Multi-Objective Based Optimization for Switched Reluctance Machines Using Fuzzy and Genetic Algorithms

Satit Owatchaiphong

The Sirindhorn International Thai-German Graduate School of Engineering

King Mongkut’s University of Technology North Bangkok 1518, Pibulsongkram Rd., Bangsue, Bangkok, Thailand

E-mail: satito@kmutnb.ac.th

Nisai H. Fuengwarodsakul

The Sirindhorn International Thai-German Graduate School of Engineering

King Mongkut’s University of Technology North Bangkok 1518, Pibulsongkram Rd., Bangsue, Bangkok, Thailand

E-mail: nisaif@kmutnb.ac.th

Abstract -- This paper presents a design methodology for sizing a preliminary design of a switched reluctance machine. The proposed method combines the use of genetic and fuzzy algorithms together to simplify the design method. Genetic algorithms (GA) are utilized for handling a multiple objective problem, whereas fuzzy algorithms (FA) simplify a definition of fitness evaluated functions for GA. Knowledge of design guidelines as well as specified dimensions is counted as the optimization objectives in the design process. Difficulty and complexity for describing an increased number of the fitness functions are declined by means of fuzzy description. Therefore, this method is much convenient to provide the means for multi-objective based optimization problems. An application is set to describe the functionalities of the proposed method. Simulation results verify that the improved GA with fuzzy algorithms gives better performances for the multi-objective optimization problems than those of conventional genetic algorithms.

I. INTRODUCTION

A switched reluctance machine (SRM) is doubly salient machine. Its structures are familiar with those structures of stepper motors. SRMs have concentrated windings placed on its stator, but the rotor is only a stack of soft magnetic steel sheets without coils or magnets.

In most conventional design processes as shown in Fig.1, a preliminary model of a SRM is approximately formed based on design guidelines published in [1] [2]

[3] and mostly designer's experiences. Performances of the generated model are evaluated by the optimization objectives. Afterwards, the dimensions of the model are altered based on these results. By repeating the process, an optimal design is developed. This iteration process consumes much time and requires the great experience of designers to develop a well-optimized model. It is still difficult to globally find out an optimized solution from multi-objective problems, if many machine parameters have to be concerned.

Fig.2. shows a normalized design process presented in [4], the use of GA is applied for treating all design parameters in the multi-objective optimization design problems. However, most of them separate specified dimensions and design guidelines from optimization constraints. After reforming processes, new generated models are regulated by the specified dimensions to eliminate invalid models having impossible dimensions and to ensure the existent of the specified dimensions.

This step blocks flow of the reforming process without regarding of fitness values. In optimization presented in [5], the specified dimensions and design guidelines are

included in the fitness evaluation as the optimization objectives. As result, the optimized model also inherits the specified dimensions. It leads to standardize design processes of SRMs by congregating every consideration in a single step. However, this increases the number of objective function.

In [6], it presents the convergence problem of genetic algorithms for multi-objective problems that causes by improperly defined objective functions. Since a very good score of one objective functions can compensate bad scores of other objective functions, the fitness results in a standard score, which influences the parent selection process. Well-described objective functions can prevent incompetence compensation of each objective, but it is difficult when many objectives are concerned.

Fig.1. Conventional design procedure

Fig.2. Normalized design process by handling every design consideration in a single step

In this paper, FA is utilized for comforting the definition of the objective functions. They are still as simple described as before. The objectives are not expressed by mean of FA [7], but it helps to make a decision whether the evaluated fitness is good by itself

Costumer's requirement

Estimating model by design rules

Calculating model performances

Evaluating fitness of model from performances, specified dimension and design rules

Reforming model Costumer's requirement

Estimating model by design rules and checking specified dimension

Calculating model performances

Evaluating fitness of model from performances

Reforming model

PEDS2009

1530

or compensated by each objective. Considering each objective, the total fitness score is scaled by FA before passing to the reforming process.

II. OBJECTIVE FUNCTIONS

To describe functionality of the proposed process, a 3 phase 6/4 SRM is optimized for a normal application.

An average torque of the machine is maximized, while outer dimensions are given. A ventilator is installed for cooling at the end of machine. Therefore, optimization objectives concerning machine performances are torque at a specific current density. An average torque of SRMs is calculated by a flux linkage diagram proposed in [1]

[2] [8]. The average torque are determined at the current density of 8 A/mm2 based on the cooling method for fan cooled machines presented in [1]. To score the fitness value of the torque objective, an average torque value is conversed to a per-unit value.

f1 = f(T/Tref) (2) Where Tref is torque reference to convert fitness into per unit system.

As mentioned, the outer dimensions of SRMs are given, an outer radius, Rs, and stack length, Lstk. The objective functions are expressed by (3) and (4). The unsatisfactory models should be rejected in the parent selection by means of the survival rules of GA.

f2 = f(Rs/Rs,ref) (3) f3 = f(Lstk/Lstk,ref) (4) Where Rs,ref and Lstk,ref are the given outer radius and stack length, respectively. Besides the mentioned objectives regarding to the given dimensions, the other objectives in (5) and (6) are implemented by design guidelines presented in [1][2]. For a 3 phase SRM, the yoke, ys, should be thicker than a half of the pole width, bs, to prevent yoke from being saturated before the pole is saturated. Another objective is a relationship of rotor and stator pole. The rotor pole, βr, should be greater than the stator pole, βs.

f4 = f(ys/bs) (5) f5 = f(βs/βr) (7) The fitness is calculated by.

fitness = k.(f1.w1+f2.w2+f3.w3+f4.w4+f5.w5) (8) Where w1, w2, w3, w4 and w5 are weighted average, which are used for increasing or reducing scores determined by the objective functions according to the priority of each objective, while k is the scaling factor determined by means of fuzzy description. Regarding fitness values of each objective, FA judges if a total fitness of each model becomes good by itself or by incompetent compensation, and calculates a scaling factor. Sequentially, the total fitness is scaled by this scaling factor.

III. PROPOSED METHOD

Most of automatic design processes utilizing genetic

algorithms, only the total fitness value is used for evaluating how good the model is. The value is an important value which is used in the parent selection process. To calculate this value effectively, all of scoring functions must be together determined to prevent compensation which can happen when a very good score of a function compensates a bad score of other functions.

The total fitness value turn out good in spite of the model is actually poor.

Fig.3. and Fig.4. present scoring functions of torque and outer diameter, respectively. Both dotted lines are directly expressed by optimization criterion and limitation as mentioned in the previous section. The high torque producing models get high scores, while the limitation is set for the outer diameter of machine.

Without compensation protection shown by the solid line in Fig.3, a very high score of torque criterion can cover the zero score of outer diameter limitation. Besides torque, the given dimensions can be expressed by the solid line shown in Fig.4. The most preferred outer diameter gets the highest score, otherwise the score is low.

Fig.3. Scoring function of average torque

Fig.4. Scoring function of outer diameter

However, in this paper, there are six considerations, two torque objectives, two given dimensions and two design guidelines. This makes it complicate and difficult

PEDS2009

1531

to determine the limitation for each scoring functions to prevent the high scores from compensating each others.

In this paper, the proposed method simplifies definition of scoring functions by cooperating with fuzzy algorithms. The performances of starting and nominal torque, outer diameter, stack length, ratio of stator yoke thickness and pole and ratio of stator and rotor pole are calculated by the simple scoring functions shown by the dotted lines in Fig.3. and Fig.4.

Parallel to the fitness values calculated by the scoring function, a fuzzy scale factor is calculated by mean of fuzzy description. A total fitness score is calculated by multiplying the fitness with the fuzzy scale using (8). As shown in Fig.5, the total fitness is afterward evaluated by genetic algorithms in the reforming process.

Fig.5. Evaluation of fitness for reforming process of genetic algorithms

Fig.6. Membership function of torque

Fig.6. shows a membership function of torque, which is classified in three fuzzy sets, low, medium and high.

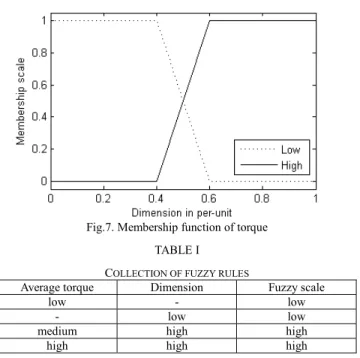

The membership function is not determined by a crisp function, but a triangle and a trapezoidal function. The triangle and trapezoidal are two simple characteristics of membership functions. There are many characteristics of membership functions, for example, s-, pi-, z-function, and etc. They are suitable for different work [7]. Fig.7.

shows a membership function of dimension, which is classified in two fuzzy sets, low and high.

Fig.7. Membership function of torque TABLE I

COLLECTION OF FUZZY RULES

Average torque Dimension Fuzzy scale

low - low

- low low

medium high high high high high

By considering combination of fuzzy sets between torque and dimension, it can easily decide that the model is good or bad. It can tell that either torque or dimension is bad. It does not matter if other objectives are good, then the model is considered as bad. In other words, a scaling factor that is mentioned in the previous section can be determined. By Table1 providing collection of fuzzy rules, the fuzzy scale is determined to scale the fitness score received from the scoring criteria.

IV. SIMULATION RESULTS

The proposed process has been implemented in MATLAB, a widely-used calculation program, whereas machine models and performances are generated and analyzed by PCSRD, a commercial analysis program for SRMs. Conventional GA and the proposed GA and FA based optimizations were examined under the identical conditions. The result presents an improvement of the torque by 4.04 percents by the conventional GA based optimization presented in [5]. Each optimized models from both methods were simulated in details. Table2 presents comparison results of both machines. Besides average torque, the outer dimensions of the proposed method are closed to the given specifications.

TABLE II

COMPARISON BETWEEN CONVENTIONAL GA BASED AND GA WITH FA

BASED OPTIMIZATION

Fig.8. and Fig.9. present better result of the proposed process compared with conventional GA, average fitness

Comparison lists

Reference value

GA based optimization

GA and FA based optimization Outer diameter in mm. 170 168.8 169.75

Stack length in mm. 120 119.5 120 Average torque in Nm. 30 32.12 33.42

Current density in

A/mm2 8 8 8

Calculating model performances

Calculating fuzzy scale

Calculating total fitness using (8)

Calculating fitness score of each criteria

Evaluating fitness by genetic algorithms

PEDS2009

1532

and average pole angle ratio. Both present the identical scores in the first generation. Later, the average fitness of the proposed process is much better improved. The stator and rotor pole ratio is also closed to 1 mentioned in the design guidelines that rotor pole should be a little wider than stator pole.

Fig.8. Comparison results of fitness between optimization with and without using fuzzy scaling

Fig.9. Comparison results of pole angle ratio between optimization with and without using fuzzy scaling

Fig.10. Comparison results of nominal torque before and after scaling with fuzzy scale

Besides the comparison results of the GA based and proposed methods, Fig.10. presents the average value of nominal torque of the proposed method before and after scaling by fuzzy algorithms. It is very different in the early generations and becomes closed together after the 14th generation. It means that the scoring factor is closed to 1. It presents prevention of the compensation problem that can leads to a diverted solution.

V. CONCLUSION

The study has improved and realized the normalized design process of SRMs presented in [5]. The uses of genetic and fuzzy algorithms were combined. All design parameters and objectives are handled in a single step.

The difficulty for describing the objective and fitness functions is eliminated by fuzzy algorithms. Finally, the design process successfully optimized the examined machine for the assignments and the average torque of the machine was improved and the model also inherited the specific dimensions. The comparison results were discussed. It verified the functionalities of the proposed method.

VI. REFERENCES

[1] T.J.E Miller, Switched Reluctance Motors and Their Control.

London: Oxford University Press, 1993.

[2] ───, “Optimal Design of Switched Reluctance Motors,” IEEE Transaction on Industrial Applications, Vol.49, no.1, pp.15-27, February 2002.

[3] M.N. Anwar, I. Husain and A.V. Radun, “A Comprehensive Design Methodology for Switched Reluctance Machines,” IEEE Transaction on Industrial Applications, Vol.37, pp.1684-1692, November 2001.

[4] Skaar S.E., R. Nilssen, Genetic Optimization of Electric Machines, a State of the Art Study. Department of Electrical Power Engineering, NTNU, Norway, 2004.

[5] S. Owatchaiphong, N.H. Fuengwarodsakul, “Multi-Objective Based Optimization for Switched Reluctance Machines Using Genetic Algorithms,” EECON, 2008. 31st Electrical Engineering Conference, pp., October 2008.

[6] David E. Goldberg, Genetic Algorithms in Search, Optimization and Machine Learning. Boston, MA, USA: Addison Wesley Publishing Company, Inc. 1989.

[7] W. Siler, J. J. Buckley, Fuzzy Expert Systems and Fuzzy Reasoning. New Jersey: John Wiley & Sons, Inc, 2005.

[8] N.H. Fuengwarodsakul, J.O. Fiedler, S.E. Bauer and R.W. De Doncker, “New Methodology in Sizing and Predesign of Switched Reluctance Machines Using Normalized Flux-Linkage Diagram,” Industry Applications Conference, vol. 4, pp. 2704- 2711, October 2005.

PEDS2009

1533