Effects of Biodiesel and Engine Load on Nanoparticle

Emissions from a Heavy-Duty Diesel Engine

Yi-Jyun Liou1, Li-Hao Young1, Man-Ting Cheng2, Hsi-Hsien Yang3, Ying I. Tsai4 and Lin-Chi Wang5

1 Dept. of Occupational Safety and Health, China Medical University, Taichung, Taiwan 2 Dept. of Environmental Engineering, National Chung Hsing University, Taichung, Taiwan 3 Dept. of Environmental Engineering and Management, Chaoyang University of Technology, Taichung, Taiwan

4 Dept. of Environmental Engineering and Science, Chia Nan University of Pharmacy and Science, Tainan, Taiwan

5 Dept. of Chemical and Materials Engineering, Cheng Shiu University, Kaohsiung, Taiwan

ABSTRACT

Diesel engine exhaust contains large numbers of fine particles that degrade air quality and contribute to adverse human health effects. This study aims to characterize the changes of nanoparticle number emission characteristics from a heavy-duty diesel engine, operating with selected blends of low-sulfur biodiesel (B2_S50, B10, and B20) and engine loads (0%, 25%, 50%, 75%) under steady cycle. Raw exhaust were sampled with a rotating disc thermo-dilution system, followed by measurements of number size distributions of 10 – 1000 nm non-volatile particles using a scanning mobility particle sizer and condensation particle counter (SMPS) system. The results show that the particle number emission concentrations decrease with

increasing blends of biodiesel from 2% to 20%, resulting in a particle number reduction of 35%. Increasing the engine load from 25% to 75%, on the other hand, resulted in a particle number increase of 64%. Among various loads, the highest particle number emission concentrations were observed when running on B2_S50 fuel under idle condition, with the presence of non-volatile nucleation mode particles. The number size distributions of non-volatile particles showed an increase of mode diameters when increasing engine load, whereas increasing blends of biodiesel resulted in a relatively small increase of mode diameters. Overall, the present results show that the increase of biodiesel content in fuels resulted in a minor reduction of nanoparticle number concentration and small increases of particle mode diameters. The increase of engine load resulted in moderate increases of particle number concentration and moderate increases of particle mode diameters.

KEYWORDS

Introduction

Diesel engine has found widespread use in on-road vehicles and off-road equipments.

However, its exhaust contains large numbers of fine particles that have been linked to a variety of adverse health effects[1] and environmental impact[2]. Heavy-duty diesel engines are of special

interest because these vehicles contribute significantly to the on-road PM2.5 emission despite

comprising only a small fraction of total vehicles. Most of the diesel particle mass is contributed by the accumulation particles (> 50 nm), whereas the vast majority of particle number is

contributed by nanoparticles (< 50 nm). As mass-based particle emission standards have become increasingly stringent, growing attention is directed towards measurements of nanoparticle number concentration. Number-based method has shown of improved detection limit, accuracy, discrimination power, variability and reduced volatile artifacts over the conventional gravimetric method[3].

The number size distribution of diesel engine particles is typically bimodal; a nucleation mode (< 30 nm) and an accumulation mode. The former arises from nucleation of H2SO4/H2O or

low-volatile organic compounds, whereas the latter comprises of soot formed in the engine. The occurrence, sizes and concentrations of the modes depend on engine type, speed, load, fuel type, aftertreatment devices and sampling conditions[4]. As nucleation is nonlinear by nature, the

variability of nucleation particle concentrations is considerably larger than that of accumulation particles. This gives rise to the measurements of non-volatile particles larger than 23 nm, i.e., soot particles, developed by the Particulate Measurement Programme (PMP) and currently adopted in the UNECE Regulation.

As part of a larger project that aims to develop low-cost and high-efficiency diesel exhaust aftertreatment devices, this study set out to characterize the dependency of non-volatile

submicrometer particle number size distributions in raw exhaust on engine load and low-sulfur biodiesel. Laboratory experiments were conducted on a heavy-duty diesel engine with an engine dynamometer. The results serve as the baseline data needed to evaluate the reduction efficiencies of the aftertreatment devices under study.

Experimental Methods

The experiments were conducted on a 6-cylinder, 6 L, naturally aspirated, water-cooled, direct-injection diesel engine (Hino W06E). The engine was tested using three out of the 13 European Steady Cycle modes: mode 1 (Idle, 0% load), mode 3 (1800 rpm, 25% load) and mode 9 (1800 rpm, 50% load). The biodiesel fuels were prepared using low-sulfur (< 50 ppmw) biodiesel (B2) that is further blended with waste cooking oil to 10% (B10) and 20% (B20) biodiesel fuels.

Raw exhaust were directly sampled with a rotating disc thermo-dilution system (TDS), followed by measurements of number size distributions of 10-1000 nm non-volatile particles using a scanning mobility particle sizer and condensation particle counter (SMPS) system[5]. In the TDS, the raw exhaust was first diluted and then heated to 300 °C to remove volatile

compounds. The SMPS was operated with a sample and sheath flow of 0.3 and 3 lpm, producing one average particle number size distribution every 3.5 min.

Results and Discussion

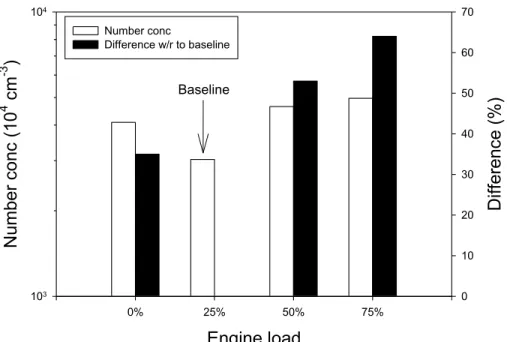

The average particle number emission concentrations under different engine loads are presented in Figure 1. Also included is the concentration difference with respect to 25 % load (baseline); idle condition was not used as the baseline because its particle emission characteristics are substantially different from other test conditions, discussed below. As shown, the measured number emission concentrations ranged from 3.0×107 – 5.0×107 cm-3, which is 103 times higher than typical ambient particle number concentration. Under idle condition, the number emission concentrations were higher than that under 25% load but lower than 50% and 70% load.

Beginning from 25% load, the number emission concentrations increase with increasing engine load; the concentration differences are in the range of 50-70%. This observed trend is consistent with earlier studies[6,7].

Engine load 0% 25% 50% 75% Nu mb er c on c ( 10 4 c m -3 ) 103 104 Differ en ce ( %) 0 10 20 30 40 50 60 70 Number conc Difference w/r to baseline Baseline

Figure 1. Average particle number emission concentrations under different engine loads. The measured average particle number size distributions under different engine loads are shown in Figure 2. The size distributions under idle condition are bimodal and very different from other test conditions, showing a predominant nucleation mode of 14.5 nm and a

substantially minor accumulation mode of ~70 nm. This shows the persistence of non-volatile nucleation mode particles after thermal treatment of 300 °C, contradicting to the notion that nucleation particles are completely volatile[8]. Kittelson et al.[6] suggested ash nuclei may form if the metal-to-carbon is sufficiently high, of which the metals come from metallic additives in the lubricant oil. Under higher engine loads, the size distributions were unimodal with a

accumulation mode of diameter greater than 50 nm. In addition, the mode diameter increases with increasing engine load. As fuel injection increases with increasing engine load, it is suggested that more soot particles are produced as a result of diffusion combustion.

Particle Diameter, Dp (nm) 10 100 1000 N umb er C on ce ntr ati on dn /dlo gd p( 10 7 #/c m 3 ) 0 2 4 6 8 10 12 14 16 0% (dmode:14.5 nm) 25% (dmode:56.4 nm) 50% (dmode:75.1 nm) 75% (dmode:91.5 nm) B2_S50 w/o aftertreatment Load

Figure 2. Average particle number size distributions under different engine loads.

EFFECTS OF BIODIESEL

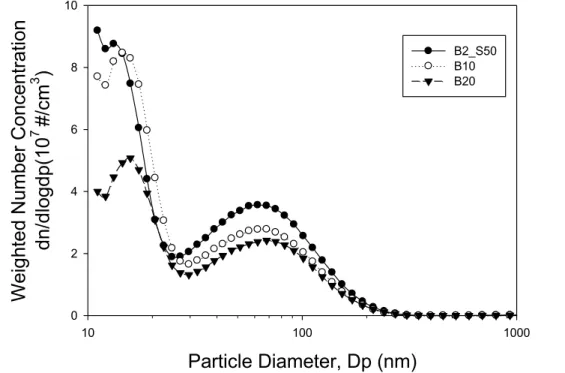

Figure 3 shows the weighted number size distributions with the engine running on different blends of biodiesel fuel. To focus on the effects of biodiesel fuels, data weighting was carried out with respect to the engine load (0%:25%:50%=1.5:1:1), based on the weighting factors given in European Steady Cycle. As a result, the presented size distributions are all bimodal. As shown, the number emission concentrations decrease with increasing biodiesel content in the fuel. Using B2_S50 as the baseline, the reduction ranged from 21-40%. Meanwhile, the particle mode diameters increase with increasing biodiesel content in the fuel. This is in line with results reported in Kittelson[4] but contradicts with a number of other studies[9]. The observed disparities between the presented results and earlier studies are likely due to the differences in sampling protocol. The major difference is the thermo-conditioning of diesel particles prior to

measurements in the present study whereas most of the earlier studies did not. The removal of low-volatile compounds in the sample exhaust evidently would change the number size

distributions; most likely a shift towards smaller particle sizes. More work is needed to examine these issues and their associated implications in human and environmental health.

Particle Diameter, Dp (nm) 10 100 1000 We igh ted N umb er C on ce ntr ati on dn /dlo gd p( 10 7 #/c m 3 ) 0 2 4 6 8 10 B2_S50 B10 B20

Figure 3. Weighted particle number size distributions with the engine running on different blends of biodiesel fuel.

SUMMARY

The present results show that the increase of biodiesel content in fuels resulted in a minor reduction of nanoparticle number concentration and small increases of particle mode diameters. The increase of engine load resulted in moderate increases of particle number concentration and moderate increases of particle mode diameters. High number concentrations of non-volatile nucleation mode particles were observed only under idle condition. More work is needed to elucidate the effects of condensable vapors on the number size distributions and their associated implications in human and environmental health.

ACKNOWLEDGMENTS

The financial and administrative support from the Taiwan EPA and NSC under the Contract# of NSC 98-EPA-M003-002 and NSC-99-EPA-M-002-002 are gratefully acknowledged.

REFERENCES

[1] US EPA Health assessment document for diesel engine exhaust; National Center for

Environmental Assessment, Office of Transportation and Air Quality: Washington, DC, 2002; EPA/600/8-90/057F.

[2] Eldering, A., Cass, G.R. J. Geophy. Res. 1996, 101, 19343-19369.

[3] Andersson, J.; Giechaskiel, B.; Munoz-Bueno, R.; Dilara, P. Particle Measurement

Programme (PMP) Light-Duty Inter-Laboratory Correlation Exercise (ILCE LD); PMP

Working Meeting; Final Report No. GRPE-PMP-18-2. [4] Kittelson, D.B. J. Aerosol Sci. 1998, 29, 575-588.

[5] Heim, M.; Kasper, G.; Reischl, G. P.; Gerhart, C. Aerosol Sci. Technol. 2004, 38, 3-14. [6] Kittelson, D.B.; Watts, W.F.; Johnson, J.P. J. Aerosol Sci. 2006, 37, 913-930.

[7] Zhu, L.; Cheung, C.S.; Zhang, W.G.; Huang, Z. Aerosol Sci. Technol. 2010, 44, 362-369. [8] Schneider, J.; Hock, N.; Weimer, S., Borrmann, S. Environ. Sci. Technol. 2005, 39,

6153-6161.