MATERIALS

CHEM~ST#‘YsND

ELSEVIER Materials Chemistry and Physics 40 (1995) 168-172The effects of Nd203 additives

and A1203-Si02-Ti02

sintering

aids on the electrical

resistivity of (Ba,Sr)Ti03

PTCR ceramics

Chun-Hung

Lai a, Chen-Tsang

Weng b, Tseung-Yuen

Tseng b,*

‘Deparhent of Electronics Engineering, Lien-Ho College of Technology and Commerce, Miao-Li, Taiwan, ROC b Department of Electronics Engineering and Institute of Electronics, National Chiao-Tung Universiy, Hsinchu, Taiwan, ROC

Received 28 January 1994; accepted 28 December 1994

Abstract

The influences of Nd donors and A1203-Si02-Ti02 (AST) sintering aids on the electrical properties of (Ba,Sr)TiO, materials have been investigated. The room-temperature resistivity and the temperature coefficient of the anomalous resistivity rise were used to characterize the performance of the samples. From derivations based on the Heywang-Jonker barrier model, both characterizing parameters are expected to increase as a result of higher acceptor-state density at the grain boundary. The surface acceptor density, whose value was extracted from the slope in the Arrhenius plot of resistivity versus l/(T+,,), where E, is the measured permittivity and T the absolute temperature, was found to decrease with the Nd content and increase with the AST dopant. A satisfactory interpretation of the observed variations in resistivity-temperature curves caused by additions of various dopants was thus obtained in the light of the resultant acceptor state density.

Keywords: Positive temperature coefficient of resistance; Acceptor-state density; Grain boundaries; Pennittivity; Barriers

1. Introduction

Doped BaTiO, ceramic semiconductors exhibit the property of positive temperature coefficient of resistance (PTCR) [l]. The transition temperature, which is near the ferroelectric Curie point T,, shifts to lower tem- perature upon substitution of S?+ for Ba’+. Those PTC resistors with different ‘switching’ temperatures can find applications in current limiters and thermal controllers [2,3]. In view of these potentials, various fabrication techniques have been attempted to inves- tigate the PTCR behavior and to improve the specimen performance. However, most of the reports are restricted to pure BaTiO, ceramics with a 120 “C Curie point

M-61.

The PTCR phenomenon is found only for ceramic materials. The presence of grain boundaries, in which the surface states reside and act ,as the trap centers for charge carriers, is therefore believed to be re- sponsible for the PTCR effect. A widely accepted model that elucidates the conduction mechanism of the PTCR phenomenon has been proposed by Heywang and Jonker [4-6]. Heywang ascribed the anomalous rise in resistivity for T> T, to the formation of a Schottky barrier, whose

* Corresponding author.

0254-0584/95/$09.50 0 1995 Elsevier Science S.A. All rights reserved SSDI 0254-0584(95)01473-8

height increases owing to the decreasing permittivity (Curie-Weiss behavior). Jonker then modified this model by considering the nonvanishing spontaneous polarization to explain the simultaneous low resistivity and low permittivity at T < T,. In view of this anomalous resistivity jump, observed only in semiconducting ce- ramics, and being strongly influenced by the acceptor states in the scheme of the Heywang-Jonker barrier theory, it can be inferred that the donor concentration in the grain as well as the acceptor densities at the grain boundary play a dominant role in the PTCR performance; i.e., the ‘resultant’ numbers of charge carriers and trap centers determine the resistiv- &y-temperature curves significantly. Both parameters are complicated functions of the firing conditions, say, sintering temperature, soaking duration, cooling rate and ambient atmosphere, etc. [7,8]. The influence of nonstoichiometric formulations and various additives, such as different kinds and amounts of donors, the addition of 3d elements and the sintering aids, has also received attention [9-111. Interpretations from the point of view of defect chemistry and microstructure are often offered to explain the effect of various pre- paring conditions [ 10,111.

In this study, we prepare a series of (Ba,.,Sr,,)TiO, PTCR samples with varying added Nd contents and discuss the donors’ effect in terms of their compensating

ability for the acceptor density. Excess Al,O,-SiO,-TiO, (AST), an effective liquid phase sintering aid, is also introduced with a view to providing higher reprodu- cibility and a lower soaking temperature. The role of AST dopants as a beneficial factor for increasing the acceptor states is emphasized. The PTCR performance, determined mainly by the properties of the semicon- ducting grains and insulating grain boundaries, is then interpreted as a consequence of the interaction of donor and AST additives. The resultant acceptor-state density is calculated and treated as the key parameter for the explanation of the effect of various additives.

2. Experimental

PTCR specimens containing different donor con- centrations varying between 0.16 and 0.28 at.%

Nd were prepared with the formulation

(Ba,,_,Sr,,,Nd,)TiO, + y mol% AST. In the current study, y was selected to be 5, 7, 10 and 12. The excess AST powder serves as a liquid-phase former and was prepared by mixing Al,O,-SiO,-TiO, in the mole ratio 4:9:3 [12,13], which was calcined at 1000 “C for 1 h. Commercially available BaCO,, SrCO,, Nd,O, and TiO, were used as the starting materials. The mixture with the above-mentioned composition was mixed thoroughly in a plastic jar and mechanically ball-milled for 24 h in deionized water with plastic-coated iron ball media. The milled slurry was then dried by an IR lamp and calcined at 1100 “C for 2 h.

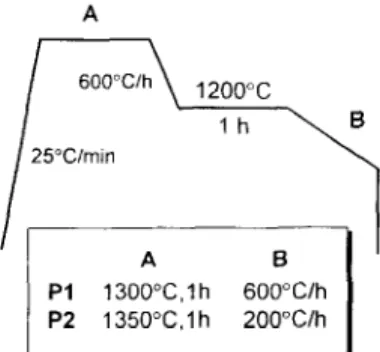

After being pulverized, sieved through a 140 mesh screen and pressed into a disk shape, the pellets were stacked in an Al,O, crucible and then sintered in air. With the temperatures at which liquid phases occur for the BaO-TiO, and BaTiO,-SiO, systems taken into consideration (1312 and 1260 “C, respectively [14,15]), it was decided to sinter the samples at 1300 or 1350 “C. Also, in light of the temperature below which the vacancy compensation dominates over the electron com- pensation [16], the soaking treatment was selected to be at 1200 “C for 1 h. The sintering profiles used are depicted in Fig. 1, in which Pl and P2 stand for different sintering conditions,

Resistivity-temperature (p-T) characteristics were measured using a Hewlett-Packard HP4140B instrument (PA meter/d.c. voltage source) from 30 to 300 “C in air using a two-probe method. An In-Ga (60:40) alloy was rubbed on both surfaces to provide ohmic contacts for testing. The resistivity is obtained from the calculated value of the resistance multiplied by a geometrical factor A/t, where A is the area of the disk and t the thickness.

The grain size is determined by the linear intercept method via scanning electron micrographs (SEMs) of

Fig. 1. The sintering profile used for the preparation of the PTCR specimens. Pl and P2 have different A and B values, as shown in the figure. AST=12 mol% by Pl Nd content 0 016% v 0 28 % ,I.~~~l~~~.‘~~~~l~‘.~l.~~‘~~~~~~~~~.J 0 50 100 150 200 250 300 350 Temperature (“C)

Fig. 2. PTCR characteristics as a function of the Nd concentration. The Pl profile is adopted and the AST amount is fixed at 12 mol%.

polished surfaces, and the dielectric constant is mea- sured at 10 kHz.

3. Results and discussion

Fig. 2 shows the resistivity-temperature (p-2) char- acteristics as a function of Nd content, while the amount of excess AST dopant is kept at 12 mol% and profile Pl is adopted. Obviously, a gradual transition in the PTCR performances can be observed; i.e., the room- temperature resistivity p,, and the steepness of the rising part of the PTCR curve decrease with the Nd con- centration. Also, the PTC jump, defined as log(p,,,/ pmin), becomes smaller when more Nd is added.

The temperature coefficient of resistivity, TCR, is calculated to measure the steepness of the rising part of the p-T plots, given as

TCR = W&k) T,- T,

170 C.H. Lai et al. I Materials Chemistry and Physics 40 (1995) 168-172 where ps=2pmin, pP= (pspmax)1’2, and T, and T, are the

temperatures corresponding to pP and ps. The calculated TCR values together with p. are listed in Table 1, in which the grain size d is obtained from the typical microstructure shown in Fig. 3 (for 0.16 at.% Nd).

According to Jonker’s conclusions [8] derived from the barrier theory, a higher acceptor-state density N, will lead to a larger pmax and a lowering of the tem- perature at which pmax occurs, i.e., a larger TCR. A procedure to extract N, is then developed to confirm this statement quantitatively [17,18]. The height of the potential barrier is given by

4(T) = eN,2/8e, cm (1)

where T is the absolute temperature in K, e the electronic charge, +, the permittivity of free space, e, the relative permittivity of the BaTiO, material within the grain boundary layer, n the charge-carrier concentration in the bulk, and N, the concentration of the occupied acceptor states. From the dielectric theory, as derived by Wernicke 1191, the measured dielectric constant E, is substituted for E, using the following relationship:

E, = E,(dD) (2)

with b=N& the barrier width and d the grain size. Thus, the barrier height 4 in Eq. (1) can be expressed in the form

region, say, within Tmi, and T,,,,,, as usually assumed by previous workers [21]. A typical permittivity char- acteristic is shown in the inset of Fig. 4 (for 0.16 at.% Nd). As seen from Fig. 4, the data points lie approx- imately on a straight line, which implies the validity of Eq. (4). The constant A and the slope thus obtained are listed in Table 1.

We depict the dependence of TCR and N, on Nd content in Fig. 5, from which one can infer that the decreasing TCR caused by larger Nd content is ascribed to the resulting smaller N,. This suggests the dual function of donor dopants: supporting the charge carrier in the grain and compensating for the acceptor at the grain boundary. This statement applies only to a certain range of donor contents, of course. Since the acceptor- state density N, reflects the barrier height at the grain boundary, and therefore the grain boundary resistance, it is reasonable to explain the influence of Nd on the observed bulk resistivity p. in Fig. 2 via the reduction of N,. This agrees with the results of previous works, which show that even at temperatures well below the Curie point the grain boundaries are the primary con- tributor to the electrical resistance [22,23].

4(T) = edN&,e, (3)

Finally, by emphasizing the point that the PTCR effect is a grain boundary phenomenon and approximating the resistivity in terms of Eq. (3) for the Cp expression, we have

P= p. exp(WW = p.

exp[We/(~mT)l

(4)

where p. is assumed to be constant [20] andA is defined as

The inset in Fig. 6 shows a schematic representation of the complex impedance plot for PTCR materials, in which the separation of the contributions from the grains and/or the grain boundaries is possible [24]. Grain boundary resistance is primarily the dominant one, and the comment near the real-axis intercept demonstrates this point. This is why the former inference of effect of Nd on p. concerns the grain boundary property and relates to the acceptor-state density N,. A series of specimens containing various AST contents, with a view to adjusting the N,, was then prepared using the P2 profile to examine the speculated similar dependence of p. and TCR on N,. The results are shown in Figs. 6 and 7.

A = e2d/8eok (5)

which is a grain-size-dependent constant. From Eq. (4), an Arrhenius plot of In p versus (e,,,T)-l is expected to exhibit a linear relationship with a constant N, value, and the acceptor-state density N, can be determined from the slope provided that the constant A is known and N, equals N, in a certain selected temperature

The function of AST additions as the electron traps which induce Schottky barriers accounts for the in- creasing p. and TCR. This rule of more AST leading to more N, is evidently valid for 5-12 mol% AST and for all Nd contents between 0.16 and 0.28 at.%. More- over, both p. and TCR decrease with Nd for certain AST amounts, as expected from the results in Fig. 3. It should be noted that the AST amount required to Table 1

Room-temperature resistivity and grain size for the samples shown in Fig. 2” Nd content (at.%) PO (a cm) TCR (%/“C) d km) Constant A (lOeh cm* K) Slope (10’ K) N, (IO’” cm-‘) 0.16 307.45 8.9 12.3 3.23 74.29 23 0.20 115.64 6.6 11.2 2.94 35.28 12 0.24 87.28 6.1 8.5 2.23 19.4 8.7 0.28 47.86 3.9 7.5 1.97 12.4 6.3

Fig. 3. Typical scanning electron micrograph of samples in the present study, for 0.16 at.% Nd.

2~ _-.I_/--

00 0.5 1.0 1.5 2.0

1 07/(T&,J [K]

A

2.5

Fig. 4. Typical plots of log P~.~. vs. (~,,,7-)-’ for 0.16 at.% Nd. The inset shows the dielectric constant measured at 10 kHz.

AST=12 mol%

8-

01 1 / , I I / I I I I I . 15

015 020 0.25 0.30

Nd Content (at.%)

Fig. 5. TCR and calculated acceptor-state densities Ns vs. Nd contenl for the samples shown in Fig. 2.

180 / I 150 - 720 - g 0 .; goL > .s .Y 60 - 30 - -/m(Z) 024% 0-A I ’ 3 6 9 12 15

AST Content (mol%)

Fig. 6. Dependence of the room-temperature resistivity po on the amount of excess AST for several Nd contents (in at.%). The P2 profile is used. The inset is the typical complex impedance plot for PTCR ceramics, in which the fact that the grain boundary resistance dominates over pu is stressed.

9- 8- 6- 5- 4- 0.16 % 0.20 % 0 24 % 0.28 % 31 ’ L ’ ’ L ’ s b ’ a B 3 6 9 12 15

AST Content (mol%)

Fig. 7. Effect of AST content on the TCR. The Nd content is indicated (in at.%).

make a difference in N,, and therefore the resulting p0 and TCR, is higher than the corresponding Nd amount, i.e., the increment in Nd amount is 0.04 at.%, while there must be up to 2 mol% in the case of AST. This phenomenon probably relates to the issue of partial incorporation of Nd into the grain and the role of AST as a liquid-phase former existing at the grain boundary. It needs further research and is beyond the scope of the current study.

It is therefore concluded that, for those PTCR ce- ramics doped with AST sintering aids, the overall p-T behavior depends on the interaction of donors (Nd) and acceptors (AST). Although the TCR and PTC jumps seem to increase with decreasing Nd amount, one should note that the room-temperature resistivity

172 C.H. Lai et al. I Materials Chemistry and Physics 40 (1995) 168-172

increases simultaneously. In view of the applications as a switch or current limiter for PTCR ceramics, there often exists a compromise between p0 and TCR in pursuit of a ‘better’ p-T characteristic.

4. Conclusions

Investigation on the variation of the room-temper- ature resistivity and TCR with Nd and AST additives reveals that the electrical properties of the PTCR materials (Ba,.,Sr,,)TiO, are determined mainly by the grain boundary nature, which can be characterized by a useful parameter: the acceptor-state density N,. Both p0 and TCR increase with N,. In summary, the addition of Nd donors not only makes ceramics semiconductive, but also exerts an influence on the reduction of the acceptor-state density N,, which in turn affects the TCR value (Figs. 2 and 5). The experimental data (Figs. 6 and 7) show that AST additions act not only as the liquid-phase formers to enhance the sintering but also as useful contributors to the electron traps at the grain boundary.

Acknowledgement

This work was supported in part by the National Science Council of the Republic of China under Project No. NSC 81-0404-E009-103. References 111 121 [31 [41 t51 [61 [71 PI PI PO1 WI w 1131 P41 t151 WI P71 WI P91 PO1 PI P21 v31 i241

A.L. MicheIi, Am. Ceram. Sot. Buff., 56 (1977) 783.

E. Awdrich, PhiZips Tech. Rev., 30 (1969) 170.

0. Saubri and K. Wakino, IEEE Trans. Component Parts, CP- 10 (1963) 53.

W. Heywang, Solid-State Electron., 3 (1961) 51. W. Heywang, J. Am. Ceram. Sot., 47 (1964) 484. G.H. Jonker, Solid-State Electron., 7 (1964) 895.

T.Y. Tien and W.G. Carlson, J. Am. Ceram. Sot., 46 (1963) 297.

G.H. Jonker, Mater. Rex Bull., 2 (1967) 401.

H. Kamioka and K. Umetani, Jpn. Patent No. 487455 (27 Dec. 1966).

T.Y. Tseng and Y.Y. Lu, J. Mater. Sci. Lett., 7 (1988) 182. H.F. Cheng, J. Appl. Phys., 66 (1989) 1382.

Y. Matsuo, M. Fujimura, H. Sasaki, K. Nagase and S. Hayakawa, Am. Ceram. Sot. Bull., 47 (1968) 292.

W.Y. Hong and C. McCutcheon, Ceram. Bull., 62 (1983) 231. H.M. O’Bryan and J. Thompson, J. Am. Ceram. Sot., 57 (1974) 522.

D.E. Rase and R. Roy, J. Am. Ceram. Sot., 38 (1955) 389. J. Daniels, Philips Res. Rep., 31 (1976) 487.

C.H. Lai and T.Y. Tseng, L Am. Ceram. Sot., 76 (1993) 781. C.H. Lai, Y.Y. Lu and T.Y. Tseng, J. Appl. Phys., 74 (1993) 3383.

R. Wernicke, in L. Levinson (ed.), Grain Boundary Phenomena in Electronic Ceramics, American Ceramics Society, Columbus, OH, 1981, p. 272.

D.Y. Wang and K. Umeya,I. Am. Ceram. Sot., 73 (1990) 1574. J. Illingsworth, H.M. Al-Ahak, A.W. Brinkman and J. Woods, J. Appl. Phys., 67 (1990) 2088.

H. Rehme, Phys. Status Solidi, 26 (1968) Kl.

H. Ihrig and M. Kierk, Appl. Phys. Left., 35 (1979) 307. R.N. Basu and H.S. Maiti, Trans. Indian Ceram. Sot., 45 (1986) 140.