鐵-鈀-銀合金之磁性相微結構與磁性

研究成果報告(精簡版)

計 畫 類 別 : 個別型

計 畫 編 號 : NSC 95-2221-E-151-063-

執 行 期 間 : 95 年 08 月 01 日至 97 年 07 月 31 日

執 行 單 位 : 國立高雄應用科技大學模具工程系

計 畫 主 持 人 : 林英志

計畫參與人員: 博士班研究生-兼任助理人員:林建鋒

報 告 附 件 : 國外研究心得報告

公 開 資 訊 : 本計畫涉及專利或其他智慧財產權,1 年後可公開查詢

中 華 民 國 97 年 12 月 27 日

先進工程學刊 第三卷 第二期

Journal of Advanced Engineering Vol. 3, No. 2, pp. 123-128 / April 2008

123

鐵-鈀-銀合金之磁性相微結構與磁特性

Magnetic Structure and Magnetic Property of Fe-Pd-Ag Alloys

林英志

*1李驊登

1林建鋒

2Yin-Chih Lin

*1, Hwa-Teng Lee

1, Chien-Feng Lin

2摘要 本研究論文主要利用穿透式電子顯微鏡(TEM),X-ray繞射儀,調幅式示差掃 描量熱計(DSC),與超導量子干涉磁化儀(SQUID),探討鐵-30鈀-4銀磁性合金固溶 處理,與固溶處理後再經400-500℃,時效於各種不同時間之磁性相微結構與磁特 性關係,TEM、X-ray繞射與DSC實驗結果證實,此合金固溶與時效處理後,在fcc L10麻田散鐵相變態間,存在一中間相,此中間相為L1m單斜晶結構,其晶格常 數為 a = 3.208 Å, b = 3.696 Å, c = 3.127 Å, 及 β= 91.997°,此中間相可能為一種 適性相麻田散鐵。 超導量子干涉磁化儀之磁性量測結果顯示,固溶處理試樣,其ZFC與FC之磁 化曲線並不聚合,一直到室溫TR= 300K,當試樣固溶處理,再經500℃/100小時之 時效處理後,則其ZFC與FC之磁化曲線呈現鋸齒狀(serrated),此現象表示有兩種 磁性相,存在時效處理之試樣內部,此兩種磁性相包括單斜晶L1m與序化型正方晶 L10微結構,這兩種磁性相具有不同之磁異向性(magnetic anisotropy)。 關鍵詞:鐵-鈀-銀合金,TEM與X-ray繞射,DSC,中間相L1m微結構 Abstract

This investigation reports on TEM, X-ray diffraction, DSC, and SQUID magne-tometer study of magnetic structures formed in Fe-30Pd-4Ag alloys solution treated and then thermally aged at 400-500℃ for various times. The results reveal that an in-termediate structure appears between thefcc→ L10 martensitic transformation. The

intermediate phase, denoted L1m, has a monoclinic structure with lattice parameters of

a = 3.208 Å, b = 3.696 Å, c = 3.127 Å, and β= 91.997°, which indicates that the monoclinic structure is possibly adaptive martensite, as confirmed by TEM, X-ray dif-fraction, and DSC.

The SQUID test shows that the ZFC and FC curves of the ST specimen do not coalesce until they reach room temperature at TR= 300 K. The serrated ZFC and FC

curves of the specimen aged at 500℃ for 100 h indicate that two phases exist in the aged specimen. The two phases are comprised of monoclinic L1mphase and tetragonal

ordered L10structure, which have differing magnetic anisotropy.

Keywords: Fe-Pd-Ag alloys, TEM and X-ray diffraction, DSC, Intermediate L1m

struc-ture

I. INTRODUCTION

Ferromagnetic shape memory alloys (FSMAs) have recently attracted attention for application as a magnetic actuator material. In FSMAs, a large strain by magnetic field-induced twinning/detwinning has been discovered [1-2]; in addition, FSMAs can achieve a large displace-ment and quick response by magnetic field-induced L10

martensitic transformation or by magnetic field-induced

rearrangements of L10martensitic twinning

magnetostric-tion. Therefore, FSMAs will become the most potential actuator material for magneto-mechanical applications in the near future [1-2]. At the moment, several systems of FSMAs, such as Ni-Mn-Ga, Co-Ni-Al, Fe-Pt, and Fe-Pd, have been attracting much more research. Among these alloy systems, the Fe-Pd alloys have a better mechanical property (ductility), a higher Curie temperature (~500℃),

1國立成功大學機械工程研究所 2崑山科技大學機械工程研究所

*

Corresponding author. E-mail: lin3312@cc.kuas.edu.tw

1Department of Mechanical Engineering, National Cheng Kung University, Tainan, Taiwan, R.O.C. 2Department of Mechanical Engineering, Kun Shan University of Technology, Tainan, Taiwan, R.O.C. Manuscript received 9 November 2007; accepted 25 January 2008

and a large magnetization anisotropy constant (K1=

1.45×107ergs/cm3). Despite the disadvantage of this alloy, namely the limited stability of the L10phase, it is possible

both to extend the stability range of the L10martensite and

to improve the softness of the Fe-Pd alloys with the addi-tion of a third alloy element. Addiaddi-tion of the third element can usually induce a strong influence on the L10

marten-sitic transformation [3]. Therefore, in this study, we select Ag as the third alloy element for the Fe-Pd alloys. The L10

martensitic transformation and magnetic property of the composition Fe-30Pd-4Ag alloys are investigated in the present work.

II. EXPERIMENTAL PROCEDURE

The Fe-30Pd-4Ag (at%) alloys were formed by melt-ing by pure electrolytic iron (99.9%), pure palladium (99.95%), and pure silver (99.95%) in an arc vacuum fur-nace under a controlled protective argon atmosphere. The cast ingots were sealed in evacuated quartz capsules and homogenized at 1050C for 60 hours and subsequently forged to a thickness of 2~3mm. After forging, the speci-mens were sliced and sealed in evacuated quartz capsules again and solution treated (ST) at 950C for 1.5 hours be-fore being quenched in ice water. The aging treatment was performed in the temperatures range of 400-550C for various amounts of time. Thin foils for TEM were pre-pared by double jet electropolishing in a solution contain-ing 82% acetic acid, 9% perchloric acid, and 9% methanol at a temperature in the range of -7C~10C using a current density of 2A/cm2 to 4A/cm2. Transmission electron mi-croscopy (TEM), with a double tilt stage, was performed in an analytical type high resolution electron microscope (Hitachi HF-2000) with a field emission gun operated at 200 kV, and a JEM-2100F operated at 200 kV, respec-tively. The X-ray diffraction patterns were detected at room temperature using an X-ray diffractometer (Siemens D5000 Karlsruhe) with Cu-Kradiation, and diffraction angles were in the 2ranges from 35to 140.The mart-ensitic phase transformation temperatures of the samples that were only solution treated and those that were solution treated and then thermally aged were determined with dif-ferential scanning calorimetry (2920 MDSC V2.6A). A temperature range from -50 to 220℃was scanned at a rate of 10℃/min during heating. (i.e., The samples were scanned in a temperature range from -50 to 220℃ at a heating rate of 10℃/min). The magnetic property zero-field-cooled (ZFC) and zero-field-cooled (FC) measurements were carried out with a superconducting quantum inter-ference device (SQUID) magnetometer. The temperature dependence of mass susceptibility (where = M/H, = density) measurements on samples cooled under 20000 Oe were made in the temperature range from 0 K to 350 K by induction method.

III. RESULTS AND DISCUSSION

1. γfcc phase transformation into the monoclinic L1m

phase+L10structure observed by TEM

Figure 1(a) shows an essential transmission electron microscopy (TEM) selected area diffraction pattern (SADP) with zone axis [011]L10//[23 2]L1m of the Fe-30Pd-4Ag

alloy solution treated (ST) at 950C for 1.5 h and quenched in ice water (hkl denotes the ordered L10phase;

hkl denotes the monoclinic L1mstructure). On the basis of

the diffraction pattern analysis, a dim satellite spot beside the {200}L10position can be seen in the SADP micrograph,

an indication that the as-quenched γfcc phase separation

into the L10structure should be a weak first ordering

reac-tion [4-5]. This first ordering reacreac-tion begins during the solution treatment (ST) and quenching in ice water. Figure 1(b) is a dark field (DF) image formed using the (11 1)L10

reflection corresponding to Fig. 1(a). In this image, the first ordered L10 structure, in bright contrast with a

twinned structure (tetragonal), can be distinctly observed in the early phase transition. Figure 1(c) is a dark field (DF) image formed using the (221)L1m monoclinic reflection

corresponding to Fig. 1(a). The DF image of Fig. 1(c) re-veals that the initial intermediate L1mmonoclinic phases

Fig. 1 TEM micrographs of the Fe-30Pd-4Ag alloys solution treated (ST) at 950℃for 1.5 h and quenched in ice water: (a) SADP of the zone axis [011]L10//[23 2]L1m(hkl denotes the ordered L10

phase; hkl denotes the monoclinic L1mstructure), (b) DF image

of (11 1)L10ordered L10reflection corresponding to (a), (c) DF

image for (221)L1mreflection corresponding to (a), (d) BF

林英志 李驊登 林建鋒 Yin-Chih Lin, Hwa-Teng Lee, Chien-Feng Lin

125

are comprised of modulated structures with tiny antiphase boundaries (APBs). Figure 1(d) is a bright field (BF) struture. The SADP of the TEM micrograph taken from the alloy ST then thermally aged at 450C for 100 h is shown in Fig. 2(a), in which the zone axis reveals the [112]

L10//[41 3]L1m(hkl denotes the ordered L10phase; hkl

de-notes the monoclinic L1mstructure). The two phases'

re-flection spots are clearly shown in the SADP image (Fig. 2(a)). By calculating the X-ray diffraction d-spacing in association with the SADP image measurements, it is found that the adaptive L1m martensite has a monoclinic

structure with lattice parameters of a = 3.208 Å, b = 3.696 Å, c = 3.127 Å, and β= 91.997°, and the ordered L10, a

normal martensitic structure with lattice parameters of a = 3.878 Å, c = 3.696 Å, and c/a= 0.953.

Figure 2(b) is a dark field (DF) image formed using the monoclinic (11 1)L1mreflection corresponding to Fig.

2(a). The DF image in Fig. 2(b) reveals that the intermedi-ate L1m monoclinic phases are comprised of microtwins

and antiphase boundaries (APBs). These planar faults strongly support the mechanism of coercivity in the aged Fe-Pd-Ag alloy system; it has tended to favor microtwins and APBs pinning the magnetic domain wall motion, which has been illustrated as a possible source of magnetic hardening [6-8]. Figure 2(c) is a bright field (BF) image. For further confirmation of the existence of two phases in

Fig. 2 TEM micrographs of the Fe-30Pd-4Ag alloys ST and aged at 450 ℃ for 100 h: (a) SADP of the zone axis [112]L10//[41 3]L1m

(hkl denotes the ordered L10phase; hkl denotes the monoclinic

L1mstructure), (b) DF image for (11 1)L1mreflection

corre-sponding to (a), (c) BF image, (d) high resolution TEM (HRTEM) micrograph showing the antiphase boundaries (APBs) and two phases' d-spacing

the aged alloy, a high resolution TEM (HRTEM) image (Fig. 2(d)) taken from the same specimen shows the pres-ence of the monoclinic L1mstructure with an ordered L10

phase, and the antiphase boundaries (APBs –i.e., the faint black curved image) in the matrix, as indicated by an ar-row. Due to the appearance of the APBs, the aged L10

phase should be reasonably inferred as a second ordered structure, and the APBs pinning the magnetic domain wall motion are further demonstrated as a possible source of magnetic hardening of the alloy after ST followed by thermal aging. By careful measurements of the lattice space of Fig. 2(d), it is found that the d-spacing of the monoclinic L1mstructure is 2.38 Å, and the ordered L10

phase is 2.2 Å; therefore, the plane (Fig. 2(d)) can be rea-sonably inferred to be (011)L1mand (111)L10, respectively.

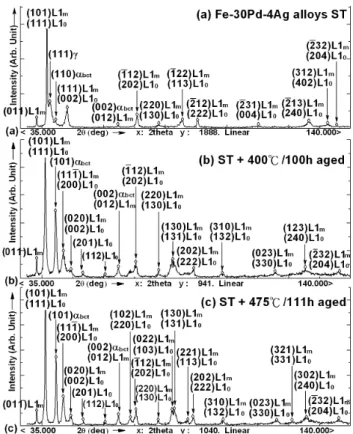

2. X-ray diffraction pattern analysis

Figures 3(a)-(c) represent a series of X-ray diffraction patterns of the alloys that were solution treated and those solution treated and then thermally aged at 400C and 475C for various times. The X-ray diffraction pattern of the alloy ST at 950C for 1.5 h and quenched in ice water

Fig. 3 X-ray diffraction patterns of the alloy solution treated and those ST and then thermally aged at 400 and 475C for given times: (a) 950C for 1.5 h ST and quenched in ice water, (b) ST and aged at 400C for 100 h, and (c) ST and aged at 475 C for 111 h. (bct denotes the body centered tetragonal martensite, L1m

de-notes the adaptive L1mmonoclinic structure, and L10denotes the

is shown in Fig. 3(a), in which reflections of two phases (101)L1m and (111)L10 are the main diffraction peak. The

(111)and (110)bctpeaks also appear; in addition, there is

an observable (011)L1m peak in the X-ray diffraction

pat-tern. The X-ray experiment results exhibit that an interme-diate structure appears between the fcc→ L10martensitic

transformation, which occurs in the early ST treatment. Simultaneously, the X-ray experiment also demonstrates that the addition of silver (Ag) to the Fe-Pd alloy system enhances the L1mand L10phase formation. When the alloy

is aged at 400C for 100 h, many adaptive L1mmonoclinic

structures and ordered L10martensitic phases appear in the

X-ray diffraction patterns, in addition to the (111)phase

separation to the (110)bct+L1m+L10 structures, as shown

in Fig. 3(b). It is also interesting to note that the X-ray diffraction peak for the plane (002)L10, (202)L10, (113)L10

reflections corresponding to the ST specimen in Fig. 3(a) have been transformed into the tetragonal splitting peak (200)L10;(002)L10, (220)L10;(202)L10, and (131)L10;(113)L10

reflections when the specimen has been aged at 475C for 111 h, as shown in Fig. 3(c). These splitting peaks are the result of the formation of the completely ordered tetrago-nal L10martensitic structures attendant on the L1m→ L10

phase transformation reaction. Comparison of the L10

tetragonal splitting peaks of Figs. 3(b) and 3(c) reveals that the axial ratio c/a of the ordered L10 martensite gradually

decreased when the aging temperature was lowered to 400C. On the other hand, the degree of tetragonality de-velops as the specimen is aged at a lower temperature of 400C, in which case it gives rise to an increase in the anisotropy and enhances the magnetic coercivity in the Fe-Pd-Ag alloy [9-11].

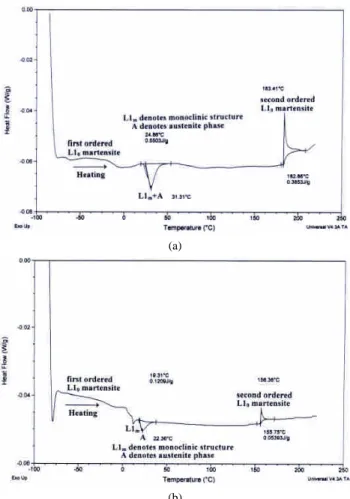

3. Martensite L10phase transformation temperature

Martensitic L10phase transformation temperatures of

the specimen ST at 950℃ for 1.5 h and quenched in ice water were determined by differential scanning calo-rimetry (DSC). The results are shown in Fig. 4(a). Two distinct peaks in the heating direction are observed, indi-cating a two-step phase transition [12-13]. The first endo-thermic peak in the heating direction corresponds to the superposition of the L1m(monoclinic phase)+A (austenite

structure) with L1ms = 24.86℃, L1mf= 52℃, As = 28℃,

and Af = 54℃. The subscript “s”denotes the temperature

at which the phase transformation starts, and the “ f”de-notes the temperature at which the phase transition finishes. The second DSC peak (i.e., the exothermic peak) corre-sponding to the second ordered L10 martensite phase is

determined to have transformation temperatures ML10s =

183℃ and ML10f= 204℃ (here ML10sdenotes the second

ordered L10 martensite phase transition start). The DSC

study indicates the martensitic phase transition during heating as follows; a weak first ordered L10martensite→

L1m(monoclinicphase)→ A (austenitestructure)→ se

c-ond ordered L10martensite. From the DSC chart, it is

in-ferred that the L1mphase transforms to second ordered L10

martensite in addition to the direct transformation from A

(austenite) to second ordered L10 martensite during

heat-ing of the sample. Figure 4(b) shows a DSC heatheat-ing curve of a specimen ST and then thermally aged at 475℃ for 111 h. The DSC chart reveals two endothermic peaks and one exothermic peak during heating. This is referred to as a three-step transformation on heating [14-15]. Two endo-thermic peaks correspond to the L1m(monoclinic phase)

and A (austenite structure) with L1ms= 12.5℃, L1mf= 18

℃, As = 19.4℃, and Af = 37.5℃, respectively. The one

exothermic peak indicating the second ordered L10

mart-ensite phase was determined to have transformation tem-peratures ML10s = 156℃ and ML10f= 162.5℃.

Compari-son of the DSC chart of Fig. 4(a) with Fig. 4(b) indicates that when the specimen was ST and then thermally aged at 475℃ for 111 h (Fig. 4(b)), the phase transition tempera-tures of the L1m(monoclinic structure), the A (austenite

phase), and the second ordered L10 martensite phase

transformation moved toward the lower temperature, con-current with the transition heat flow peak intensity also decreasing. An intermediate structure appearing between thefcc→ L10martensitic transformation, confirmed by TEM

(a)

(b)

Fig. 4 DSC curves of Fe-30Pd-4Ag alloys (a) ST, (b) ST then thermally aged at 475 ℃ for 111 h, indicating that a three-step phase trans-formation occurred during heating the aged sample

林英志 李驊登 林建鋒 Yin-Chih Lin, Hwa-Teng Lee, Chien-Feng Lin

127

and X-ray diffraction, is discussed in the above Section. The results of TEM and X-ray diffraction with DSC analy-sis are exactly coincident [16].

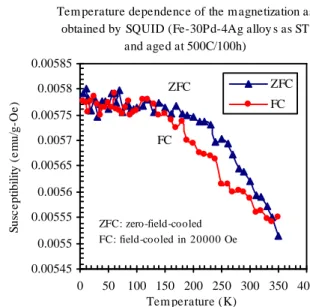

4. Magnetic property

Figure 5 shows the temperature dependence of the magnetic mass susceptibility (= M/H, where = den-sity) of the alloy ST at 950℃ for 1.5 h and quenched in ice water, as measured by SQUID. The measured values display both the zero-field-cooled (ZFC) data and the field-cooled (FC) data within a field of 20000 Oe. Figure 5 indicates the tendency of the ZFC and FC data for -T curves to decrease as the temperature increases. The ZFC data for the -T curve progressively decreases as 1/T, in accordance with the Curie-Weiss law [17]. In Fig. 5, it is also found that the tiny peak in the mass susceptibil-ity-temperature (-T) curve occurs when the blocking temperature (TB) is near 70 K (TB= 70 K) for the ZFC data.

It is interesting to note that in Fig. 5, the ZFC and FC curves do not coalesce above the blocking temperature (TB

= 70 K) until they reach room temperature at TR = 300 K.

Furthermore, the ZFC data lies above the FC data all the way to room temperature. This result is explained as fol-lows: Upon cooling of the sample in a magnetic field (20000 Oe), the magnetic particles become un-trapped (i.e., unblocked) in their higher-magnetized state and have the thermal energy required to pass over the potential barriers to return to their lower-magnetized equilibrium configura-tion [18]. The ZFC and FC curves measured by SQUID for the alloy ST and then thermally aged at 500℃ for 100 h are shown in Fig. 6. This -T curve for the ZFC and FC data measurements were also performed in a magnetic field

Temperature dependence of the magnetization as obtained by SQUID (Fe-30Pd-4Ag as ST at 950 C/1.5h)

0.004 0.0042 0.0044 0.0046 0.0048 0.005 0 50 100 150 200 250 300 350 400 Temperature (K) S u sc ep ti b il it y (e m u /g -O e) ZFC FC ZFC: zero-field-cooled FC: field-cooled in 20000 Oe ZFC F C

Fig. 5 Temperature dependence of the magnetic susceptibility of the alloys solution treated (ST) at 950℃for 1.5 h and quenched in ice water. The measurements were carried out both at zero-field-cooling (ZFC), and at field-cooling (FC) in a field of 20000 Oe

of 20000 Oe. Figure 6 gives an indication that the blocking temperature (TB) for the aged sample is not clear.

The serrated (edge and step) ZFC and FC curves occur in the specimen aged at 500℃ for 100 h, which indicates that two phases exist in the aged sample. The two phases are comprised of monoclinic L1m phases and tetragonal

ordered L10 structures, which have differing magnetic

anisotropy.

IV. CONCLUSIONS

1. TEM selected area diffraction pattern (SADP) reveals that the orientation relationships between the L10; L1mcan

be demonstrated as [011]L10//[23 2]L1m and

[112]L10//[41 3]L1m, respectively.

2. The DSC study indicates the martensitic phase transition during heating of the sample as follows; a weak first or-dered L10 martensite → L1m (monoclinic phase) → A

(austenitestructure)→ second ordered L10martensite.

3. The serrated (edge and step) ZFC and FC curves re-vealed in the aged specimen illustrate that two phases exist in the aged sample. The two phases are comprised of monoclinic L1mphases and tetragonal ordered L10

struc-tures, which have differing magnetic anisotropy.

ACKNOWLEDGEMENTS

The authors would like to express their sincere appre-ciation to the National Science Council of the R.O.C. for supporting this work (under Grant-in-Aid for project No. NSC-95-2221-E-151-063).

Tem perature dependence of the m agnetization as obtained by SQUID (Fe-30Pd-4Ag alloy s as ST

and aged at 500C/100h) 0.00545 0.0055 0.00555 0.0056 0.00565 0.0057 0.00575 0.0058 0.00585 0 50 100 150 200 250 300 350 400 Tem perature (K) S u sc e p ti b il it y (e m u /g -O e ) ZFC FC FC ZFC ZFC: zero-field-cooled FC: field-cooled in 20000 Oe

Fig. 6 Temperature dependence of the magnetic susceptibility of the alloys ST and thermally aged at 500℃for 100h. The measure-ments were carried out both at zero-field-cooling (ZFC), and at field-cooling (FC) in a field of 20000 Oe

REFERENCES

[1] T. Wada, T. Tagawa and M. Taya, “Martensitic transformation in Pd-rich Fe-Pd-Pt alloy,”Scripta Materialia, vol. 48, pp. 207-211, 2003.

[2] H. Kato, Y. Liang and M. Taya, “Stress-induced FCC/FCT phase transformation in Fe-Pd alloy,”Scripta Materialia, vol. 46, pp. 471-475, 2002.

[3] K. Tsuchiya, T. Nojiri, H. Ohtsuka and M. Umemoto, “Effect of Co and Ni on martensitic transformation and magnetic properties in Fe-Pd ferromagnetic shape memory alloys,”The Japan Institute of

Metals, Materials Transactions, vol. 44, pp. 2499-2502, 2003.

[4] J. J. Felten, T. J. Kinkus, A. C. E. Reid, J. B. Cohen and G. B. Olson, “Solid-solution structure and the weakly first-order dis-placive transformation in Fe-Pd alloys,”Metallurgical and

Mate-rials Transactions A, vol. 28A, pp. 527-536, 1997.

[5] H. Xu and J. M. K. Wiezorek, “Transmission electron microscopy of room temperature deformed polytwinned L10-Ordered FePd,”

Acta Materialia, vol. 52, pp. 395-403, 2004.

[6] T. J. Klemmer, D. Hoydick, H. Okumura, B. Zhang and W. A. Soffa, “Magnetic hardening and coercivity mechanisms in L10

or-dered FePd ferromagnets,”Scripta Metallurgica et Materialia, vol. 33, pp. 1793-1805, 1995.

[7] T. J. Klemmer, C. Liu, N. Shukla, X. W. Wu, D. Weller, M. Tanase, D. E. Laughlin and W. A. Soffa, “Combined reactions associated with L10ordering,”Journal of Magnetism and Magnetic Materials,

vol. 266, pp. 79-87, 2003.

[8] T. Sohmura, R. Oshima and F. E. Fujita, “Thermoelastic FCC-FCT martensitic transformation in Fe-Pd alloy,”Scripta Metallurgica, vol. 14, pp. 855-856, 1980.

[9] T. Okazaki, H. Nakajima and Y. Furuya, “Large magnetostriction of Fe-29.6 at% Pd alloy ribbon under tensile stress,”The Japan

In-stitute of Metals, Materials Transactions, vol. 44, no. 44. pp.

665-668, 2003.

[10] T. Sakamoto, T. Fukuda, T. Kakeshita, etal, “Influence of magnetic field direction on rearrangement of martensite variants in an Fe-Pd alloy,”The Japan Institute of Metals, Materials Transactions, vol. 12, pp. 2495-2498, 2003.

[11] E. C. Oliver, T. Mori, M. R. Daymond and P. J. Withers, “Neutron diffraction study of stress-induced martensitic transformation and variant change in Fe-Pd,”Acta Materialia, vol. 51, pp. 6453-6464, 2003.

[12] L. Tan and W. C. Crone, “In situ TEM observation of two-step martensitic transformation in aged NiTi shape memory alloy,”

Scripta Mater, vol. 50, pp. 819-823, 2004.

[13] V. A. Chernenko, J. Pons, E. Cesari and I. K. Zasimchuk, “ Trans-formation behavior and martensite stabilization in the ferromag-netic Co-Ni-Ga heusler alloy,”Scripta Mater, vol. 50, pp. 225-229, 2004.

[14] C. Segui, V. A. Chernenko, J. Pons, E. Cesari, V. Khovailo and T. Takagi, “Low temperature-induced intermartensitic phase trans-formations in Ni-Mn-Ga single crystal,”Acta Materialia, vol. 53, pp. 111-120, 2005.

[15] C. Jiang, Y. Muhammad, L. Deng, W. Wu and H. Xu, “ Composi-tion dependence on the martensitic structures of the Mn-rich Ni-Mn-Ga alloys,”Acta Materialia, vol. 52, pp. 2779-2785, 2004. [16] Y. C. Lin, H. T. Lee, S. U. Jen and Y. T. Chen, “Magnetic structure

of an Fe-Pd-Rh alloy,”Journal of Applied Physics, vol. 101, no. 9, 09N514, 2007.

[17] B. D. Cullity, Introduction to Magnetic Materials, ed. by M. Cohen, Addison-Wesley, Reading, Massachusetts, USA, chap.1-2, 1972. [18] B. J. Hickey, M. A. Howson, S. O. Musa, G. J. Tomka, B. D.

Rain-ford and N. J. Wiser, “Superparamagnetism in melt-spun CuCo granular samples,”Magn. Magn. Mater, vol. 147, pp. 253-259, 1995.

16th International Conference on Composites/Nano Engineering (ICCE-16) 2008, July 20-26, 2008, Kunming, Yunnan, China.

1

RECRYSTALLIZATION OF FERROMAGNETIC Fe-Pd-Rh ALLOYS

Yin-Chih Lin

1, 2, Hwa-Teng Lee

1, and Chien-Feng Lin

31Department of Mechanical Engineering, National Cheng Kung University, Tainan, Taiwan 2

Department of Mold and Die Engineering, National Kaohsiung University of Applied Sciences 415 Chien Kung Road, San Ming District, Kaohsiung, Taiwan, ROC

3Department of Mechanical Engineering, National Kaohsiung First University of Science and Technology

Introduction

Recrystallization is the formation of a new set of strain-free and equiaxed grains that have low dislocation densities. The driving force that produces this new grain structure is the difference in internal energy between the strained and unstrained material [1]. The new grains form as very small nuclei and grow, until they completely consume the parent material. Thus, recrystallization of strained metals can be used to refine the grain structure. In addition, recrystallization leads to reduced hardness in increased ductility in the material, which could lead to improvements in ferromagnetic shape memory alloys (FSMA), such as Fe-Pd-Rh materials used in magneto-mechanical applications. In this paper, we report the results of an experimental investigation of the influence of annealing temperature and time on recrystallization in generating ultra fine grain sizes. The bulk FSM Fe-30Pd-2Rh (at%) alloys were forged to produce a 40% reduction in thickness. Then thermal annealing treatments were performed to induce recrystallization. The evolution of the optimum ultra fine grain size (< ASTM G. S. 10 #) during isothermal annealing at 950 ℃/3h and 1050

/1.5h

℃ was studied by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS).

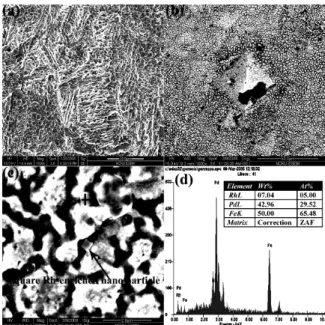

Results and Discussion

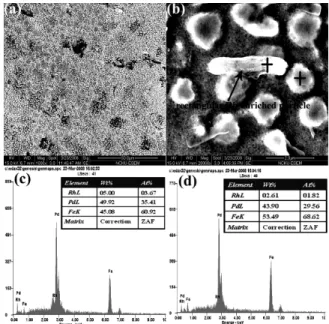

Figure 1(a) shows a SEM micrograph of the alloys in the deformed state after about a 40% reduction in thickness produced by forging. The slip bands, slip steps, and dislocation cells (or substructures) are clearly discernable. Since the corresponding x-ray diffraction data of the deformed sample reveals the {202}L10 reflection to be the main diffraction peak,

as shown in Fig. 3, it can be reasonably inferred from Fig. 1(a) that strain-induced fcc → L10 phase

transformations have taken place on the {202} plane in the strain-forged sample. The atomic displacements of the strain-forged specimen tend to occur in indistinct, complex, three-dimensional regions in slip bands along the {101} (i.e., {202}) planes, which also indicate the large atomic displacement along the <1 01> direction [2-4]. The micro-twin microstructures in Fig. 1(a) are likely to

Fig. 1 SEM micrographs of the alloys: (a) as ~40% strain-forged reduction in thickness; (b) forged specimen followed recrystallization at 950 ℃ for 3 h; (c) higher magnification of ultra fine grains; (d) EDS spectra taken from the square Rh-enriched nano particle (shown in (c), marked with).

be strains with L10 martensite nuclei lying on the

{101} plane of the strain matrix [2-4]. Figure 1(b) shows the strain-forged sample annealed at 950 ℃ for 3 h and quenched in ice brine. In this figure, the ultra fine grain sizes induced by recrystallization (< ASTM G. S. 10 #) are clearly demonstrated. Also, the plastic micro-indentation in Fig. 1(b) indicates that the process of recrystallization has resulted in the ultra fine grain having increased ductility. An enlarged fine grain image, taken from SEM, is shown in Fig. 1(c). The square nano particle heterogeneously exists in the grain boundary, as indicated by the arrow. Qualitative x-ray energy-dispersive spectrometry (EDS), taken from the SEM image, was performed to examine the partitioning of atoms during recrystallization. Figure 1(d) presents the EDS spectra taken from the square nano particle (in (c), marked with) which exists in the grain boundary, revealing an Rh content of about 5 at% Rh. The square Rh-enriched nano particles are heterogeneously distributed over the grain boundary, pinning the grain growth, as indicated by the arrow in the SEM photograph (Fig. 1(c)). From the EDS

2

the deformed {101} plane, as the alloys were strain-forged to produce a 40% reduction in thickness. Owing to recrystallization and grain growth being one type of atom diffusion mechanism, the higher melting point (1966 ℃) of Rh, with its higher activation energy and slower diffusion rate, leads to the retention of the square Rh-enriched nano particle in the grain boundary. The pinning of the grain growth by the Rh-enriched nano particles can be reasonably demonstrated as a possible source of the ultra fine grain sizes of the alloys resulting from deformation and annealing recrystallization. These ultra fine grain sizes enhance the ductility of the FSMA Fe-30Pd-2Rh (at%) for use in magneto-mechanical applications. Figure 2(a) shows alloys strain-forged to a 40% reduction in thickness, thermally annealed at 1050 ℃ for 1.5 h, and quenched in ice brine. This figure also reveals ultra fine grains that were generated by recrystallization. A corresponding enlarged SEM micrograph of the ultra fine grains is shown in Fig. 2(b). The rectangular Rh-enriched nano particle pinning the grains is indicated by the arrow. The EDS spectra showing Rh-enriched content, taken from the rectangular nano particle (in (b), marked with), are shown in Fig. 2(c), and the EDS spectra showing Rh-depleted content, taken from the ultra fine grain structure (in (b), marked with ), are shown in Fig. 2(d). Comparing the two spectra, a great disparity in rhodium is found. The intensity of rhodium content in the rectangular nano particle is markedly higher

Fig. 2 SEM micrographs of the alloys: (a) as forged specimen after recrystallization through annealing at 1050 ℃ for 1.5 h; (b) higher magnification of the ultra fine grains; (c) EDS spectra taken from the rectangular Rh-enriched nano particle (in (b), marked with ); (d) EDS spectra taken from the ultra fine grain structure (in (b), marked with).

Fig. 3 X-ray diffraction patterns for the alloys strain-forged to a (~40%) reduction in thickness. (L1mdenotes the adaptive

L1mmonoclinic structure, and L10denotes the ordered L10

martensitic phase).

(3.67 at% Rh), as demonstrated in Fig. 2(c). It is also interesting to note that the square Rh-enriched nano particle apparently grew into a rectangular Rh-enriched nano particle as the annealing temperature increased to 1050 ℃/1.5 h. Figure 3 represents the x-ray diffraction patterns of the alloys strain-forged to a (~40%) reduction in thickness, in which reflections of two phases, (211)L1m and

(202)L10, are the main diffraction peaks. The x-ray

results show that the strain-forged specimen induces the fcc → L10+L1m phase transition, and the strain

with L10 martensite nuclei lying on the {202} or

(101) plane of the strain matrix causes the main peak (202)L10 to be observable in the x-ray diffraction

patterns.

Conclusion

Investigation with scanning electron microscopy (SEM) reveals that square or rectangular Rh-enriched nano particles are heterogeneously distributed along the grain boundary when strain-forged specimens are annealed at 950℃/3h or 1050℃/1.5h and quenched in ice brine. The pinning of grain growth by the Rh-enriched nano particles can be reasonably inferred as a possible contributor to the ultra fine grain sizes of the alloys, resulting from a strain-forged (~40%) reduction in thickness with subsequent recrystallization through thermal annealing. The ultra fine grain size (< ASTM G.S.10 #) provides improved ductility in FSM Fe-30Pd-2Rh alloys for use in magneto-mechanical applications.

References

1. William D. C. Jr. “Materials Science and Engineering An

Introduction”, chap. 7, p. 180. John Wiley & Sons, Inc., N.

Y. (2002).

2. Wang, L., Fan, Z. and Laughlin, D. E. Trace analysis for magnetic domain images of L10 polytwinned structures.

Scripta Materialia, 47 (2002) 781-785.

3. Kato, H., Liang, Y. and Taya, M. Stress-induced FCC/FCT phase transformation in Fe-Pd alloy. Scripta Materialia, 46 (2002) 471-475.

4. Okazaki, T., Ueno, T., Furuya, Y., Spearing, M. and Hagood, N. W. Detectability of stress-induced martensite phase in ferromagnetic shape memory alloy Fe-30.2at% Pd by Barkhausen noise method. Scripta Materialia, 52

16th International Conference on Composites/Nano Engineering (ICCE-16) 2008, July 20-26, 2008, Kunming, Yunnan, China. 3

RECRYSTALLIZATION OF

FERROMAGNETIC Fe-Pd-Rh

ALLOYS

Yin-Chih Lin

1, 2and Hwa-Teng Lee

11

Department of Mechanical

Engineering, National Cheng Kung

University, Tainan, Taiwan

2

Department of Mold and Die Engineering,

National Kaohsiung University of Applied

Sciences, 415 Chien Kung Road, San Ming

District, Kaohsiung, Taiwan, ROC

Dear YC

The above attached two page abstract

will appear in World Journal of

Engineering,

upon

receipt

of

registration fee and attendance of

ICCE-16

regards

David Hui

- Original Message

---From:David Hui

To:Lin Yin-Chih

Sent: Sunday, May 04, 2008 6:30 PM Subject: RE: abstract

The above paper title is accepted for oral

presentation at ICCE-16 July 20-26,

2008 in Kunming, China

Please submit detailed two page abstract,

follow

abstract

format

in

web.

The

prepayment form is attached.

regards

David Hui

abstract

Fe-30Pd-2Rh (at%) ferromagnetic shape

memory (FSM) alloys were forged to a

40-45% reduction in thickness and thermally

annealed at 950-1000 ℃ for various times to

generate recrystallization. Investigation with

scanning electron microscopy (SEM) reveals

that square or rectangular Rh-enriched nano

particles are heterogeneously distributed along

the grain boundary. The pinning of grain

growth by the Rh-enriched nano particles can

be

reasonably

inferred

as

a

possible

contributor to the ultra fine grain sizes of the

alloys resulting from recrystallization.

摘要

鐵-30 鈀-2 銠(at%)鐵磁性形狀記憶合金,

經 40-45%鍛造變形後,再於 950-1000 ℃/

持溫各種不同時間退火處理,產生再結晶組

織。利用掃描式電子顯微鏡觀察顯示,微細

方形或細長方形富銠之奈米微顆粒不均勻

的散佈在晶界,這些富銠之奈米微顆粒存在

晶界,並阻礙晶粒的生長,被合理的推論是

造成此種鐵磁性形狀記憶合金,再結晶處理

後晶粒微細化的可能貢獻者。

4

參加 ICCE-16 國際學術研討會

心得報告

摘要

個 人 此 次 出 國 所 參 加 的 會 議 名 稱 為

16th

International

Conference

on

Composites/Nano Engineering (ICCE-16),此

會議屬於國際性重要的大型學術會議,每年

均舉辦一次,此次會議在大陸雲南昆明滇池

舉行,明年聽說要在美國舉辦。

此次會議主要議題包括:陶瓷複合材

料,奈米材料,電性與磁性材料,金屬與合

金材料,奈米製程,薄膜蒸鍍工程,表面鍍

膜,及其它相關材料科學與工程議題,個人

此次所參加之議題為磁性材料,所發表之研

究論文題目為:鐵-鈀-銠 鐵磁性合金之再

結晶,本研究主要利用鍛造方法使此磁性合

金產生應變變形,再利用退火再結晶方法使

此磁性合金產生超微細晶粒,進而大幅提升

此磁性材料的延性,使此磁性材料能適合使

用於將電磁能-轉換為機械能之應用。

本文

(A) 參加 ICCE-16 國際學術研討會之目的

ICCE 為一重要的國際學術研討會,該

研討會每年均舉辦一次,今年為第 16 屆,

個 人 係 第 一 次參 加 此一 國 際 性 學 術研 討

會,而參加此國際學術研討會之主要目的

為:(1)提升學校在國際上的學術地位,(2)

瞭解目前先進國家學者在磁性材料及相關

材料應用方面之研究方向,(3)增進個人在磁

性材料研究的見識,(4)認識相同研究領域的

國際友人,並作學術交流,(5)吸收國際上著

名學者之研究成果,(6)將個人之研究成果

激勵個人在磁性材料學術上研究的動能。

(

B) 參加 ICCE-16 國際學術研討會之過程

此次 ICCE-16 國際學術研討會舉辦日

期為 7 月 20 日至 7 月 26 日,地點在大陸雲

南昆明滇池舉行,此時正值放暑假,所以出

國參加國際學術研討會不用請假。個人於 7

月 20 日早上 4 點 30 分,由旅行社派接駁車

從住家接送出發,沿途共接送 6~7 位乘客,

接駁車由台南仁德交流道上高速公路已經

是早上 5 點,而由高速公路直達高雄小港機

場大概是早上 6 點,個人辦妥行李拖運後,

等到 7 點 20 分才登機,搭乘華信航空公司

AE 821 (07:45)飛機飛至香港,飛機到達香

港時間大約是早上 9 點 40 分,在香港辦理

轉機手續後,一直在機場等到中午 12 點 30

分 , 才 搭 乘 中 國 東 方 航 空 公 司 MU 734

(12:30)飛機飛至雲南昆明,於昆明機場提領

行李辦妥出關手續,時間大約是下午 3 點

30 分,走出機場與臺大材料所連雙喜教授

共搭計程車至雲南昆明滇池,到達昆明滇池

研討會會場大約是下午 4 點,接著辦理旅館

住宿繳費,再辦理研討會註冊繳費報到,時

間已經快接近晚上 7 點,個人用完晚餐後就

回住宿旅館休息。隔天第一天研討會,早上

安排為專題演講,共有六~八篇傑岀論文發

表,發表者有美國人、日本人、韓國人、大

陸人、德國人、澳洲人、英國人、瑞士人、

波蘭人、奧大利亞人………等,研討會

第二天以後,每天均分為四組三場論文發

表,即早上 8:00~11:00 AM 為第一場,中午

12:00~3:00 PM 為第二場,及下午 3:30~6:30

PM 為第三場。個人的研究論文被大會安排

在星期三(7 月 23 日)下午 3:30~6:30 PM 於 D

組會議廳發表,證明請參考附錄照片。

論文發表後,個人每天均從研討會議程

表,找出個人所感興趣的論文主題,並參與

該論文主題發表之聽講。星期五為此研討會

16th International Conference on Composites/Nano Engineering (ICCE-16) 2008, July 20-26, 2008, Kunming, Yunnan, China. 5

![Fig. 1 TEM micrographs of the Fe-30Pd-4Ag alloys solution treated (ST) at 950 ℃ for 1.5 h and quenched in ice water: (a) SADP of the zone axis [011] L10 //[23 2] L1m (hkl denotes the ordered L1 0](https://thumb-ap.123doks.com/thumbv2/9libinfo/8767763.210540/3.892.462.823.667.1027/micrographs-alloys-solution-treated-quenched-sadp-denotes-ordered.webp)