Archaeometry 48, 4 (2006) 565–580. Printed in Singapore

*Received 9 May 2005; accepted 3 January 2006. †Corresponding author: email maalingc@ntu.edu.tw © University of Oxford, 2006 Blackwell Publishing Ltd Oxford, UK ARCH Archaeometry 0003-813X © University of Oxford, 2006 XXX 2006 48 4 ORIGINAL ARTICLE

Physicochemical compositional analysis of ceramics Maa-ling Chen

PHYSICOCHEMICAL COMPOSITIONAL ANALYSIS OF CERAMICS: A CASE STUDY IN KENTING, TAIWAN*

MAA-LING CHEN†

Department of Anthropology, National Taiwan University, Taipei, 10617 Taiwan

The composition of ceramics does not just reflect the component of some specific, unprocessed, geological, raw material source, but also certain forms of human behaviour involved in its manufacture. The purpose of this research project is to apply the acid-extraction chemical method, complemented by a thin-section petrographic study, to the compositional analyses of certain local ceramic collections (mainly from several sites in the southern Taiwan area). The results present the raw materials that the ceramic manufacturers of the two cultural traditions (O-laun-pi Phase II and Phase III–IV), which overlapped temporally, used. These materials came from the same sources, but the ceramics were manufactured in different ways. Particularly, the people of O-laun-pi Phase III–IV also procured certain materials from either local sources or from somewhere in eastern Taiwan to make their pots. The results also indicate that there might have been a variation in terms of their manufacture among sites of the same cultural tradition.

KEYWORDS: CERAMICS, COMPOSITIONAL ANALYSIS, ACID-EXTRACTION METHOD,

TAIWAN, NEOLITHIC *Received 9 May 2005; accepted 3 January 2006.

8 University of Oxford, 2006

THE CONCEPT AND METHODS OF COMPOSITIONAL ANALYSIS

Archaeologists have increasingly been realizing that traditional classification frameworks are not designed to understand historical or cultural differences in craft production. They are also not sufficiently flexible to provide units for analysis that can be interpreted in culturally

‘processual’ ways (Peacock 1970; Bishop et al. 1982; Rice 1982; Rice 1987, 43). Therefore,

as early as the 1850s, the potential for the compositional analyses of craft production, mainly

of ceramics, has been recognized (Orton et al. 1993, 19; Rice 1987, 371–90). Since then, it

has been developed to study the socio-economic interpretation of craft production (Matson

1981; Bishop et al. 1982; Orton et al. 1993, 19; Rice 1982), such as manufacturing processes,

production province and organization, trade of certain craft goods, and even social boundaries. The advantages of compositional analyses with regard to the paste or fabric units of ceramics have been the focus of research related to archaeology. The method of compositional analysis measures the properties of products and raw resources and, thereby, allows us to distinguish among the sources of raw materials used in pottery manufacturing. The results relate products to local resources, clay and tempers, and distinguish between local and non-local products. They establish the probable relationships of pottery to geographically localized raw materials and therefore can suggest places of material procurement and ceramic production. This helps us to recognize the possibility that resources or products were exploited or manufactured locally, or were brought in from outside the region, thereby allowing the identification of some form of social interaction or exchange during the process in which the raw materials were

566 Maa-ling Chen

procured or the products were gained. This permits the integration of questions involving the

socio-economic processes of craft production (Peacock 1970; Bishop et al. 1982; Rice 1982).

Meanwhile, the composition of pottery is, in part, determined by cultural practices. Environ-mental, social and cultural constraints (such as the type and range of ceramics production, the available technology and the form of land use) influence the form and choice of a particular

strategy, or combination of strategies, for the procurement of resources (Bishop et al. 1982;

Burton and Simon 1996). Therefore, compositional analysis of paste is useful in interpreting the variability of paste characteristics, as well as the technological variations and technical

choices made in manufacturing (Bishop et al. 1982; Rice 1982; Burton and Simon 1996).

In the early stage, the compositional analysis of ceramics focuses mainly on petrographic (or mineralogical) analysis. However, the identification of the assemblages of minerals is a scientific as well as an artistic endeavour, which relies on the experience of analysts (Peacock

1970; Bishop et al. 1982). Meanwhile, it is very difficult to present the characteristics of

pastes and use them to identify the different production locations and exchange systems if the tempers or inclusions are very common to the indigenous sediments, or if the geological setting in a region is very diverse—and especially if the procurement of raw materials for manufac-turing pottery was carried out in several different locations in the region, or if old potsherds were ground and recycled as temper during the manufacture of the pottery. Furthermore, the analysis requires the destruction of more than 20–30 g of potsherd material. If the grains are too small, or if the accessory grains are too few for characterization, the results will become inaccurate. Therefore, it is difficult to utilize a petrographic study when dealing with a large number of samples, as this factor will limit its application to the study of subjects where a large number of samples is required.

Given this disadvantage, to address topics such as the regional socio-economic aspects of

ceramic production requires the analysis of more intensive sampling (Bishop et al. 1982;

Burton and Simon 1993), and petrographic analysis needs to be complemented with a type of chemical compositional analysis that is less destructive, and that is inexpensive. Chemical compositional analysis studies the chemical elements in the paste and can make up for the limitations of mineralogical analysis. However, the techniques of chemical analysis are either too expensive and involve a great deal of labour, or use hazardous and toxic chemicals that are not easily accessible. The acid-extraction method of compositional analysis presented and

suggested by Burton and Arleyn is safe, inexpensive, minimally destructive (only 1–2 cm2

or 0.20–0.21 mg of each potsherd is needed), less labour-intensive with simple procedures, uses widely available instrumentation and produces extremely precise results (Burton and Simon

1993, 1996; Stone 1992; Stark et al. 1995). The method mainly distinguishes the 12 major and

minor elements (Al, Ba, Ca, Fe, K, Mg, Mn, Na, P, Sr, Ti and Zn) of clay paste: these are not trace elements, but are the major and most abundant elements in the ceramic paste; they are less susceptible to sampling heterogeneity, and they can be measured with great precision and reproducible results (Burton and Simon 1993). The acid-extraction method was developed to facilitate the adequate processing of large numbers of samples for fine-grain studies. The validity of the method was evaluated and criticized by Michael Glascock, Hector Neff and

Daniela Triadan (1997) (see Neff et al. 1996; Triadan 1997; Triadan et al. 1997), who compared

the results both from using this method and from using INAA. The results of the evaluations and critiques can be seen in Burton and Simon (1996).

To study the regional socio-economic aspects of ceramic production requires a total ceramic representation rather than a focus on a single, particular ware. Also, such comparisons often require a method that does not depend on measuring a trace element to distinguish pastes from

Physicochemical compositional analysis of ceramics 567

more homogeneous sources. Therefore, in consideration of the subject matter, the research aims, the expense, the accessibility of the method and the precise results that this study requires, the acid-extraction method of chemical compositional analysis was judged to be the most worthy method to use for this research. The purpose of this research is to apply the acid-extraction method complemented by a petrographic study to the compositional analysis of a ceramic collection in Kenting National Park, on the southern tip of Taiwan. It is hoped that the paste used in the manufacture of the ceramics and its sources will be identified, and that the technology of the pottery production will be better understood.

THE REGIONAL BACKGROUND OF THE STUDIED CASES

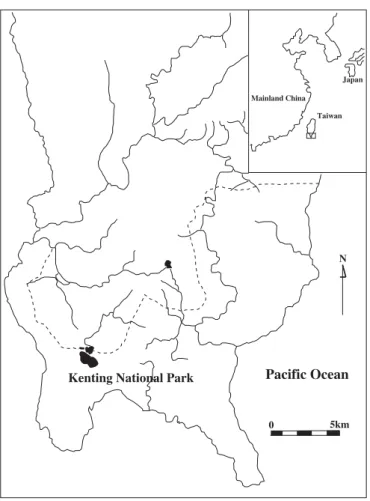

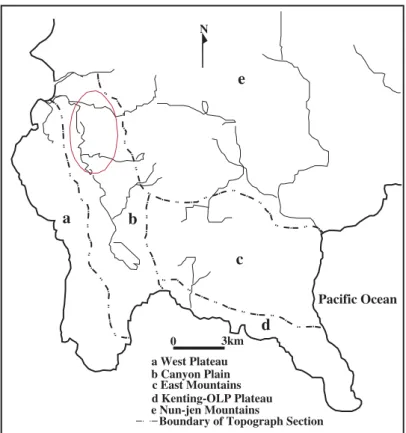

Kenting National Park, which is located on the southern tip of Taiwan (see Fig. 1), is one of the most famous archaeological areas in Taiwan. Sixty archaeological sites have been dis-covered in the park. The sites can be classified into 10 cultural phases, which cover a period of about 5000 years, from the Paleolithic O-laun-pi Phase I (hereafter OLP) to the historic Han

Chinese Phase that dates to as early as ad 1660. OLP Phase I, which dates to around 4800 bp,

568 Maa-ling Chen

appears to be a persistent Upper Palaeolithic culture of East Asia, and is characterized by a lithic industry consisting solely of chipped tools in the pebble and flake tool tradition. OLP Phase II (also called the Kenting Phase and regarded as the Red Cord-Marked Ware cultural tradition), OLP Phase III–IV and the Hsiang-lin Phase are Neolithic cultures, with technolo-gies capable of pottery manufacturing and food production. The subsequent phases are the Kuei-shan Phase, the Ami Phase, the Paiwan Phase, the Siraya Phase and, finally, the Han Chinese Phase. The knowledge and understanding of prehistory in this region are still limited. Expect for OLP Phase I, the chronology was established mainly on the basis of the ceramic collections in the region. The differences among the ceramic collections—whether historical or cultural—the detailed cultural and social contexts that these ceramic collections represent, and the adaptation history of the population in this special region can all add to the cultural history of the island. However, all of these still require further studies in order to be identified and fully understood.

OLP Phase II was designated by Kuang-Chou Li as the first Neolithic culture in Kenting

National Park that is assigned to the Red Cord-Marked Ware tradition, and dates from 4500 bp

to 2300 bp (Li 1983, 1985; Chen 1998). This culture survived through fishing, hunting,

gath-ering and cultivation. Whether its people originally migrated to Taiwan from a neighbouring

area, evolved independently from the Cord-Marked Ware culture,1

or were influenced by other cultures through interaction with neighbouring areas is still disputed among archaeologists. Also, its relationship with subsequent phases is the subject of debate. Similar material remains of OLP Phase II, which were first discovered at the Kenting site in 1930, were found later in 13 other sites spread out over the eastern and western coastal zones of Kenting National Park

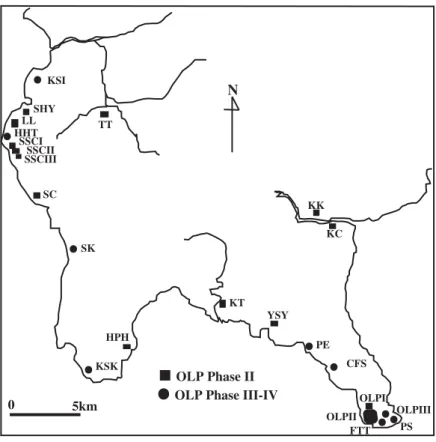

(Li 1985; see Fig. 2). The OLP Phase III–IV that followed dates from 3700 bp to 1900 bp

(Chen 1997, 1998) and is characterized by colour-painted ware. This culture also relied on fishing, hunting, gathering and cultivation for its livelihood. The material remains of OLP Phase III–IV were first found at the sites OLP II and Fan-tse-toun (Li 1983; hereafter FTT) and, later, at eight other sites (Chen 1997, 1998; Li 1985; and see Fig. 2). Because of the similar distributions of settlement locations and subsistence systems, the relationship between these two cultural phases, OLP Phase II and Phase III–IV, has been a disputed subject among archaeologists. The remains of OLP Phase II consist mostly of red cord-marked pottery. In contrast, OLP Phase III–IV remains are mostly red plain ceramics that are remarkable examples of painted pottery (although few in number), Red Cord-Marked Ware and others. Furthermore, the ceramic remains of OLP Phase III–IV are also characterized by the firing temperature of the ceramics, the treatment of the clay, the grain size and the mineral combinations found in the temper, all of which distinguish these remains from those of OLP Phase II (Huang 1984). The dating data imply a partial temporal overlap of OLP Phase II and OLP Phase III–IV (Chen 1998). What is the relationship between the two cultural traditions? How did these two populations in the area interact, if the dating data are valid? In addition, OLP Phase III–IV sites present two different settlement patterns. Some sites, such as Kai-shan, Chan-fan-shi, Fan-ti-tou, OLPII and OLPIII (hereafter KS, CFS and FTT, respectively), are located under rock shelters; while other sites, such as Hou-hsien-tung, Shui-keng, Kou-shan-koun, Pen-er and Pai-sha (hereafter HHT, SK, KSK, PE and PS, respectively), are found in settlements that are spread out along open coastal terraces. However, initial studies and preliminary results show that these settlements were more likely to have been residential and self-contained (Chen 1997). Certain socio-economic ways in which these settlements interacted with one another in

Physicochemical compositional analysis of ceramics 569

the area should contain some information for re-evaluating previous studies on settlement systems. All of these questions require more detailed information regarding the technologies, and the cultural and social contexts of ceramic manufacture of the two phases, and these approaches should benefit in the future from compositional analysis of ceramics.

RESEARCH TOPICS AND METHOD

The intention of the study was to analyse pottery across different sites in OLP Phase II and Phase III–IV. It was hoped that from compositional analyses, knowledge could be gained on the procurement of materials, the province of production and the technologies used in the manufacture of these ceramic collections that would be useful in the near future for the further examination and refinement of the chronology and organization of production, and that would address the questions about the relationship between these two cultural phases, and the detailed cultural and social contexts of both.

Two sites, Kenting (hereafter KT, and dated to 4500 bp) and Lou-lin (hereafter LL, and

dated to 2300 bp), were selected to represent the early and late periods of OLP Phase II; while

five sites, namely HHT, SK, CFS, OLPII and FFT, were chosen from OLP Phase III–IV for analysis. Due to financial limitations, a total of only 200 potsherds from the sites were sampled and their distribution is shown in Table 1. There was little possibility of acquiring

570 Maa-ling Chen

information on the functional and morphological type of the pottery, and only one type—red pottery with different surface decorative styles (cord-marked, plain, colour-painted, engraved line, relievo line and nail-impressed)—was represented by the fragmentary potsherd collec-tions. Therefore, some technological variables such as surface treatment, inclusion grain-size and density, and hardness, which were the most visible characteristics and could be used as criteria in the classification of all potsherds, were used as criteria in classifying these selected potsherds for analysis. This was done to identify the relationship between variations in techni-cal choice and paste. Seven types of potsherds were defined: (a) those with surfaces that were smoothened or evenly ground (these were the potsherds that had colour-painted decoration); (b) those having high density (> 50%) and large grain-size inclusions (0.5 –1.0 mm); (c) those having high density (50%) and small grain-size inclusions (0.1– 0.5 mm); (d) those having very low density and small grain-size inclusions (< 0.1 mm), but looking soft (hardness < 3); (e) those having very low density and small grain-size inclusions (< 0.1 mm), but looking hard (hardness > 3); (f ) those having shiny special inclusions such as pyroxene, amphibole and mica, and appearing to be dark brown or yellow-brown in colour; and (g) badly rusted pot-sherds, with a stratum of muddy rust. A small amount of ground powder (0.20 – 0.21 mg) was taken from each potsherd sample for acid-extraction compositional analysis. Meanwhile, 23

potsherd samples were selected2

to complement the chemical analysis for petrographic analysis. ANALYSES AND RESULTS

The results of petrographic analysis and chemical analysis/clustering analysis by k-means

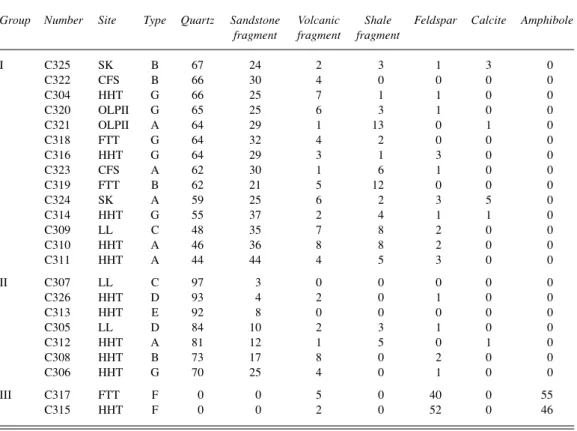

The results of the petrographic study (see Table 2) classify the samples into the following three main groups according to their mineral assemblages:

(I) This group consists mostly of samples that contain a great deal of quartz and sandstone fragments; the grains are semi-round as a result of the washing selection process. The paste samples contain no biological or fossil fragments that match the general inclusions of the sediments of the Hen-chun West Plateau, where the sites are located. The materials might have come from sediments in the streams flowing off the Central Mountains, east of the West

2 Due to the sample size requirement, the ceramic samples were mainly from OLP Phase III–IV sites.

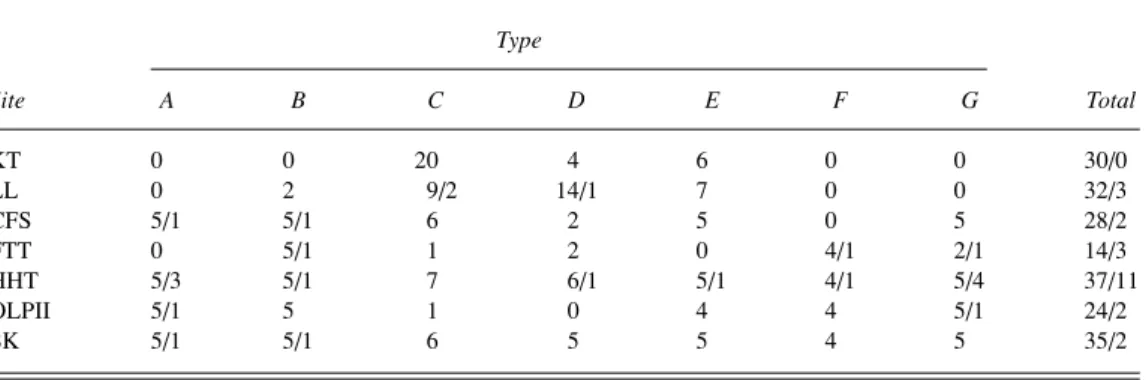

Table 1 The number of different types of potsherd samples: chemical analysis/petrographic analysis

Site Type Total A B C D E F G KT 0 0 20 4 6 0 0 30/0 LL 0 2 9/2 14/1 7 0 0 32/3 CFS 5/1 5/1 6 2 5 0 5 28/2 FTT 0 5/1 1 2 0 4/1 2/1 14/3 HHT 5/3 5/1 7 6/1 5/1 4/1 5/4 37/11 OLPII 5/1 5 1 0 4 4 5/1 24/2 SK 5/1 5/1 6 5 5 4 5 35/2

Physicochemical compositional analysis of ceramics 571

Plateau. This indicates that the sources are local, but they are not from areas near the sites (see Fig. 3).

(II) These samples are over 70% quartz and are very fine-grained. This implies that the materials might have come from the same location as the first group but have undergone a more intensive washing selection process, or have come from different sources altogether. (III) This group includes only samples of type F, which contain special and fresh amphiboles, without any quartz or sandstone fragments. This indicates that the potters intentionally collected special raw materials from certain locations, or sediments, to manufacture their pottery. The sediments contained in this special material can be found in certain areas within the studied region (called the Kenting Strata, and distributed throughout the East Mountain Section and the western part of the Nan-jen Mountain Section; see Figs 3 (c) and (e)) as well as outside the studied region in eastern Taiwan. In order to be able to reach any firm conclusions on the precise locations of the source, an analysis of the mineral composition of the entire paste matrix is needed, but it is most likely to be local rather than from outside the region, since the source can be found locally.

The amounts of the 12 elements contained in each potsherd were identified through acid-extraction compositional analysis and became the data set for the statistical analyses.

Clustering analysis was carried out using the SPSS k-means program. Clustering analysis

pro-duced results at the 2-, 3-, 4-, 5- and 7-clusters levels in the k-means analysis. After analysing

Table 2 The results of petrographic analysis

Group Number Site Type Quartz Sandstone

fragment

Volcanic fragment

Shale fragment

Feldspar Calcite Amphibole

I C325 SK B 67 24 2 3 1 3 0 C322 CFS B 66 30 4 0 0 0 0 C304 HHT G 66 25 7 1 1 0 0 C320 OLPII G 65 25 6 3 1 0 0 C321 OLPII A 64 29 1 13 0 1 0 C318 FTT G 64 32 4 2 0 0 0 C316 HHT G 64 29 3 1 3 0 0 C323 CFS A 62 30 1 6 1 0 0 C319 FTT B 62 21 5 12 0 0 0 C324 SK A 59 25 6 2 3 5 0 C314 HHT G 55 37 2 4 1 1 0 C309 LL C 48 35 7 8 2 0 0 C310 HHT A 46 36 8 8 2 0 0 C311 HHT A 44 44 4 5 3 0 0 II C307 LL C 97 3 0 0 0 0 0 C326 HHT D 93 4 2 0 1 0 0 C313 HHT E 92 8 0 0 0 0 0 C305 LL D 84 10 2 3 1 0 0 C312 HHT A 81 12 1 5 0 1 0 C308 HHT B 73 17 8 0 2 0 0 C306 HHT G 70 25 4 0 1 0 0 III C317 FTT F 0 0 5 0 40 0 55 C315 HHT F 0 0 2 0 52 0 46

572 Maa-ling Chen

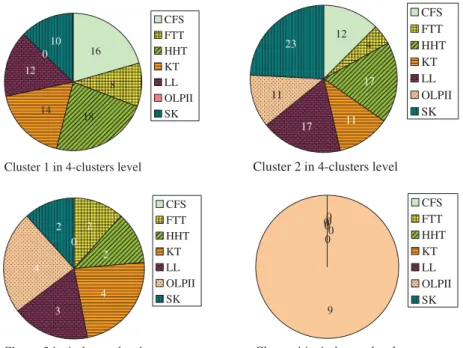

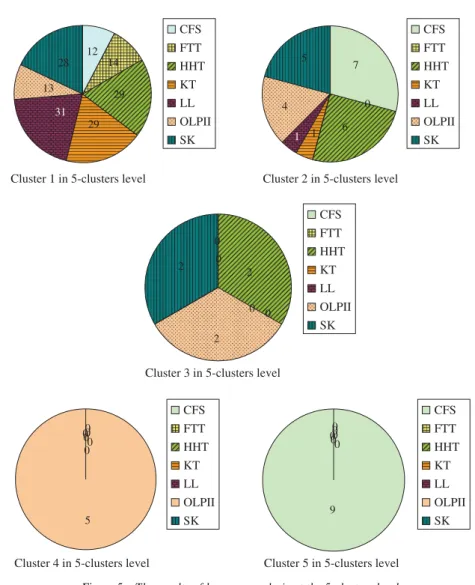

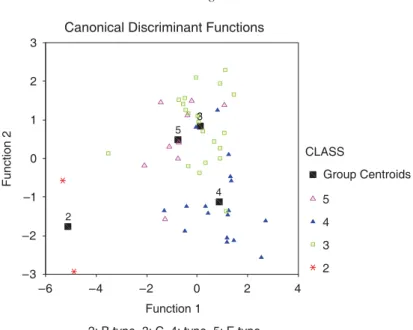

the 2-clusters level group, most of the potsherd samples (86.5%) formed one large cluster, while the rest of the 27 potsherd samples (13.5%) formed another smaller cluster, but they did not form two groups according to their cultural affiliations, as was expected. An analysis of the 3-clusters level group showed a similar result, except that cluster 1 at the 2-clusters level was separated into two groups. At the 4-clusters level, the results showed that nine potsherd samples of different types from the OLP II site were clustered into one single group (see Fig. 4). At the 5-clusters level, cluster 3 as grouped by the analysis contained potsherd samples from only the OLP Phase III–IV site. Cluster 4 had only five samples from OLPII, while cluster 5 contained only nine samples from CFS (see Fig. 5). The remaining analyses indicated almost the same results. A detailed examination of the components of cluster 2 at the 2-clusters level and of cluster 3 at the 3-clusters level revealed that they contained mostly type F potsherds (10/16) from OLP Phase III–IV, except for the CFS site. This result indicates a very interesting correspondence with the outcome of petrographic analysis. The study identified the mineral components of the paste samples and identified the possible locations of their sources. The study also defined and distinguished the special properties of the type F samples. These results verified and supported

the chemical element components results of the k-means analysis. To examine and confirm

even further the results of both the petrographic and the chemical compositional analyses, a factor analysis, which is mainly used to analyse the characteristics of components of a group, was carried out on both the data of the mineral assemblages and the chemical element components.

Physicochemical compositional analysis of ceramics 573

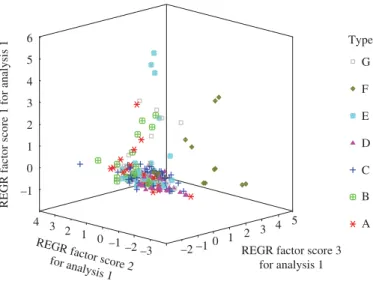

Factor analysis

The results of the factor analysis on mineral components data identified two factors: one contained only type F samples and the other included the rest of the samples (see Fig. 6). The results of factor analysis on the chemical element components data presented a similar and corresponding pattern (see Fig. 7). The results identified the following three factors: the first one contains only type F samples, the second consists of most of the samples, and the third one

includes only samples from OLPII. This result is also similar to the result from k-means analysis

at the 4-clusters level, which grouped certain samples from OLPII only into a single cluster.

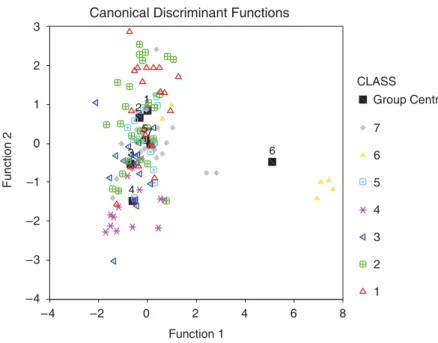

Discriminant analysis

Since some samples from OLP Phase III–IV indicated a certain amount of diversity, discriminant analysis was also carried out on the data. The analysis included only cluster 1 at the 2-clusters

level of the k-means analysis, since this was the one that contained most of the samples (87%)

but that contained less information to help understand the data. The analysis focused on detecting whether the pottery pastes varied among the different cultural affiliations, sites and types. The results of discriminant analysis on the samples from OLP Phase II and Phase III–IV show that there is a significant difference between the two sample sets. The Box’s M test, with

an F score of 10.838 at an F level of 0.001, reveals this significance. The results also show that

80% and 96.7% of the samples from OLP Phase II and Phase III–IV were originally correctly classified. The results also show that there is a significant difference in samples among sites and among types of OLP Phase II, but less heterogeneity among types of OLP Phase III–IV

574 Maa-ling Chen

Figure 5 The results of k-means analysis at the 5-clusters level.

Physicochemical compositional analysis of ceramics 575

(see Figs 8, 9 and 10). This reveals that the potsherd pastes from the two different cultural affiliations are different and can be distinguished from each other, but not visibly. Meanwhile, the different types of potsherd samples are meaningfully different from those from OLP Phase II, but not from those from OLP Phase III–IV.

Figure 7 The results of factor analysis on chemical element assemblages from acid-extraction analysis.

Figure 8 The results of discriminant analysis on samples from different sites: 89.6% of original grouped cases

576 Maa-ling Chen

DISCUSSION

The results of the physical and chemical compositional analyses do reveal certain interesting patterns and information to help us better understand the material resources, particular technologies and certain socio-economic aspects of pottery manufacturing during the studied periods in the Kenting region. It has already been demonstrated by previous studies that the pottery manufactures of the two cultural traditions are different in many respects. These ana-lyses not only revealed these differences in even more precise detail, but also explored certain interesting patterns for further study.

First, the clustering and factor analyses on chemical element components could not classify the potsherd samples into different groups according to their cultural affiliations, nor could they determine their original excavation sites; but, instead, they classified most of them together into one large group. The corresponding patterns and interpretations can be derived from the results of the petrographic analysis. From the study, geologists were able to deter-mine that most of the samples probably had the same deter-mineral composition, and that the raw materials were probably obtained from the same source in the studied region itself: from the sediments of streams flowing down the Central Mountains, east of the Hen-chun West Plateau area. The factor analysis on the chemical element components showed that most of the samples had the same composition, and verified that the raw materials of groups I and II were obtained from the same sources. This indicates whether these locations were nearby or remote, and whether all the potters at all the sites used raw materials from the same places to make their pottery (see Fig. 3). Could the potters at all the sites have procured their materials from the same sources, or were the raw materials procured at certain sites and traded to others?

Figure 9 The results of discriminant analysis on samples of types from OLP Phase II: 82.0% of original grouped

Physicochemical compositional analysis of ceramics 577

Could it also be the case that the pottery itself was produced at certain sites and traded to others? In any event, the results of the discriminant analyses indicate that the pottery types from the various sites can be distinguished from each other, and hence rule out the possibility of pottery being traded between and among sites. To synthesize, the raw materials came from the same sources and were processed in different ways in various manufacturing locations. Whether the potters at all of the sites procured their own raw materials from the same sources or an exchange system might have existed for the procurement of raw materials among sites is so far unknown and needs to be studied in further detail.

Second, the k-means and factor analyses of the chemical element compositions and mineral

components distinguished a small group from the others and showed that this group contained mostly F type samples from OLP Phase III–IV. The mineral component showed that the F type samples consisted of certain amphiboles without any quartz or sandstone fragments. This in-dicates that the potters of OLP Phase III–IV intentionally went to a certain place to obtain the special materials to manufacture certain pottery. According to geologists, the special mineral composition of the F type samples might be found either in the deposits in the Kenting Strata in the studied region or in certain geological zones in eastern Taiwan. If this special material came from eastern Taiwan, then was the clay, temper or the finished article of pottery imported into the studied region? In what kind of socio-economic context, and through what kind of social or economic interaction or exchange system, was the material or pottery transported? Is it also possible that the people of OLP Phase III–IV brought the pottery with them when they first moved into the region? In any event, it is more logical to assume that the materials came

Figure 10 The results of discriminant analysis on samples of types from OLP Phase III–IV: 52.0% of original

578 Maa-ling Chen

from a local source, as they can also be found locally. In order to answer these questions, the entire paste matrix needs to be studied and compared with possible source samples. Whatever the source, these findings already imply a very interesting subject, worthy of further study. These special pastes were only procured by potters from OLP Phase III–IV sites. This shows that the ceramic manufacturing techniques of the two cultural traditions were different in more significant ways than just decoration, surface treatment, grain size, density of temper and firing, as was previously known. Whether a special technological, social, economic or ideological context existed in which the potters procured this particular material to make their pots has yet to be identified.

The discriminant analyses still distinguished sample pastes from each other according to their different cultural origins, sites and even types of OLP Phase II. Since the materials of most samples came from the same sources, the variations must have occurred during the manu-facturing process. This implies that the ceramic manumanu-facturing technologies varied between the different cultural groups, and among the sites, at the detailed or micro-level. Meanwhile, the manufacturing technologies of OLP Phase II made the pastes of the sample types varied and distinguishable from one another. Comparably, the techniques that the potters of OLP Phase III–IV applied in their pottery manufacturing might have made the pastes of the sample types less varied, and thus indistinguishable. This result strengthens the findings of a previous study, which state that the pottery manufacturing traditions of the two cultural groups were different. The relationship between these two cultural traditions could be addressed more clearly, since they overlap temporally.

In all of the analyses, the type A samples, all of which were from OLP Phase III–IV, and whose surfaces were smoothened or polished, and decorated with coloured patterns, were grouped with most of the other samples. This shows that the materials used for the type A samples were just the same as those used for the others, and were not specially chosen. The type G samples were not found in the ceramic collections in OLP Phase II and were, along with most of the other samples, classified into the same large cluster. The type G samples were the ones that rusted badly. Whether only certain post-depositional processes or their combination with certain surface characteristics caused some potsherds to rust is still unknown. However, this phenomenon implies that the geological settings of the post-deposition of OLP Phase II and Phase III–IV might have been different, even if some sites were located in the same areas, since both used the same materials for making their pots. At the same time, whether the technology or special materials used to manufacture type F have kept them rust-free even if they were deposited in the same geological setting as the others in OLP Phase III–IV is also unknown.

Both the k-means and factor analyses distinguished some samples from others and into

single groups at individual sites, such as CFS and OLPII of OLP Phase III–IV. Does this imply that although the sites of OLP Phase III–IV shared certain cultural constraints with others in some ways, they might have still made their own unique technical choices, which dis-tinguished them from the others? The settlement patterns of OLP Phase III–IV are of two types and previous studies (Chen 1997) suggest that this might be the result of adaptation to local geographical characteristics, since temporary and functional differences were not the causes. This suggestion needs to be verified by evidence through other forms of tests. Both CFS and OLPII happen to be located in rocky sheltered areas. Would this imply that the different types of settlement patterns might have been accompanied by certain differences in their cultural and social contexts, at least in pottery manufacturing? Perhaps further analysis of pottery manu-facturing and its context might help to answer this question.

Physicochemical compositional analysis of ceramics 579 CONCLUSIONS

To summarize, the results obtained from acid-extraction chemical compositional analysis and collaborated by petrographic analysis confirm the findings of previous research, but present the phenomena in even more precise detail and explore certain patterns that were not present in earlier studies. The two studied cultural traditions were partial temporally overlapping and the settlement patterns of OLP Phase III–IV present variations. Compositional analyses explored the possible variations in the pottery manufacturing technologies of the two cultural traditions and of the sites. This makes subjects such as possible social or economic interactions, causes of the differences in settlement patterns, and social or cultural boundaries among the sites complex and interesting subjects for further study. Meanwhile, the availability and precision of the technique of analysing the chemical element components in acid extraction were con-firmed by the results of the petrographic analysis. However, due to the lack of information regarding the functions of the potter, the results of all the analyses in the current research might be interpreted incorrectly if the influence of this aspect is ignored. All of the informa-tion needs to be verified by further analyses of more potsherd and source samples, which should be corroborated by a systematic analysis of their technological and decorative styles, before any conclusions can be drawn or before further applications can be made. In conclu-sion, acid-extraction chemical compositional analysis, which has the advantages of low cost and minimal sample destruction, can be applied to a large number of samples and yet still produce sensitive, precise and accurate results. If it is used in tandem with other related approaches, this is a promising method for obtaining information on the material procurement, production province, manufacturing technologies and even certain socio-economic contexts of craft production.

ACKNOWLEDGEMENTS

This paper was originally presented at WAC-5, in 2003. I wish to express my deepest gratitude to Dr James Burton and the Archaeological Chemical Laboratory of the University of Wisconsin for carrying out the acid-extraction chemical compositional analysis, and also to Professor Wen-shan Chen of the Department of Geology, National Taiwan University, for conducting the petrographic analysis on the ceramic samples and for discussing the results. I also extend my appreciation to the following individuals: the scholarship sponsor at the Harvard–Yenching Institute; Dr Yuchun Lee and Dr Scarlet Chiu, for their help in the statistical program; and the two referees for their comments, which helped to improve this paper.

REFERENCES

Bishop, R. L., Rands, R. L., and Holley, G. R., 1982, Ceramic compositional analysis in archaeological perspective,

Advances in Archaeological Method and Theory, 5, 275–330.

Burton, J. H., and Simon, A. W., 1993, Acid extraction as a simple and inexpensive method for compositional char-acterization of archaeological ceramics, American Antiquity, 58(1), 45 –59.

Burton, J. H., and Simon, A. W., 1996, A pot is not a rock: a reply to Neff, Glascock, Bishop, and Blackman,

American Antiquity, 61(2), 405 –13.

Chen, Maa-ling, 1997, Settlement patterns, subsistence systems, and their changes in Kenting National Park during

O-luan-pi Phases III and IV, Ph.D. dissertation, Arizona State University, Tempe.

Chen, Maa-ling, 1998, What dating results imply: redefining the separation of O-luan-pi Phase III and Phase IV, and the potential relationship between O-luan-pi Phase II and Phase III, The Bulletin of the Department of Archaeology

580 Maa-ling Chen

Huang, Jui-chin, 1984, Changes in the prehistoric ceramics of O-Luan-Pi, Unpublished master’s thesis, Department of Anthropology, National Taiwan University.

Li, Kuang-Chou, 1983, Report of archaeological investigations in the O-luan-pi Park at the southern tip of Taiwan, National Taiwan University Press, Taipei.

Li, Kuang-Chou, 1985, Report of archaeological investigations in the Kenting National Park on the southern tip of

Taiwan, National Taiwan University Press, Taipei.

Matson, F. R., 1981, Archaeological ceramics and physical sciences: problem definition and results, Journal of Field

Archaeology, 8(4), 448 –56.

Neff, H., Glascock, M. D., Bishop, R. L., and Blackman, M. J., 1996, An assessment of the acid-extraction approach to compositional characterization of archaeological ceramics (comments), American Antiquity, 61(2), 389 – 404. Orton, C., Tyers, P., and Vince, A., 1993, Pottery in archaeology, Cambridge University Press, Cambridge. Peacock, P. D. S., 1970, Scientific analysis of ancient ceramics: a review, World Archaeology, 1, 379 – 89.

Rice, P. M., 1982, Pottery production, pottery classification, and the role of physicochemical analyses, in Archaeological

ceramics (ed. J. S. Olin and A. D. Franklin), 45 –56, Smithsonian Institution, Washington, DC.

Rice, P. M., 1987, Pottery analysis: a source book, The University of Chicago Press, Chicago.

Stark, M. T., Vint, J. M., and Herdke, J. M., 1995, Compositional variability in utitarian ceramics at a Colonial Period site, in Ceramic chronology, technology, and economics (ed. J. M. Herdke and M. T. Stark), 273 –96, Roosevelt Community Development Study Anthropology Papers no. 14, vol. 2, Center for Desert Archaeology, Tucson. Stone, T., 1992, The process of aggregation in the American Southwest: a case study from Zuni, Unpublished Ph.D.

dissertation, Arizona State University, Tempe.

Triadan, D., 1997, Ceramic commodities and common containers: production and distribution of White Mountain

Red Ware in the Grasshopper Region, Arizona, Anthropological papers of the University of Arizona, vol. 61,

University of Arizona Press, Tucson.

Triadan, D., Neff, H., and Glascock, M. D., 1997, An evaluation of the archaeological relevance of weak-acid extrac-tion ICP: White Mountain Redware as a case study, Journal of Archaeological Science, 24, 997–1002.