FP03

1530

Proceedings of the 37th IEEE Conference on Decision & Control Tampa, Florida USA December 1998Petri Net Based Modeling and GA Based Scheduling for

a Flexible Manufacturing System

Yung- Y i Chung, Li- Chen Fu, and Ming- Wei Lin

Department of Computer Science and Information Engineering

National Taiwan University, Taipei, Taiwan,

R.O.C.

Abstract

In this paper, a genetic algorithm (GA) embedded adaptive scheduling over a timed place Petri net (TPPN) model provides a new method for a flexible manufacturing system (FMS). The chromosome rep- resentation of the search nodes is constructed directly from the T P P N model of an FMS. A TPPN based schedule builder receives a chromosome and an initial marking as input, and then produces a near-optimal schedule.

1

Introduction

In this paper, we develop a T P P N modeling approach for FMSs, and implement it as an automatic Petri net generator (APNG) [3, 2, 41. The APNG developed

here has a graphic user interface that facilitates users

to input the specification of an FMS, based on which the operator can create a TPPN model of the FMS. In addition, a GA search based adaptive scheduling method is also proposed t o find an effective schedule [5,2,41.

2

TPPN Model Generator

The hierarchical view of the entire system model con- tains two major sub-models [4]. One is called Trans- portation Model and the other is called Process-Flow Model. The objective of the Transportation Model is t o model the behavior of the material handling de- vices traveling from the current stop t o its destina- tion stop, and that of the Process-Flow Model is t o describe the behavior of parts routing and resources assignment. Each sub-model interacts with the other by using some common places. For example, when Job n needs t o call AGV a t o move t o a specified stop

i , the Process-Flow Model of Job n will add a token in the place r n v i a , which is also a place in the Move- ment Control Module of AGV a of the Transporta- tion Model as a command. When AGV a arrives at the specified stop i, the Movement Control Module of

AGV a will place a token in the place a t i a , which 0-7803-4394-8198 $1 0.00 0 1998 IEEE

4346

is also a place in the Process-Flow Model of Job n t o acknowledge that AGV a just arrives at the specified stop.

3

Genetic Algorithm Scheduler

Genetic Algorithm Scheduling

Schedule Builder

A schedule builder is dedicated t o transforming a chro- mosome t o a feasible schedule wherely, we can evalu- ate the aforementioned indirect chromosome represen- tation. Based on a T P P N model of the system, the evolution of the system can be described by the change of marking in the net. So, given a T P P N model and a chromosome, the schedule builder can generate a fea- sible schedule in terms of the firing sequence of tran- sitions in the timed place Petri net model according

to the chromosome. The firing sequence of transitions provides the order of the initiation of operations.

Fitness Function

The fitness value of chromosome can be determined after the schedule builder generates the schedule.

In the current implementation, we use the makespan, due date, and machine utilization as the performance measure, which are represented by f i ,

fz and f3, respectively. Then, we use linear scaling

method t o scale the value between 100 and 0 and get the scaled value

fi

t ofi.

Finally, we define the fitness values for each chro- mosome as follow:

fi = W I

fi

+

W Z.f;

+

~3* f i

where w1 t o w3 is predefine weighted number.

Genetic Operations

Reproduction In the implementation, we use the

scheme where the probabilities of selection are calcu- lated in the form:

f i pseledi = -

I "

t

F 4000

2000

Figure 1: The System Layout.

Figure 3: History of Jobl & Job2.

Figure 2: The Process Flow Graph of J o b l & Job2.

.

Then, the actrual number of chromosome ci is cal- culated by spinning the weighted roulette wheel.Crossover The chromosome representation d e

scribed above contains information about plan selec- tions, resource assignments of every operation, and resource competition resolutions. We can create new chromosomes by exchanging portions of two old chro- mosomes simply.

Adaptive Scheduling

We use the implementation of the proposed adaptive scheduler [l]. We define WIP and the condition for the schedule generator, which generates the partial schedule in the current segmented GA search for every job. Although, the scheduling strategy may not pro- vide an optimal schedule, when the number of parts t o be processed is very high, it can generate an effective schedule in a shorter time interval.

4

Experiment Results

System Layout and Process Flow

This example illustrates a prototype FMS. The layout of this target system is shown in Figure 1. And Figure 2 shows the process flows of the two jobs.

4347

Implementation Results

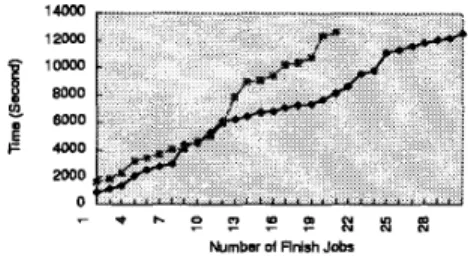

In Figure 3, the relation between the number of com-

pleted parts and the completion time is shown. In average, GA embedded search takes about 9 minutes for one generation on our PC.

5

Conclusion

In this paper, we consider the FMS scheduling prob- lem. We first propose a systematic Petri net model- ing for an FMS. The entire TPPN model is composed of two sub-models, one is Transportation Model and the other is Process Flow Model. Then, we propose

an adaptive scheduling method incorporating the GA

search.

It

not only generates an efficient schedule but also allows one t o set the different priorities among the jobs.References

[l] Carlos F. G. Bispo, Jo60 J. S. Sentieiro, and Fbger D. Hibberd. Adaptive scheduling for high- volume shops. IEEE f i n s . on Robotics and Au- tomation, 8(6):696-706, December 1992.

[2] Doo Yong Lee and Frank DiCesare. Integrated models for scheduling flexible manufacturing sys- tems. In Proc. IEEE Int. Conf. on Robotics and Automation, pages 827-832,1993.

[3] James Lyle Peterson. Petri Net Theory and the modeling of Systems. PrenticeHall, Englewood

Cliffs, N.J., 1981.

[4]

Tien-Hsiang Sun, Chao-Weng Cheng, and Li-ChenFu. A Petri net based approach t o modeling and scheduling for an FMS and a case study. IEEE Dan$. on Industrial Electronics, 41(6):593400,

December 1994.

[5] Takeshi Yamada and Ryohei Nakano. A Genetic Algorithm applicable t o large-scale job shop prob- lems. In Parallel Problem Solving from Nature,