Research Express@NCKU - Articles Digest

Research Express@NCKU Volume 11 Issue 1 - October 16, 2009 [ http://research.ncku.edu.tw/re/articles/e/20091016/4.html ]

Characteristics of polyimide-based

nanocomposites containing plasma-modified multi-walled carbon nanotubes

Wan-Jung Chou1, Cheng-Chien Wang2, Chuh-Yung Chen1,*

1Department of Chemical Engineering, National Cheng-Kung University, Tainan 70101, Taiwan

2Department of Chemical and Materials Engineering, Southern Taiwan University, 710, Tainan, Taiwan

ccy7@ccmail.ncku.edu.tw

Composites Science and Technology,(Apr.15,2008);68(10-11):2208-2213

Nanocomposites are a class of composites in which the dimensions of the reinforcing phase are of the order of nanometers. These

nanocomposite materials are explored with a view to attaining enhanced mechanical features for efficient load transfer and tear

resistance,and to achieve certain levels of electrical conductivity through a percolation network for charge mitigation and electromagnetic

shielding. The use of single-walled- (SWCNT) and multi-walled carbon nanotubes(MWCNT) in polymeric composites in order to enhance their properties has attracted much attention recently. Much of the work in this area has concerned polyimides, which are widely used in

applications ranging from microelectronics to aerospace. Due to their insulating nature, significant levels of electrostatic charge may

accumulate on their surfaces, causing local heating and premature degradation of electronic components or space structures. To address this issue of the dispersion of MWCNT in polymer materials, we have used the

“grafting modification” method, which involves functionalization of CNT by plasma treatment to enhance their compatibility with a polyimide matrix. Starting with acid pretreatment of the MWCNT under sonication, the grafting of maleic anhydride moieties under plasma conditions not only improves their dispersal in polymer matrices, but also enhances the electrical conductivity and the mechanical andthermal properties of the resulting nanocomposites.

The polyimide nanocomposites were manufactured by a three-step method. First, mCNT were dispersed in DMAc under ultrasonication for 1 h, and then ODA was added to this DMAc solution with stirring for 2 h to obtain a mCNT-ODA suspension solution.Next, an equimolar amount of PMDA was added to the mCNT- ODA suspension solution. After stirring the suspension solution for 6 h, mCNT/PMDA-ODA polyamic acid (PAA) prepolymer was obtained. The entire reaction was carried out with stirring in a nitrogen-purged flask immersed in an ultrasonic bath at 25℃. Finally, the mCNT/PAA suspension solution was cast onto a glass plate and dried in an oven at 70℃ for 2 h, and the mCNT/PAA film thus obtained was thermally cured in an air-circulating oven at 300℃ to obtain a solvent-free, freestanding mCNT/polyimide film. A series of such mCNT/polyimide nanocomposite films was prepared with mCNT concentrations ranging from 0.0 to 3.0 wt

% (0.0 to 4.1 vol %).

Fig. 1 shows a plot comparing the conductivities of the mCNT/polyimide (mCNT/PI) composites and

1 of 3

Research Express@NCKU - Articles Digest

Fig. 1 Comparison the volume conductivities at different mCNT and CNT contents in the polyimide matrix.

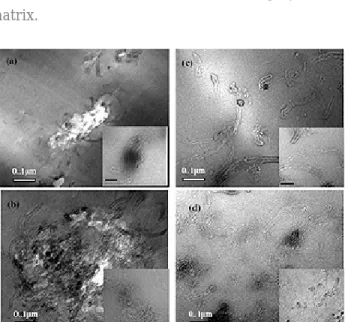

those of the original CNT/polyimide (CNT/PI) composites under similar conditions. Dispersal of the mCNT within the polyimide clearly leads to a lower percolation threshold. This increased conductivity is expected to be due to the reduced number of filler- filler hops required to cross a given distance by virtue of the good dispersion of mCNT in the matrix. Fig. 2 shows TEM micrographs of CNT/polyimide and mCNT/polyimide at 0.5 wt%. It’s clear that mCNT have better dispersion than CNT in the polyimide matrix. The mCNT thereby has a more pronounced effect on the percolation threshold than the CNT.

Fig.2 TEM images of CNT/polyimide and mCNT/

polyimid composite films: (a) CNT-0.5 wt%, (b) CNT-1.0 wt%, (c) mCNT-0.5 wt% and (d) mCNT- 1.0wt%.

Fig. 3 shows the Young’s modulus of the polyimide nanocomposites plotted against the mCNT

concentrations. The Young’s modulus increases to 2.27 GPa when 0.05 wt% mCNT is incorporated into the polyimide. The addition of 0.5 wt% of the mCNT to the polyimide further increases the Young’s modulus to 4.56 GPa, which is 110% higher than that of the neat polyimide. Fig. 4 shows the tensile strength (TS) and the elongation at break of the mCNT/PI nanocomposites plotted against mCNT content. The tensile strength of the nanocomposites clearly increases at low mCNT content (0•0.5 wt %), but decreases at high mCNT content (above 0.5 wt

%). This collapse of the mechanical properties beyond 0.5 wt% of the additive can be attributed to aggregation of the mCNTs. The CNT modified by plasma treatment with maleic anhydride may interact with the polyamic acid or dianiline. Hence, the

affinity of the mCNT for the polyimide matrix isexpected to exceed that of the unmodified CNTs. The maximum TS value, 249 MPa, was seen for the mCNT/PI with a 0.5 wt% mCNT loading, which is 100%

higher thanthat of the neat polyimide. Owing to the huge surface energy of mCNTs, they could not For this reason, the tensile strength is decreased at high mCNT content.

A series of mCNT/polyimide nanocomposites has been successfully prepared using mCNTs modified by plasma treatment. The conductivity of the mCNT/PInanocomposites could be increased by more than four orders of magnitude. At an mCNT content of 0.5 wt%, there is good dispersal of the mCNT in the polyimide matrixdue to chemical interactions between them. The Young’s modulus, tensile strength, and elongation at break of mCNT/PI films are markedly higher than those of the unmodified-CNT/polyimide films.

2 of 3

Research Express@NCKU - Articles Digest

Fig.3 Young’s Modulus with different CNT content. Fig.4Tensile strength and Elongation @ break with different mCNT content.

3 of 3