Polylactic Acid Bone Scaffolds Made by Heat Treatment

Jia-Horng Lin

1,2,b, Hsiu-Ying Chung

3,c, Kun-Da Wu

1, Shih-Peng Wen

1,

Chao-Tsang Lu

4and Ching-Wen Lou

5,a1Laboratory of Fiber Application and Manufacturing, Department of Fiber and Composite Materials,

Feng Chia University, Taichung City 407, Taiwan, R.O.C.

2School of Chinese Medicine, China Medical University, Taichung 40402, Taiwan, R.O.C. 3Department of Materials Science and Engineering, Feng Chia University, Taichung City 407,

Taiwan, R.O.C.

4Institute of Life Sciences, Central Taiwan University of Science and Technology, Taichung 406,

Taiwan, R.O.C.

5Institute of Biomedical Engineering and Material Science, Central Taiwan University of Science

and Technology, Taichung 406, Taiwan, R.O.C.

acwlou@ctust.edu.tw, bjhlin@fcu.edu.tw, chychung@fcu.edu.tw

Keywords: polylactic acid (PLA), heat treatment, bone scaffold, porosity, surface observation

Abstract. Polylactic acid (PLA) has a widespread application, such as bone scaffolds, in biomedical

field. This study creates PLA bone scaffolds, which has a structural stability, by using 150 denier (D) PLA plied yarn. 75 D PLA filaments are combined and then twisted into plied yarn. During the twisting process, the twists per inch (TPI) are varied. The resulting plied yarn undergoes heat treatment, and then is evaluated with mechanical property tests, determining an optimal TPI of 9. The plied yarn is then braided into PLA bone scaffolds. PLA bone scaffolds, thermally treated or not, are observed by a stereomicroscope and tested for porosity and tensile strength. According to test results, the optimal TPI is 9, which results from the optimal tensile strength. However, the variation in elongation of various 150 D plied yarn is not significant. When observed by a stereomicroscope, PLA bone scaffolds, which are thermally treated, have a compact filament arrangement. This is due to thermal bonding between filaments; in addition, the heat treatment duration is short, so the PLA filaments are not melted completely, resulting in a stable, hollow structure. According to porosity and tensile strength test, PLA bone scaffolds that are thermally treated exhibit a lower porosity and tensile strength due to the compact arrangement and tender phenomenon of the filaments. As a result, the optimal PLA bone scaffolds are made of 150 D plied

with a TPI of 9, followed by a heat treatment at 165 ℃ for ten minutes.

Introduction

Bone tissue engineering is composed of materials engineering and life sciences, inclusive of artificial structure. Implanting bone scaffolds in vivo, for example, is one way to help bone regeneration. Stainless steel, once used for artificial bone scaffolds, may lead to demineralization, resulting in a transplant failure [1-4]. Therefore, polymers appear to be suitable materials used in bone scaffolds. Being a type of poly(α-hydroxyesters), PLA is a biodegradable polymer, and commonly used in surgeries, such as devices for bone fracture internal fixation [5]. From 2007 to 2012, Lin et al. have utilized biomaterial, fiber, knitted and braid in bone scaffold products [8-12]. This study combines and then twists PLA filaments into plied yarn, after which the yarn is multilayer-braided into PLA bone scaffold on a 16-spindle braiding machine. This gives a three-dimensional, porous structure to the resulting bone scaffolds. Finally, the multilayer bone scaffolds

a b

are thermally treated to avoid delamination, and their structures are further reinforced. Relevant tests are subsequently performed to evaluate the bone scaffolds.

Experimental Material

75 denier (D) PLA filaments (Unitika Ltd., Japan) have a maximum tensile strength of 3.9 g/D and elongation of 30 %.

Preparation of PLA Plied Yarn

75D PLA filaments are combined into 150D PLA filaments and then twisted into 150D PLA plied yarn. During the twisting process, TPI is varied as 7, 8, 9, 10, and 11. The plied yarn then

undergoes heat treatment at 100 ℃ for one hour to prevent untwisting. The equation of TPI is given

below. TPI=R/T×D×π (1). where TPI is the twists per inch, R is the rotation speed of the rotor (rpm), T is the rotation speed of the take-up roller (rpm), and D is the diameter of take-up roller [6].

Preparation of PLA Bone Scaffolds

Thermally-treated 150D PLA plied yarn is collected by a carrier, which is then mounted on the 16-spindle braiding machine (Nan Hsing Machinery & Co., Ltd.) for the multilayer-braid process. During the multilayer-braid process, a stainless steel rod with a diameter of 5 mm is placed in the center, allowing plied yarn to be braided around it. The 15-layer PLA braids, i.e., bone scaffolds, are then thermally treated at 165 ℃ for 10 minutes, after which the metallic rod is removed and the resulting multilayer bone scaffolds are cropped.

Tests

Mechanical Property Test of PLA Plied Yarn

As specified in ASTM D2256, an automatic tensile tester for yarn (FPA M Nr.29163, Textechno H. Stein GmbH & Co. KG, Germany) is employed to evaluate the tensile strength and elongation of the yarn. The distance between clamps is 250 mm, the tensile speed is 300 mm/min, and the full load is 100 N. Twenty samples of each specification are tested.

Superficial Observation of PLA Bone Scaffolds

The PLA bone scaffolds are trimmed to 1 cm long, and a stereomicroscope (SMZ-10A, Nikon Instruments Inc., Japan) is used to observe the lateral and cross-section of the bone scaffolds.

Porosity Test of PLA Bone Scaffolds

The PLA bone scaffolds are trimmed to 1 cm long, and their porosity is counted according to

the following equation [7]. ρs={1-[(ms/(π×(R2-d2)×l)] / ρi}×100 %. where ρs is the real porosity of

the samples, ms is the sample weight, R is outer diameter of the samples, d is the internal diameter

of the samples, l is the sample length, and ρi is the material’s porosity (1.24g/cm3).

Tensile Strength of the PLA Bone Scaffolds

A universal testing instrument (HT-9109, Hung Ta Instrument Co., Ltd., ROC) is used to test the scaffolds as specified in ASTM STP893.

Results and Discussion

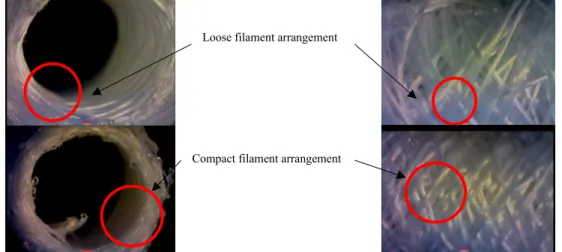

Loose filament arrangement

Compact filament arrangement

Figure 1 The (a) tensile strength (b) elongation of 150D PLA plied yarn as related to TPI. Figure 1(a) illustrates the tensile strength of the PLA plied yarn. The optimal tensile strength of plied yarn occurs when TPI is 9 or 11. However, the standard deviation of tensile strength has a wider range at a TPI of 11, determining the optimal TPI of 9. Figure 1(b) illustrates that elongation of the PLA plied yarn is similar, regardless of TPI. As being non-elastic, PLA filaments have a low elongation and tend to break easily. The elongation of PLA plied yarn is thus within 45-55 %.

Superficial Observation of PLA Bone Scaffolds

Figure 2. The (a)cross-section (b) lateral of PLA bone scaffold without heat treatment (c) Cross-section (d) lateral of PLA bone scaffold thermally treated at 165 ℃ for 10 minutes (scale bar = 1000μm).

According to Figures 2(a) and (b), without heat treatment, the filaments of PLA bone scaffolds are arranged in a disordered manner; on the contrary, after heat treatment, PLA filaments of the bone scaffolds are arranged in a compact manner as shown in Figures 2(c) and (d).This is due to the

heat treatment, 165 ℃ for 10 minutes. The temperature reaches the melting point of PLA filaments

and thus starts melting the filaments. However, heat treatment duration of 10 minutes will allow only parts of the filaments to melt, resulting in thermal bonding between them. Therefore, with the help of heat treatment, PLA bone scaffolds yield a more compact and ordered filament arrangement.

Porosity of PLA Bone Scaffolds

Figure 3 shows that the control group, i.e., PLA bone scaffolds without heat treatment, exhibit the optimal porosity. This is due to the loose filaments’ arrangement which PLA bone scaffolds have, creating more space between PLA filaments. Conversely, after heat treatment, the PLA bone scaffolds display a lower porosity. This occurs because the melting of PLA filaments cause thermal bonding, causing the filaments to be arranged in a more compact manner.

Figure 3. Porosity of PLA bone scaffolds as related to heat treatment. Control group is PLA bone scaffolds not thermally treated.

Tensile Strength of the PLA Bone Scaffolds

PLA bone scaffolds that thermally treated have a stable structure. However, the temperature of the treatment reaches the melting point of the PLA filaments and causes tender of them, decreasing the friction between the filaments and thus decreasing the tensile strength.

Figure 4. Tensile strength of the PLA bone scaffolds with and without heat treatment.

Conclusion

The optimal TPI of 9 results from the optimal tensile strength of 150D PLA plied yarn. However, the variation in elongation of the plied yarn with various TPI is not significant, and the yielded elongation falls between 45-55%. The observation by a stereomicroscope indicates that heat treatment influences PLA bone scaffolds by creating thermal bonding and generating a more compact filament arrangement. In addition, a heat treatment duration of 10 minutes keeps PLA filaments from being completely melted, creating a stable, hollow structure. Finally, the porosity and tensile strength of the PLA bone scaffolds that are thermally treated decrease by 9 % and 36 %, respectively.

Acknowledgements

This work would especially like to thank National Science Council of the Republic of China, Taiwan, for financially supporting this research under Contract NSC 100-2622-E-166-001-cc3.

References

[1] C.C. Huang, C.W. Lou, C T. Lu, S.H. Huang, C.Y. Chao and J.H. Lin: Advanced Materials Research Vol. 123-125 (2010), p. 975-978.

[2] C.C. Huang, C.T. Lu, C.Y. Chao, T.C. Huang, C.W. Lou and J.H. Lin: Advanced Materials Research Vol. 97-101 (2010), p. 2249-2252.

[3] M.C. Lu, Y.T. Huang, J.H. Lin, C.H. Yao, C.W. Lou, C.C. Tsai and Y. S. Chen: J Mater Sci-Mater M Vol. 20 (2009), p. 1175-1180.

[4] C.W. Lou, J.J. Hu, Y.S. Chen, S.P. Wen, K.C. Lin and J.H. Lin: Advanced Materials Research Vols. 287-290(2011), p. 2669-2672.

[5] Middleton JC, Tipton AJ: Biomaterial Vol. 21(2000, p.2335–46.

[6] J. H. Lin, I. S. Tsai, and W. H. Hsing: J Text I Vol.89 (1988), p.266-273.

[7] S. Chung, N.P. Ingle, G.A. Montero, S.H. Kim and M.W. King: Acta Biomater Vol. 6 (2010) , p. 1958–1967.

[8] C.W. Lou, Y.S. Chen, C.W. Lin, C.L. Huang, W.C. Chen and J.H. Lin: Applied Mechanics and Materials Vol. 184-185(2012), p. 1371-1374.

[9] C.W. Lou, M.H. Li, W.C. Chen, J.J. Hu, C.T. Lu and J.H. Lin, : Applied Mechanics and Materials Vol. 184-185(2012), p.1501-1504.

[10] C.W. Lou, C.H. Yao, Y.S. Chen, C.T. Lu, W.C. Chen, K.C.Yen and J.H. Lin: Accept to Journal of Biomaterials Science-Polymer Edition(2011).

[11] J.H. Lin, C.T. Lu, C.H. He. C.C. Huang and C.W. Lou: J Compos Mater Vol. 45(2011), p. 1945-1951.

[12] J.H. Lin, C.W. Lou, C.H. Chang, Y.S. Chen, G.T. Lin and C.H. Lee: J Mater Process Tech Vol.192-193(2007), p. 97-100.