This article was downloaded by: [National Chiao Tung University 國立交通大學] On: 27 April 2014, At: 19:52

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Aerosol Science and Technology

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/uast20

Mechanism of Particle Impaction and Filtration by the

Dry Porous Metal Substrates of an Inertial Impactor

Cheng-Hsiung Huang a & Chuen-Jinn Tsai a a

Institute of Environmental Engineering , National Chiao Tung University , Hsin Chu, Taiwan Published online: 30 Nov 2010.

To cite this article: Cheng-Hsiung Huang & Chuen-Jinn Tsai (2003) Mechanism of Particle Impaction and Filtration by the Dry Porous Metal Substrates of an Inertial Impactor, Aerosol Science and Technology, 37:6, 486-493, DOI: 10.1080/02786820300968 To link to this article: http://dx.doi.org/10.1080/02786820300968

PLEASE SCROLL DOWN FOR ARTICLE

Taylor & Francis makes every effort to ensure the accuracy of all the information (the “Content”) contained in the publications on our platform. However, Taylor & Francis, our agents, and our licensors make no

representations or warranties whatsoever as to the accuracy, completeness, or suitability for any purpose of the Content. Any opinions and views expressed in this publication are the opinions and views of the authors, and are not the views of or endorsed by Taylor & Francis. The accuracy of the Content should not be relied upon and should be independently verified with primary sources of information. Taylor and Francis shall not be liable for any losses, actions, claims, proceedings, demands, costs, expenses, damages, and other liabilities whatsoever or howsoever caused arising directly or indirectly in connection with, in relation to or arising out of the use of the Content.

This article may be used for research, teaching, and private study purposes. Any substantial or systematic reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any

form to anyone is expressly forbidden. Terms & Conditions of access and use can be found at http:// www.tandfonline.com/page/terms-and-conditions

°2003 American Association for Aerosol Research Published by Taylor and Francis

0278-6826/03/$12.00 + .00 DOI: 10.1080/02786820390112641

Mechanism of Particle Impaction and Filtration

by the Dry Porous Metal Substrates of an Inertial Impactor

Cheng-Hsiung Huang

1and Chuen-Jinn Tsai

Institute of Environmental Engineering, National Chiao Tung University, Hsin Chu, Taiwan

1Current address: Department of Environmental Engineering and Health, Yuanpei University of Science

and Technology, Hsin Chu, Taiwan

This study has investigated numerically the particle collection efficiency curves of inertial impactors with a dry porous metal sub-strate covering a wide range of particle diameters. The results show that the penetrating air causes higher inertial force for particles near the surface of the dry porous metal substrate than that of the flat plate, which increases the collection efficiency due to in-ertial impaction mechanisms. The calculated collection efficiency curve will be sharper than that assuming 100% filtration efficiency (ideal filtration) and there is a minimum value of<2% at√St = 0.05∼ 0.07 (corresponding to dp= 0.1∼ 0.5 µm) for different Re

and K. The collection efficiency increases to 15% for the ultra-fine particles with a diameter of 0.01µm when Re = 3,000 and

K= 568,000 cm−2. When √St→ 0, the collection efficiency will approach the curve considering ideal filtration due to diffusion mechanisms.

INTRODUCTION

Using the dry porous metal substrate as the collection surface of an inertial impactor has the advantage that high concentration liquid particles can be sampled without an overloading problem because of its capillary action. However, the particle collection efficiency for the impactor with a porous metal substrate is higher than that with a flat plate substrate (Tsai et al. 2001). This is due to some air penetration into the dry porous metal substrate resulting in a different particle collection efficiency curve (Huang et al. 2001) than that predicted by the traditional theory (Marple 1970; Marple and Liu 1974; Marple and Willeke 1976; Rader and Marple 1985).

Rao and Whitby (1978) found this phenomenon for the im-pactor with filter substrates. Their experimental results indicated

Received 3 July 2001; accepted 28 August 2001.

The authors would like to thank the Taiwan National Science Coun-cil of the Republic of China for the financial support of this project under contract NSC 90-2211-E-009-004.

Address correspondence to Dr. Cheng-Hsiung Huang, Institute of Environmental Engineering, National Chiao Tung University, No. 75 Poai Street, Hsin Chu, Taiwan, China. E-mail: cjtsai@cc.nctu.edu.tw

that the performance of impactors was significantly affected by the nature of the collection surface. Using the glass fiber filter as an impact collection surface reduced particle bounce, but altered the shape of the efficiency curve. At low Stokes numbers, the particle collection efficiency of the glass fiber filter was much higher than that of the oil-coated glass plate. One of the probabil-ities for the increase in the collection efficiency was attributed to the aerosol jet penetration into the filter surface (Rao and Whitby 1978). Turner and Hering (1987) indicated the glass fiber mats used in the impactor reduced bounce-off, but also collected a significant number of particles smaller than the critical particle size. This excess particle collection was due to the interception of particles on streamlines penetrating into the fiber mat.

In the previous study (Huang et al. 2001), the collection ef-ficiency of the impactor with the dry porous metal substrates was obtained by assuming 100% filtration efficiency. That is, particles carried by the penetrating air into the dry porous sub-strate are assumed to be collected. The results showed that the excess particle collection efficiency increases with a decreasing resistance factor of the porous metal substrate, K, an increasing Reynolds number, which is based on the nozzle diameter, Re

(Re= (ρU0W )/µ, where U0is the air velocity at the nozzle,ρ

is the air density, andµ is the air viscosity), and a decreasing nozzle diameter, W, when√St → 0 (St, Stokes number, St = (ρpCd2pU0)/9µW, where C is the Cunningham slip correction

factor,ρpis the particle density, and dpis the particle diameter). The dimensionless parameter

φ = ρU0 2Kµt µ Dc W ¶0.9 ,

where t is the thickness of the porous metal substrate and Dc is the diameter of the porous metal substrate had been intro-duced to determine the excess particle collection efficiency by the porous metal substrate, and the theory predicted the numer-ical results very well. However, there is an additional filtration effect of penetrating aerosol particles by the porous metal sub-strate that was not included in the previous study. It is believed 486

MECHANISM OF PARTICLE IMPACTION AND FILTRATION 487 that if the filtration effect was considered, the particle collection

efficiency of the impactor with dry porous metal substrate will be decreased.

To investigate the mechanism of particle impaction near the surface of the porous metal substrate and the effect of the particle filtration on the collection efficiency curves of the porous metal substrate, flow field and particle trajectories were simulated. The filtration efficiency of particles inside the porous substrate was calculated at different effective collector diameters, resistance factors of the porous metal substrate, and Reynolds numbers, which are based on the nozzle diameter, to obtain a complete particle collection efficiency curve covering a wide range of particle diameters.

METHOD

The particle collection efficiencies of the inertial impactors were simulated using the numerical models described in Huang et al. (2001). The flow field in the inertial impactor was simulated by solving the two-dimensional (2D) Navier–Stokes equations in the cylindrical coordinate. The fluid flow in the impactor was assumed steady, incompressible, and laminar, and air was as-sumed to be at 20◦C and 1 atm. The governing equation was dis-cretized by means of the finite volume method and solved by the SIMPLE algorithm (Patankar 1980). Grid independence checks were performed using different grid spacings. These checks re-vealed that approximately 40,000 grids were necessary to obtain a grid-independent solution. After obtaining the flow field, the particle equations of the motion were solved numerically to ob-tain particle trajectories and collection efficiency. If the particle concentration and velocity profiles are assumed to be uniform at the entrance of the nozzle, then the ideal collection efficiency (assuming 100% filtration efficiency) can be calculated as

ηideal = µ rc (W/2) ¶2 , [1]

where rc is the critical radius within which particles will be collected.

For calculating the filtration efficiency by the porous metal substrate, an analytical formula is required. The overall collec-tion efficiency, ET, of the porous metal substrate can be ex-pressed as in Otani et al. (1989):

ET = 1 − exp µ − 3αLηS 2(1− α)Df ¶ , [2]

whereηsstands for the collection efficiency of a single-collector,

α is the solid volume fraction (α = 0.433 for porous metal

sub-strate; Poon et al. (1994), Df is the effective collector diameter, and L is the particle traveling distance inside the porous metal substrate. The single-collector efficiency may be expressed by

ηS = ηD+ ηG+ ηR+ ηI, [3]

whereηD,ηG,ηR, andηIrepresent the collection efficiencies by diffusion, gravity, interception, and impaction, respectively. The

collection efficiency of a single collector may be estimated as in Otani et al. (1989). Since the porous substrate has a granular-like structure, the predictive equations of Otani et al., which are applicable in this structure for a wide range of filtration conditions, were used to calculate the collection efficiency of individual filtration mechanism.

ηD= AScBReCf, [4] B= −23+ Re 3 f 6(Re3 f+2.0×105), A= 8.0, C = −2/3, for Ref < 30, A= 40.0, C = −1.15, for 30 ≤ Ref < 100, A= 2.1, C = −1/2, for Ref ≥ 100, [5] ηG= G 1+ G, [6] ηR = 16R2−Ref ±¡ Re1f/3+ 1¢3, [7] ηI = Stk3 f eff 1.4 × 10−2+ Stk3 f eff , [8]

where the parameters Sc, G, R, and Stkeffare defined as

Sc= Pe Ref , [9] G= Cd 2 p(ρp− ρ)g 18µu0 , [10] R= dp Df , [11] Stf eff= Stf µ 1.0 +1.75 (1 − α) Ref 150α ¶ [12]

where Pe, Ref, and Stf are the Peclet, Reynolds, and Stokes numbers, respectively, and are defined as

Pe= u0Df D , [13] Ref = ρu0Df µ , [14] Stf = ρpd2pCu0 9µDf , [15]

where D is the diffusion coefficient, u0 is the average air

ve-locity inside porous metal substrate, C is the Cunningham slip correction factor, andρpis the particle density.

The effective collector diameter, Df, may be calculated by

Df =

s

16α(1 + 2ξ)

εK Kh

, [16]

whereε, ξ, and Kh are the inhomogeneity factor (ε = 1.57 for the porous metal substrate; Poon et al. (1994)), slip coefficient, and hydrodynamic factor defined by

ξ = 0.998 µ 2λ Df ¶ , [17] Kh = −0.25α2+ α − 0.5 ln α − 0.75 + ξ(0.5α2− ln α − 0.5), [18]

whereλ is the air mean free path.

The particle collection efficiency of the impactor with porous metal substrate can be calculated as

η = ηideal× ET ave, [19]

where ET aveis the average of the filtration efficiency of a particle that is collected by the porous substrate. ET aveis calculated as

ET ave= rc X i=1 Qi× ET mi Qc , [20]

where Qi denotes the flow rate represented by the ith radial position at the inlet of the nozzle; ET miis the filtration efficiency

Figure 1. Particle trajectories inside the porous metal substrate at Df= 126 µm and Re = 3,000 at the radial position of the nozzle corresponding to 15% of the total flow.

of a particle entering at the ith radial position; and Qcis the flow rate corresponding to the critical radius.

RESULTS AND DISCUSSION Particle Trajectories

Figure 1 illustrates the particle trajectories inside the porous metal substrate at different√St when Df = 126 µm and Re = 3,000 for the radial position at the nozzle inlet corresponding to 15% of the total flow. The figure only shows half of the im-pactor and the particles start at the radial position of the nozzle corresponding to 15% of the total flow. rcis the critical radius across the nozzle which demarcates the starting radial position for a particle to be collected by the substrate or not. If a particle starts at a radial position smaller than rc, then the particle will be collected. Dc is the diameter of the porous substrate while Df is the effective collector diameter of the porous substrate. The diameter of the porous substrate is about 200 times the effective collector diameter. At a low Stokes number, √St ≤ 0.05, the particle trajectories are close to the air streamlines. For particles with a greater Stokes number, e.g.,√St ≈ 0.16, the particle tra-jectories deviate from the corresponding streamlines due to the higher particle inertial force. The larger the Stokes number is,

MECHANISM OF PARTICLE IMPACTION AND FILTRATION 489 the larger the distance that the particle trajectory deviates. The

particles will be collected inside the porous metal substrate by the inertial impaction, diffusion, interception, and gravitational settling mechanisms.

Particle Impaction Near the Substrate Surface

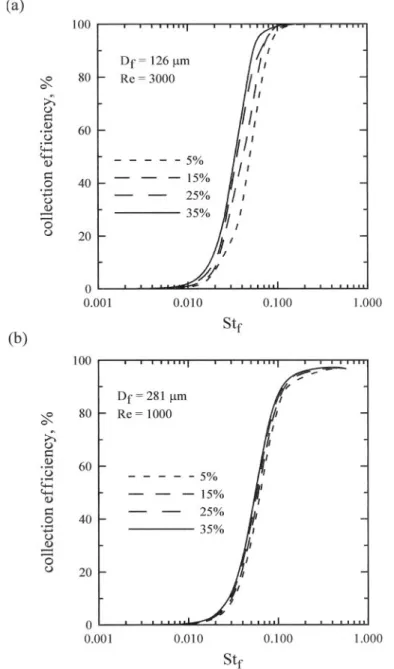

Once the penetrating air enters the porous metal substrate at a high velocity, the controlling collection mechanism is inertial impaction for large particles. Figure 2 shows the particle collec-tion efficiency as a funccollec-tion of Stokes number, Stf, at different radial positions corresponding to 5, 15, 25, and 35% of the total flow assuming the penetrating depth of 0.1 cm. It is seen that

Figure 2. Particle impaction efficiency at different radial positions of the nozzle corresponding to 5, 15, 25, and 35% of the total flow. (a) Df = 126 µm, (b) Df = 281 µm.

impaction occurs near the surface with 100% efficiency for parti-cles with a Stokes numbers>0.1, as shown in Figure 2a. When the effective collector diameter is increased and the Reynolds number is decreased, the efficiency decreases to 82∼ 87% for

Stf = 0.1, as shown in Figure 2b.

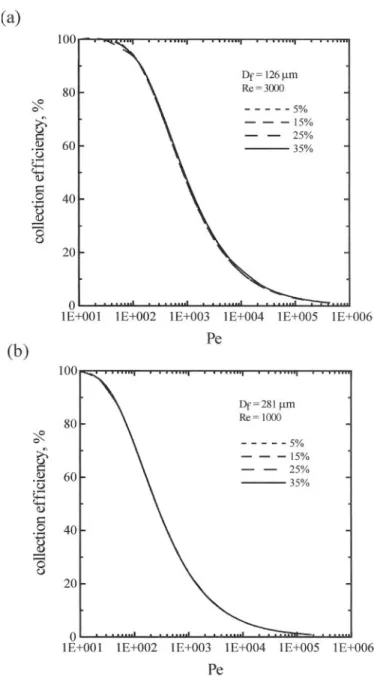

Particle Diffusion inside the Substrate

The penetrating air has the lowest velocity when it is about to exit the porous metal substrate when Brownian diffusion is the dominant mechanism for fine particles. Figure 3 shows the particle collection efficiency as a function of Peclet number, Pe, at different radial positions corresponding to 5, 15, 25, and 35%

Figure 3. Particle diffusion efficiency at different radial positions of the nozzle corresponding to 5, 15, 25, and 35% of the total flow. (a) Df= 126 µm, (b) Df= 281 µm.

of the total flow for the thickness of 0.1 cm near the air outlet from the porous metal substrate. It is seen that the particle collection efficiency is 100% due to the diffusion mechanism when Pe is >40, as shown in Figure 3a. When the effective collector diameter is increased and the Reynolds number is decreased, the efficiency decreases to 90% for Pe= 40, as shown in Figure 3b.

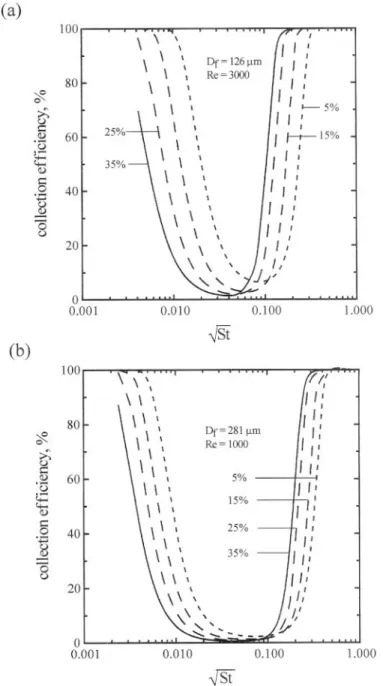

Filtration Efficiency Curve of the Porous Metal Substrate

Figure 4 shows the filtration efficiency of the impactor with porous metal substrate including inertial impaction, diffusion, interception, and gravitational settling mechanisms at different radial positions corresponding to 5, 15, 25, and 35% of the total

flow based on the average air velocity and the particle traveling distance inside the porous metal substrate. It is seen that there is a substantial shift of filtration efficiency curves to the left for the case of a larger initial radial position (corresponding to higher flow rate) compared to the smaller radial position, as shown in Figure 4a. When the effective collector diameter is increased and the Reynolds number is decreased, the filtration curves have a similar trend, as shown in Figure 4b.

Figure 5 shows the average filtration efficiency, ET ave, of the impactor with porous metal substrate for different particle sizes at Re= 3,000 and K = 568,000 cm−2. There is a minimum filtration efficiency of about 5% at the particle size of 0.1µm

MECHANISM OF PARTICLE IMPACTION AND FILTRATION 491

Figure 4. Filtration efficiency of the impactor with the porous metal substrate at different radial positions corresponding to 5, 15, 25, and 35% of the total flow. (a) Df= 126 µm, (b) Df = 281 µm.

(corresponding to √St = 0.05) in the curve. When the parti-cle size is smaller, the filtration efficiency increases due to the diffusion mechanism. Beyond the particle size of minimum effi-ciency, the filtration efficiency increases with increasing particle size due to the interception and impaction mechanism. When the particle is as large as 1µm, the collection efficiency increases to 97%.

Collection Efficiency Curves at Different Re andK

Figure 6 shows the particle collection efficiency curves of the impactor with porous metal substrate for the different Reynolds

numbers at the resistance factor of 568,000 cm−2. Considering the surface impaction and ideal filtration mechanism only, dotted lines show that there is a large shift of the collection efficiency curve of the impactor with the porous metal substrate to the left of the flat-plate impactor. This is because the penetrating air causes a higher inertial force for particles near the surface of the porous metal substrate than that of the flat plate. However, as the penetrating air carries the particles into the porous metal substrate, the filtration effect of the porous metal substrate must be considered when calculating the overall particle collection efficiency. Solid lines show that the collection efficiency curves, although less sharp than those of the flat plate substrate, have left

Figure 5. Average filtration efficiency of the impactor with the porous metal substrate for different particle sizes at Re= 3,000 and K= 568,000 cm−2.

tail ends that are close to zero collection efficiency. These collec-tion efficiency curves resemble those that appeared in Kavouras and Koutrakis (2001) and hence are more realistic.

For Re= 3,000, it is seen that for larger particles with

√

St= 0.24 (corresponding to dp= 0.8 µm), the particle

col-lection efficiency is close to the case of ideal filtration because of the inertial impaction and interception mechanisms by the porous metal substrate. There is a minimum value of about 2% at

√

St= 0.05 (corresponding to dp= 0.1 µm), which corresponds

to the most difficult particle size to collect during the impaction

Figure 6. Particle collection efficiency curve of the impactor with the porous metal substrate for different Re at K=

568,000 cm−2.

Figure 7. Particle collection efficiency curve of the impactor with the porous metal substrate for different K at Re= 1,500.

process. For ultrafine particles with√St= 0.013 (corresponding to dp= 0.01 µm), the collection efficiency increases to 15%. In the case of Re= 500, the minimum efficiency is about 0.3% at

√

St= 0.06 (corresponding to dp= 0.5 µm) and for an ultrafine

particle with√St= 0.0127 (corresponding to dp= 0.05 µm), the collection efficiency increases to 2%. For both cases, when

Re= 500 and 3,000 the collection efficiency will approach the

ideal filtration curve due to the diffusion mechanism in the limit of√St→ 0.

Figure 7 shows the influence of K on the particle collection efficiency for the impactor with the porous metal substrates at

Re= 1,500. It is seen that the collection efficiency curve will

be sharper than that assuming 100% filtration efficiency (dotted lines) and there is a minimum value of about 1% at√St= 0.07

MECHANISM OF PARTICLE IMPACTION AND FILTRATION 493 (corresponding to dp= 0.3 µm) when K = 500,000 cm−2. When

the resistance factor of the porous metal substrate is increased to 107cm−2, the collection efficiency curve becomes close to that

of the ideal filtration assumption. In this case, the excess particle collection by the porous metal substrate can be neglected. Also, in the limit of√St→ 0, the collection efficiency will approach the ideal filtration curve due to the diffusion mechanism when the asymptotic theory developed by Huang et al. (2001) can be used to predict the excess particle collection efficiency by the porous metal substrate.

CONCLUSIONS

As the penetrating air carries particles into the dry porous metal substrate of the inertial impactor, the effect of particle filtration by the dry porous metal substrate on the particle col-lection efficiency must be considered. This study shows that the particle trajectories inside the dry porous metal substrate are different for different particles’ Stokes numbers. The collection efficiency curves of inertial impactor with porous metal substrate considering filtration effect are less sharp than those of the flat plate substrate, and the curves are still S-shaped when the low tail ends approach a zero collection efficiency.

For larger particles, the penetrating air causes a higher col-lection efficiency near the porous metal substrate surface due to the inertial impaction mechanism. There is a minimum value of about 0.3∼ 2% at the particle diameter of 0.1 ∼ 0.5 µm when

Re= 500 ∼ 3,000 and K = 5 × 105 ∼ 107cm−2. In the case of

Re= 3,000 and K = 568,000 cm−2, the collection efficiency

in-creases to 15% for ultrafine particles with a diameter of 0.01µm. For different Re and K, the collection efficiency will approach the ideal filtration curve (assuming 100% filtration efficiency) due to the diffusion mechanism in the limit of√St→ 0.

Although dry porous substrates have the advantage that solid particle bounce can be minimized, caution should be observed

when designing a cascade inertial impactor with porous sub-strates because ultrafine particles will be collected on the upper stages, resulting in a bias to particle size distribution mea-surement. Thus the collection efficiency of ultrafine particles must be measured when designing this kind of inertial impactor.

REFERENCES

Huang, C. H., Tsai, C. J., and Shih, T. S. (2001). Particle Collection Efficiency of an Inertial Impactor with Porous Metal Substrates, J. Aerosol Sci. 32:1035– 1044.

Kavouras, I. G., and Koutrakis, P. (2001). Use of Polyurethane Foam as the Impaction Substrate/Collection Medium in Conventional Inertial Impactors,

Aerosol Sci. Technol. 34:46–56.

Marple, V. A. (1970). A Fundamental Study of Inertial Impactors, Ph.D. thesis, Mechanical Engineering Department, University of Minnesota, Minneapolis, MN.

Marple, V. A., and Liu, B. Y. H. (1974). Characteristics of Laminar Jet Impactors,

Environ. Sci. Technol. 8:648–654.

Marple, V. A., and Willeke, K. (1976). Impactor Design, Atmos. Environ. 10:891–896.

Otani, Y., Kanaoka, C., and Emi, H. (1989). Experimental Study of Aerosol Filtration by the Granular Bed over a Wide Range of Reynolds Numbers,

Aerosol Sci. Technol. 10:463–474.

Patankar, S. V. (1980). Numerical Heat Transfer and Fluid Flow., Hemisphere, Washington, DC.

Poon, S. W., Pui, D.Y. H., Lee, C. T., and Liu, B. Y. H. (1994). A Compact Porous-Metal Denuder for Atmospheric Sampling of Inorganic Aerosols,

J. Aerosol Sci. 25:923–934.

Rader, D. J., and Marple, V. A. (1985). Effect of Ultra-Stokesian Drag and Particle Interception on Impaction Characteristics, Aerosol Sci. Technol. 4:141–156.

Rao, A. K., and Whitby, K. T. (1978). Non-Ideal Collection Characteristics of Inertial Impactors—I: Single-Stage Impactors and Solid Particles, J. Aerosol

Sci. 9:77–86.

Tsai, C. J., Huang, C. H., Wang, S. H., and Shih, T. S. (2001). Design and Testing of a Personal Porous-Metal Denuder, Aerosol Sci. Technol. 35:611– 616.

Turner, J. R., and Hering, S. V. (1987). Greased and Oiled Substrates as Bounce-Free Impaction Surfaces, J. Aerosol Sci. 18:215–224.