namely,共1兲 glass transition temperature, Tg共 ⬃ 100°C兲, 共2兲 onset temperature 共160°C兲 for transforming cage to network struc-ture, and共3兲 immobilization temperature 共170°C兲. In contrast, a rapid curing rate enabled the formation of small porogen size 共 ⬃ 12 nm兲 in the hybrid films and yielded better mechanical strength.

© 2011 The Electrochemical Society. 关DOI: 10.1149/1.3529246兴 All rights reserved.

Manuscript submitted June 22, 2010; revised manuscript received November 18, 2010. Published January 13, 2011.

As the feature size of microelectronic devices continues scaling down, the increase in resistance-capacitance共RC兲 delay, cross talk noise, and power dissipation in the interconnect structure become the limiting factors in the ultra-large-scale integration of integrated circuits.1To further reduce the delay, materials with low dielectric constants共low-k兲 ranging from 2.65 to 3.0 were introduced to re-duce the parasitic capacitance 28–37% less than that of SiO2 共k = 4.2兲 and 19–28% less than that of fluorosilicate glass 共k = 3.7兲.2 Moving further toward a 45 nm node and beyond, the incorporation of porosity, in which air has kair= 1, the lowest attainable value,3 becomes essential for producing viable low-k materials with k ⬍ 2.5.4

Conventionally, porous low-k dielectric films are generally formed following the deposition of a low-k matrix with a thermally liable pore generator 共porogen兲5 such as norbornene-derivative,6 polyoxyethylene ether,7and amphiphilic block copolymers共ABCs兲, including poly共ethylene oxide-b-propylene oxide-b-ethylene oxide兲8,9 and poly共methyl methacrylate-co-dimethylaminoethyl methacrylate兲,10,11which are burned out by thermal treatment at low temperatures, typically艋200°C immediately following the deposi-tion of the film.

However, various problems associated with the integration of as-deposited porous dielectrics have been identified.12,13These in-clude 共1兲 high leakage and device reliability at the barrier/low-k interface because of insufficient coverage for large pores,12and共2兲 large variation in RC delay caused by the significant roughness in the dielectric due to etching.13To solve these problems, a postint-egration porogen removal scheme14based on material design and process integration has been proposed. It employs high-temperature porogen to defer the formation of a porous low-k dielectric until the completion of the copper chemical-mechanical polishing 共CMP兲 step, and then thermally removes the sacrificial porogen from the hybrid dielectric film, as illustrated in Fig.1. In the postintegration porogen removal scheme, the porogen in the hybrid low-k matrix/ porogen films must survive at the highest possible processing tem-perature 共preferably 300–350°C兲 cycling of back-end-of-line pro-cessing steps. Accordingly, the decomposition temperature共Td兲 of high-temperature porogen candidates must exceed 350°C to implement the postintegration porogen scheme. Polystyrene-b-polybutadiene-b-polystyrene 共SBS兲 with Td ⬎ 350°C is a favorable candidate porogen because of its thermal stability. In addition, its amphiphilic characteristics can significantly improve the miscibility of the MSQ/porogen hybrid, which prevents phase separation prior to the burning out step.8,9

For such hybrid films to survive the backend processing such as the CMP step in the postintegration porogen removal scheme, the hybrid low-k material should possess sufficiently strong mechanical strength. Moreover, the mechanical property, such as Young’s modu-lus of the hybrid films, depends on the porogen morphology, size, and size distribution, among other factors, including, for instance, the chemical structures of the matrix and degree of cross-linking. Yet, the interaction between the porogen and low-k matrix during curing and their impact on the porogen size of low-k/porogen hybrid films are not fully understood. Thus, it is of critical interest to un-derstand the porogen behavior and how to control its size in the low-k matrix/porogen hybrid films before burning out porogen to form a porous low-k film.

In this paper, a commercial, spin-on organosilicate, i.e., methyl-silsesquioxane 共MSQ兲 was selected as the matrix and a high-temperature porogen such as SBS, was employed as the sacrificial component. The effects of the curing rate共slow, 2°C/min vs rapid, 200°C/min兲 and cure temperature on the porogen size in the hybrid low-k films cured up to 200°C were studied by in situ grazing inci-dence small-angle X-ray scattering共GISAXS兲, viscosity measure-ment, and Fourier transform infrared共FTIR兲 analysis. The impact of the MSQ structure during the thermal cure process on the porogen aggregation behavior and its correlation with porogen size will be described and elucidated.

Experimental

The low-dielectric-constant matrix, MSQ, was obtained from Gelest, Inc. MSQ has two main structures; namely, a cage structure and a network structure.15,16 Polystyrene-block-polybutadiene-block-polystyrene共28% polystyrene Mw = 90,000 g/mole兲 triblock copolymer, as the high-decomposition-temperature porogen 共Td ⬃ 390°C兲, was obtained from Sigma-Aldrich Co. To form hybrid low-k films, MSQ and SBS at 5 wt % loading were dissolved in tetrahydrofuran共THF兲 to form a hybrid low-k solution without spe-cial treatment such as surfactants to further minimize the porogen size. The solution was initially filtered through a 0.20m PTFE filter共Millipore, Inc.兲, and then spun onto a 共100兲 silicon wafer at 2000 rpm for 30 s at room temperature to obtain a film thickness of 500 nm.

The sizes of the porogen in the hybrid low-k films were then characterized by in situ GISAXS under two curing profiles:共1兲 slow curing at 2°C/min and 共2兲 rapid curing at approximately 200°C/min. In situ 2D GISAXS data were collected from 30 to 210°C in intervals of 20°C, in which data collection times are 5 and 2 s for slow and rapid curing profiles, using beamline 17B3 of the National Synchrotron Radiation Research Center, Hsinchu, Tai-wan. All of the GISAXS data were obtained using an area detector

*Electrochemical Society Active Member. z

that covered a q range from 0.01 to 0.1 Å−1, and the incident angle of the X-ray beam 共0.5 mm diameter兲 was fixed at 0.2° with an X-ray energy of 10 keV. Then, the pore size was analyzed by sphere model fitting and Guinier’s law.17-23

The interaction between MSQ and SBS was examined by an in situ viscosity measurement usingARES共Rheometric Scientific兲. The

viscosity data were collected from room temperature to 200°C共1兲 at a slow curing rate共2°C/min兲, and 共2兲 isothermally at 200°C. The structural change and the degree of cross-linking of MSQ in the MSQ/porogen hybrid films were investigated as a function of tem-perature ranging from 25 to 200°C by FTIR spectroscopy using a Magna-IR 460共Nicolet, Inc.兲 in a transmission mode with 64 scans at a spectral resolution of 2 cm−1.

The elastic modulus共E兲 of the hybrid film was measured using a nanoindenter 共MTS, Nano Indenter XP system兲 with a Berkovich tip. The samples were cured up to 200°C following two different curing profiles to form hybrid low-k films. In the slow curing method, the sample was cured in a quartz tube furnace under N2at a curing rate of 2°C/min to 200°C for 30 min. In the rapid curing method, the samples were cured for 30 min directly on the hot plate preheated at 200°C. The nominal film thickness of hybrid films for nanoindentation is 1200 nm, while the indentation depth is kept at 100 nm.

Results and Discussion

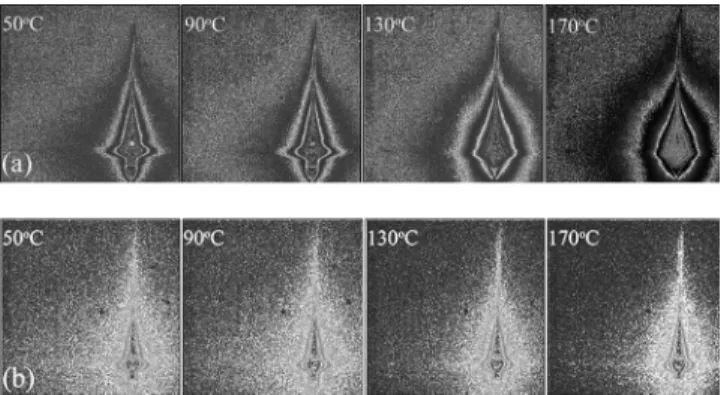

The porogen size of the hybrid low-k films before burning out were first characterized by in situ GISAXS. Figures2aand2bshow the 2D GISAXS scattering patterns of the hybrid low-k films for various curing temperatures 共50–210°C兲 at two different curing rates. In Fig.2a, the scattering patterns of the hybrid low-k film cured at a slow curing rate showed significant transition between 90 and 170°C. In contrast, the scattering patterns of the low-k films cured at a rapid curing rate exhibited little variation, as illustrated in Fig. 2b. These scattering patterns indicate that the SBS porogens showed much diffusion and aggregation activity within the MSQ matrix when the hybrid film was cured at a slow curing rate. In contrast, the diffusion and aggregation of SBS within the MSQ ma-trix is very limited when the hybrid low-k film was cured at a rapid rate.

From GISAXS scattering patterns, the porogen sizes in the MSQ/ SBS films cured under different rates at temperatures between 50 and 210°C can be further determined. In this paper, a particulate system18 was used to analyze the scattering data by treating the pores in the matrix the same as the particles in the hybrid film. When the particle concentration is low, the scattering of the pores in the matrix does not mutually interact. Accordingly, the scattering intensity of individual particle, I共q兲, could be defined by Eq.1

I共q兲 = np共p−m兲2V p

2P共q兲S共q兲 关1兴

where the wave vector q = 4−1sin is defined by the wave-length and the scattering angle 2 of X rays, np is the number density of particles,pandmare the scattering density of the par-ticle and the matrix, respectively, Vp denotes the volume of the particle, P共q兲 is a form factor, and S共q兲 is a structure factor. The structure factor S共q兲 is close to 1 in a low-concentration system and thus can be ignored. Therefore, the scattering profile of I共q兲 is only related to the form factor P共q兲 of the particles. As a result, I共q兲 can be furthered to the Guinier’s expression,19-21 involving radius of gyration Rgas described by Eq.2

I共q兲 = np共p−m兲2V p

2exp

冉

− q2Rg23

冊

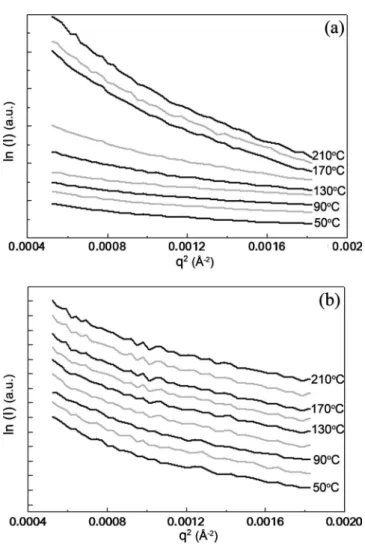

关2兴In this case, a linear relationship exists between ln共I兲 and q2, with a slope of 共−Rg2/3兲. Figures 3a and 3b show the ln共I兲 plot against q2in the 2D GISAXS scattering patterns of the hybrid low-k films cured at various temperatures under slow curing and rapid curing conditions, respectively. The slope, i.e., Rgsize, showed that the porogen Rgsize increased nonlinearly with the curing tempera-ture between 50 and 210°C in the slowly cured system as shown in Fig.3a, but varied little with temperatures between 50 and 210°C in the rapidly cured system, as shown in Fig.3b. Since the shape of the SBS porogen in the hybrid film is close to a sphere as confirmed by a scanning electron microscope, the pore size d could be deduced from d = 2共5/3兲1/2R

g.22,23In addition, the porogen size distribution is estimated from the change of the slopes in the low-q region; for instance, monodispersity corresponds to a single slope. As a result, the calculated porogen size and distribution of the hybrid low-k films as a function of curing temperatures under slow curing and rapid curing conditions are shown in Fig.4. Upon slow curing to 210°C, as shown in Fig.4a, the porogen size/distribution increased from 12.7⫾ 2.3 nm to 32.8 ⫾ 5.4 nm. Moreover, the increased rate of pore size became noticeable at T⬎ 110°C, and more significant between 130 and 170°C 共from 17.5 ⫾2.9 nm to 31.2 ⫾ 4.9 nm兲, but showed little variation between 170 and 210°C 共from 31.2 ⫾ 4.9 nm to 32.8 ⫾ 5.4 nm兲. In

con-Figure 1. Schematic diagrams of damascene processing steps based on a

postintegration porogen removal scheme.

Figure 2. 2D GISAXS scattering patterns of the hybrid low-k films as a

function of cure temperature under共a兲 slow curing and 共b兲 rapid curing conditions.

trast, the porogen size/distribution remained about 12⫾ 2 nm with a narrow size distribution upon rapid curing up to 210°C, as shown in Fig.4b.

Subsequently, the interaction between the SBS porogen and the MSQ matrix was examined by an in situ viscosity measurement from room temperature to 200°C 共1兲 at a slow curing rate 共2°C/min兲, and 共2兲 at a rapid curing rate, i.e., isothermally at 200°C, as shown in Figs.5aand 5b, respectively. For the slowly cured system shown in Fig.5a, the viscosity increased linearly up to about 3800 s or 100°C when it reached the first plateau. In this period, the viscosity was strongly influenced by the solvent, i.e., THF, whose boiling point is 66°C. At this time, the molecular chains of MSQ and porogen hardly diffused and aggregated because the hybrid films behaved like a solid as the solvent, THF, was slowly evaporated, leading to film shrinkage and an increase of viscosity.24 Beyond 100°C, the viscosity initially remained around 210,000–230,000 poise in the plateau, then dropped drastically to 130,000 poise above 160°C and up to 170°C, and subsequently increased again up to⬃250,000 poise at 200°C. In the plateau stage 共100 to 160°C兲, the glass transition temperature 共Tg兲 of the hybrid film played an important role on the viscosity. For the low-k matrix MSQ, it has a Tgaround 88–111°C depending on the ratio of hy-droxyl and methoxy groups within the precursor.25In contrast, the porogen SBS has a Tgaround 98–105°C depending on the weight percentage of polystyrene and polybutadiene.26Based on differential scanning calorimetry measurement, the Tg’s of SBS and MSQ in this study were 90 and 100°C, respectively. As the temperature exceeded

100°C, i.e., Tg of MSQ, the molecular chains of the MSQ matrix became relaxed or “rubberlike,” which further enhanced the mobil-ity of the SBS particles, resulting in a slight reduction of viscosmobil-ity to ⬃210,000 poise. It is believed that SBS particles aggregated readily as facilitated by the rubberlike MSQ matrix at T艌 Tg.

As the temperature was increased to about 160°C, the drastic drop of viscosity in the MSQ/SBS hybrid film was presumably caused by the plasticization of H2O released at the onset of the significant MSQ cross-linking reaction, which will be further eluci-dated by FTIR analysis in the following section. After 170°C, the viscosity resumed its increasing trend up to 200°C as H2O was evaporated rapidly while the cross-linking of the low-k MSQ matrix continued. As a result, significant aggregation of the SBS porogen occurred during the 160–170°C stage due to its high mobility in a much reduced viscosity condition. This explained the rapid increase of porogen size and distribution at temperatures between 150 and 170°C; then the porogen size leveled off due to the limited mobility

Figure 3. ln共I兲-q2plots along q

xyfrom 2D GISAXS scattering patterns of the hybrid low-k films cured at various temperatures under共a兲 slow and 共b兲 rapid curing conditions.

Figure 4. Porogen sizes in the hybrid low-k films as a function of cure

of the SBS porogen as the viscosity increased beyond 170°C. On the other hand, Fig.5b shows the in situ viscosity of the hybrid film cured rapidly at 200°C. In this system, the viscosity rapidly reached a plateau of⬃250,000 poise at 400 s. This suggested that the low-k MSQ matrix became very dense and rigid in a short period, inducing enormous viscosity in the film and preventing any aggregation of porogen. Thus, the size of the porogen was confined to ⬃12 nm with tight distribution immediately upon fast cure.

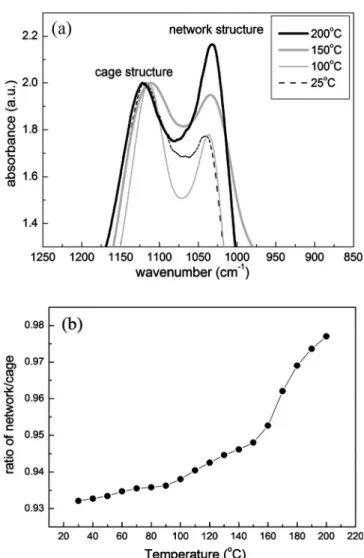

It becomes clear that the structure state of the low-k MSQ matrix at T艌 Tgduring the cure step plays a critical role on the viscosity of the hybrid film and porogen size. As a result, FTIR was employed to examine the structure state of the MSQ matrix in the MSQ/ porogen hybrid films as a function of cure temperature. Figure6a

shows FTIR spectra of the hybrid films cured up to various tempera-tures such as 25, 100, 150, and 200°C. Two peaks at 1130 and 1030 cm−1were attributed to Si–O stretching in the cage and net-work structures, respectively.15In addition, all IR spectra were nor-malized to the intensity of cage Si–O stretching at 1130 cm−1and the ratio of specific absorption band to the cage Si–O absorption band was defined by its peak intensity to that of the cage Si–O band in this study for simplicity. The absorption intensity at 1030 cm−1 associated with the stretching of network Si–O changed slightly be-tween 25 and 100°C based on the band broadening even though the peak height remained the same, but its intensity increased signifi-cantly when the curing temperature was raised above 100°C. To carefully examine the change rate of structural transformation from cage Si–O to network Si–O structure, the ratio of the network/cage

structure in the MSQ/SBS hybrid films is shown in Fig.6bfor slow cure profile from 30 to 200°C at an interval of 10°C. The ratio increased gradually from 0.932 to 0.938 when the cure temperature was raised from 30 to 100°C. Afterwards, the ratio rose up from 0.938 at 100°C to 0.952 at 160°C, due to the condensation of silanol 共Si–OH兲 groups in the MSQ precursor.27

Yet, at T between 160 and 170°C, there was a faster increase in the ratio of the network/cage structure共from 0.952 to 0.962兲 as evidenced by the change of slope shown in Fig. 6b. This indicated that MSQ underwent extensive structural transformation from cage Si–O to network Si–O structure through the cleaving of the Si–O–Si group in the cage structure and condensation reaction, i.e., cross-linking with a by-product of H2O.27For a short duration, the released H2O can serve as a plas-ticizer in the MSQ/SBS hybrid film, reducing its viscosity between 160 and 170°C as shown in Fig.5a. From 170 to 200°C, the ratio of network/cage structure increased at a slightly lower rate from⬃0.96 up to 0.98 as the transformation to a rigid, 3D network structure continued. Continued cross-linking of the MSQ matrix in conjunc-tion with the fast evaporaconjunc-tion of H2O accounted for the increasing viscosity above 170°C in Fig.5a.

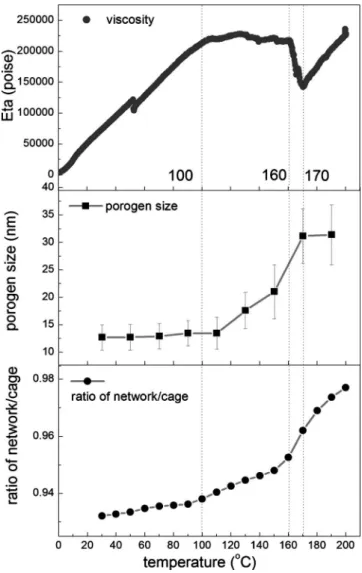

Summarizing the results of in situ viscosity measurement, the structural variation of the MSQ matrix by FTIR analysis, and poro-gen size by GISAXS as a function of temperature in Fig.7, the

Figure 5. Viscosity of the hybrid low-k films as a function of cure

tempera-ture under共a兲 slow curing profile at 2°C/min to 250°C and 共b兲 isothermal at 200°C.

Figure 6. 共a兲 IR spectra of MSQ/SBS hybrid films cured up to various

temperatures: 25, 100, 150, and 200°C.共b兲 The ratio of network/cage struc-ture in the MSQ/SBS hybrid films as a function of cure temperastruc-tures be-tween 30 and 200°C at an interval of 10°C.

effect of the MSQ structure during the thermal cure process on the porogen aggregation behavior and its correlation with porogen size can be described and elucidated below.

For the as-spun MSQ/SBS hybrid films in this paper, the SBS porogen共5 wt %兲 could be considered as nanoparticles in the MSQ matrix, whose structure could change from a precursor at room tem-perature to a lightly cross-linked or even highly cross-linked struc-ture depending on the cure temperastruc-ture and cure rate. In turn, the structure of the MSQ matrix during the thermal cure process af-fected the porogen aggregation behavior and the porogen size in the MSQ/SBS hybrid films. According to the in situ viscosity measure-ment, porogen size measurement by GISAXS, and FTIR analysis summarized in Fig. 7, the interaction between the SBS porogen particles and the MSQ matrix for the slow cure profile could be divided into four stages; namely, 共1兲 below 100°C, 共2兲 100 to 160°C,共3兲 160 to 170°C, and 共4兲 above 170°C up to 200°C. This highlights three critical temperatures:共1兲 glass transition tem-perature, Tg 共 ⬃ 100°C兲, 共2兲 onset temperature of network Si–O transformation 共170°C兲, and 共3兲 immobilization temperature 共160°C兲, which controlled the microstructure of the MSQ matrix and, in turn, the porogen segregation and porogen size during the thermal cure process.

For temperatures below 100°C in the slow cure system, SBS porogen particles hardly diffused and aggregated within the MSQ matrix because the hybrid films behaved as a solid when THF

sol-D = kBT

6r 关3兴

where kBis the Boltzmann constant, T is the absolute temperature, is the viscosity of the system, and r is the particle radius. At this stage, the SBS particle aggregation depended on its diffusivity, which increased with共1兲 increasing temperature due to higher col-lision frequency and共2兲 reduced viscosity, , which is a measure of the steric barrier for the SBS particle to move within the MSQ matrix. Thus, the relaxation of the SBS and MSQ molecular chains at T⬎ Tgled to reduced viscosity and higher diffusivity of the SBS particles. Such high diffusivity enhanced SBS collision and led to the aggregation of SBS porogen from 13 to 22 nm.

At T⬎ 160°C, the cross-linking of the MSQ precursor contin-ued. But, we observed a noticeable transformation of the MSQ ma-trix from a loose cage Si–O structure to a dense network Si–O structure which served as a 3D steric barrier to the migration of the SBS particles within the MSQ matrix. One expected the viscosity of the hybrid films to increase from 170 to 200°C as a higher degree of cross-linking took place and more network Si–O structure was formed. Instead, the viscosity dropped drastically to 130,000 poise in the third stage共160 to 170°C兲. It is believed that when extensive transformation of cage to network Si–O occurred at T⬎ 160°C, a large amount of H2O by-products could serve as a plasticizer in the MSQ/SBS hybrid film and result in a significant reduction of vis-cosity. Furthermore, this enhanced the aggregation of SBS porogens resulting in a faster change of porogen size from 22 to 31 nm be-tween 150 and 170°C.

In the final stage共170 to 200°C兲, most H2O is believed to be dried up prior to 170°C. In addition, the cross-linking of the MSQ matrix with a 3D and highly cross-linked Si–O network structure at

T⬎ 170°C made the MSQ/CBS hybrid like a solid with very high

viscosity, ⬃250,000 poise. Thus, SBS porogens were trapped or “frozen” within the highly cross-linked MSQ matrix, leading to an approximately constant porogen size 共 ⬃ 31–32 nm兲 beyond T ⬎ 170°C. This also accounted for the small porogen size and tight distribution 共12 ⫾ 2 nm兲 in the MSQ/porogen hybrid films cured rapidly at 200°C/min.

The elastic moduli of the hybrid films cured under slow and fast profiles measured by the nanoindentation method were 4.9 and 5.6 GPa, respectively. For the same degree of MSQ cross-linking, their difference in the modulus was caused by the different porogen sizes.31 Based on an in situ GISAXS measurement for the hybrid film cured in the slow curing step, the porogen aggregated and formed an interconnected mass in the matrix with sizes up to 33 nm, reducing the mechanical strength of the hybrid film. In contrast, the hybrid film cured rapidly possessed higher strength due to a smaller porogen size共⬃12 nm兲 trapped within a highly cross-linked MSQ matrix. Thus, the rapid curing method makes the MSQ/high-temperature porogen hybrid films strong in mechanical property with small porogen size and practical for the postintegration poro-gen removal scheme. In addition, the rapid curing method has been widely adapted in the industry to shorten the processing time and reduce cost.32,33The low-k films are typically prepared using a soft bake on the hot plate to remove the solvent, then cured or hard

Figure 7. The viscosity, porogen size, and network/cage structure ratio of

baked at a higher temperature in the furnace to burn out the porogen. Based on the results of this paper, we recommend that the soft-bake temperature is kept below the glass transition temperature of the porogen when the rapid curing method is used. On the other hand, the hard-bake temperature should be kept at least higher than the immobilization temperature of the low-k matrix, which is⬎170°C for the MSQ matrix in this paper.

Conclusion

A commercial, spin-on organosilicate, i.e., MSQ was selected as the low-k matrix and a high-temperature porogen, such as SBS, was employed as the sacrificial component in this paper. The effect of the MSQ structures under different thermal cure profiles共slow, 2°C/min vs rapid, 200°C/min兲 on the porogen aggregation behavior and its size in the hybrid MSQ/SBS films cured up to 200°C were investi-gated by in situ GISAXS, viscosity measurement, and FTIR analy-sis. For slow curing, significant porogen diffusion and aggregation occurred between 100 and 200°C, at which the porogen size in-creased from 12 to 34 nm. The aggregation of SBS in the hybrid MSQ/SBS films was greatly influenced by the structural state of the MSQ matrix at three controlling temperatures; namely, 共1兲 glass transition temperature, Tg共100°C兲, 共2兲 onset temperature 共160°C兲 for transforming Si–O cage Si–O to network Si–O structure, and共3兲 immobilization temperature 共170°C兲. The porogen size started growing as SBS porogen aggregated at T⬎ Tg of MSQ, then in-creased at a higher rate at T⬎ 160°C as the viscosity drastically dropped down to⬃130,000 poise due to the plasticization of a vast amount of H2O released by the condensation reaction involving the transformation of cage Si–O to network Si–O structure, and finally remained about constant at⬃32 nm after 170°C, at which the MSQ matrix was highly cross-linked to immobilize SBS particles. In con-trast, upon rapid curing, the SBS porogen was trapped within a rapidly formed, well-cross-linked MSQ matrix, leaving its size un-changed at approximately 12 nm with tight distribution. Further-more, the elastic modulus of the hybrid film cured rapidly possessed higher strength due to the smaller porogen size. Thus, the rapid curing method makes the MSQ/high-temperature porogen hybrid films strong in mechanical property with small porogen size and practical for the postintegration porogen removal scheme. In sum-mary, this paper elucidates the interaction mechanism between po-rogen and the MSQ matrix and its correlation with popo-rogen size. In addition, we provide a methodology for controlling the porogen size by adjusting the curing profile in terms of cure temperature and rate.

Acknowledgments

The authors thank Kuo-Yuan Hsu for viscosity rheometer tests and Dr. Chiu-Hun Su and Kuei Fen Liao for their assistance in the GISAXS measurements. This work was financially supported by National Science Council of Taiwan through contract no. NSC

98-2221-E009-177 and no. NSC 99-98-2221-E009-177.

National Chiao Tung University assisted in meeting the publication costs of this article.

References

1. M. T. Bohr, Solid State Technol., 9, 4共1996兲.

2. P. W. Lee, S. Mizuno, A. Verma, H. Tran, and B. Nguyen, J. Electrochem. Soc., 143, 2015共1996兲.

3. S. Yang, P. A. Mirau, C. D. Pai, O. Nalamasu, E. Reichmanis, E. K. Lin, H. J. Lee, D. W. Gidley, and J. Sun, Chem. Mater., 13, 2762共2001兲.

4. M. Fayolle, G. Psaaemard, O. Louveau, F. Fusalba, and J. Cluzel, Microelectron.

Eng., 70, 255共2003兲.

5. M. Ree, J. Yoon, and K. Heo, J. Mater. Chem., 16, 685共2005兲.

6. A. M. Padovani, L. Rhodes, S. A. B. Allen, and P. A. Kohl, J. Electrochem. Soc., 149, F161共2002兲.

7. S. Baskaran, J. Liu, K. Dormansky, N. Kohler, X. Li, C. Coyle, G. E. Fryxell, S. Thevuthasan, and R. E. Williford, Adv. Mater., 12, 291共2002兲.

8. T. Yamada, H. Zhou, K. Asai, and I. Honma, Mater. Lett., 56, 93共2002兲. 9. S. Yang, P. A. Mirau, C. Pai, O. Nalamasu, E. Reichmanis, J. C. Pai, Y. S. Obeng,

J. Seputro, E. K. Lin, H. Lee, et al., Chem. Mater., 14, 369共2002兲.

10. H. C. Kim, J. B. Wilds, C. R. Kreller, W. Volksen, P. J. Brock, V. Y. Lee, T. Magbitang, J. L. Hedrick, C. J. Hawker, and R. D. Miller, Adv. Mater., 14, 1637 共2002兲.

11. Q. R. Huang, W. Volksen, E. Huang, M. Toney, C. W. Frank, and R. D. Miller,

Chem. Mater., 14, 3676共2002兲.

12. J. N. Sun, Y. Hu, W. E. Frieze, W. Chen, and D. W. Gidley, J. Electrochem. Soc., 150, F97共2003兲.

13. K. Mosig, T. Jacobs, K. Brennan, M. Rasco, J. Wolfe, and R. Augur, Microelectron.

Eng., 64, 11共2002兲.

14. J. Calvert and M. Gallagher, Semicond. Int., 26, 52共2003兲.

15. W. C. Liu, C. C. Yang, W. C. Chen, B. T. Dai, and M. S. Tsai, J. Non-Cryst. Solids, 311, 233共2002兲.

16. A. Zenasni, F. Ciaramella, V. Jousseaume, C. L. Cornec, and G. Passemard, J.

Electrochem. Soc., 154, G6共2007兲.

17. Y. H. Lai, Y. S. Sun, U. Jeng, J. M. Lin, T. L. Lin, H. S. Sheu, W. T. Chuang, Y. S. Huang, C. H. Hsu, M. T. Lee, et al., J. Appl. Crystallogr., 39, 871共2006兲. 18. R. J. Roe, Methods of X-Ray and Neutron Scattering in Polymer Science, Chap. 5,

Oxford University Press, New York共2000兲. 19. A. Guinier, Ann. Phys., 12, 161共1939兲.

20. D. J. Kinning and E. L. Thomas, Macromolecules, 17, 1712共1984兲. 21. J. S. Pedersen, J. Appl. Crystallogr., 27, 595共1994兲.

22. L. A. Feigin and D. I. Svergun, Structure Analysis by Small Angle X-ray and

Neutron Scattering, Plenum, New York共1987兲.

23. A. Guinier and G. Fournet, Small-Angle Scattering of X-rays, John Wiley & Sons, New York共1955兲.

24. J. Fuwukawa, Polym. Bull. (Berlin), 10, 336共1983兲.

25. Q. R. Huang, H.-C. Kim, E. Huang, D. Mecerreyes, J. L. Hedrick, W. Volksen, C. W. Frank, and R. D. Miller, Macromolecules, 36, 7661共2003兲.

26. R. J. Young and P. A. Lovell, Introduction to Polymers, Chapman & Hall, London 共1991兲.

27. H. W. Ro, E. S. Park, C. L. Soles, and D. Y. Yoon, Chem. Mater., 22, 1330共2010兲. 28. C. Y. Wang, Z. X. Shen, and J. Z. Zheng, Appl. Spectrosc., 54, 209共2000兲. 29. N. Wiener, J. Math. Phys., 2, 131共1923兲.

30. H. T. Healy and Y. C. Zhang, Phys. Rep., 254, 215共1995兲. 31. G. Ouyang, G. Yang, C. Sun, and W. Zhu, Small, 4, 1359共2008兲.

32. T. Yamazaki, M. Hirakawa, T. Nakayama, and H. Murakami, in IEEE Proceedings

of the International Interconnect Technical Conference, IEEE, p. 119共2009兲. 33. T. Kokubo, A. Das, Y. Furukawa, I. Vos, F. Iacopi, H. Struyf, J. V. Aelst, M.

Maenhoudt, Z. Tokei, I. Vervoort, et al., in IEEE Proceedings of the International