行政院國家科學委員會專題研究計畫 成果報告

應用 4D 動態模擬於工作空間最佳化配置之研究

研究成果報告(精簡版)

計 畫 類 別 : 個別型

計 畫 編 號 : NSC 99-2218-E-151-001-

執 行 期 間 : 99 年 01 月 01 日至 99 年 12 月 31 日

執 行 單 位 : 國立高雄應用科技大學土木工程系

計 畫 主 持 人 : 吳翌禎

報 告 附 件 : 出席國際會議研究心得報告及發表論文

處 理 方 式 : 本計畫可公開查詢

中 華 民 國 100 年 03 月 28 日

一、前言:

隨著新工程技術、新資訊技術、新管理方法的不斷出現,營建工程計畫規模

不斷地擴大、建築形式也日益複雜,如何在計劃執行過程中,提出合理施工計畫、

精確掌握施工進程、有效地運用工地資源以及迅速地進行工作區域動線佈置及安

排,以縮短工期、降低成本、提高品質,這些都是業者和相關工程管理人員的共

同努力目標。良好的施工規劃可使營建工程施工順暢並提升其生產效率,然而國

內目前營建業之工作空間規劃卻大多仍需依賴工程師的經驗,其利用二維平面圖

來規劃整個建地之相關工作區域配置,多著重於靜態空間分配,而未考量整體工

程作業工項與相關活動資源(人員、設備、物料)互動所需之空間使用效益。實

際上,工作空間之需求會隨著工程的進行而產生變化,所以進行工作空間規劃時,

必頇將時間因素分別納入工程可用空間與工作空間需求的考量,對於營建工程來

說,空間是一種有限資源,不同的工班會在同一空間施作而互相衝突,物料堆置

空間也常常會與工人施作空間重疊,甚至工程設備(如起重機、吊車、鑽孔機具、

貨車)運作時,亦會影響可用空間的大小。根據Sanders et al. [1]的研究指出,空

間衝突亦是造成營建生產力損失的主要問題之一,因為工作空間造成的生產效率

損失高達65%,通道阻礙使生產力損失達58%,空間衝突除了會影響施工進行與

施工效率,而造成工期延宕問題之外,對於施工安全性也有重大影響。如何全面

性的考量相關工程因素,進行工作空間最佳化配置、動線規劃及動態調整工作空

間範圍,此乃工作空間規劃的困難處之一,也是目前缺乏有效輔助工具的主要原

因之一。

二、研究目的:

營建工程中組織團隊規模龐大且專業分工介面多而複雜,其相關活動資源物

件在工程施工階段常會產生空間衝突或是動線不適的問題造成施工效率折損,而

直接影響生產力的表現,為了協助相關工程人員解決上述工作空間衝突及動線規

劃問題,以降低生產力的損失,本研究運用4D動態模擬技術視覺化呈現空間衝

突分析的過程與結果,利用Microsoft VB.NET程式軟體開發一4D視覺化空間衝突

分析模組,在3D模型環境中建立工作空間靜態及動態移動模式及衝突呈現的基

本模式,改善二維平面的空間衝突分析無法呈現實際工作空間狀態的缺點;此模

組考量各工程物件之相關影響因子,建置空間衝突偵測功能,透過不同顏色及警

示方式來呈現不同衝突之狀況;考慮實際工程中,人員的工作空間、設備的移動

及物料搬運等位置的變換行為,導入相對速度參數來呈現人員、機具移動速度的

不同,以動態方式模擬工作空間的變化及空間衝突產生的過程。

三、文獻探討

在工作空間的相關理論中,Riley及Sanvido[2]將作業空間類型與作業空間的

概念分類,更加以闡述在複雜的工地中空間使用行為模式之分類。而Akinci等人

[3, 4]在2002年則利用時空衝突的概念建立了空間衝突分析的機制與空間衝突的

分類,清楚將衝突類型分成五類,分別是設計衝突、安全上的危險、損壞衝突、

擁擠、無影響,並且認為工作空間的需求隨著時間而改變,同時衝突的比率不同

亦造成不同程度之影響,Akinci等人更提到衝突作業造成生產力的降低、增加無

附加價值之作業、中斷工作流程、延遲作業的開始時間。而關於國內相關研究部

分,像是吳俊達[5]於其研究中發展一建築工程施工作業空間規劃與衝突分析流

程,運用目前營造廠普遍使用的進度排程軟體Microsoft Project與電腦輔助繪圖軟

體Autodesk AutoCAD作為作業空間規劃的平台,以進行作業空間衝突之分析與

解決對策之研擬。紀宛君[6]建置一大型結構實驗室資源管理輔助系統以虛擬實

境(Virtual Reality)配合平面資訊的方式呈現,管理者得以和虛擬場景溝通,達

到互動的功能,除了可進行空間管理與場地配置,同時也使空間規劃資訊和實驗

排程資訊銜接上,提供空間管理與衝突檢測的機制。而近期研究中,許多研究皆

利用空間語法(Space Syntax)進行最佳化的空間配置與建議。如,仲闓立[7]利

用空間語法之概念將工程CAD圖面轉換成對應之拓樸結構,再利用空間分析因

子(Spatial Analysis Parameters)來評估空間屬性,當空間衝突發生時,利用空

間屬性進行衝突分析。

有關4D動態模擬技術方面的研究,大約在1990年左右,就已經有一些研究

人員開始致力於虛擬實境及視覺化技術應用於施工過程上的研究,雖然當時4D

營建管理系統尚未成形,但是虛擬實境的應用卻是發展4D營建管理系統的一個

重要概念,像是Retik在1993年發表的文章中就提出利用非沉浸式的虛擬實境技

術來模擬及呈現整個施工過程[8],然而所謂4D時代的來臨,一般會從史丹佛大

學的CIFE研究中心在1990年中期開始推動了幾個成功的4D CAD相關研究案例

開始說起。CIFE當時建置了幾個相當成功的4D模型案例,例如San Mateo Health

Facility[9, 10]計畫及Walt Disney Imagineering計畫,就相當引人注目,這些成功

的研究案例,除了鼓舞了CIFE持續且積極地投入4D的研究之外,也帶動了一連

串的研究風潮。如Akinci等人於2002年應用4D營建管理系統於空間規劃上,他們

所開發的4D Workplanner Space Generator和4D Workplanner Time–Space Conflict

Analyser兩個系統,就是利用4D營建管理系統來模擬分析工程空間及時間上的衝

突[11]。而國內的相關研究如2006年呂明娟[12]在其碩士論文中建置建築結構工

程4D模擬系統,希望透過視覺工具預先模擬時間與空間同時發展的細節,在工

程施工前發現設計衝突點,並加以管制,降低施工中設計變更的可能性,進而提

高生產力。2006年謝尚賢等人於國立台灣大學與中鼎工程公司的建教合作計畫中

開發了一套名為Construction Director的4D營建管理系統[13, 14],其可結合專案

時程資料及3D模型,隨時間的移動以動態方式模擬工程中不同階段的施工狀態。

2008年吳翌禎等人[15]於研究中建置一視覺化專案管理系統,應用4D

+Multi-

Data-View展示概念[16],希望透過4D動態模擬及相關工程屬性之多維度視覺化

展示及查詢,協助工程監管單位進行工程專案管理。

四、研究方法

本研究主要目的是設計一4D視覺化空間衝突分析系統來應用於分析及偵測

空間衝突問題,此系統可讓工程規劃人員能透過視覺化的展示平台,有效率的進

行工程空間配置及動線規劃,減少衝突問題,進而提昇整個工程專案之效率。本

研究擬將研究內容分為資料蒐集與文獻回顧、空間衝突分類及影響因子定義、系

統分析與設計、雛形系統實作及系統測試與總結報告撰寫,研究步驟如圖一,其

內容分述如下:

資料蒐集與文獻回顧 雛形系統實作 空間衝突分類 及影響因子定義 系統分析與設計 系統測試與總結報告 撰寫 工作空間配置與動線規劃 4D動態模擬 系統分析 系統設計 圖一、研究步驟(1)資料蒐集與文獻回顧

文獻回顧為研究論文撰寫的過程中不斷進行的程序,一般來說文獻回顧的工

作包括了文獻收集以及整理,對於文獻收集過程中主要包括幾項重要的要素,包

括文獻的來源分析、查詢方式等等,在研究初期對於研究領域尚未清楚的認知與

瞭解時,搜尋技巧的掌握會加快文獻收集的速度及精準度,而對於文獻整理的工

作來說是較為耗時耗力的,不過研究架構就必頇在這些文獻中進行不斷的整理與

思考中學習與形成。本研究文獻回顧的重點是:(1)蒐集整理工作空間配置與動

線規劃之相關技術與研究。(2)蒐集整理4D動態模擬之相關技術與研究。(3)適合

本研究當作案例分析與比較之文獻案例資料。

(2)空間衝突分類及影響因子定義

本研究參考Akinci et al. [3]的論文將空間衝突類型分為四類,分別是設計衝

突、安全上危險、損壞衝突、擁擠,並且考慮工作空間需求會隨著時間的改變而

變化,且在同時間也會有不同的空間衝突產生,形成衝突的比率不同亦會造成不

同程度的影響。這四類的空間衝突種類定義如下:

設計衝突:工程中之分項工程通常分屬不同設計部門,在各自發展設計圖說

的狀況下,複雜的建築、結構、水電、環控、消防等設施,在空間配置上常

會發生介面衝突。例如,機電設備設計空間不足安裝空間緊靠結構體、管線

交疊造成天花板高度不足等。

安全上衝突:工區中具有動能或活動中的機具設備與人員的工作空間發生衝

突因而產生危險。例如,工程車輛行駛動線上與其他機具衝突、起重機吊裝

作業範圍內與其他作業人員空間重疊、挖土機的工作範圍中有其他工項進行

等。

損壞衝突:為執行某工程項目必頇損壞已完成工項,造成重工的情況。例如,

設備搬運動線上的通道或門無法讓設備通過必頇拆除。

擁擠:工作需求空間不足或重疊。例如,物料儲存空間太小造成物料堆置重

疊、預計放置物料的地點被佔用等、室內裝修工程材料堆置影響人員通行及

物料搬運、施工便道同時有多輛工程車輛進出等。

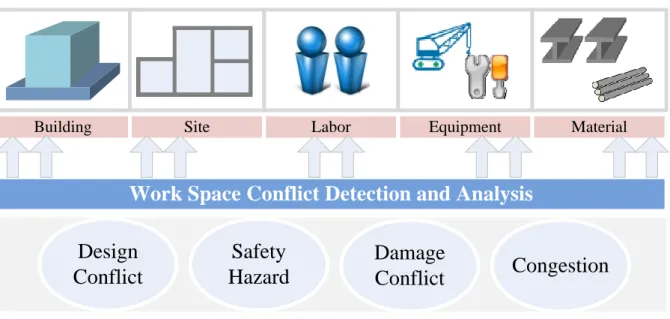

本研究從相關文獻與工程實務中可以歸納出營建工程施工過程中可能影響

空間配置及動線規劃之工程物件,包含建地、建物、人員、設備、物料等五大項,

其說明及範例,如表1 所述。

表1 五大工程物件 工程物件 說明 範例 建 物 我施工之建築物相關構件。 柱、梁、牆、門、窗…等。 建 地 工區基本空間規劃。 施工區域、物料存放區、工地道 路…等等。 人 員 參與工程之相關人員。 工人、監督人員、警衛…等等。 設 備 完成建物所需之工具、機械 設備等。 卡車、起重機、吊車、幫浦…等等。 物 料 施工所需物件。 H型鋼、鋼筋、水泥、模板…等等。(3)系統分析與設計

本研究主要目的即是應用建築資訊模型建置一4D視覺化空間衝突分析模組

來偵測及分析空間衝突問題。系統架構如圖一所示,最底層為建築資訊模型,本

研究希望結合工程相關資訊來協助更精確地進行空間衝突偵測與分析,其包含

3D物件模型、排程之時程資料、工程物件屬性、資源指派資料及本研究所制訂

的工作空間資料模型。第二層為Bentley MicroStation為主要視覺化展示平台。第

三層為本研究所開發之視覺化空間衝突分析模組,可進行設計衝突、安全上危險、

損壞衝突及擁擠等衝突狀況偵測與分析。

圖二 4D視覺化空間衝突分析模組之系統架構在進行工作空間衝突分析時,工程物件可以區分為靜態物件與動態物件兩大

類,靜態物件如建物、建地、定置的機具設備、堆置的物料、停放的車輛、限定

工作範圍內的人員等。動態物件如走動的人員、操作中的機具設備、搬運中的物

料、行駛的車輛等。本研究所定義之工作空間包含各工程物件在不同狀態下的本

身物件空間、延伸的操作空間及安全空間,並分成靜態工作空間與動態工作空間

兩種,說明如下:

靜態工作空間-以淺藍色顯示

是指固定於某位置點的靜態物件之工作空間,進行衝突分析時該空間不會變

動。如建築物、鄰房、施工架佔用空間、堆置的鋼筋空間、堆置的模板空間、定

置機具的運轉空間、停放的車輛空間、限定範圍內的人員工作空間等等。

動態工作空間-以橙色顯示

是指工區中動態物件之工作空間,必頇隨時間及空間變動來間進行衝突偵測

與分析。如搭設中施工架空間、搬運物料通行空間、活動式機具運轉空間、行駛

中車輛的安全空間、走動人員的工作空間等等。

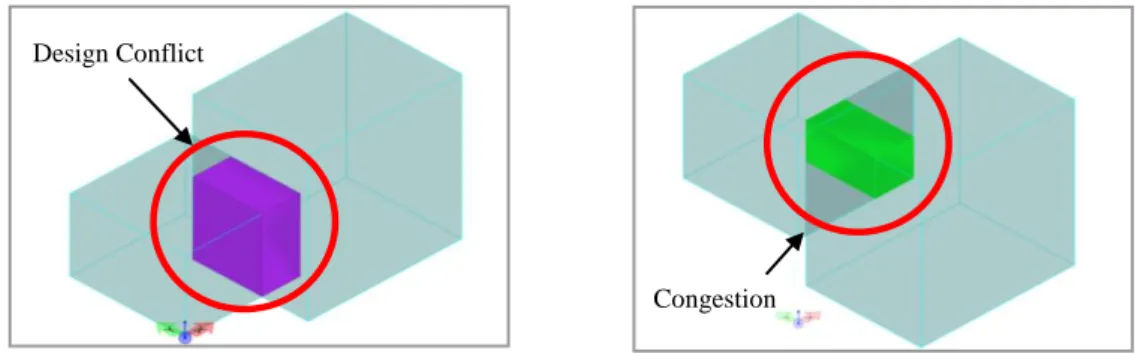

表2 工作物件狀態顏色表 工程物件 顏色 靜態物件 動態物件探討上述靜態工作空間與動態工作空間的交互衝突狀態,將空間衝突呈現方

式歸類為三種基本模式加以說明,並定義不同空間衝突種類的呈現顏色。如表2

所示,空間衝突的模擬過程中,為區分靜態工作空間、動態工作空間以及不同種

類的空間衝突的顯示狀況,本研究定義不同顏色及警示方式來呈現,除了讓使用

者容易分辨發生工作空間衝突的位置、大小及形狀外,亦可分類不同空間衝突屬

性。

表3 空間衝突種類顏色與空間衝突屬性表 顏色 衝突種類 靜態-靜態 動態-靜態 動態-動態 紫色 設計衝突 介面衝突 無 無 紅色 安全上衝突 無 無 機具與人員 黃色 損壞衝突 無 設備搬運與結構體 無 綠色 擁擠 物料與物料 人員與物料 機具與機具

(4)雛型系統實作

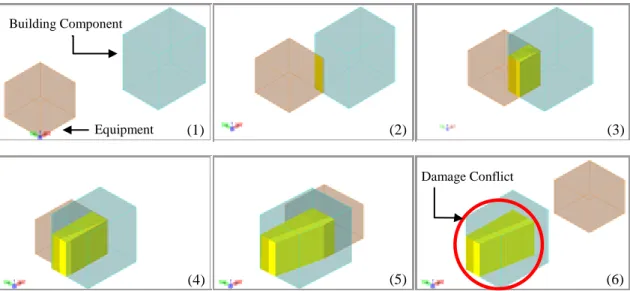

靜態工作空間與靜態工作空間衝突模式

靜態工作空間與靜態工作空間可能發生空間衝突的狀況有設計衝突(例如,

機電設備設計空間不足安裝空間緊靠結構體、管線交疊造成天花板高度不足等)

、

擁擠(例如,物料儲存空間太小造成物料堆置重疊、預計放置物料的地點被佔用

等)。圖三(a)呈現的是設計衝突,以紫色顯示在2個藍色靜態工作空間發生衝突

的部份;圖三(b)以擁擠為例,工作空間衝突的部份以綠色顯示。

(a) (b) 圖三 靜態空間與靜態空間衝突型式展示圖 動態工作空間與靜態工作空間衝突模式

動態工作空間與靜態工作空間可能發生空間衝突的狀況有損壞衝突(例如,

設備搬運動線上的通道或門無法讓設備通過必頇拆除等)、擁擠(例如,室內裝

修工程材料堆置影響人員通行或物料搬運等)。圖四以損壞衝突為例,橘色代表

設備工作空間、藍色代表建物工作空間,設備往建物方向移動,如果設備移動方

向路徑不變,在移動過程中可能會撞上建物,產生損壞衝突,其損壞區域以黃色

顯示。

圖四 動態空間與靜態空間衝突型式展示圖

動態工作空間與動態工作空間衝突模式

動態工作空間與動態工作空間可能發生空間衝突的狀況有安全上衝突(例如,

起重機吊裝作業範圍內有其他機具的穿越、挖土機的迴旋範圍中有其他工項進行

等)、擁擠(例如,施工便道同時有多輛工程車輛進出等)。圖五以安全上衝突

為例,橘色方體代表2個動態工作空間如人員與設備,設定其以1:2的相對速度

進行移動,兩方移動過程中,在紅色區域會產生安全上的危險。

圖五 動態空間與動態空間衝突型式展示圖(5)系統測試與總結報告撰寫

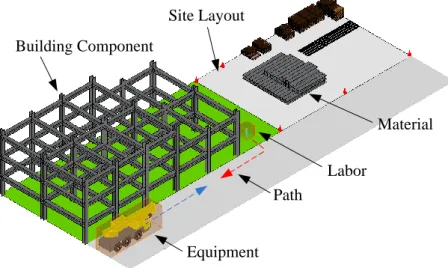

本研究以一工程案例來模擬展示工作空間互相衝突的情形,工區背景是一正

在興建中的鋼骨鋼筋混凝土大樓,模擬的情境是當移動式吊車以15km時速欲進

入工區吊裝位置時,正好有人員在附近進行物料搬移,移動速度為時速5km。首

先設定吊車及人員的位置點、工作空間大小、移動相對速度及目的座標後進行空

間衝突偵測及運算,並將程式執行結果在3D繪圖模型中以動態方式呈現。圖六

為工區基本配置圖,左下角橘色方體代表吊車工作空間,中央位置橘色方體代表

人員工作空間;圖七(a)顯示人員工作空間移動至可能與吊車動線產生安全衝突

的位置;圖七(b)顯示2個動態工作空間移動後開始產生衝突之位置;圖七(c)顯示

2個工作空間持續移動,衝突的空間逐漸擴大;圖七(d)顯示模擬完成,紅色方體

呈現工作空間衝突發生的位置、大小、形狀及衝突型態。

圖六 工區基本配置 (a) (b) (c) (d) 圖七 4D動態工作空間衝突模擬過程五、結果與討論

工作空間是一種有限資源,在工程建造過程中同一個空間無法同時提供多個

工程物件同時使用,為了提升營建工程生產效率,最有效的方法就是避免工作空

間衝突的發生。本研究之成果已在3D模型環境中建立工作空間動態移動及產生

衝突的基本呈現模式,並分析各工程物件之相關影響因子,開發出4D視覺化空

間衝突分析模組,並於程式中建置空間衝突偵測功能,能夠透過不同顏色的警示

方式來呈現不同衝突之狀況。從模擬成果中可以發現,在3D模型環境中呈現空

間衝突的位置、大小、形狀及狀態具有較為真實的效果,利用視覺化的展示可讓

工程人員能夠迅速瞭解可能發生的狀況,並提供決策上的幫助。本研究期望將此

模組與最佳化數值模型整合,導入最佳化理論產生空間配置及動線規劃之建議方

案,提供最佳化空間配置及動線規劃建議等研究之基礎;並進一步與建築資訊模

型及相關活動資源物件的資訊整合,以建築資訊模型作為空間衝突分析資料建構

及資訊呈現的平台,提供後續最佳化數值模型分析及4D動態模擬的應用,協助

工程人員解決空間配置及動線規劃相關問題。

七、參考文獻

[1] Sanders, S.R., Thomas, H.R. and Smith, G.R., 1989, “An analysis of factors

affecting labor productivity in masonry construction. " PTI # 9003,

Pennsylvania State University, University Park, PA.

[2] Riley, D. R. and Sanvido, V. E., 1995, “Patterns of Construction-Space Use in

Multistory Building,” Journal of Construction Engineering and Management,

ASCE, 121(4), pp. 464-473.

[3] Akinci, B., Fischer, M., Kunz, J. and Levitt, R., 2002, “Representing Work

Spaces Generically in Construction Method Models,” Journal of Construction

Engineering and Management, ASCE, 128(4), pp. 269-305.

[4] Akinci, B., Fischer, M., Levitt, R., and Carlson, R., 2002. “Formalization and

Automation of Time-Space Conflicts Analysis,” Journal of Computing in Civil

Engineering, 16(2), pp. 124-134.

[5] 吳俊達,2001,碩士論文,建築工程施工作業空間規劃與衝突分析流程之

研究,國立臺灣大學。

[6] 紀宛君,2006,碩士論文,大型結構實驗室資源管理輔助系統之研究,國

立臺灣大學。

[7] 仲闓立,2006,碩士論文,以Space Syntax(空間語法)分析施工要徑空間

特性之研究,國立臺灣大學。

Visualization and Intelligent Design in Engineering and Architecture, Elsevier

Science, New York, pp. 587~599.

[9] Collier, E. and Fischer, M., 1995, “Four-Dimensional Modeling in Design and

Construction,” Technical Report, No. 101, Center for Integrated Facility

Engineering, Stanford, CA.

[10] Collier, E. and Fischer, M., 1996, “Visual-Based Scheduling: 4D Modeling on

the San Mateo County Health Center”, Proceedings of the Third Congress on

Computing in Civil Engineering, ASCE, Anaheim, CA, June 17-19, pp.

800-805.

[11] Akinci, B., Fischer, M., and Kunz, J., 2002. “Automated Generation of Work

Spaces Required by Construction Activities,” Journal of Construction

Engineering and Management, 128(4), pp. 306-315.

[12] 呂明娟,碩士論文,建築結構工程4D 模擬系統之研究,國立台灣大學,

2006。

[13] Hsieh, S. H., Chen, C. S., Liao, Y. F., Yang, C. T. and Wu, I. C., 2006,

"Construction Director: 4D Simulation System for Plant Construction,"

Proceedings of the 10th East Asia-Pacific Conference on Structural Engineering

and Construction, August 3-5th, Bangkok, Thailand.

[14] Hsieh, S. H., Chen, C. S., Liao, Y. F., Yang, C. T. and Wu, I. C., 2006,

"Experiences on Development of a 4D Plant Construction Simulation System,"

Proceedings of the 11th International Conference on Computing in Civil and

Building Engineering, June 14-16th, Montreal, Canada.

[15]

I. C. Wu and S. H. Hsieh, 2008, “VisPMIS:A Visual Project Management

Information System”, Proceedings of the 11th East Asia-Pacific Conference on

Structural Engineering and Construction, November 19-21th, Taipei, Taiwan,

2008.

[16] 吳翌禎,2007,“多維度工程專案資訊整合管理與視覺化之研究",博士論

文,土木工程研究所,國立台灣大學。

1

國科會補助專題研究計畫項下出席國際學術會議心得報告

日期: 100 年 3 月 25 日

一、參加會議經過

International Conference on Construction Applications of Virtual Reality(CONVR)是每

年一次的國際研討會,來自全球各地的學者將針對各種資訊科技及虛擬實境輔助工程的技術,進行

國際性交流與討論。本次第十屆 CONVR 研討會由日本宮城大學主辦,日本大阪大學、中央大學,英

國 Teesside 大學協辦。會議地點在日本宮城縣仙台市國際中心。會議舉辦時間為 2010 年 11 月 4

日至 5 日。本次會議目的針虛擬實境和增加實境(Augmented Reality, AR)等技術,應用於建築、

工程、施工(AEC)上的各項研究進行交流。會議主題包含混合實境、增加實境在 AEC 的應用;建

築資訊模型(BIM)

;模擬與視覺化(Simulation and Visualization)

、3D 及遊戲引擎(Game Engine)

等。 仙台市是日本東北地方政治和經濟的中心城市。它雖然是一座百萬人口的大都市,卻有著優

美的自然景觀。廣瀨川流經仙台市中心,櫸樹林蔭道鬱鬱蔥蔥。仙台市是一座與自然相協調的現代

化都市,並以此聞名於日本。特別是市區中心的林蔭道和公園綠木繁茂,因而還有“森林之都”之稱。

仙台並擁有 20 多所大學,還有半導體研究所等許多各種先端科技研究所,每年都會有許多大中小

規模的國際會議在此召開。本次研討會便是在擁有正規的國際會議場所的「仙台國際中心」舉辦。

在一個簡單的開幕儀式之後,就馬上進行兩場專題演講,一是 Stanford University 土木與環境

計畫編號

NSC 99 - 2218 - E - 151 - 001 -

計畫名稱

應用 4D 動態模擬於工作空間最佳化配置之研究

出國人員

姓名

吳翌禎

服務機構

及職稱

高雄應用科技大學 土木工程系

助理教授

會議時間

99 年 11 月 4 日至 99

年 11 月 5 日

會議地點

日本 仙台

會議名稱

International Conference on Construction Applications of Virtual Reality(CONVR)

發表論文

2

工程系的教授 Prof. Kincho H. Law,題目為“Emerging Applications of Computing, Information

and Communication Technologies in Architectural and Civil Engineering”。第二場是 Teesside

University 營 建 工 程 系 的 教 授 Prof. Nashwan N. Dawood , 題 目 為

“Building Information

Modelling (BIM): A Visual & Whole Life Cycle Approach”,皆下來就是第一天的研討會議程,

本次 CONVR 研討會,僅安排二場報告一同進行,並集中所有與會人員一同參與國際專家學者的演

說,讓與會人員不會錯過太多講題,並可以有時間與主講人進行互動,獲得充分的交流,是十分妥

善的安排。本次研討會的晚宴安排在鐘景閣舉辦,鐘景閣為伊達政宗在仙台的居所,擁有 100 年以

上歷史建築物,是日本政府指定之古蹟,除了讓與會者享用到當地的特色食物外,亦參觀了傳統日

式建築;最為重要的是,所有與會人員共聚三小時,充份的討論及進行交流,達到分享學術研究及

經驗的目的。第二天議程包含論文報告及第三場 Keynote,由 Columbia University 教授 Prof.

Feniosky Peña-Mora 進行專題演講, 題目為”D4AR – 4 Dimensional Augmented Reality – Models

for Automation and Interactive Visualization of Construction Progress Monitoring”,其

餘時間皆進行分組報告。兩天行程結束之後,主辦單位還於報到櫃臺貼心贈送紀念品。

3

Keynote Prof. Nashwan N. Dawood 演講

本人報告情況

Keynote Prof. Kincho H. Law 演講

Keynote Prof. Feniosky Peña-Mora 演講

4

二、與會心得

此次研討會的議題範圍較小,與會的人士的研究領域皆是極相關,此次研討會是一個中小型的研討

會,透過嚴格審查僅只有 50 篇的論文可以在此研討會中發表,發表討論的時間也較一般研討會長,

在會議過程中透過討論與交流可以清楚了解各國家在 IT 應用於 AEC 領域上的進展及研究成果,此

行深感收穫豐碩。

三、建議

國內研討會大多交流活動重於實質研究的探討,建議未來國內辦研討會可以朝向這樣以技術探討為

主的方式進行,能提高研討會品質,不要流於形式。

五、攜回資料名稱及內容

1. 2010 CONVR 論文集紙本

2. 2010 CONVR 論文集 名片型隨身碟

六、其他

無

10th International Conference on Construction Applications of Virtual Reality, 2010

1

4D WORKSPACE CONFLICT DETECTION AND ANALYSIS SYSTEM

I-Chen Wu, Assistant Professor

Department of Civil Engineering, National Kaohsiung University of Applied Sciences kwu@cc.kuas.edu.tw

Yen-Chang Chiu, Research Assistant

Department of Civil Engineering, National Kaohsiung University of Applied Sciences chiouyannjang@yahoo.com.tw

ABSTRACT: Construction activities require a set of adequate workspaces to be executed in a safe and productive

manner. This research classifies these required workspaces of activity into five categories: building component spaces, site layout spaces, people working spaces, equipment spaces and material spaces. All of these spaces change and move in three dimensions and across time throughout the construction process. Different activities may occasionally interfere with each another whilst working in the same space, causing space conflicts. In order to avoid the problem of space conflicts during the construction stage, this research develops a 4D workspace conflict detection and analysis system. Our system is implemented on top of Bentley MicroStation which supports both visualization of a 3D building model with capabilities for 3D object manipulation and information querying, and provides an API (Application Programming Interface) for functionality extensions. In this system, four types of space conflict are implemented: design conflict, safety conflict, damage conflict and congestion. Moreover, this system provides a visual environment, such as 3D visualization and 4D simulations, to present work space utilization of the ongoing project and the conflict status of activities with different colors. In this paper, the design and implementation of the 4D workspace conflict detection and analysis system is discussed and sample construction example is used to demonstrate the applicability of the system.

KEYWORDS: 4D, Conflict Detection, Conflict Analysis, Workspace, Construction Management

1. INTRODUCTION

Space is regarded as a limited resource on construction sites. This becomes apparent when two or more trades are working in the same construction space, potentially interfering with each another, or when the workspace of on-site personnel conflict with material stacking space. These kinds of activity space conflicts occur frequently, severely affecting the process and efficiency of construction and resulting in productivity loss. Construction productivity is thus influenced by a variety of factors. Many researchers have studied the factors that cause loss of productivity in construction sites. Kaming et al. (1998) indicated that space conflicts have been identified as a one of the major causes of productivity loss in construction. Sanders et al. (1989) reported efficiency losses of up to 65% due to congested workspaces and losses up to 58% due to restricted access. Space conflicts can occur in many parts of the construction site and in various stages throughout the construction process. Inadequate workspace and interference during travel can result in access blockage, congestion, safety hazards, and heighten the risk of damaging the end product (Oglesby et al. 1989; Thabet 1992; Tommelein et al. 1992, 1993; Riley and Sanvido 1995; Akinci et al. 1998). Various approaches to ameliorate space conflict have been presented to address the above-mentioned issues. The approach taken in Guo (2002) focused on space availability due to time and scheduling, applying two typical tools, AutoCAD for space planning and MS Project for scheduling, to solve space conflicts. In the past decade, 4D simulation (or 4D CAD) technology, which bind 3D models with their corresponding construction schedules in their simplest form, has made rapid development in providing engineers with an effective tool to manage the coordination complexity of the site, especially in managing conflicts before actual construction commences. The rapid emergence of 4D simulation technology is not only driven by the rapid advancement of information technology, but also by increasing recognition from the construction industry of the benefits of using the 4D CAD applications to increase productivity, improve project coordination, and optimize on-site resources. 4D visualization has emerged as an interesting 4D space planning and visualization tool. 4D space planning specification and construction work development have been investigated by Riley (1998). Akinci et al. (2002a, 2002b, 2002c) also executed similar research which reduces non-value-adding activities due to time-space conflicts. A time-space conflict analysis based on a 4D production model was then proposed. Mallasi’s research developed an innovative computer-based tool dubbed PECASO (Patterns Execution and Critical Analysis of Site-space Organization). There is potential for this system to assist site managers in the assignment and identification of workspace conflicts (Mallasi 2004; Dawood and Mallasi 2006). Though much

Nov. 4-5, 2010

2

Building

Site

Labor

Equipment

Material

Work Space Conflict Detection and Analysis

Design

Conflict

Safety

Hazard

Damage

Conflict

Congestion

of the research has targeted the space scheduling problem, much less literature is concerned with workspaces for dynamic working objects on construction sites, such as labor and equipment. This is further complicated by the variable requirements of different activities and the change in the location and size of the workspace over time. This study considered the space availability of construction sites in relation to scheduling, productivity loss due to path interference, and space constraints. This research has developed a conflict detection and analysis module based on a 4D CAD system to solve space conflict issues for various working objects in a construction site. Section 2 seeks to define workspace and analyzes the types of workspace conflicts. Section 3 discusses the design and implementation of the conflict detection and analysis module. Section 4 demonstrates the applicability of the 4D workspace Conflict Detection and Analysis System with a construction example. Finally, Section 5 draws our conclusions from the study.

2. DEFINITION OF WORKSPACE CONFLICT

A concept diagram of this research is shown below in Fig. 1. The most important impact factors for this research are the requisite workspace for activities during construction, the method of workspace aggregation and the various types of workspace conflict. These will be discussed as follows.

Fig. 1: A concept diagram of this research.

2.1 Workspace

Space is a resource that may cause crucial problems during construction. The construction workspace is a combination of resources, including building component spaces, site layout spaces, human workspaces, equipment spaces and material spaces.

Building component: Building component means a specific design or structural element. Each building component, such as a column, beam or wall, is assigned a workspace. The space assigned is the physical space taken up by the building component, as well as providing a buffer required to keep a safe distance around them.

Site layout: Construction engineers have to properly allocate construction spaces, such as material storage, the construction site, construction roads and the site office, to minimize the cost of labor and material travel such that the operation is accomplished quickly and efficiently, whilst ensuring the safety of both labor and equipment.

Labor: Labor crews need a set of workspaces for constructing building components safely and productively. That is why construction sites need to provide enough space for working and safety, in order to reduce productivity loss and minimize accidents.

10th International Conference on Construction Applications of Virtual Reality, 2010

3

In this manner, the workspace assignment for equipment must consider operation clearance and hazards. Examples of common equipment are cranes, pumps, temporary facilities, and so on.

Material: Construction sites need to provide adequate room to store materials properly and allow safe access to them. This kind of workspace assignment must consider protected areas for materials to ensure that they will not be destroyed.

Workspace as defined by this research is shown in formula 1. Each object in the model (building component, site layout, labor, equipment and material) has its own space, as well as space needed for operation and safety. This research will calculate how much workspace each object needs and assigns it to them for workspace conflict detection and analysis.

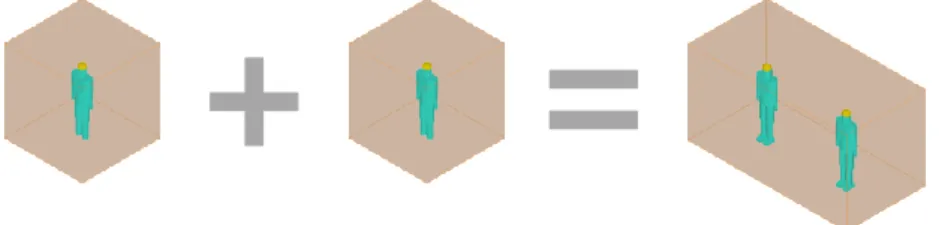

2.2 Workspace aggregation

Construction activities need a set of work spaces to be executed in a safe and productive manner. An example of this would be the pouring of concrete into pad foundation which requires a concrete mixer and a concrete vibrator to accomplish the task. Sufficient workspace needs to be provided for these two pieces of equipment to be able to maneuver safely. Therefore, we must consider workspace aggregation to calculate numerous workspaces at the same time to accurately detect and analyze workspace conflict. In this research, workspaces are created using Constructive Solid Geometry (CSG), a technique used in solid modeling. CSG allows a user to create a complex surface or object by using Boolean operators. The simplest cuboids are used in this research to represent workspaces. We classify workspace aggregation into two ways, with the first being the direct combination of workspaces. For example, since labor objects and equipment objects need independent spaces to operate and for a safety buffer, we can therefore directly combine their workspace cuboids into compound objects using operations such as the merger as shown in Fig. 2. Another aggregation is the combination of working objects. For example, building components and material objects require no space between each other so we can merge two of these objects when they have been installed or assembled, with the workspace for the combined object then recalculated and new workspace cuboids created as shown in Fig. 3.

Fig. 2: Direct combination of workspace cuboids.

Fig. 3: Combination of working objects.

2.3 Conflict types

Project managers need to understand the different types of workspace conflict to develop customized solutions for managing them. According to the literature review, we introduced four major types of conflicts into our system as follows.

2.3.1 Design conflict

Current construction projects are more complex and have more participants involved. When different participants design their own separate parts of the building, design conflicts may occur. We can say that a design conflict occurs

Nov. 4-5, 2010

4 when a building component conflicts with another. Lack of space and pipeline overlap, for example, may arise from conflict between inappropriate electrical equipment design and HVAC pipe design. The causes of these conflicts are not construction related, but rather, design related.

2.3.2 Safety Hazard

The leading safety hazards on construction sites include being struck by falling objects, motor vehicle crashes, excavation accidents and electrical hazards. A safety hazard conflict occurs when a hazard space generated by an activity conflicts with a labor crew space required by another activity. People are not allowed to pass or stand underneath any loading or digging equipment. Labor crews are to remain at a safe distance from all equipment while it is in operation. When a hazard space conflicts with a labor crew space, it creates a safety hazard situation for the labor crew.

2.3.3 Damage conflict

In order to complete a particular activity, damage to the object or component that is completed in the previous activity may be sustained. A damage conflict occurs when a labor crew space, equipment space, or hazard space required by an activity conflicts with the protected space required by another activity. An example of this is if a worker wants to set up equipment in the correct position and the exit is too narrow or small, they must then remove the door for handling equipment.

2.3.4 Congestion

A congestion conflict occurs when a labor crew and a piece of equipment or material required by an activity needs the same space at same time causing a lack of space or space overlap. Examples of this are when storage space is too small caused by material stacking and overlap, where too many workers are working on the same building component causing congestion or when a large number of construction vehicles are entering or leaving the construction site at the same time causing congestion.

3. CONFLICTS DETECTION AND ANALYSIS MECHANISMS

The implementation of our 4D workspace detection and analysis system was carried out in Microsoft’s VB.NET environment. During the simulation, the 3D objects in the construction site model are highlighted in different colors depending on their conflict types.

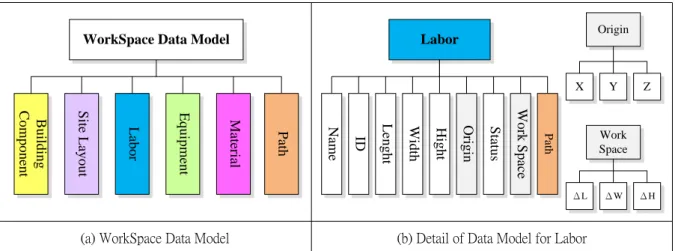

3.1 Workspace Data Model

A data model is an abstract model that describes how data is represented and accessed. This research proposed a workspace data model for data definition and storage. This data model includes six main classes, each with their own sub-classes and attributes for detecting and analyzing workspace conflicts as shown in Fig. 4.

Fig. 4: Workspace data model.

WorkSpace Data Model

B u ild in g C o m p o n en t S ite L ay o u t M at er ia l E q u ip m en t L ab o r P at h Labor N am e O rig in S ta tu s W o rk S p ac e ID Leng h t W id th P at h H ig h t Origin X Y Z Work Space ΔL ΔW ΔH

10th International Conference on Construction Applications of Virtual Reality, 2010

5

3.2 Conflict Detection and Analysis Module

This research divided working objects into two categories according to their status: static working objects and dynamic working objects. Static working objects include building components, gatherings of people, parked equipment and materials stacks. Dynamic working objects include working people and equipment in operation or transportation. The simulation and visualization of the different working objects is discussed in the following sections.

3.2.1 Color Schema

We defined four colors to visualize the workspace conflicts in 3D environment. Table 1 shows the color scheme implemented with examples of the kind of working objects that will raise the specific conflict.

Table 1: Color schema for workspace conflicts.

Color Conflict Type Static vs. Static Dynamic vs. Static Dynamic vs. Dynamic

Purple Design Conflict Design Interference None None

Red Safety Hazard None None Equipment vs. Labor

Yellow Damage Conflict None Equipment vs. Building None

Green Congestion Material vs. Material Labor vs. Material Equipment vs. Equipment

3.2.2 4D Visualization

This research provides tools for defining the relationships between the objects in the 3D model and time schedule. The system will detect and analyze workspace conflicts between various working objects during 4D visualization.

Static working object vs. Static working object

Design or congestion conflicts may occur between two static working objects as shown in Fig. 5. For example, design interference between subcontracter and material.

Fig. 5: Conflict visualization between two static working objects. Static working object vs. Dynamic working object

Damage conflict or congestion conflict may arise from interaction between a static working object and a dynamic working object. Fig. 6 shows a simple case of equipment being driven to the building component. Assuming construction sites are unable to provide enough path space, damage conflict will occur.

Congestion Design Conflict

Nov. 4-5, 2010

6 Fig. 6: Conflict visualization between a static working object and a dynamic working object.

Dynamic working object vs. Dynamic working object

Construction sites need to provide enough space for all laborers and equipment as well as for material transportation. For example, where many trucks want to move from the entrance to each working area at same time, congestion conflicts will occur. Fig. 7 is a schematic simulation of labor and equipment. As they move along their own path, a safety hazard conflict occurs.

Fig. 7: Conflict visualization between two dynamic working objects.

4. DEMONSTRATION

A simple construction site was used as an example to test and demonstrate the functionality of our 4D workspace conflict detection and analysis system, as shown in Fig. 8. Users can create 3D models of working objects (building component, site layout, labor, equipment and material) within the system, which will then calculate and assign the required workspaces for these objects. In this case, the system will only analyze conflicts that deal with labor and equipment for calculatiion efficiently. As labor and equipment moves along a specified path the system will automatically detect and analyze workspace conflicts.

Fig. 9 shows the 4D visualization workspace conflicts detection and analysis. In our system, users can observe the whole process simulation. Dynamic working objects, labor and equipment are represented by orange boxes, while the location and size of safety hazard conflicts are depicted by red boxes.

Labor

Safety Hazard Conflict Equipment (1) (2) (3) (4) (5) (6) Building Component Equipment Damage Conflict (1) (2) (3) (4) (5) (6)

10th International Conference on Construction Applications of Virtual Reality, 2010

7

Fig. 8: A simple construction site example.

(a) (b)

(c) (d) Fig. 9: 4D visualization of conflict detection and analysis.

5. CONCLUSIONS

Large numbers of building components, workers, equipment as well as materials share limited space during construction. Since space constraints may affect the moving path of resources and productivity, it is essential to detect and analyze workspace conflicts in advance, such that the available space can be used more efficiently. For this reason, this research develops a 4D workspace conflict detection and analysis system for solving space issues in construction sites. In this paper, the 3D CAD system, Bentley MicroStation, was integrated with schedule information for the dynamic identification of space conflicts and 4D visualization. The system can simultaneously detect and analyze workspace conflicts with various working objects, as well as visually representing the location, size, scope and type of workspace conflicts. This will assist project managers in quickly grasping the status of an ongoing project, in order to make decisions. In addition, a simple construction project example was used in this research to demonstrate the functionality and applicability of the 4D workspace

Path

Building Component

Material

Site Layout

Labor

Equipment

Nov. 4-5, 2010

8 conflict detection and analysis system. The workspace conflict that this research focuses on is a common issue in space management. In future, a numerical model and optimization theory will be introduced into our system for space and path planning optimization.

6. ACKNOWLEDGMENTS

The authors would like to thank the R.O.C. National Science Council for their financial support under Grant No. NSC99-2218-E-151-001.

7. REFERENCES

Akinci, B., Fischer, M., and Kunz, J. (2002a). “Automated Generation of Work Spaces Required by Construction Activities,” Journal of Construction Engineering and Management, 128(4), pp. 306-315.

Akinci, B., Fischer, M., Kunz, J. and Levitt, R. (2002b), “Representing Work Spaces Generically in Construction Method Models,” Journal of Construction Engineering and Management, ASCE, 128(4), pp.269-305.

Akinci, B., Fischer, M., Levitt, R., and Carlson, R. (2002c). “Formalization and Automation of Time-Space Conflicts Analysis,” Journal of Computing in Civil Engineering, 16(2), pp.124-134.

Akinci, B., Fischer, M., and Zabelle, T. (1998). “Proactive Approach for Reducing Non-value Adding Activities Due to Time-space Conflicts.” Proceedings of the 8th Annual Conference Lean Construction, Guaruja, Brazil. Dawood, N., and Mallasi, Z. (2006), “Workspace Competition: Assignment, and Quantification Utilizing 4D Visualization,” Computer-aided Civil and Infrastructure Engineering, Vol. 21, 498-513.

Guo, S.J. (2002), “Identification and Resolution of Work Space Conflicts in Building Construction,” Journal of Construction Engineering and Management, 128(4), pp.287-294.

Kaming, P. F., Holt, G. D., Kometa, S. T., and Olomolaiye, P. O. (1998), “Severity diagnosis of productivity problems - a reliability analysis, ” International Journal of Project Management, 16(2), pp.107–113.

Mallasi, Z. (2004), “Identification, and Visualisation of Construction Activities’ Workspace Conflicts Utilizing 4D CAD/VR Tools, ” Proceedings of the 1st ASCAAD International Conferend, e-Design in Architecture, KFUPM, Dhahran, Saudi Arabia.

Oglesby, C.H., Parker, H.W., and Howell, G.A. (1989), “Productivity Improvement in Construction”, McGraw-Hill Inc, New York, NY.

Riley, D.R. and Sanvido, V.E. (1995), “Patterns of Construction-Space Use in Multistory Building,” Journal of Construction Engineering and Management, ASCE, 121 (4), pp.464-473.

Riley, D.R. (1998), “4D space planning specification development for construction work spaces,” Proceedings of the Intentional Computing Congress, ASCE, Reston, VA, pp.354-363.

Sanders, S.R., Thomas, H.R., and Smith, G.R. (1989), “An Analysis of Factors Affecting Labor Productivity in Masonry Construction,” PTI # 9003, Pennsylvania State University, University Park, PA.

Thabet, W.Y. (1992), “A Space-Constrained Resource-Constrained Scheduling System for Multi-Story Buildings.” Ph.D. Diss., Civil Engineering Department, Virginia Polytechnic Institute and State University, Blacksburg, VA. Tommelein, I.D., Levitt, R.E., and Hayes-Roth, B. (1992), “SightPlan Model for Site Layout.” ASCE, Journal of Construction Engineering and Management, 118 (4), pp.749-766.

Tommelein, I.D. and Zouein, P.P. (1993), “Interactive Dynamic Layout Planning,” Journal of Construction Engineering and Management, ASCE, 119 (2), pp.266-287.