Effects of the catalyst pretreatment on CO

2

sensors made

by carbon nanotubes

C.S. Huang

a,b,⁎

, B.R. Huang

c, C.H. Hsiao

a, C.Y. Yeh

b, C.C. Huang

b, Y.H. Jang

da

Department and Institute of Electronic Engineering, National Yunlin University of Science and Technology, Taiwan, 64002

b

Graduate School of Optoelectronics, National Yunlin University of Science and Technology, Taiwan, 64002

c

Graduate Institute of Electro-Optical Engineering, National Taiwan University of Science and Technology, Taiwan, 106

d

Department of Materials Science and Engineering, National Chiao-Tung University, Taiwan, 300 Available online 11 September 2007

Abstract

A novel CO2sensor was made by carbon nanotubes (CNTs). The CNTs were synthesized by catalystic thermal chemical vapour deposition at

700 °C. Prior to the synthesis, the Fe catalysts were pretreated by H2plasma for different times. Two terminal resistance of the as-grown CNTs mat

was measured under different CO2concentrations. It was found that without the catalyst pretreatment, the sensitivity was about 4% when the

CNTs mat was exposed to 800 mTorr CO2 concentration. However, with various catalyst pretreatment times of 5, 10, 15 and 20 min, the

sensitivity was 3.69%, 6.27%, 9.54%, and 12.1%, respectively. The Raman spectroscopy showed the ID/IGdecreased from 0.668 to 0.539 as the

catalyst pretreatment time increased. The XPS also showed the correlation of surface chemical components with the Raman spectroscopy. The Fe catalyst H2plasma pretreatment affected both the graphitization and surface binding sites of CNTs.

© 2007 Elsevier B.V. All rights reserved.

Keywords: Catalyst; H2plasma; Carbon nanotubes; Sensor

1. Introduction

Gas monitoring is important in many circumstances such as manufacture processes and environmental protection. Tradi-tional gas sensors made by using semiconducting oxides have to be operated at high temperature [1], and this limits the applications operated at the room temperature. In searching for new materials capable of operating at the room temperature, carbon nanotubes (CNTs) is the most promising candidate. Many researches[2–6]used the electrical properties of CNTs to carry out various gas sensors. The electrical resistance of CNTs was found to increase when exposed to reducing gas species (such as NH3[7], CO2[8,9], N2[10]and ethanol[11]etc.), but

to decrease when exposed to oxidizing ones (such as O2[12]

and NO2[13]).

CO2, being one kind of greenhouse gas, has attracted some

researches of CO2sensors on controlling industrial processes

[14]and monitoring air quality[15]. In this paper, CO2sensors

was made by CNTs with different catalyst pretreatments. The sensitivity showed great correlation with catalyst pretreatments. Raman and XPS spectroscopies suggested that graphitization of CNTs helped to increase the sensitivity.

2. Experimental details

A 16 nm Fe layer was deposited as catalysts on (100) p-type silicon substrate by RF sputtering with 150 W power and at 40 sccm Ar gas flow rate. Then, prior to the growth of CNTs, such catalyst-deposited samples were pretreated by H2

microwave plasma for 5, 10, 15, 20 min, respectively. The microwave power was 700 W, with the work pressure of H2

2 Torr and the temperature kept at 400 °C. Finally, CNTs were synthesized by the thermal CVD system at 700 °C N2was used

as the carrier gas during the 60 min temperature rising process, at a flow rate of 100 sccm with 6.5 Torr. Reaching the 700 °C growth temperature, N2 was switched off and C2H2 was

Available online at www.sciencedirect.com

Diamond & Related Materials 17 (2008) 624–627

www.elsevier.com/locate/diamond

⁎ Corresponding author. Chien-Sheng Huang, 123 University Road, Section 3, Douliou, Yunlin 64002, Taiwan. Tel.: +886 5 5342601; fax: +886 5 5312063.

E-mail address:huangchs@yuntech.edu.tw(C.S. Huang).

0925-9635/$ - see front matter © 2007 Elsevier B.V. All rights reserved. doi:10.1016/j.diamond.2007.08.039

switched on at a flow rate of 30 sccm with 3.5 Torr for 20 min. Then, C2H2was switched off and the reactor was slowly cooled

down to room temperature in N2ambient. As-grown CNTs mat

was examined by Raman spectroscopy and X-ray photoemis-sion spectroscopy (XPS) for the graphitization of sp2 carbon bonding and surface chemical composition.

CO2sensing experiments were carried out by a high vacuum

I–V measurement system. The resistance of various CNTs mats was measured under a series of CO2filling and pumping cycles,

with the filling pressure from 50 mTorr to 800 mTorr. All experiments were conducted at room temperature.

3. Results and discussion

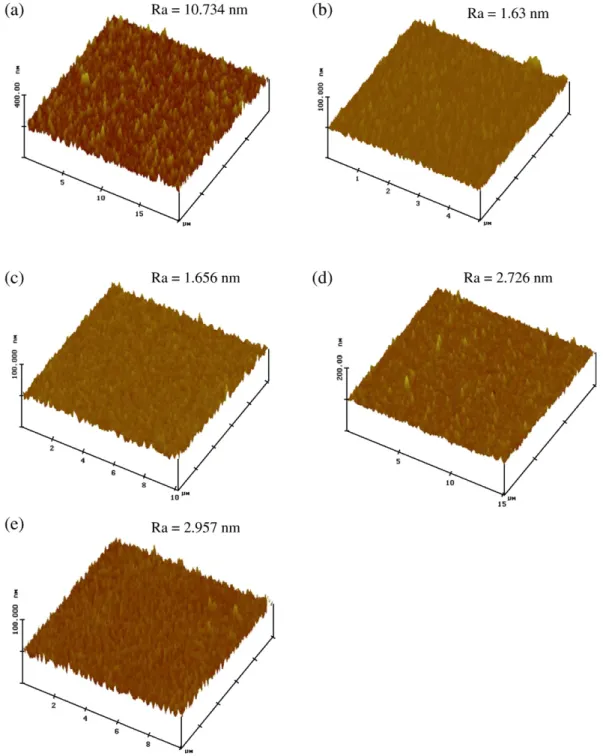

Fig. 1 showed the surface morphologies of Fe catalyst layer after H2plasma treatment for different time. Since the temperature

was kept at 400 °C during the H2 plasma treatment, one Fe

catalyst-deposited sample, heating to 400 °C for 20 min without H2plasma, was shown inFig. 1(a) for comparison. It was found

that heating would make the Fe atoms aggregated, and the surface mean roughness Rawas 10.734 nm. As shown inFig. 1(b), H2

plasma treatment made the surface mean roughness decrease to 1.63 nm for 5 min treatment time. As treatment time increased to

Fig. 1. AFM images of the Fe catalyst nano-film, (a) only 400 °C heating, (b)–(e) pretreated by H2plasma at 400 °C for 5, 10, 15, and 20 min, respectively.

625 C.S. Huang et al. / Diamond & Related Materials 17 (2008) 624–627

10, 15, 20 min, the surface mean roughness increased to 1.656, 2.726, 2.957 nm, respectively shown inFig.1(c)–(e). Apparently,

the effect of H2plasma was more than providing heat energy to

the Fe catalyst nano-film [16]. The surface roughness of Fe catalyst nano-film had effects on the following growth of CNTs mat, e.g. the density and graphitization.

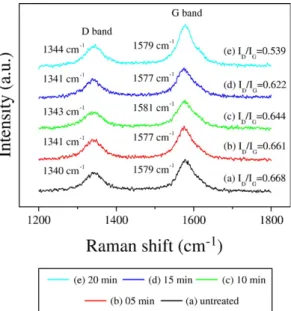

Fig. 2showed the Raman spectra (taken with the 532 nm Nd: YAG laser line) of the CNTs mat. Both the typical D band (∼1350 cm− 1) and G band (∼1580 cm− 1) for multi-walled

CNTs appeared [17]. The Lorentzian components fitting gave the peak values and the ratio ID/IG, which would be an

graph-itization index for CNTs. Smaller ID/IG ratio indicated high

graphitic crystallinity of CNTs. Without H2 plasma

pretreat-ment, the ID/IGratio was 0.668. As the H2plasma pretreatment

time increased from 5, 10, 15 to 20 min, the ID/IG ratio

decreased from 0.661, 0.644, 0.622 to 0.539, respectively. This also indicated that disordered carbon bonds decreased as the ratio decreased. Since there were plenty of oxygen and some

moisture in the air, the oxygenic contaminants were possibly found on the surface of as-grown CNTs mat. As the XPS shown inFig. 3, without H2plasma pretreatment, the O/C ratio was

0.084. As the H2plasma pretreatment time increased from 5, 10,

15 to 20 min, the O/C ratio decreased from 0.072, 0.062, 0.061 to 0.029, respectively. The tendency was reasonable since the decrease of disordered carbon bonds reduced the chemiadsorp-tion of oxygenic contaminants. The evidence of chemiadsorbed oxygenic contaminants was shown in Fig. 4, with the higher C1s binding energies which were recognized as C–O bonding (∼285.7 eV).

Fig. 5 showed the resistance variations to time of as-grown CNTs mat upon exposure to a series of CO2filling and pumping

cycles, with the filling pressure from 50 mTorr to 800 mTorr. Since as-grown CNTs were p-type and CO2were categorized as

reducing species, the resistance CNTs mat would increase when exposing to CO2ambient[9]. Sensitivity (S) was defined as the

ratio S = [(RCO2−R)/R]×100, where RCO2represented the CO2

-adsorbed saturated resistance of CNTs mat in CO2ambient during

the filling half-cycle and R represented the resistance in pumping

Fig. 2. The Raman spectra of as-grown CNTs mats, (a) without H2plasma and

(b)–(e) pretreated by H2plasma at 400 °C for 5, 10, 15, and 20 min, respectively.

Fig. 3. XPS of as-grown CNTs mats, (a) without H2 plasma and (b)–(e)

pretreated by H2plasma at 400 °C for 5, 10, 15, and 20 min, respectively.

Fig. 4. XPS C1s spectra of as-grown CNTs mats, (a) without H2plasma and (b)–

(e) pretreated by H2plasma at 400 °C for 5, 10, 15, and 20 min, respectively. The

Gaussian fitting shows the C–O bonding at about 285.7 eV.

Fig. 5. The typical resistance variations to time of as-grown CNTs mat measured at room temperature under various CO2pressures, from 50 mTorr to 800 mTorr

and back to 50 mTorr without H2plasma.

half-cycle.Fig. 6showed the sensitivity calculated fromFig. 5. The sensitivity of CNTs mat without H2plasma pretreatment was

3.66% under 800 mTorr CO2 concentration. After H2 plasma

pretreatment for 5 to 20 min, the sensitivity increased from 3.69% to 12.1% under 800 mTorr CO2concentration. The increase of

sensitivity S seemed according to the graphitization of CNTs mats. There are four possible sites for adsorption on CNTs mat: internal (endohedral), interstitial channels, external groove sites, and external surfaces[18,19]. Since the CNTs mat was not packed compactly, the external surfaces of each CNTs played the major roles in the adsorption, and hence the sensitivity showed cor-relation with the graphitization and surface chemical of as-grown CNTs.

4. Conclusions

The Fe catalyst pretreatment by H2plasma has great effects

on the graphitization and surface chemical compositions of as-grown CNTs. The sensitivity of CO2gas sensor made by CNTs

was therefore affected. Acknowledgment

This research is supported by the National Science Council of R. O. C. under grant Numbers NSC 2221-E-224-020-, NSC

95-2221-E-224-041-, 95-2221-E-224-069-. We also thank Dr. Joshua Tsai of National Taiwan University for ESCA measurement. References

[1] H. Tang, K. Prasad, R. Sanjines, F. Levy, Sensors and Actuators. B, Chemical 26 (1995) 71.

[2] C. Cantalini, L. Valentini, L. Lozzi, I. Armentano, J.M. Kenny, S. Santucci, Sensors and Actuators. B, Chemical 93 (2003) 333.

[3] Y.X. Liang, Y.J. Chen, T.H. Wang, Applied Physics Letters 85 (2004) 666. [4] Yoon Taek Jang, Seung Il Moon, Jin Ho Ahn, Yun Hi Lee, Byeong Kwon

Ju, Sensors and Actuators. B, Chemical 99 (2004) 118–122.

[5] Jing Li, Yijiang Lu, Qi Ye, Martin Cinke, Jie Han, M. Meyyappan, Nano Letters 3 (2003) 929.

[6] C.S. Huang, B.R. Huang, Y.H. Jang, M.S. Tsai, C.Y. Yeh, Diamond and Related Materials 14 (2005) 1872–1875.

[7] S. Chopra, K. McGuire, N. Gothard, A.M. Rao, Applied Physics Letters 83 (2003) 2280.

[8] Keat Ghee Ong, Kefeng Zeng, Craig A. Grimes, IEEE Sensors Journal 2 (2002) 82.

[9] O.K. Varghese, P.D. Kichambare, D. Gong, K.G. Ong, E.C. Dickey, C.A. Grimes, Sensors and Actuators. B, Chemical 81 (2001) 32.

[10] Jijun Zhao, Alper Buldum, Jie Han, Jian Ping Lu, Nanotechnology 13 (2002) 195.

[11] F. Villalpando-Paez, A.H. Romero, E. Munoz-Sandoval, L.M. Martinez, H. Terrones, M. Terrones, Chemical Physics Letters 386 (2004) 137–143. [12] Philip G. Collins, Keith Bradley, Masa Ishigami, A. Zettl, Science 287

(2000) 1801.

[13] Jing Kong, Nathan R. Franklin, Chongwu Zhou, Michael G Chapline, Shu Peng, Kyeongjae Cho, Hongjie Dai1, Science 287 (2000) 622. [14] S.L. Well, J. DeSimone, Angewandte Chemie. International Edition 40

(2001) 518–527.

[15] T. Lindgren, D. Norback, K. Anderson, B. Dammstrom, Aviation, Space, Environmental Medicine 71 (2000) 774–482.

[16] M. Chen, C.M. Chen, H.S. Koo, C.F. Chen, Diamond and Related Materials 12 (2003) 1829–1835.

[17] M.S. Dresselhaus, G. Dresselhaus, P.H. Avouris, Carbon Nanotubes: Synthesis, Properties and Applications, Vol. 80 of Springer Series in Topics in Applied Physics, Springer-Verlag, Berlin, 2001.

[18] G. Stan, M.J. Bojan, S.M. Gatica, M.W. Cole, Physical Review B 62 (2000) 2173–2180.

[19] K.A. Williams, P.C. Eklund, Chemical Physics Letters 320 (2000) 352. Fig. 6. The sensitivity S of as-grown CNTs mat, without H2 plasma and

pretreated by H2plasma at 400 °C for 5, 10, 15, and 20 min, respectively.

627 C.S. Huang et al. / Diamond & Related Materials 17 (2008) 624–627