓋之子題為生物技術與生物製程、牛乳中具生物活性

的成分、應用於食品加工的酵素基因工程、分子傳染病學於食品

工業之應用等。生物技術與生物製程著重於微生物基因的鑑定與

移植,及其於食品加工之應用,與會者亦提出呼籲,安全法規之

確立是必需,以免生物科技之不當使用,而危害人類;牛乳中具

生物活性的成分主要是lactoferrin,它是一種蛋白質,可與鐵結合,

已有報告指出是免疫系統的生長因子,且可避免因微生物之污染

而造成之乳酪蛋白質的分解,會中亦提到一種細胞膜脂肪,

shinolipid,可抑制結腸癌(colon cancer)細胞之生長,故是有潛力

的機能性食品;應用於食品加工的酵素基因工程主要探討自微生

物 生 產 與 碳 水 化 合 物 反 應 有 關 之 酵 素 ( 如 葡 萄 糖 澱 粉 酵 素

(glucoamylase)之生產技術;分子傳染病學於食品工業之應用研討

會乃以生物技術與生物製程為主軸,將之應用於致病性微生物的

監控與滅菌。基因工程亦可用於食品原料(如穀物)結構之改變,

使產品具特殊質地或較長的保存期。

(9) 品質管制:涵蓋改進品質的測量系統、食品守則(Food Code)、食品

流通系統之品質、最佳品質管理之設計等。改進品質的測量系統

研討會中提出品質即成本的觀念,退貨造成成本之提高,可利用

產品設計與製程設計及控制的方法來避免,收集客戶抱怨與退貨

原因,是改善品質的好方法;編印食品守則的主要目的是使製造

廠商與販賣者有規則可循,此舉不但提昇食品服務業或販賣者的

服務品質,且確保食品之安全性;製造廠商對產品之品質管制固

然重要,但食品流通系統之品質亦不可忽視,產品自出廠至消費

者,流通系統也是維持品質的關鍵,故需偵測其弱點並加以改進;

ISO 9000或HACCP常用於製程之管制,但也可用於最佳品質管理

之設計,從企畫、管理、團隊組織等著手,建立生產良好品質的

產品之根基,以合理價位提供良好品質的產品,即可於市場中立

於不敗之地。

(10)法規、標示、與教育:涵蓋新產品上市的技術與法律問題、法律

改變時工業的優勢與弱點、減少卡洛里之主要營養成分的標示、

建立北美營養物之參考資訊、瞭解過去,準備將來等。新產品上

市的技術與法律問題討論新產品上市時所需考量的事實,如量化

生產的可行性與安全性、法規、產品標示等,所使用之原料與配

料以天然物最能符合市場需求,產品的”定位”更是重要課題,需

考量多種因素,如潛在消費者的需求、競爭性產品的特性、替代

性產品的可能優勢等,同時需掌握上市的時機,避免產品提前曝

光,保護配方等資訊,均影響產品能否立足於市場;法律改變時

工業的優勢與弱點乃討論過去於佛羅里達州中,柑橘工業相關法

律之改變,引發該工業之加工製程之改進的經驗,並進而討論將

來於全球市場中,相關法律可能改變的趨勢以及因應之道;經由

市場調查,標示無油脂、低卡洛里的產品最受歡迎(接受度為

40%),有些特殊脂肪與碳水化合物,只有部份為人體吸收,故

標示低卡洛里,但此類產品需經美國FDA認可後,才能上市;由

於一般人之飲食常超出每日攝取之建議量,造成肥胖問題,如能

建立”可攝取之最高量”,有助於降低肥胖問題,但該資訊之評估,

需確實瞭解營養物質之真實分佈與消費型態,再依所得數據建立

模式,進行評估,以建立北美營養物之參考資訊庫;將來市場變

動的腳步很快,需從過去的經驗,培養所需人才,除技術外,個

人特性之磨練,如創造性、情緒穩定性、資訊性、客觀性、及負

責性等均是成功之鑰。

(11)營養、生理與市場:涵蓋營養、孩童營養、海洋生物之營養與保

健、每日建議攝取量、膳食與荷爾蒙、食物過敏、中國大陸的食

品市場等。營養研討會以烘焙食品、嬰兒食品等為對象,討論其

所含營養成分的分析、鑑定方法與含量的計算方法之建立,以使

分析數據更可靠;孩童營養之與會者提出,孩童與嬰兒均處於生

長期,需另外訂定所需攝取的營養物質,如碳水化合物、礦物質、

鹽類等,並應研擬限制孩童攝取過多脂肪與甜味料的政策方針,

使下一代有健康之飲食習慣;海洋生物可提供人類許多營養物

質,其中成分,如EPA, DHA等,具有特殊功能性,與會者就此議

題進行討論;目前之每日建議攝取量乃於二次世界大戰後公佈實

施,顯得已過時,美國FDA正著手,就食物之營養價值、保健功

能、及可能發生的毒性進行評估,第一階段中,將會鑑定約30種

食物的成分,同時也將擬定特定族群的每日建議攝取量;飲食習

慣影響人體中荷爾蒙之生理活性,間接影響腫瘤細胞之生長,膳

食與荷爾蒙研討會之與會者就如何改善飲食習慣,達到預防癌症

的方法進行討論;食物過敏的案例與日俱增,故引起大眾之注目,

而為食品安全的問題,與會者就其定義、法規、及標示進行熱烈

之討論,並提出建議,凡導致大多數人食物過敏的產品,均應回

收並停產,以保障消費者的權益;中國大陸是僅次於美國的第二

經濟大國,如何開發其市場,是許多企業想要瞭解的話題,會中

討論中國大陸食品市場的機會與如何掌握商機,與可能面臨之障

礙與困難,Dr. C. Z. Shyers 指出台灣、香港等可作為中國大陸與

美國市場與美國企業的橋樑,美國企業使能順利發展業務。

二、與會心得

本次與會收穫良多,並藉此機會與海外人士討論”兩國論”,發現

多數海外華人支持李總統的理念。就科技研討會的收穫,摘要如下:

1.世界各國均面臨快速之改變,為使企業能維持競爭力,產品與市場

之開發是維持公司成長的關鍵,”定位”是開發產品之首要之務,市

場的需求是開發產品之動力,兩者同等重要,故技術之研究需與市

場的需求相配合,即建立產學合作的互動關係,以最經濟與最有效

的方式生產符合市場需要的產品,並提昇產業技術。

2.學會可整合各種人才,成立以任務為目的之團隊,為企業界及社會

服務,更可擔任社會教育的媒介,以客觀且積極的態度教育社會,

並參與安全法規之確立,使法規簡易可行,而企業得以遵行,尤其

是有關食品安全、衛生、營養及膳食,使整個社會之飲食更健康,

不僅造福於社會,更使下一代有健康的飲食習慣。

3.食品之發展以有益人體健康為導向,如低卡洛里、低脂、低糖等食

品,或具保健功能成分的產品,但需有適當的法規,規範產品之標

示,以免消費者受騙與被誤導,就技術而言,改善產品之色、香、

味,使其可口且健康,以維持市場佔有率,是食品研究人員的一大

挑戰。

4.由於網路之發展,將造成市場、經濟等之變動,企業必須提早準備,

因應各種變化,同時地域性之界線趨於模糊,國際化是必然之趨勢,

為達到此目的,企業內人員之安排與培養,國際法規之了解,產品

世界化但口味地方化,是企業成長的必要條件。

5.為使企業維持競爭力,如何改善或設計製程,節省生產成本是一大

課題,故食品工程之教育需加強推廣,並使業者、社會瞭解食品工

程對食品工業之貢獻,擬定的課程內容需符合業界所需,如此,畢

業生才能發揮所學,為業界貢獻。

6.食品物化是一新課題,其中食品玻璃轉換現象是許多論文探討之主

題,該現象影響食品質地之改變與保存期限,如何將觀念應用於產

品之開發與改進,是學者努力的方向。

三、建議

1.除了企業國際化以外,我國之學術研究亦需國際化,國內學者應多以

英文發表論文,以獲得國際間之肯定,同時應多參與國際團體之執

行委員會,以立足於國際社會。

2.為因應將來加入WTO ,國內之食品標示、衛生、安全法規均應及早

訂立,使業界有所遵循,同時維護國內消費者之安全與健康,故需

產官學的人士共同推動。

3.我國之食品科技相關研究已達國際水準,應有主辦世界性會議之能

力,不僅有助於技術人員之國民外交,同時可讓外國人了解我國之

民俗、文化,同時有助於國內企業之國際化。

4.國內之學術團體,應可廣泛收集資料,加以整理與分析,進而提供

社會有關食品安全、衛生、營養等相關資訊,建立國人正確之觀念,

健康之飲食習慣,達到普遍教育的目的。

5.國內應著重於傳統產品之研究開發,不僅使製程連續化,節省生產

成本,同時使產品之保存期限延長,如此產品國際化之成功率將會

大幅提高,可提高食品工業之出口值。

6.國內之學術團體應逐漸與國外學術團體建立聯盟體系,加速人員、

技術、資訊等之交流,可以設立網路網站為初期目標。

四、攜回資料名稱及內容

大會議程、大會論文摘要等,及參展廠商名錄,與有關擠壓技術、

食品流變學與玻璃轉換現象之研究論文,歡迎有興趣者索取參考。另

本人藉與會時機,購買兩本參考書:Handbook of Food Engineering 與

Food Emulsion: Principles and Practice,歡迎有興趣者借閱。

附件二、出席國際會議發表論文

The Glass Transition and Expansion Temperature of Extrudates Made from Rice Flour and Dextrin

Chia-Mao Chen and An-I Yeh*

Graduate Institute of Food Science and Technology National Taiwan University

59, Lane 144, Keelung Road, Sec. 4, Taipei, Taiwan

e-mail: yehs@ccms.ntu.edu.tw

Tel: +886-2-2363-3148 Fax: +886-2-2362-0849

* Correspondent

ABSTRACT

Rice pellets were prepared by single-screw extrusion cooking at in-barrel water content

from 45 to 55%. The glass transition (Tg) and expansion (Te) temperature of rice pellet have

been determined by differential scanning calorimetry (DSC) and non-contact infrared

thermometer, respectively. Tg and Te had similar dependence on equilibrium moisture and

good linear relationship with r2 of 0.95. Te was 20 – 90

o

C higher than Tg, which indicated that

the expansion of pellet occurred at rubbery region. There existed a maximum expansion at 10% equilibrium moisture due to the transition of pellet from brittle to ductile with the

moisture content. The addition of dextrin reduced the average molecular weight as well as Tg,

but increased the expansion ratio due to decreasing the viscosity. Gordon-Taylor equation was

found to fit well (r2 = 0.89) Tg determined for the pellets without dextrin. A model has been

developed to estimate Tg for the pellet consisting of rice flour, water and dextrin.

INTRODUCTION

Extrusion cooking has been used for manufacturing third generation snack. The extrudate becomes a pellet or semi-product after drying and is shelf stable due to the presence of glassy state. Pellets can be puffed and seasoned by packers for final products or puffed at home by consumers. The formulation is very complicated even with a major component of starch. It would be beneficial to the product development if the relationships between expansion condition and formulation are understood.

Glass transition is a second-order phase transition and defines a transition from a brittle, metastable amorphous solid to a rubbery unstable amorphous liquid. Molecular weight,

structure, and plasticizers govern the glass transition temperature (Tg), which is relevant to

food processing operations (e.g., freezing, drying, extrusion) and correlates well with quality

attributes (e.g., texture, stability, and flavor release in low-moisture systems)1,2. The

manipulation of Tg creates specific product texture. One may add low molecular weight

components to soften texture or add high molecular weight components to assist in setting product texture. Also, adjusting the operating and storage conditions can maintain the

product quality attributes relevant to the Tg of the end product. Kaletunc and Breslauer

3

have

proposed Tg as a criterion for adjusting extruder operating conditions to produce extrudate

with optimal textural properties, as well as to select optimum storage conditions to improve stability and shelf life of extruded products. The transition of glassy pellet to puffed-product is a key to process and product development. It is believed that the pellet expands only at

rubbery state. In other words, the expansion temperature would be in the range of Tg and Tg

+100oC. However, the experimental evidence on this phenomenon is limited.

composition, and molecular weight to Tg have been reported 4-6

. Orford et al.7 and Roos &

Karel8 have discussed the methods to predict of Tg of amorphous food components as a

function of composition and molecular weight. Such predictive capability would be useful for food process and product development, and for studying effects of physical state on deteriorate changes as a function of temperature, water content, and time. Couchman-Karasz

equation (eq’n 1) was used to predict Tg of amylopectin-water

9

.

(1)

where wi is the weight fraction of component i, and ∆Cpi is the difference in specific heat

between the liquid and glass state at Tg. Let k= ∆Cp2 /∆Cp1, equation (1) becomes

Gordon-Taylor equation.

(2)

Gordon-Taylor equation fits well the data of amorphous carbohydrates-water system8. Both

Couchman-Karasz and Gordon-Taylor equations underestimated Tg for extruded corn meal

melt10 due to the complexity of the system. It becomes more complicated to deal with ternary

mixtures. Couchman-Karasz equation was extended to estimate Tg.

(3)

Thus the extra component was taken into account. Another approach was to apply equation

2 2 1 1 2 2 2 1 1 1 p p g p g p g C w C w T C w T C w T ∆ + ∆ ∆ + ∆ = 2 1 2 2 1 1 kw w T kw T w Tg g g + + = 3 3 2 2 1 1 3 3 3 2 2 2 1 1 1 p p p g p g p g p g C w C w C w T C w T C w T C w T ∆ + ∆ + ∆ ∆ + ∆ + ∆ =

(2) to starch and sugar in the ratio used to obtain Tg of the dry mixture, this value is put into

the equation again with water as a second component. Thus Tg can be expressed as

(4)

where k1 = ∆Cpsugar/∆Cpstarch and k2 = Cpstarch/Cpwater with the assumption of ∆Cpstarch

representing ∆Cp for the dry mixture of starch and sugar. Equation (4) was found to be better

than equation (3)9. However, Brent et al.10 reported that equation (4) did not work well for

amylopectin-zein-water system and suggested that further work was needed to develop a model applicable to biopolymer systems.

The objectives of this study were to evaluate the relationships between Tg and expansion

temperature (Te) of pellet and to establish a model for estimating Tg of extrudates consisting

of rice flour, dextrin, and water.

MATERIAL AND METHODS

Polished Japonica rice (first crop in 1996) was purchased from Fen-Yuan Agriculture Association in Central Taiwan. The rice

was ground using a stamp-mill to pass a 80-mesh (ASTM) screen. The proximate composition was reported 11

as water 12.8±0.20%, crude protein 6.66±0.29%, crude lipid 0.46±0.01%, ash 0.42±0.02%, and 79.7±0.58% of total carbohydrate. The total starch content was 89.2±0.68% (d.b.) and amylose content was 27.5±0.3% (based on the dry weight of starch). Dextrin (0-20%) (Matsu-Tani Chemical Co., Idan Shi, Japan) having a dextrose equivalent (DE) value of 40 was added basing upon the weight of rice flour. The admixture was put in the silent cutter and distilled water was sprayed on it. The silent cutter not only provided the mixing, but also prevented the admixture from caking. The admixture had a moistue content of 40% (w.b.) with uniform water distribution. The pre-conditioned admixture was stored at

4 o C before use. Extrusion ) )]( ( [ ) ( ) ( ) ( 3 2 2 3 2 1 1 3 3 3 2 2 1 2 2 3 2 1 1 1 3 2 2 w k w w w k w T w w w k k T w w w k T w w k w Tg g + + g + g + + + + + =

The extrusion cooking was conducted in triplication by using a single screw extruder 11

(Tai-Yu Co., Taipei, Taiwan). The bore of the profiled barrel had a diameter of 8.5 cm. The L/D ratio was 5.1:1 and the compression ratio was 2.1:1 when a forward element was used. A diaphragm type pressure transducer and a thermocouple were inserted into the die for measuring die pressure and temperature. A torque transducer (TP-10KMCB, Kyowa Co., Ltd., Tokyo, Japan) was fitted between the motor and gear box to measure the torque. A dynamic strain amplifier (DPM-700B, Kyowa Co., Ltd., Tokyo, Japan) was used to amplify the signal which was recorded by a personal computer. The energy losses in bearing and the drive train were assumed negligible, as they did not affect the reproducibility of the control system. The screw profile was built up by segmented forwarding elements except that 2 cm non-flight element was used near the tip of the screw. The non-flight element was in cylindrical shape with a screw root diameter of 6.3 cm. The forwarding element had a flight height of 1 cm. There were two barrel sections of jacketed and jacketed. Water was flowing inside the jacket for cooling. A heating tape around non-jackted barrel was used for heating. There was a thermocouple attached on the surface of non-jacketed barrel to measure the barrel

temperature. The heating tape and water flow were on-off controlled to keep the non-jacketed barrel at 88+2 o

C. A slit die with a width of 85 mm and height of 3 mm was used to form sheet-type extrudate.

From the preliminary tests, a screw speed of 82.5 rpm and a feed rate of 8±0.3 kg/h were selected. Low screw speed was to minimize the wearing of screw which was very costly. Low feed rate was to keep smooth running and avoid blocking of the feed port. The extruder was run at starved-fed conditions in this study. Pre-conditioned rice flour was fed into the extruder via a twin-screw feeder which was calibrated before the experiments every times. During the experiments, the rice flour in the hopper of feeder was controlled manually at a given level (5 cm above the screw). Thus, the feeding was kept smoothly and consistently with a deviation of ±0.3 kg/h. Additional water was pumped into the extruder to maintain the in-barrel water content being at set points of 45, 50, and 55 ±0.3 %. After stable operations were established, judged by constant torque readings and product output, extrudates were cut by a mold with a diameter of 3 cm, collected,

and dried by an air oven at 40 o

C to prepare the dry pellet with moisture content about 12%. The dry pellet was equilibrated with different saturated salt solution to have different equilibrium moisture for the expansion experiments.

Glass transition temperature

A change in specific heat measured by differential scanning calorimetry (DSC) was applied to determine the glass transition temperature. The dry pellet was ground by a rotary speed mill (Pulverisette 14, Fritsch, Germany) to pass a 20-mesh screen. The powder was equilibrated with saturated salt solution in a desiccator to varying moisture content, which was doubly checked by

AOAC12 method. Once the moisture content was confirmed, sample (about 80 mg) was put in a

crucible for thermal analysis using a DSC (DSC 121, Setaram Co., France) equipped with a liquid nitrogen cooling system. The crucible was hermetically sealed using aluminum O-ring and the

reference was an empty crucible. The temperature range was set from 30 to 220oC and the scan rate

was 5oC/min. The glass transition temperature was determined from the thermogram according to

the method of Sperling13.

Expansion temperature

The equilibrium moisture content of the pellet was doubly checked by AOAC12 method before

the experiment. A homemade lab-scale oven with temperature controller was used to carry out the

expansion of equilibrated pellets at an oven temperature of 350oC. A non-contact infrared

thermometer (Ray PM30L3U, Raytek Co., Santa Cruz, CA) with data acquisition and analysis software (DataTemp 2, Raytek Co.) determined the temperature at the central point when the pellet started expansion. Five replications were conducted for obtaining the average initial expansion

temperature (Te).

Bulk density

A densimeter (MD-200S, Mirage Co., Osaka, Japan) was used to determine the bulk density of pellets and expanded products by applying the principle of Archimedes. Silicone oil was used as the solvent to avoid the dissolution of samples. Five replications were carried out for obtaining the average bulk density. The expansion ratio was calculated as the ratio of bulk density of pellet to expanded product.

Intrinsic viscosity

According to the literature methods 14,15

, dry pellets were ground by a rotary speed mill (Pulverisette 14, Fritsch, German) to pass a

screen of 80 mesh (ASTM). The samples were refluxed with 85% methanol for 24 hr, then dried by an air oven at 40 o

C. The dried sample (about 0.15 g) was mixed with 25 mL 0.5N KOH and heated in boiling water while purging with nitrogen gas. The heated sample was cooled first and then centrifuged (9,000 x g) for 10 min. The supernatant was pre-filtered using filter paper and filtered via a glass

fiber filter (G4). The total polysaccharide in the filtrate was determined by phenol-sulfuric method 16

. The intrinsic viscosity was

determined at 25+0.1 o

All the experiments were conducted in triplication and the data were analyzed using Sigmaplot for Windows. Thus the regressed curves and correlation coefficients were obtained. Since the variations in data were less than 6%, the average values were reported without showing the error bars or standard deviations.

RESULTS & DISCUSSION

DSC data showed that there was only one inflection point for Tg. Apparently

extrusion cooking resulted in a homogenous extrudate and the pellet was amorphous17,18.

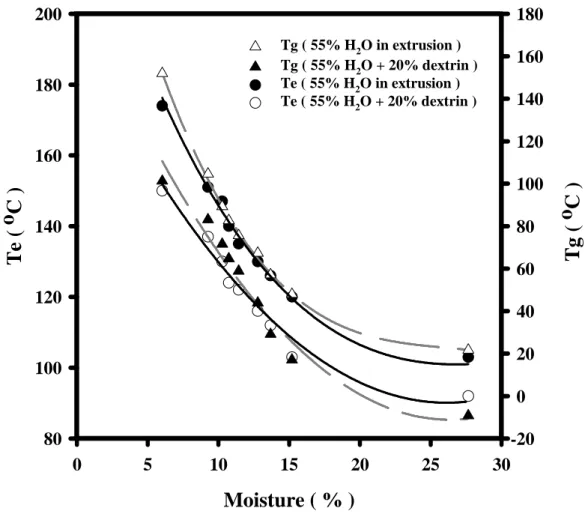

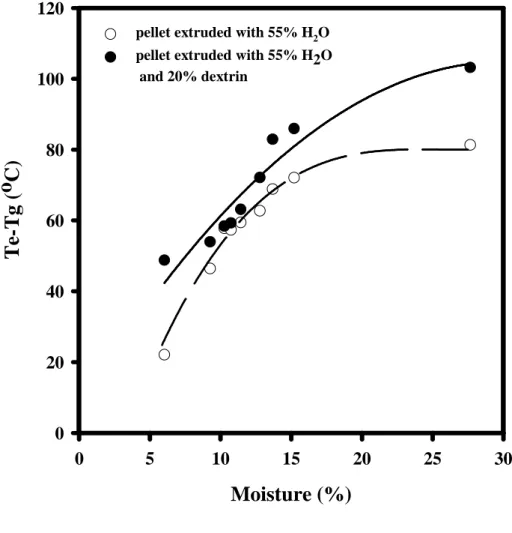

Figure 1 illustrates the dependence of glass transition temperature (Tg) and expansion

temperature (Te) on the equilibrium moisture content of pellet, which was extruded at

in-barrel water content of 55%. The equilibrium moisture acted as a plasticizer and lowered both

Tg and Te. The Tg obtained was little higher than that for amylopectin

9

, but showed similar moisture dependence pattern. The difference may be due to the compositions and preparation

of sample. Tg reached a finite value when the equilibrium moisture content was higher than

20%. The pellet without dextrin yielded a finite Tg higher than freezing point of water and

was classified as water-sensitive polymer19. With the addition of 20% of dextrin, Tg was

lowered and yielded a finite value lower than the freezing point of water. The addition of dextrin modified the pellet from water-sensitive polymer to water-compatible polymer. The intrinsic viscosity of pellet was reduced from 92.7 mL/g to 86.5 mL/g by adding 20% dextrin. It appeared that the major effect of dextrin was to decrease the average molecular weight of

the pellet. Te exhibited similar dependence on the equilibrium moisture content, but was

higher than Tg. The Addition of dextrin also decreased Te due to the reduction in molecular

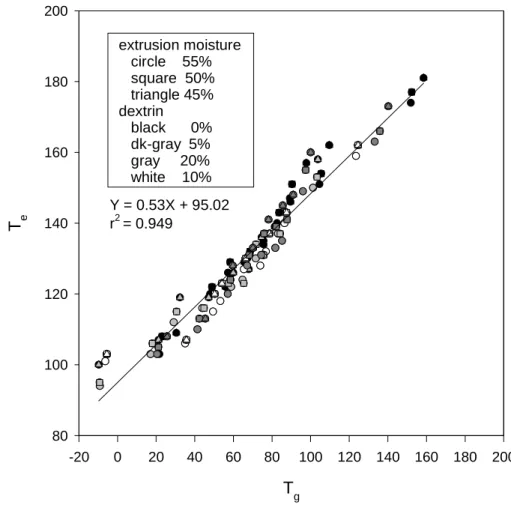

weight. Te increased linearly with Tgwith a correlation coefficient (r

2

) of 0.95 (Fig. 2). The regressed equation is

where Te is the initial expansion temperature ( o

C) and Tg is the glass transition temperature in

o

C. Thus Tgwas a good reference point for studying the expansion of pellet.

The data showed that Te were 20

o

~100oC above Tg (Fig. 3) at the experimental

conditions. This difference was similar to which (Te – Tg ≒ 10 ~ 70

o

C) occurred during

frying20. Since melting temperature is mostly 100oC higher than Tg, Te appears to be in

rubbery state. The value of (Te-Tg) increased as Tg decreased. Both increasing equilibrium

moisture content and adding dextrin resulted in an increase in (Te-Tg). More energy was

required to evaporate water at high moisture content. Thus, the value of (Te-Tg) increased with

moisture content. The expansion ratio (data not shown) was reduced by the softening effect of moisture. The addition of dextrin caused a formation of crust, which could hold more water

vapor and resulted in higher (Te-Tg). In this case, the expansion ratio was increased. For

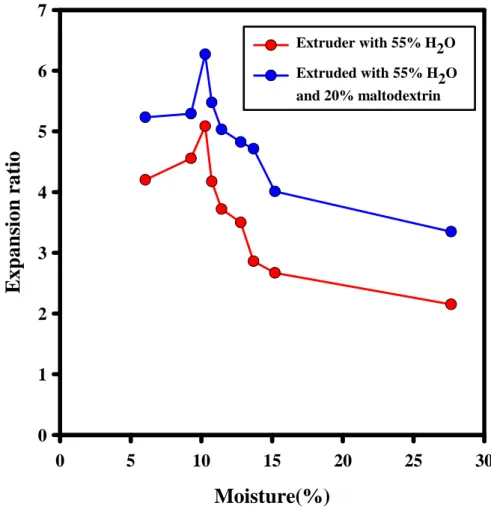

example, the expansion ratio was increased from 5.12 to 5.83, 6.07, and 6.56 by adding 5%, 10%, and 20% dextrin, respectively, for the pellet extruded at 55% water content. Lowering in-barrel water content resulted in lower expansion ratio. The expansion ratio of pellet with 20% dextrin extruded at 45% in-barrel water content was 4.41. Both extrusion condition and formulation affected the expansion behaviour of pellet.

There existed an equilibrium moisture (10%) yielding the maximum expansion of the pellet (Fig. 4). The expansion ratio was dramatically decreased when the moisture was raised from 10 to 15%. The expansion ratio might be related with mechanical properties of materials at rubbery state. The pellets were weak and soft with low elongation and low energy

to break point as the equilibrium moisture increased21. In other words, the pellets were not

completely elastic but acted more like stiff gel-like materials. Thus, it was more difficult to expand, which resulted in lower expansion ratio. The expansion ratio did not drop too much

when the equilibrium moisture increased from 15 to 25%. It was difficult to have a uniform size and distribution of air bubbles at high moisture content. As the moisture content was reduced from 10 to 5%, the pellet became brittle and harder for expansion. Therefore, the pellet yielded lower expansion ratio. Intrinsic viscosity affected the expansion ratio as shown in Fig. 5 for the 10% equilibrium moisture pellet extruded at 55% water content with

the presence of dextrin or not. The expansion ratio decreased linearly (r2 = 0.89) as the

intrinsic viscosity increased at the experimental conditions. In other words, the lower the molecular weight, the higher the expansion. Addition of dextrin reduced the average molecular weight as well as viscosity at rubbery state. The reduction in viscosity increased the

expansion20.

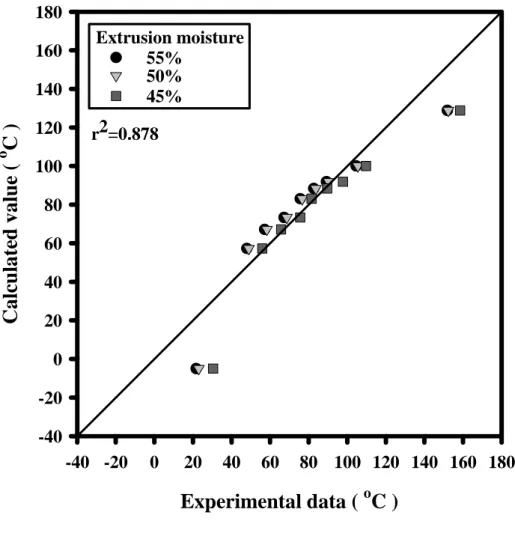

The pellets consisted of rice flour and water, and thus were considered as binary mixtures. Gordon-Taylor equation was used to fit the experimental glass transition temperatures for the samples without dextrin. Fig. 6 illustrates the comparison between the experimental data and calculated values. Although Gordon-Taylor equation was reported to

underestimate Tg of extruded corn meal

10

, the fitting was very well (r2 = 0.88). The regressed

value of k in equation 2 (Gordon-Taylor equation) was 0.245 which was almost exactly equal

to the ratio (0.242) of △Cpstarch(0.47 J/g.k) to △CpH2O (1.94 J/g.k) from literature

9

. The

results demonstrate that Gordon-Taylor equation can be used to predict Tg of the extruded rice

pellet. This may be due to low protein and fat content in rice flour. Thus, starch dominated the properties of pellet after extrusion processing.

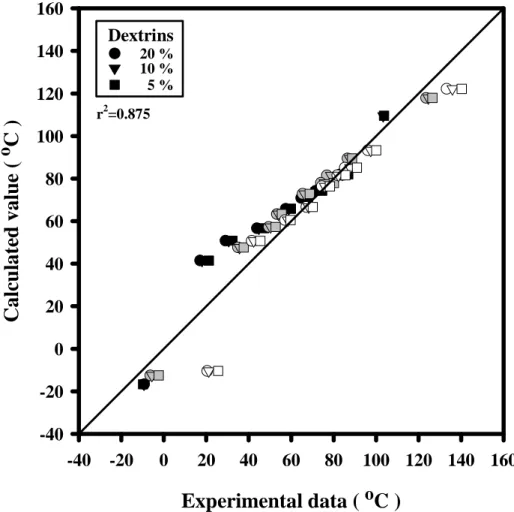

Once dextrin was added in the formulation, the pellets became ternary mixtures.

An equation has been developed to calculate Tgof ternary mixtures consisting of rice flour,

(5)

The ternary mixture was considered to be a linear combination of two binary mixtures. The

first term in equation (5) represented the binary mixture of water (w1) and rice flour (w2) and

the second term was for the binary mixture of water and dextrin (w3). The distribution of

water in the two binary-mixtures was assumed to be dependent upon the weight fraction of

rice flour and dextrin. Thus the terms of w1[w2/(w2+w3)] and w1[w3/(w2+w3)] represented the

distribution of water in two binary-mixtures, respectively. These terms were used to modify

Gordon-Taylor equation for calculating Tg of binary-mixtures. The total weight fraction (the

term in the square bracket) in each binary-mixture was used as a weight-factor for calculating

Tg of the whole system. Equation 5 appears to be a modified Gordon-Taylor eq’n, in which k1

and k2 was similar to the ratio of △Cpstarch/△CpH2O and △Cpdextrin/△CpH2O, respectively. It

is more complicated than the expanded Couchman-Karasz eq’n but much simpler than the

dual applications of Gordon-Taylor eq’n9. Fig. 7 illustrates the comparison between

experimental and calculated Tg’s with r2 of 0.88. Both the regressed values of k1 and k2 were

equal to 0.221. The regressed k1 was 8.7% lower than 0.242 as mentioned above. Again,

the starch dominated the property of pellet. When the literature data of dextrin with DE of 35

was used (△Cpdextrin = 0.53 J/g.k)

22

, the regressed k2 was 19% lower than the calculated value

(0.273). The high correlation coefficient (r2 = 0.88) indicated that equation (5) was

acceptable for predicting Tg of the pellet consisting rice flour, dextrin, and water.

ACKNOWLEDGMENT

] ) ( [ ) ( ) ( ] ) ( [ ) ( ) ( 3 3 2 3 1 3 2 3 2 3 1 3 3 2 3 2 3 1 1 2 3 2 2 1 2 1 3 2 2 1 2 2 1 3 2 2 1 1 w w w w w w k w w w w T w k w w w T w w w w w w w k w w w w T w k w w w T w T g g g g g + + + + + + + + + + + + + =This study is part of the project sponsored by the National Science Council of the Republic of China (project no. NSC 87-2313-B-002-067). The financial support is greatly appreciated.

REFERENCES

3. Kaletunc, G. and Breslauer, K.J. Glass transitions of extrudates: Relationship with

processing-induced fragmentation and end-product attributes. Cereal Chemistry 70 (1993)

548-552.

1. Levine, H. and Slade, L. Collapse phenomena: Aunifying concept for interpreting the behaviour of low moisture foods. In ‘Food Structure: Its Creation and Evaluation’, (J.M.V. Blanshard and J.R. Mitchell, eds), Butterworths Co., London (1988) pp. 149-180.

2. Noel, T.R., Ring, S.G. and Whittam, M.A. Glass transition in low moisture foods. Trends

in Food Science and Technology 1 (1990) 62-67.

8. Roos, Y. and Karel, M. Water and molecular weight effects on glass transitions in

amorphous carbohydrates and carbohydrate solutions. Journal of Food Science 56(6)

(1991) 1676-1681.

4. Fox, T.G. and Flory, P.J. Second-order transition temperatures and related properties of polystyrene. I. Influence of molecular weight. Journal of Applied Physics 21 (1950) 581

5. Gordon, M. and Taylor, J.S. Ideal copolymers and the second-order transitions of synthetic

rubbers I. Non-crystalline copolymers. Journal of Applied Chemistry 2(9) (1952) 493-500.

6. Tant, M.R. and Wilkeo, G.L. An overview of the nonequilibrium behavior of polymer

glasses. Polymer Engineering and Science 21 (1981) 874

7. Orford, P.D., Parker, R. and Ring, S.G. Aspects of the glass transition behaviour of

mixtures of carbohydrates of low molecular weight. Carbohydrate Research 196 (1990)

11

20. Della Valle, G., Vergnes, B., Colonna, P. and Patria, A. Relations between rheological

properties of molten starches and their expansion behaviour in extrusion. Journal of Food

13. Sperling, L.H. Glass-rubber transition behavior. Chap. 8 In ‘Introduction to Physical Polymer Science’. (L.H. Sperling, ed.), John Wiley & Sons, New York. (1993) P. 322.

14. Greenwood, C.T. Viscosity-molecular weight relations. In ‘Methods in Carbohydrate Chemistry Vol. IV’. (R.L. Whistler, ed), Academic Press, New York. (1964) pp. 179-188.

15. Mahanta, C.L. and Bhattacharya, K.R. Thermal degradation of starch in parboiled rice.

Starch/Stärke 41 (1989) 91-94.

16. Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, P.A. and Smith, F. Colorimetric

method for determination of sugars and related substances. Analytical Chemistry 28 (1956)

350-356.

11. Yeh, A.I. and Jaw, Y.M. Modeling residence time distributions for single screw extrusion

process. Journal of Food Engineering 35 (1998) 211-231.

12. AOAC Official Methods of Analysis 14th ed. (S. Williams ed.), Association of Official

Analytical Chemists, Washington, D.C. (1984).

9. Kalichevsky, M.T., Jaroszkiewicz, E.M. and Blanshard, M.V. A study of the glass

transition of amylopectin-sugar mixtures. Polymer 34(2) (1993) 346-358.

17. Lee, H.S. and Kim, W.N. Glass transition temperatures and rigid amorphous fraction of

poly (ether ether ketone) and poly (ether imide) blends. Polymer 38(11) (1997)

2657-2663.

18. Van Soest, J.J.G. and Knooren, N. Influence of glycerol and water content on the structure

and properties of extruded plastic sheets during aging. Journal of Applied Polymer Science

64 (1997) 1411-1422.

10. Brent, J.L. Jr., Mulvaney, S.J., Cohen, C. and Bartsch, J.A. Thermomechanical glass

transition of extruded cereal melts. Journal of Cereal Science 26 (1997) 301-312.

22. Orford, P.D., Parker, R., Ring, S.G. and Smith, A.C. Effect of water as a diluent on the glass transition behaviour of malto-oligosaccharides, amylose and amylopectin.

International Journal of Biological Macromolecules 11(2) (1989) 91-96.

molecular mass on the properties of extruded thermoplastic starch. Polymer 37(16) (1996)

3543-3552.

19. Slade, L. and Levine, H. Beyond water activity: Recent advances based on an alternative

approach to the assessment of food quality and safety. CRC Critical Reviews in Food

Figur e Captions

Figure 1. The dependence of glass transition and expansion temperature on equilibrium moisture. The pellet was extruded at 55% in-barrel water content.

Moistur e ( % )

0 5 10 15 20 25 30T

e

(

o

C

)

80 100 120 140 160 180 200T

g

(

o

C

)

-20 0 20 40 60 80 100 120 140 160 180 Te ( 55% H2O + 20% dextr in ) Tg ( 55% H2O in extr usion ) Tg ( 55% H2O + 20% dextr in ) Te ( 55% H2O in extr usion )Figure 2. Expansion temperature increased linearly with glass transition temperature. r2=0.949 r2=0.949 Tg -20 0 20 40 60 80 100 120 140 160 180 200 T e 80 100 120 140 160 180 200 extrusion moisture circle 55% square 50% triangle 45% dextrin black 0% dk-gray 5% gray 20% white 10% Y = 0.53X + 95.02 r2 = 0.949

Figure 3. Equilibrium moisture affected the difference between expansion and glass transition temperature.

pellet extr uded with 55% H2O

pellet extr uded with 55% H2O and 20% dextr in

Moistur e (% )

0 5 10 15 20 25 30T

e-T

g

(

o

C

)

0 20 40 60 80 100 120Figure 4. Expansion ratio as a function of equilibrium moisture content.

Moistur e(% )

0 5 10 15 20 25 30E

x

p

a

n

si

o

n

r

a

ti

o

0 1 2 3 4 5 6 7Extr uded with 55% H2O and 20% maltodextr in Extr uder with 55% H2O

Figure 5. Expansion ratio decreased as intrinsic viscosity increased. [η] 80 85 90 95 100 105 110 115 120 E x p a n si o n r a ti o 3 4 5 6 7 0 % 5 % 10 % 20 % Dextrin r2=0.886

Figure 6. Comparison of experimental and calculated glass transition temperature for the pellet consisting of rice flour and water.

r 2=0.878

Exper imental data (

oC )

-40 -20 0 20 40 60 80 100 120 140 160 180

C

a

lc

u

la

te

d

v

a

lu

e

(

oC

)

-40 -20 0 20 40 60 80 100 120 140 160 180 55% 50% 45%Figure 7. Comparison of experimental and calculated glass transition temperature for the pellet consisting of rice flour, water, and dextrin.

r2=0.875

Exper imental data (

oC )

-40 -20 0 20 40 60 80 100 120 140 160

![Figure 5. Expansion ratio decreased as intrinsic viscosity increased.[η]80859095100105110115120Expansion ratio34567 0 % 5 % 10 % 20 % Dextrinr2=0.886](https://thumb-ap.123doks.com/thumbv2/9libinfo/8845025.240202/33.893.150.638.193.700/figure-expansion-decreased-intrinsic-viscosity-increased-expansion-dextrinr.webp)