Thin Solid Films 398 – 399(2001) 637–640

0040-6090/01/$ - see front matter䊚 2001 Elsevier Science B.V. All rights reserved. PII: S 0 0 4 0 - 6 0 9 0 Ž 0 1 . 0 1 3 3 1 - 1

Improvement of low dielectric constant methylsilsesquioxane by boron

implantation treatment

T.C. Chang

a,c,*, Y.S. Mor , P.T. Liu , T.M. Tsai , C.W. Chen , S.M. Sze , Y.J. Mei

b cb b b,cd Department of Physics, National Sun Yat-Sen University, Kaohsiung, Taiwan, ROCa

Institute of Electronics, National Chiao Tung University, Hsin-Chu, Taiwan, ROC b

National Nano Device Laboratory, 1001-1 Ta-Hsueh Road, Hsin-Chu 300, Taiwan, ROC c

Department of Electrical Engineering, Ching-Yun, Institute of Technology, Jung-Li, Taiwan, ROC d

Abstract

The organicsilsesquioxane, methylsilsesquioxane (MSQ), exhibits a low dielectric constant because of its lower film density

compared with thermal oxide. In this study, boron implantation treatment is investigated in order to improve the quality of MSQ. The small size of boron atoms do not damage the chemical bonding of the MSQ film. In addition, the formation of densified surfaces after boron implantation can reduce the probability of moisture uptake into the MSQ. Therefore, the leakage current of MSQ film is significantly decreased and the low-k properties of MSQ film can be maintained.䊚 2001 Elsevier Science B.V. All

rights reserved.

Keywords: Methylsilsesquioxane; Dielectric constant; Boron implantation

1. Introduction

A continuous reduction in chip size and increase in chip complexity are shifting the technology of intercon-nection towards multilevel metallization. However, RC delay w1–3x contributed from multilevel interconnects becomes an important issue which limits the perform-ance of very large-scale integrated circuits (VLSI). Therefore it is necessary to use low-k materials as a

dielectric to reduce the capacitance between the metal wires in the multiple levels of interconnecting metallization.

‘For several years the industry has recognized the need of developing low-k dielectric materials and high

conductivity metals for high performance interconnects.

Low-k dielectrics will impact both power and delay

favorably, while higher conductivity metals will reduce delay time. In order to be useful, new low-k dielectric

* Corresponding author. National Nano Device Laboratory, 1001-1 Ta-Hsueh Road, HsinChu 300, Taiwan, ROC. Tel.: q886-3-5726100; fax: q886-3-5722715.

E-mail address: tcchang@ndl.gov.tw(T.C. Chang).

materials must be carefully characterized for their elec-trical, chemical, thermal and mechanical properties. In addition, their impact on process integration, fabrication cost and device reliability must also be considered’ w2x. The organicSOG, methylsesquioxane (MSQ), which

has a dielectric constant of ;2.7, was obtained from Allied Signal Inc. w4–6x. It has been developed by increasing the number of the Si-methyl group which causes a decrease in film density. w7x In addition, the dielectric constant of the SOG film decreases with increasing organic content w8x.

In this work, we have studied the boron implantation post-treatment to improve the quality of MSQ films. Properties of post-treated MSQ films were evaluated by electrical measurement and chemical composition analyses.

2. Experimental

The unpatterned silicon wafers were coated with a single layer of MSQ film, and baked sequentially on a hot plate at 1808C for 2 min and 2508C for 1 min. The resulting wafers were followed by different implantation

638 T.C. Chang et al. / Thin Solid Films 398 – 399 (2001) 637–640

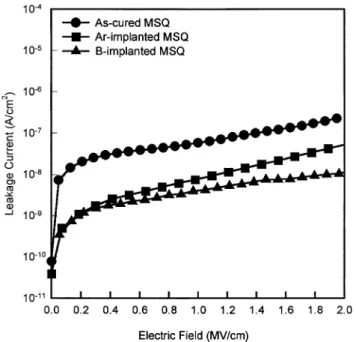

Fig. 1. The leakage current density of MSQ after various implantation treatment.

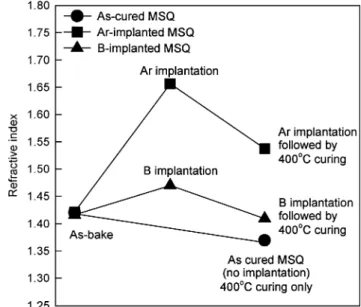

Fig. 2. The dielectric constant of MSQ after various implantation treatment.

treatments. In this work, three types of samples were grouped. The first type of wafer, which was for com-parison, was as-cured MSQ filmwyf1x. The second was treated with argon implantation under the conditions of 150 keV, a dose of 5=1015 ionsy cm and pressure of2 8=10y6 torr. The third type was treated with boron implantation under the conditions of 50 keV, a dosage of 5=1015 ions and pressure of 3=10y6 torr. Then furnace curing at 4008C was applied to the implantation-treated samples. For each implantation-treated processing, film stress, shrinkage, refractive index and Fourier transform infra-red absorption spectra (FTIR) were evaluated. The film thickness and refractive index of the dielectric film were measured by a n&k analyzer. The film stress was measured by a Tencor FLX-2320 thin film stress meas-urement. The infrared spectrometry was performed from 4000 to 400 cmy1 using a Bio-Red QS300 FTIR spectrometer calibrated to an unpatterned wafer and their data were collected in the absorbance mode, for study of the chemical structure of the MSQ films. In addition, material analysis using a thermal desorption system spectrometer (TDS) was carried out to monitor the desorbed moisture from MSQ films. Electrical char-acteristics were measured by manufacturing the alumi-num metal-insulator-semiconductor(MIS) capacitors. A

Keithley Model 82 CV meter was used to measure the dielectric constants of MSQ films. The capacitors were measured at 1 MHz with an AC bias for high frequency

C–V curves. Leakage current–voltage (I–V)

character-istics of the MSQ were measured by an HP 4145B semiconductor parameter analyzer.

3. Results and discussion

In the initial study, electrical characteristics of MSQ films were compared, to determine the effects of implan-tation treatment on the MSQ dielectric properties. Figs. 1 and 2 show both the leakage current density and dielectric constant of MSQ film after various implanta-tion treatments, respectively. The leakage currents of both implantation-treated samples were significantly decreased as compared with the un-implanted sample. The dielectric constant of B-implanted MSQ films main-tained a low value (;2.8). In contrast, the dielectric

constant of Ar-implanted MSQ film was increased com-pared with the un-implanted MSQ. These results show that the B-implantation is effective to improve the intrinsic electrical characteristics of MSQ films.

Material analyses were further used to interpret the improvement in electrical characteristics. The thickness variation in MSQ films after various implantation treat-ments is shown in Fig. 3. The decreasing thickness of all implant-treated samples result from the ion bombard-ment during implantation processing, nevertheless, it could be increased after sequential furnace curing. The thickness of Ar-implanted MSQ films was especially observed to decrease significantly. The reduction in thickness was one-third of the thickness of as-cured MSQ film. The thickness of B-implanted MSQ just decreased slightly and its thickness was almost main-tained the same as un-implanted samples after curing process. Fig. 4 shows refractive indexes of MSQ films after various implantation treatments. The refractive indexes of MSQ films all increased after implantation

639 T.C. Chang et al. / Thin Solid Films 398 – 399 (2001) 637–640

Fig. 3. The thickness variation of MSQ film after various implantation treatments.

Fig. 4. The refractive index variation of MSQ film after various implantation treatments.

Fig. 5. The stress variation of MSQ film after various implantation treatments.

treatment, whereas they decreased after sequential cur-ing. Especially, the refractive index of Ar-implanted MSQ increased dramatically. In contrast, the refractive index of B-implanted MSQ just slightly increased more than that of un-implanted MSQ. These aforementioned results suggest that the densified MSQ surfaces might be formed after the implantation processing. This is specially true for B-implanted samples due to a little changes in thickness and refractive index after implan-tation processing.

Furthermore, stress measurement was used to monitor the change in material characteristics. Fig. 5 shows the variation in the stress of MSQ film after various implan-tation treatments. Since the thermal expansion coeffi-cient is different between MSQ films and Si substrate

waMSQs13 (mmym8C), a s2.6 (mmym8C) w9,10xx,Si

this will lead to the tensile stress when MSQ films undergo a series of thermal processes. After subsequent implantation treatment, the stress of Ar-implanted MSQ film is reduced dramatically. However, the reduction in the stress of B-implanted MSQ films was less than that of Ar-implanted MSQ films. The reason for the reduction in tensile stress is explained below. When MSQ under-went ion implantation, the longitudinal thickness of MSQ decreased. This might lead to the transversal extension of the MSQ films so that the compress stress would be induced, further compensating partial tensile stress. Therefore, the obvious reduction in thickness of Ar-implanted MSQ films would lead to dramaticstress change. In contrast, the slight reduction in thickness of the B-implanted MSQ films would only induce a slight stress change, as shown in Fig. 5.

From the above mentioned results, we believe that the slight change in material characteristics is due to the

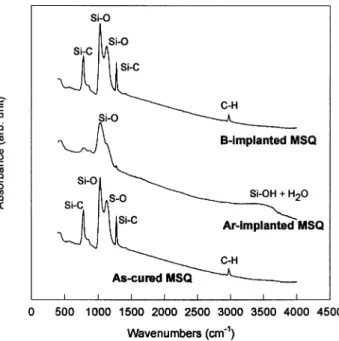

smaller volume of the boron atom compared with the argon atom. Therefore, the inevitable damage from the implantation process can be minimized by small-size boron implantation. That is why the dielectric constant of MSQ can still be maintained at a low value even after boron implantation treatment. This inference is consistent with FTIR spectra in which functional groups still are present after boron implantation. Fig. 6 shows the FTIR spectra of MSQ film after being treated with various implantation treatments. In these spectra, the

640 T.C. Chang et al. / Thin Solid Films 398 – 399 (2001) 637–640

Fig. 6. The FTIR spectra of MSQ film after various implantation treatment.

Fig. 7. The TDS spectra of MSQ film after boron implantation treatment.

intensity of the Si–C bond signal decreased dramatically and the intensity of the Si–OH bond signal increased when the MSQ was treated with argon implantation. The increase in the Si–OH intensity is thought to be due to the generation of dangling bonds resulting from breaking Si–CH bonds during argon implantation. The3 dangling bonds would easily absorb water. As a result, the MSQ becomes unstable after argon implantation. The dielectric constant of Ar-implanted MSQ film will increase due to moisture absorption. w11x However, the

intensity of the Si–C bond is maintained at a high level in the spectrum of B-implanted MSQ film. It means that the structure and chemical bonding of MSQ film would not be destroyed by B implantation. Therefore, low-k

dielectric properties can be maintained. In addition, TDS data shows moisture desorption from B-implanted MSQ film is reduced as compared with un-implanted MSQ, as shown in Fig. 7. This indicates that densified MSQ surfaces due to B-implantation treatment can enhance the resistance to moisture uptake.

4. Conclusions

In this work, the effects of boron implantation treat-ment on MSQ films have been investigated. The quality of low dielectric constant MSQ films is significantly improved by boron implantation post-treatment. The structure of low-k MSQ film is more porous than that

of silica. This porous structure generates a low dielectric constant. However, the porous structure facilitates mois-ture absorption in the MSQ film. To address this issue, boron implantation was applied to MSQ film to slightly densify the MSQ surfaces. The boron-implantation treat-ment not only enhances the resistance of MSQ films to moisture absorption but also reduce the leakage current. Due to the small volume of boron atoms, possible damage from the implantation process is minimized. Thus the low dielectric constant can be maintained. Acknowledgements

This work was performed at the National Nano Device Laboratory and was supported by Honeywell Taiwan, Incorporated, and the National Science Council of the Republicof China under Contract no. NSC90-2215-E-110-001 and No. NSC89-2215-E-231-005.

References

w1x The National Technology Roadmap for Semiconductors,

Semi-conductor Industry Association, San Jose, CA, 1997.

w2x T.E. Seidel, C.H. Ting, Mater. Res. Soc. Symp. Proc. 381(1995)

3.

w3x P.L. Pai, C.H. Ting, Proceedings of the IEEE VIMC Conference,

1989, p. 258.

w4x N.P. Hacker, J.S. Drage, VMIC Conference, 1995, p. 138. w5x J.Y. Chee, J.S. Drage, VMIC Conference, 1993, p. 128. w6x P.T. Liu, T.C. Chang, Y.S. Mor, S.M. Sze, Jpn. J. Appl. Phys.

38(1999) 3482.

w7x J. Waeterloos, H. Meynen, B. Coenegrachts, J. Grillaert, L.

Vanden hove, DUMIC Conference, 1996, p. 52.

w8x T. Nakano, K. Tokunaga, T. Ohta, J. Electrochem. Soc. 142 (1995) 1303.

w9x C.T. Chua, G. Sarkar, X. Hu, J. Electrochem. Soc. 145(1998)

4007.

w10x J.P. Schaffer, A. Saxena, S.D. Antolovich, T.H. Jr. Sanders, S.B.

Warner, The Science and Design of Engineering Materials, Irwin, Chicago, 1995, p. 572.

w11x R.A. Swalin, Thermodynamics of Solids, second ed, Wiley,