Identification and Resolution of Work Space Conflicts

in Building Construction

Sy-Jye Guo, M.ASCE

1Abstract: Numerous workers, equipment, material, temporary facilities, as well as permanent structures share the limited space during construction. Since space constraints may affect productivity and the critical path, it is essential to organize the available space efficiently and minimize space conflicts. This study considers space availability due to time and scheduling, productivity loss due to space constraints and path interference, as well as the possibility of alternative space to resolve these conflicts and optimize space usage. Herein, computer-aided design is integrated with scheduling software for the dynamic identification of space conflicts on the jobsite. Follow-up supple-mental decision criteria are then provided for conflict analysis and resolution. A prototype decision support system that combines the criteria was developed to solve this significant and complex problem more efficiently and precisely. A case study demonstrates the use and development of this system, which is very helpful to engineers and project managers.

DOI: 10.1061/共ASCE兲0733-9364共2002兲128:4共287兲

CE Database keywords: Workspace; Construction management; Buildings.

Introduction

Building construction involves various subcontractors working in a constrained area. Each subcontractor requires specific work space, equipment space, material storage, and travel paths as well as protected areas to complete his/her task. A crowded jobsite is a major cause of productivity decrease and schedule interference or delay. A detailed site layout plan with space allocation for sub-contractors reveals the space conflicts in advance, and thus im-proves the overall work flow and efficiency. However, without a space management plan, the jobsite can become chaotic, filled with interfered workers, interrupted or inefficient work, schedule delays, and numerous complaints that can destroy morale.

Traditionally, a site engineer arranges the daily activities on the jobsite according to the planned schedule. However, this re-quires space allocation to various trades of workers during spe-cific time frames. Space conflicts occur frequently on many job-sites, due to the lack of a formal procedure or methodology to identify all potential space conflicts. Even an experienced project manager may not be able to identify all of the conflicts; thus, traditionally, problems are dealt with as they arise. When serious space conflicts occur, the schedule is often delayed. Therefore, if a decision support system can be developed to help the manager identify space conflicts and suggest resolutions beforehand, then productivity will be essentially improved on the jobsite for all of the subcontractors.

Background

Space management involves three primary aspects of research— site layout planning, path planning, and space scheduling. First, site layout planning deals mainly with the layout of temporary facilities on the jobsite. Various approaches for locating the most appropriate layout of temporary facilities have been presented 共Tommelein and Zouein 1993; Yeh 1995; Cheng and O’Connor 1996; Li and Love 1998; Hegazy and Elbeltagi 1999; Zouein and Tommelein 1999兲. Geographic information systems, artificial in-telligence, and genetic algorithms have been used in previous studies to decide the best layout, according to the shortest travel distance or minimum travel cost between the temporary facilities. However, it is argued that a minimum traveling distance or cost applies only to a transportation optimization, and not directly to the optimization of the work itself, nor the shortest working pe-riod. Previous site layout studies did not pay enough attention to this argument. Furthermore, most of these studies did not consider the impact of time on space availability. For example, the jobsite office can be moved into the building itself when the structure is partially completed, thus releasing space for an alternative use. As well, time frame impact was neglected or oversimplified in most of these previous studies.

Second, path planning studies focus on the shortest route for construction equipment and operations. Based on work require-ments and the starting and destination points, the shortest, collision-free path is identified by various algorithms 共Varghese and O’Connor 1995; Lin and Haas 1996; Tserng et al. 1996兲. Typical applications include routing large vehicles or heavy-lift operations on the construction site as well as autonomous landfill using the global positioning system. However, since path plan-ning studies are concerned mainly with equipment, generally workers and material storage are not included. Also, path plan-ning researchers assume that space availability is fixed within a specific time period; that is, there is no consideration of the actual space variations during construction. These limitations constrain the significance of path planning studies on the improvement of construction productivity and space conflict resolutions.

1Associate Professor, Dept. of Civil Engineering, National Taiwan Univ., Taipei 106, Taiwan. E-mail: sjguo@ce.ntu.edu.tw

Note. Discussion open until January 1, 2003. Separate discussions must be submitted for individual papers. To extend the closing date by one month, a written request must be filed with the ASCE Managing Editor. The manuscript for this paper was submitted for review and pos-sible publication on January 23, 2001; approved on August 7, 2001. This paper is part of the Journal of Construction Engineering and Manage-ment, Vol. 128, No. 4, August 1, 2002. ©ASCE, ISSN 0733-9364/ 2002/4-287–295/$8.00⫹$.50 per page.

Finally, space scheduling combines all working elements 共worker, equipment, material, path, temporary facilities, and physical layouts兲 subjected to the variations of time frames or schedules, and thus eliminates or minimizes space conflicts be-tween these working elements. This complex problem involves space consideration as a resource, which varies with time. The space allocation procedure needs to be formally and accordingly executed based on a set of requirements or constraints of various working elements. Tommelein and Zouein 共1993兲 developed MovePlan to determine temporary facilities according to the criti-cal path method schedule. Thabet and Beliveau 共1994兲 defined work space demand and availability for high-rise building con-struction. They also proposed the concept of the space capacity factor to describe productivity loss due to space constraints. Then, in 1997, a space-constrained resource-constrained scheduling sys-tem was developed. Riley and Sanvido 共1995, 1997兲 defined construction-space use patterns in multistory buildings and pre-sented a space planning method regarding various use patterns. Recently, 4D space planning specifications and construction work space development have been investigated 共Riley 1998兲. Akinci et al.共1998兲 also executed similar research, which reduces non-value-adding activities due to space conflicts. Then, a time-space conflict analysis based on a 4D production model was pro-posed共Akinci and Fischer 1998兲.

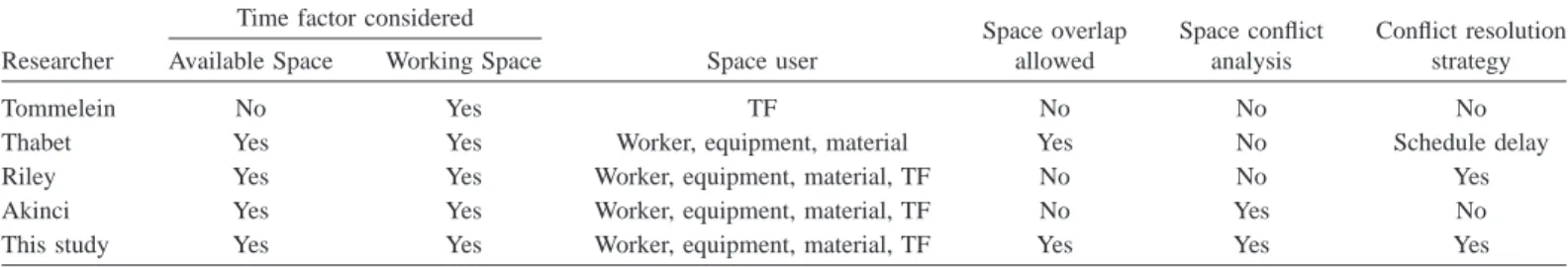

Although many researchers have targeted this complex space-scheduling problem, few studies have used a formal procedure to analyze the patterns of space conflicts, and thus provide resolu-tion strategies. Moreover, overlapping work space is not consid-ered by most studies. Table 1 summarizes the major characteris-tics of previous studies, as well as the improvement through this study. This study has attempted to overcome those assumptions and derive a more thorough result than previous studies have achieved.

Research Structure

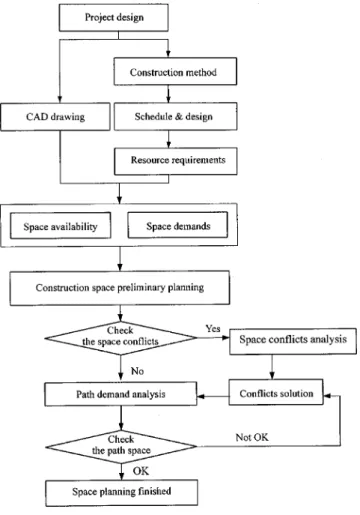

This study applied two typical tools, AutoCAD for space planning and Ms-Project for scheduling, to target the space conflict prob-lem. Notably, both software packages are well known to most engineers. Once the space conflict is detected, the analytic flow-chart provides an appropriate resolution strategy to eliminate or minimize the conflict based on the decision criteria developed herein. Fig. 1 shows the system structure. If the conflict is re-solved by space reallocation, the resolution will be fed back to the computer-aided design共CAD兲 system. The CAD system will dis-play the rearranged space planning result for various subcontrac-tors. However, if the conflict cannot be eliminated, the system will then suggest a revised schedule, according to the minimized delay caused by space conflicts. Once the original schedule is adjusted to resolve the conflicts, the system will link to MS-Project to update the revised schedule for various subcontractors.

Fig. 2 illustrates the analysis flowchart. On completion of the project design, the associated construction method, original schedule/duration, required resources, as well as the CAD draw-ing are then determined. Accorddraw-ing to the above information, space availability and demand can be compiled based on various activities and time periods. Hence, a preliminary space plan can be derived for space conflicts analysis. Initially, this system will check if there is any space conflict between the subcontractors according to preliminary space planning. If any space conflict is identified, the system’s decision criteria attempt to provide a reso-lution strategy to either resolve or minimize the conflict. When all of the conflicts are resolved, the system will execute the path demand analysis to verify if there is sufficient path space for worker/equipment traveling as well as material transportation. However, if the path demands cannot be satisfied, then the space conflict resolutions will be redone. Only when path demands are satisfied are the space conflicts really resolved and the final space planning complete.

Space Demand

The available space within building construction is divided into four categories—exterior of the jobsite, interior of the jobsite, inside the structure, and space provided by temporary structures such as platforms and scaffolds. The first two indicate only ground space. Available space inside the structure is then divided into various stories and zones. The total available space data are then compiled by the different codes of availability categories, which include the space size and time availability.

The space demand, which is derived from the original sched-Table 1. Comparisons and Features of Space Scheduling Studies

Researcher

Time factor considered

Space user Space overlap allowed Space conflict analysis Conflict resolution strategy Available Space Working Space

Tommelein No Yes TF No No No

Thabet Yes Yes Worker, equipment, material Yes No Schedule delay

Riley Yes Yes Worker, equipment, material, TF No No Yes

Akinci Yes Yes Worker, equipment, material, TF No Yes No

This study Yes Yes Worker, equipment, material, TF Yes Yes Yes

ule and broken down as a hierarchical structure, is shown in Fig. 3. Notably, an activity may include several tasks and require vari-ous working and path spaces for laborers and equipment as well as associated material storage.

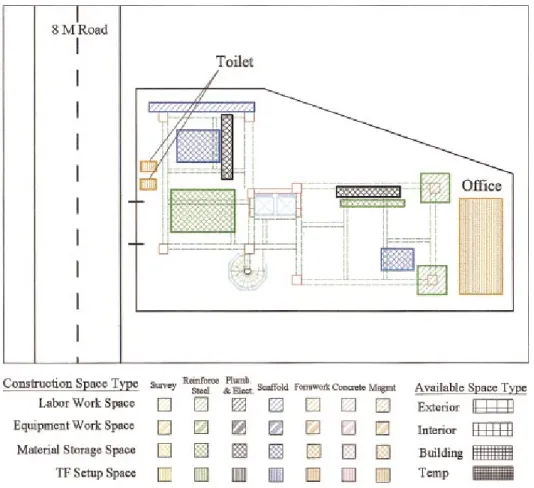

For various activities, different colors are applied for identifi-cation within CAD. Fig. 4 displays the different line patterns for the various spaces, such as working, storage, waste, or setup space. Notably, the crossed line represents working space, while

the equipment working space uses a darker line than the labor working space does. Furthermore, a double crossed line desig-nates material storage space, and a straight line identifies the setup space of temporary facilities. Thus, according to the differ-ent colors and patterns on the CAD drawing, the space user can be identified easily.

Space Conflict Identification

The space demands for various activities are specified by site engineers and displayed on the CAD drawing. Combining space demands within the same time period reveals conflicts between various activities. This is similar to the combination of various design drawings, which identify physical space conflicts within the final design. During construction, the combination of space demands can help the engineer identify potential space conflicts. Fig. 5 shows the concept of space conflict identification.

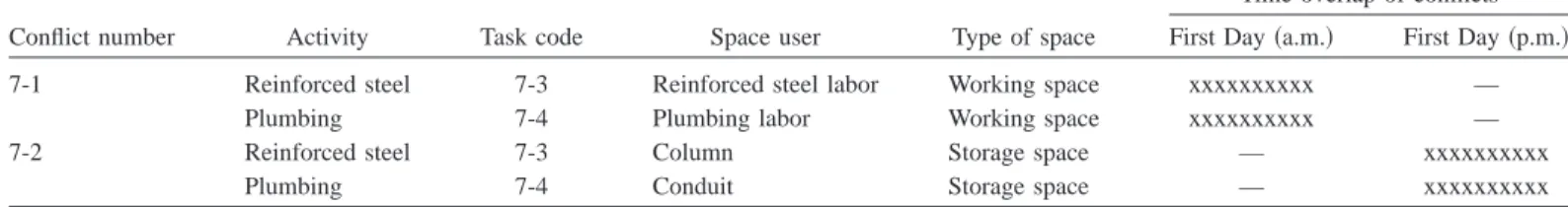

In this study, space conflict is defined as more than one space demand claim on a specific available space during the same time period. Thus, when all of the space demands of various subcon-tractors are overlapped on the CAD drawing for a specific time period, space conflicts can be detected. Table 2 shows a compiled example of space demands for various subcontractors during dif-ferent time periods.

Once a space conflict is detected, data regarding the affected activities as well as the size of the overlapped space are required for conflict analysis and resolution. The following variables are defined for subsequent analysis:

1. Interference space size—size of overlap between activities, 2. Interference space percentage共ISP兲

Fig. 2. Analysis flowchart of space planning and conflict resolution

Fig. 3. Hierarchical structure of space demand

Fig. 4. Identification of various space demands

ISP⫽interference space size

original size ⫻100% (1) 3. Interference duration—length of time for overlapped space

demand, and

4. Interference duration percentage共IDP兲 IDP⫽interference durarion

original duration ⫻100% (2) Fig. 6 demonstrates an example of these variables.

Resolution Strategy

To overcome space conflicts, three resolution strategies are con-sidered. The first strategy is to adjust the space demand, which changes the location of the space demand, or divide the original space demand into several smaller areas to eliminate space con-flicts. This approach does not alter the original schedule, and if it is feasible, it minimizes the impact on the construction site. The second strategy adjusts the planned schedule to avoid space con-flicts. Typical solutions for this strategy include adjusting the starting time of an activity, reducing the length of time for space requirements, or splitting the working time period. Typically, this approach delays the original schedule; however, a minimum delay is the decision criterion for space conflict resolution. The third strategy is a hybrid approach, which adjusts the space demand and scheduling sequence simultaneously. Thus, changing the quantity of space users or even the construction method may re-solve space conflicts.

Criteria for Resolving Space Conflict

Once the strategy is established, criteria that determine the activ-ity to be modified become essential. To resolve space conflicts, the characteristics for each involved activity must be analyzed. Hence, this research develops a series of criteria for analyzing conflicts characteristics and assists the engineer in deciding which activity requires adjustment.

1. Logical sequence between activities. If conflict is identified, the logical sequence between these activities is verified ini-tially. If a logical sequence relationship exists, the space de-mand for successive activities must be adjusted.

2. Critical path. Activities on the critical path have the priority to claim space demand; other noncritical activities will be modified.

3. Space divisibility. If the space demand can be divided into several smaller areas, then the space conflict may be elimi-nated.

4. Location change. If the space demand, such as material stor-age, can be altered, then the space conflict may be elimi-nated.

5. Space size modification. If the space demand can be adjusted or decreased, i.e., constrained to a specific limit, the space conflict could be eliminated. However, the productivity of the adjusted activity may be affected.

6. Start time of conflicting space occupation. The start time of an activity to occupy a space could be a criterion for decid-ing which activity requires adjustment.

7. Length of occupancy time. The duration of occupancy could also be a criterion for deciding on the conflict resolution approach.

Despite the aforementioned criteria, additional factors may help to analyze and resolve the conflicts. These affiliate criteria include the size of the conflict, location of the conflict, duration of the conflict, and other specific characteristics of the conflicting tasks. This study also defines the ISP and IDP for further analyses and decision rules. Table 3 summarizes categories and criteria for resolving space conflicts.

Space Conflict Reidentification

Once the original conflicts are resolved, the whole process of conflict identification and resolution must be executed again to ensure that no further space conflicts have occurred due to the adjusted space allocation or schedule rearrangement. Generally, this process can be completed in a short period. However, if fur-ther conflicts occur continuously or trigger subsequent problems, then the resolution strategy may require modification. In this cir-cumstance, rearranging space usage or the schedule may not solve all of the conflicts effectively. Hence, a hybrid approach, such as applying alternative construction methods, may be more effective.

Path Demand Verification

Although all of the space conflicts have been resolved, the space planning is not yet complete. The final step is to ensure that there is enough path space for all of the required laborers and equip-ment, and for material transportation. Therefore, a minimum path width and height were defined as follows:

Table 2. Example of Space Conflict Identification

Conflict number Activity Task code Space user Type of space

Time overlap of conflicts First Day共a.m.兲 First Day共p.m.兲

7-1 Reinforced steel 7-3 Reinforced steel labor Working space xxxxxxxxxx —

Plumbing 7-4 Plumbing labor Working space xxxxxxxxxx —

7-2 Reinforced steel 7-3 Column Storage space — xxxxxxxxxx

Plumbing 7-4 Conduit Storage space — xxxxxxxxxx

Minimum path width⫽max

再

all activities冋

min共width for labor兲 min共width for equipment兲 min共width for labor/material兲 min共width for equipment/material兲

册冎

(3)

Minimum path height⫽max

再

all activities冋

min共height for labor兲 min共height for equipment兲 min共height for labor/material兲 min共height for equipment/material兲

册冎

(4)

The minimum path width and height can be derived from the above equations to examine if the path demands can be satisfied. Items that require examination include

1. Available path from the entrance to each working area, 2. Available path from the entrance to each storage area, 3. Available path from each working area to the associated

stor-age area,

4. Available path from each working area to the other working areas with the same activity, and

5. Available path from the current storage areas to the next stage storage areas.

When all path requirements are satisfied, the space planning is complete. Otherwise, appropriate adjustments must be made to eliminate insufficient path demands. However, if path demands remain unsatisfied, the aforementioned process of space conflict resolution must be reexecuted for an alternative feasible solution.

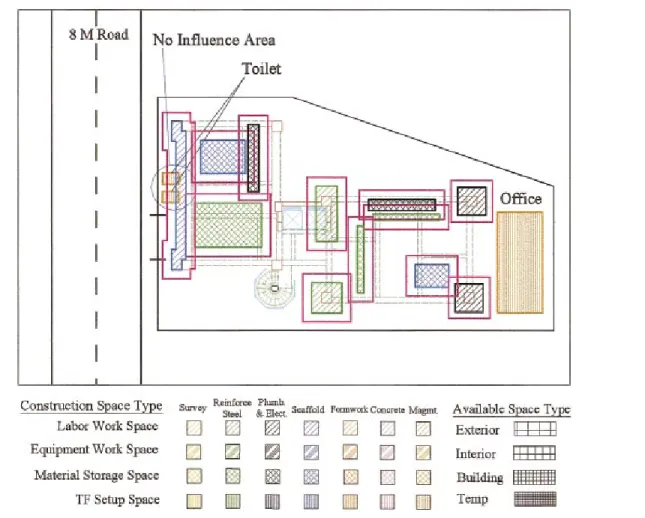

Case Illustration

A typical 12-story reinforced concrete residential building is used to demonstrate the identification and resolution of space conflicts via the decision criteria. This jobsite is approximately 1,000 m2, with a total floor area of 5,775 m2. The space planning for each floor requires various space requirements for the survey, reinforc-ing steel, plumbreinforc-ing and electrical, scaffold, formwork, concrete, and management. Fig. 7 displays the combined CAD drawings from the initial schedule as well as the space requirements of all subcontractors, which reveal many space conflicts.

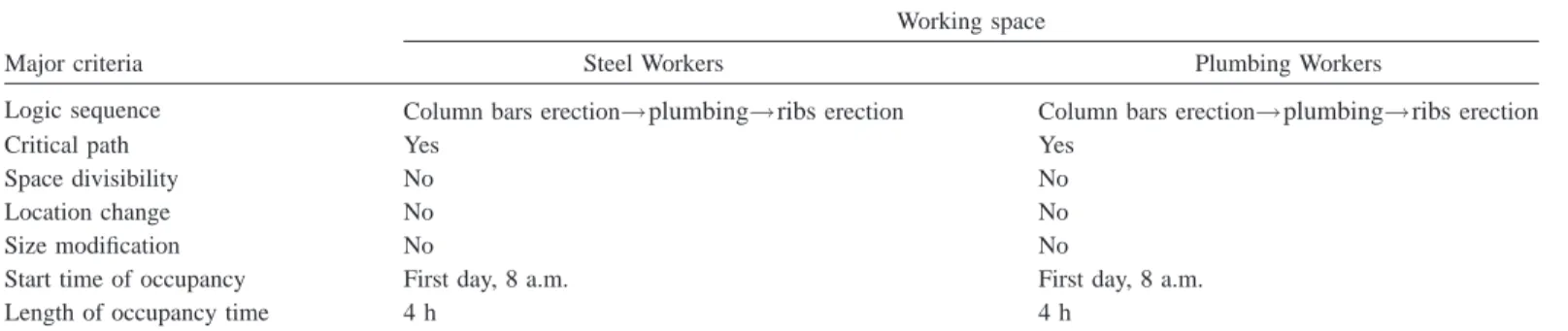

To resolve the space conflicts, the decision support system initially compiles all of these conflicts according to the space users, type of space, duration of the conflicts, location/size of the conflicts, as well as other related data of the competing activities. As mentioned previously, a list of conflicts is then established 共Table 2兲. Table 4 lists the characteristics for space conflict 7-1 共seventh floor, steel workers versus plumbing workers兲. Accord-ing to the developed criteria for conflict analyses and resolution, the procedure for resolving space conflict 7-1 is as follows:

• Step 1—Logical sequence. The column bars erection must be completed before the plumbing work, and the column ribs have to be done after the plumbing work is finished. This criterion clearly defines the working sequence for steel work-ers and plumbing workwork-ers.

• Step 2—critical path. Both the steel erection and plumbing works of these columns are on the critical path of the project. This criterion cannot distinguish the priorities for the steel workers and plumbing workers.

• Step 3—space divisibility. Both of the working spaces needed for steel erection and plumbing are around the permanent lo-cation of the columns to be erected; therefore, the required working space cannot be divided in this case, either.

• Step 4—location change. From Fig. 7, it can be found that there are two shear walls共elevator room兲 and nine columns 共edges of the building兲 that will cause space conflicts for steel workers and plumbing workers. Although the working space of each column is fixed and cannot be changed, the overall working location can be adjusted by splitting the workers up to work on a couple columns at a time. For example, the steel workers can start the column bars erection of the two columns on the east side. When the first two columns are done, the steel workers can then move to the next two columns in the center area while the plumbing workers can start to work on the first two columns. In this approach, this criterion may provide a feasible solution to this space conflict.

• Step 5—size modification. In this case, adjusting the size of the space requirements for both steel workers and plumbing workers is infeasible, since the floor area is very limited. This criterion does not help in this case.

• Step 6—start time of occupancy. Both steel workers and plumbing workers are originally scheduled to start their jobs at 8 a.m. However, according to the resolving criterion in step 1, the steel workers must erect the column bars first. As a result, the start time of the plumbing workers must be delayed for space conflict resolution.

Table 3. Categories of Criteria for Resolving Space Conflicts

Category Major criteria

Affiliate criteria

Space Related Time Related

Criteria Logic sequence Size of conflict Duration of conflict

Critical path Size of conflict Duration of conflict

Space divisibility Interference space percentage共ISP兲 Interference duration percentage共IDP兲 Location change Location of conflict Specific characteristic of conflict tasks Size modification Other related data or characteristics —

Start time of occupancy Other related data or characteristics — Length of occupancy time Other related data or characteristics —

• Step 7—length of occupancy time. Both steel workers and plumbing workers need 4 h to complete their own task. Unless the human-power is increased, the length of occupancy time cannot be reduced. On the other hand, based on the resolving criterion in step 6, the finish time of the plumbing task will be delayed.

According to the above step-by-step analyses of the criteria, a more suitable approach to resolve this problem is to adjust the planned schedule to avoid the space conflicts. Figs. 8 and 9 dis-play that by splitting the reinforcing steel tasks of the columns to be erected, the conflicts between reinforcing steel and plumbing/ electrical can be eliminated. That is, steel workers must install the column bars first; then the plumbing/electrical workers have to follow the column bars installation with pipe installation. Finally, the steel workers must complete rib bar erection for the formwork workers to follow on. Since the start time of the plumbing/

electrical workers is delayed for about 2 h, while waiting for the steel workers to install the column bars, the finish time of the plumbing/electrical work is thus delayed. Consequently, the rib bar completion is also delayed. Originally, the formwork subcon-tractor was scheduled to begin at 2 p.m. However, due to the space conflicts and proposed resolution, the formwork workers also must delay their starting time.

After the space conflict between the steel workers and plumbing/electrical workers is resolved, the decision support sys-tem examines if there are other subsequent unsolved conflicts. Although Fig. 9 displays a dummy conflict between the scaffold and temporary toilet, no actual space conflict exists. That is, the toilet did not interfere with the scaffold on the seventh floor be-cause it was on the ground level. When all of the other space conflicts are resolved and no further conflicts occur, the system will then verify if the path requirements are satisfied.

Fig. 7. 共Color兲 Conflicts identification for all subcontractors

Table 4. Characteristics for Conflict 7-1共Steel Workers versus Plumbing Workers兲 Major criteria

Working space

Steel Workers Plumbing Workers

Logic sequence Column bars erection→plumbing→ribserection Column bars erection→plumbing→ribserection

Critical path Yes Yes

Space divisibility No No

Location change No No

Size modification No No

Start time of occupancy First day, 8 a.m. First day, 8 a.m.

Fig. 8. 共Color兲 Conflict resolution between reinforcing steel and plumbing 共8 a.m.兲

According to Eqs. 共3兲 and 共4兲, the minimum path width and height for this particular case can be obtained. In the illustrated case, the material transportation is done manually without equip-ment. The path width共steel worker/rebar, plumbing worker/pipe, and carpenter/formwork兲 does not require extra space. A 1 m path width will satisfy all of the associated activities. On the other hand, all of the tasks are executed on top of the completed floor; thus, there are no path height constraints. The developed system adopts a 1 m borderline for checking all of the path width require-ments. Fig. 10 illustrates the result of the path requirement veri-fication of this case. Since all of the path requirements are also satisfied, the space planning process is complete. The decision support system will then forward these data to the schedule soft-ware and update the rearranged schedule.

Discussion and Conclusions

Numerous workers, equipment, material, temporary facilities, and permanent structures share limited space during construction. Since space constraints may affect the moving path and produc-tivity, it is essential to organize the available space efficiently, such that the space conflicts are minimized. The space availability on a site may change due to time and scheduling arrangements. Thus, site layout/space planning has been a significant and com-plex problem for construction engineers. However, the construc-tion industry has lacked efficient and systematic approaches for site layout and space planning. Therefore, when faced with a space conflict problem, many engineers rely on personal

experi-ence. However, this heuristic approach fails to consider that space availability may change with time and schedule, the possibility of alternative space, or the productivity loss due to path interference and space constraints.

This study established a procedure and criteria for identifying and resolving space conflicts. Previous researchers resolved this problem based on minimal traveling distance or cost between temporary facilities. However, this solution applies only to the transportation optimization process, and not directly to work op-timization, nor the shortest working period. Alternatively, this study considered space availability due to time and schedule, pro-ductivity loss due to path interference and space constraints, as well as the possibility of alternative space for conflict resolution and optimal usage. Herein, the CAD system was integrated with schedule software for the dynamic identification of space conflicts on the jobsite for various subcontractors. Follow-up supplemental decision criteria were then provided for conflict analysis and reso-lution. Furthermore, a prototype decision support system that combined the criteria was developed to solve this significant and complex problem more efficiently and precisely. Finally, a case study demonstrated the use and development of this system, which will be very helpful to engineers and project managers.

Acknowledgment

The writer would like to thank the National Science Council of the Republic of China for financially supporting this research under contract number NSC89-2211-E-002-135.

References

Akinci, B., and Fischer, M.共1998兲. ‘‘Time-space conflict analysis based on 4D production models.’’ Proc., Int. Computing Congress, ASCE, Reston, Va., 342–353.

Akinci, B., Fischer, M., and Zabelle, T.共1998兲. ‘‘A proactive approach for reducing non-value adding activities due to time-space conflicts.’’ Proc., 8th Annual Conf. of the Int. Group for Lean Construction, 1–16.

Cheng, M. Y., and O’Connor, J. T.共1996兲. ‘‘ArcSite: Enhanced GIS for construction site layout.’’ J. Constr. Eng. Manage., 122共4兲, 329–336. Hegazy, T., and Elbeltagi, E. 共1999兲. ‘‘EvoSite: Evolution-based model

for site layout planning.’’ J. Comput. Civ. Eng., 13共3兲, 198–206. Li, H., and Love, P. E. D.共1998兲. ‘‘Site-level facilities layout using

ge-netic algorithms.’’ J. Comput. Civ. Eng., 12共4兲, 227–231.

Lin, K. L., and Haas, C. T.共1996兲. ‘‘An interactive planning environment for critical operations.’’ J. Constr. Eng. Manage., 122共3兲, 212–222. Riley, D. R.共1998兲. ‘‘4D space planning specification development for

construction work spaces.’’ Proc., Int. Computing Congress, ASCE, Reston, Va., 354 –363.

Riley, D. R., and Sanvido, V. E.共1995兲. ‘‘Patterns of construction-space

use in multistory buildings.’’ J. Constr. Eng. Manage., 121共4兲, 464– 473.

Riley, D. R., and Sanvido, V. E. 共1997兲. ‘‘Space planning method for multistory building construction.’’ J. Constr. Eng. Manage., 123共2兲, 171–180.

Thabet, W. Y., and Beliveau, Y. J. 共1994兲. ‘‘Modeling work space to schedule repetitive floors in multistory buildings.’’ J. Constr. Eng. Manage., 120共1兲, 96–116.

Tommelein, I. D., and Zouein, P. P.共1993兲. ‘‘Interactive dynamic layout planning.’’ J. Constr. Eng. Manage., 119共2兲, 266–287.

Tserng, H. P., Veeramani, D., Kunigahalli, R., and Russel, J. S. 共1996兲. ‘‘OPSALC: A computer-integrated operation planning system for au-tonomous land fill compaction.’’ J. of Automation in Constr., 5共1兲, 39–50.

Varghese, K., and O’Connor, J. T. 共1995兲. ‘‘Routing large vehicles on industrial construction sites.’’ J. Constr. Eng. Manage., 121共1兲, 1–12. Yeh, I.共1995兲. ‘‘Construction-site layout using annealed neural network.’’

J. Comput. Civ. Eng., 9共3兲, 201–208.

Zouein, P. P., and Tommelein, I. D. 共1999兲. ‘‘Dynamic layout planning using a hybrid incremental solution method.’’ J. Constr. Eng. Man-age., 125共6兲, 400–408.