行政院國家科學委員會補助專題研究計畫成果報告

※※※※※※※※※※※※※※※※※※※※※※※※

※

※

※網路分析模式在供應鍊網路管理上應用之探討

※

※

※

※

※

※※※※※※※※※※※※※※※※※※※※※※※※

計畫類別:þ個別型計畫

□整合型計畫

計畫編號:NSC 89-2416-H-002-045-

執行期間:88 年 08 月 01 日至 89 年 07 月 31 日

計畫主持人:陳靜枝 副教授

本成果報告包括以下應繳交之附件:

□赴國外出差或研習心得報告一份

□赴大陸地區出差或研習心得報告一份

□出席國際學術會議心得報告及發表之論文各一份

□國際合作研究計畫國外研究報告書一份

執行單位:國立臺灣大學資訊管理學系

中華民國 89 年 10 月 30 日

行政院國家科學委員會專題研究計畫成果報告

網路分析模式在供應鍊網路管理上應用之探討

Applying Networ k Flow Contr ol Model and Pr oduct Tr ee

Str uctur e in Supply Chain Networ k Management

計畫編號:NSC 89-2416-H-002-045

執行期限:88 年 08 月 01 日至 89 年 07 月 31 日

主持人:陳靜枝

國立台灣大學資訊管理學系

計畫參與人員:陳書儀 國立台灣大學資訊管理學系

v 中文摘要 由於全球經濟體系的成形,企業無論大小都 感受到來自全世界的競爭壓力。不僅如此,競爭壓 力更進一步帶來對降低成本及快速反應的要求。因 此,企業不僅必須加強本身的生產技術與成本控 制,更必須在整個供應鏈網路管理中創造更高的價 值及新的市場機會。然而,目前許多關於供應鏈的 研究,都局限在觀念與方法的傳遞上,而較少見提 出量化標準的探討;即使有數量化模型的建立,也 大都較為複雜,雖然能適用於特定情況,卻不夠簡 潔,也較不適於對整體供應鏈作簡明的描述與性質 分析。在前述情況下,本研究希望提供一種較簡單 且一般化的方式,使供應鏈網路能應用傳統網路流 量中的演算法,來求解供應鏈網路中一些基本且重 要的決策參數與生產路徑。因此本研究利用供應鏈 網路與產品結構樹之特性,將原始的供應鏈網路加 以轉換,使得轉換後的供應鏈網路能直接應用最短 路徑演算法,求解包括最低成本、網路內最低成本 之生產路徑等重要的決策特性。因此,本研究之結 果只要經過轉換,就可以幫助實務界及學術界更瞭 解供應鏈之特性及應用。 關鍵詞:供應鏈網路、最短路徑問題、產品結構樹。 v Abstr actThe design and operation of supply chains (SCs) have become key issues while companies are facing more competitive global environments today. However, SC management is rather difficult with distinct complexities and uncertainties. Moreover, the related studies are either conceptual, lack of mathematical representations or too specific and complex to put in use by others. This study tries to stand in between with the construction of a general model to estimate the optimal allocation in a SC. With the help of the shortest path algorithms found in network flow models and the product tree of the final product, the mathematical representation can provide guidelines in SC decisions with little modification for practitioners.

Keywords: Supply Chain Network, Shortest Path

Problem, Product Tree. v Intr oduction

In a fast changing world, it is more and more important for a company to respond as quickly as possible so as not to fall behind its competitors [6]. To become responsive, however, a company has to work not only on its own performance but also on the management of the SCs of the products. There are quite a few studies focusing on SC management (SCM). However, there is still a lack of a general model for a SC. This problem makes it difficult for researchers to discuss and to discover certain problems in SCM. This study tried to build a general SC model with the help of maximum flow algorithms seen in network flow models [1]. With this SC model, a manager can find the maximum flow in his SC and makes the most use of the chain.

v Liter atur e Review

In this section, studies are reviewed and classified into the above two categories: concept- and model-oriented. There are many studies falling into the concept-oriented category. Lee and Billington [7] discussed the pitfalls and opportunities found in managing SC inventory. Fisher [5] constructed a grid to identify the fitness of a product and the corresponding SC. Billington [3] found that different entities in a SC lack an integrated angle to locate the bottlenecks and problems in the SC. Lee et al. [9] identified the so-called “bullwhip effect” found in many SCs. It's about that the demand order variabilities will be magnified as these demands go upstream in the SC. However, as mentioned, most of these observations are descriptive in nature.

The model-oriented studies usually give accounts of specific examples and cases in more details, sometimes including the models built. The paper of Lee and Billington [8] serves as an example of model-oriented studies. They discussed the needs of model support analysis, recorded the development process of a real case of HP DeskJet printer, and showed the lessons learned. Arntzen et al. [2] is

another example. They described the global SC model at DEC. The analysis and construction processes of the model are given along with some formulation indices and solution methods used. The impact of the model is also discussed. These cases, especially the development processes, are very helpful to any companies that want to build their own SC models. However, for most mid- to small-sized companies, it is still difficult to get handy help. Chen and Chern [4], however, had tried another way to build some general yet mathematical algorithms for SC. Nevertheless, such studies are just emerging and are still called for. v Model For mulation

To answer the call, a general model is built here utilizing the shortest path algorithms as a starting point. Since the concern is not at the shortest path algorithm itself, any algorithms, such as the classic algorithm from Dijkstra or other modified ones can be used as in [1]. Before the construction of the SC model, some terms and notations must be defined.

(

x)

y x y x y N AG , : A SC network or a product tree can be

represented by a directed graph

(

x)

y x y x y N A G , , in which x y N and x yA are the set of all nodes and all arcs in x y

G ,

respectively. Since the original SC graph needs to be converted before applying the shortest path algorithm, superscript x indicates the number of steps counted while converting the original graph, and subscript y

denotes what G stands for. For example, 1

SC

G

represents a SC network after being converted once and 0

PT

G a product tree in its original configuration.

By definition, x is an integer and x≥0.

(i, j): The directed arc from node i to node j in x y

A.

Production function: If a node performs processing work in a SC, it is said to have the production function (P-function). By definition, a node with P-function transforms components it receives into a different component or components in the product tree item set,

0

PT

N .

Production node: If a node performs P-function only, and all components sent to this node are necessary in producing outward items, it is a production node (P-node). A P-node can be further categorized as an internal or external P-node. An internal P-node not only uses the components it receives as materials for production, but also takes the items it produces again as materials to further produce other items. (All items mentioned here can be found in the product tree.) In other words, in the product tree hierarchy, an internal P-node produces product items one or more levels higher than those product items it receives. On the other hand, an external P-node produces items only one level higher (in the product tree) than what it receives. That is, an external P-node uses only what it receives as materials to produce items without using what it produces as materials. A one-item P-node is a P-node that ships out exactly one kind of item.

Distribution function: If a node ships out what it receives without processing them, it has the distribution function (D-function).

Distribution node: If a node performs D-function only, it is a distribution node (D-node). A node is further called a one-item D-node, if it is a D-node and it ships out exactly one kind of item.

x

Sϖ: The shortest sub-network vector generated in

(

x)

y x y x y N AG , from node s to t. n

( )

Sϖx is used to denote the "length" of the shortest sub-network in xSϖ.

x ij

c : The cost incurred for i to process an item and/or

deliver the item between (i, j) in

(

x)

y x y x y N A G , . x ij c isthus defined that it includes only the added costs but not the material cost except for the raw material providers.

COi: The product component produced/shipped by

node i.

ni,j: The number of COi needed to produce one COj.

It is worth mentioning that any node in a SC can possibly be at the same time with production function and distribution function. Before modeling a SC, two extra virtual nodes and some arcs have to be added in the SC. Node s and t represents the source and sink node respectively. There should also be some arcs added to link s and t to other nodes. A node i without arcs linked into it, that is, a starting node without suppliers in a SC, should add (s, i) with csi = 0. A node j without arcs linked to other node, that is, an ending node without demand nodes in a SC, should add (j, t)

withcjt = 0. GSC0

(

NSC0 ,ASC0)

is formed from the originalconfiguration of the SC and these added nodes and arcs. With these definitions, a SC, 0

(

0 0)

, SC SC SC N A

G , can

be modified and solved by the shortest path algorithm. Step 1. Differentiate the P-function from the one-item D-function by splitting node i into sub-nodes.

Step 1-1. If node i in 0

SC

N performs both P- and

D-functions, split i into one single P-subnode and one or more one-item D-subnodes,. If i is a D-node but supplying more than one kind of item, it only needs to be divided into several one-item D-subnodes. However, if iis already a P-node or a one-item D-node, nothing is done for node i in this step. Properly add and assign arcs into/from these sub-nodes that the flows are the same as they were. Arc (j, i) should be split to (j, i_1)

to (j, i_k) if node i is split to k sub-nodes. Step 1-2. Create 1

(

1 1)

, SC SC SC N A

G to denote

changes and to include new sub-nodes and arcs added or moved for this step.

Step 2. Make all P-nodes become one-item external P-nodes.

Step 2-1. Split all P-node i in 1

SC

N into one or

more external P-nodes. If iis an internal P-node, split i

into sub-nodes that acts as external P-nodes. Properly add and move required links. If an item Ii_p, where i_p

is a sub-node of i, is internally produced and used only as internal material, that is, Ii_p is not supplied to nodes

other than sub-nodes of i, 2 _ , _pi q i c should be zero.

Step 2-2. Split now all external P-nodes into one-item external P-nodes. Add and move arcs as necessary. Step 2-3. Create 2

(

2 2)

, SC SC SC N A G to denotechanges and to include new sub-nodes and arcs added or moved for this step.

Step 3. Combine the arcs linking into the same P-node in 2

SC

N and also combine nodes

providing these arcs into a new node set. Sum up downstream the corresponding costs.

Step 3-1. Check every P-node i in 2

SC

G . Combine

nodes with arcs linking into i to become a new node set

K, and also combine these arcs into a new arc (K, i)

that 3

Ki

c =

∑

j ji

c2. Properly add and move required

links. Step 3-2. Create 3

(

3 3)

, SC SC SC N A G to denote changesfor this step.

Step 4. Apply the shortest path algorithm, such as Dijkstra's or other [1] on 3

SC

G and solve for the

shortest sub-network 3 Sϖ. Step 5. Use 3 Sϖ, 3

(

3 3)

, SC SC SC N A G ,(

2 2)

2 , SC SC SC N A G , and 1(

1 1)

, SC SC SC N A G to expand Sϖ3 back into the sub-network 0Sϖ in 0

(

0 0)

, SC SC SC N A

G .

v Illustr ating Example and Manager ial Implications

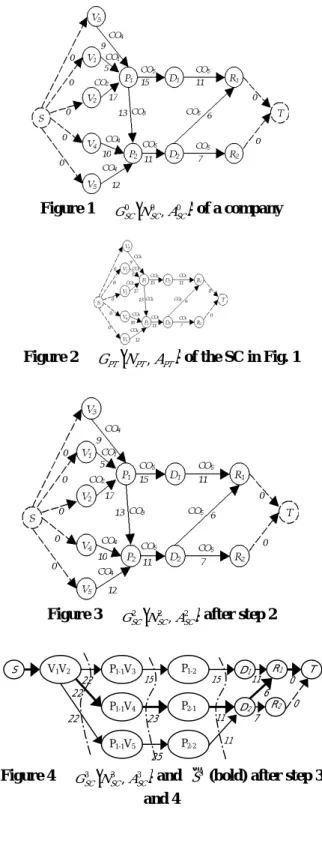

This section provides a simple example for all the steps in the previous section to show the feasibility of the formulation. There are also some managerial implications after the example. An example SC,

(

0 0)

0

, SC SC SC N A

G , is shown in figure 1 with a product tree,

(

PT PT)

PT N A

G , , shown in figure 2. COx above or at the

right side of each arc (i, j) are used to denote the components shipped from node i to j. The number under or at the left side of each arc is the cij of each (i, j). It's easy to tell that P1 and P2 both perform

P-functions. To execute step 1 and 2, P1 should be spilt

into sub-nodes P1-1 and P1-2 in order to perform

one-item external P-function, and P2.becomes P2-1 and P2-2.

The related arcs should be added as shown. The SC network, 2

(

2 2)

, SC SC SC N A

G , after step 2 is shown in figure

3 and consists of only distribution nodes and one-item external production nodes. In turn, it’s easy now to adopt step 3 to combine the costs for all these one-item external production nodes, and 3

(

3 3)

, SC SC SC N A

G is

available in figure 4. Apply the shortest path algorithm now, and get 3

Sϖ =

{

S,V1V2,P1−1V4,P2−1,D2,R1,T}

. Backtrack from Sϖ3, Sϖ0 is shown in figure 5 with boldarcs.

The shortest path found in a network is the shortest “sub-network” (in terms of cost, time, or actual distance) from a source node to a sink node. Hence it is suitable to be used in a SC to find the

lowest cost, whatever it represents, production sub-network in the SC. In a sense, it is like the critical path in the SC, and a manager can arrange the allocation of resources/orders in his SC according to the critical sub-network. Figur e 1 0

(

0 0)

, SC SC SC N A G of a companyFigur e 2 GPT

(

NPT,APT)

of the SC in Fig. 1Figur e 3 2

(

2 2)

, SC SC SC N A G after step 2 Figur e 4 3(

3 3)

, SC SC SC N AG and Sϖ3 (bold) after step 3 and 4

D

1 0 7 11 11 6 11 15 25 23 15 2222 0 V1V2 P1-1V3 P2-2 P2-1 P1-2 P1-1V5 P1-1V4 D1 R2 R1 D2 22 T 0 SFigur e 5 0 Sϖ in 0

(

0 0)

, SC SC SC N A GIt’s also possible to combine the consideration of cost and time. By properly assigning weighted factors for financial cost and temporal cost respectively, a combined cost of both time and money can be set. Utilizing the model presented here, a critical sub-network with both considerations can be found.

It is worthwhile to discuss the relating issues of the model constructed in this study to provide some insights. First of all, the model is itself general and easy to build without a large amount of money or professional knowledge. The point is important because many companies, especially in Asian regions, are small to middle size businesses. For this reason, it is not possible for them to hire or introduce complex modeling staff or technique to enhance their management in SCs. The model developed here is helpful for them to adopt and modify into their own business considerations. Second, with the help of the shortest path problem algorithm, the model can be used to generate an initial result of the possible “shortest” sub-network to produce a product in a SC. It is especially important when there is no time to develop complex models while the market are demanding fast response, or while the managers want to get an approximate yet quantitative idea about the shortest production cycle or the lowest cost possible to produce a product in their SCs. At last, because the model is split in a “product tree” fashion to apply the shortest path algorithm, it can be seen that there seems to be different “sections” or “cuts” existing in the SC. The observation is furthered by examine the different levels in a product tree that these levels have some relationships with the cuts in the supply SC networks. It is thus possible to find a way to optimize in each cut to still approach some degree of optimal solution for the whole SC. It is worth studying for the researchers or managers. By examine their own SC models, companies may get some insight to better understand and manage their SCs.

v Conclusion

The general SC model constructed in this report is a useful and practical model in many ways. First, it provides a simple yet practical fashion to build a company's SC model. With such a mathematical model and the formulation developed here, it is easy to apply the shortest path algorithms. The result is a

quantitative basis for decisions regarding the fastest production cycle, the lowest cost production path, or a weighted consideration of the both--simply adjust the weighted factors. Second, in the academic search for a more general model to represent and discuss the management of SCs, this model and formulation serves a good starting point. It is possible to add more new considerations into the formulation to improve its representative ability. Since most network flow models are deterministic, it's important to revise the formulation with some uncertainties to improve its reliability. After all, a general and applicable mathematical SC model is always called for in this competitive world. When more potential efficiency in SCs is found though such a model, it is possible for businesses everywhere to better enhance human life. v Refer ences

[1] Ahuja, Ravindra K., Thomas L. Magnanti, and James B. Orlin, Network Flows: Theory, Algorithms, and Applications, Prentice-Hall, 1993.

[2] Arntzen, Bruce C., Gerald G. Brown, Terry P. Harrison, and Linda L. Trafton, “Global Supply Chain Management at Digital Equipment Corporation,”Interface, Vol. 25, No. 1, January-February 1995, pp.69-93.

[3] Billington, Corey, “Strategic Supply Chain Management,”OR/MS Today, April 1994, pp.20-27.

[4] Chen, Shu-Yi, and Ching-Chin Chern, “Shortest Path for A Supply Chain Network,”Proceedings of the 4th Asia Pacific Decision Sciences

Institute Conference, Shanghai, China, June 9-12, 1999, pp.579-582.

[5] Fisher, Marshall L., “What Is the Right Supply Chain for your Product?”Harvard Business Review, March-April, 1997, pp.105-116. [6] Ives, Blake, Sirkka L. Jarvenpaa, and Richard O.

Mason, “Global Business Drivers: Aligning Information Technology to Global Business Strategy,”IBM System Journal, Vol. 32, No. 1, 1993, pp.143-161.

[7] Lee, Hau L., and Corey Billington, “Managing Supply Chain Inventory: Pitfalls and

Opportunities,”Sloan Management Review, Spring 1992, pp.65-73.

[8] ________, and ________, “Material Managing in Decentralized Supply Chains,”Operations Research, Vol. 4, No. 5, September-October 1993, pp.835-847.

[9] Lee, Hau L., V. Padmanabhan, and Seungjin Whang, “The Bullwhip Effect in Supply Chains,”Sloan Management Review, Spring 1997, pp.93-102.