Effect of Cyclic Flange Local Buckling on the Capacity of Steel Members 1

Tung-Yu Wua,*; Sherif El-Tawilb; and Jason McCormickb 2

a Department of Civil Engineering, National Taiwan University, Taipei, 10617, Taiwan 3

b Department of Civil and Environmental Engineering, University of Michigan, Ann Arbor, MI 4 48109, United States 5 6 ABSTRACT 7

Cyclic flange local buckling typically occurs when plastic hinges form in the beams and columns 8

of special moment resisting frames subject to seismic excitation. While local buckling in beam 9

plastic hinges has been investigated in the past for monotonic loading situations, the effect of cyclic 10

flange local buckling on beam and column behaviors is not yet well understood. In order to address 11

this shortcoming, nineteen half-scale T-section specimens are tested under cyclic axial loads in a 12

configuration intended to replicate the cyclic demands imposed on flanges of beams and columns 13

in their plastic hinge region. The main experimental variables are flange slenderness ratio, level of 14

web restraint, and loading scheme (monotonic versus cyclic). Validated computational studies are 15

performed to expand the parameter space. The test data and computational results show that T-16

section members that meet the current highly ductile limit can suffer excessive axial strength 17

degradation under cyclic axial loading. The effect of slenderness ratios on column compression 18

capacity due to strength degradation of flanges is evaluated and quantified. 19

Keywords: cyclic response; local instability; steel structures; capacity; seismic loading 20

* Corresponding author at: Department of Civil Engineering, National Taiwan University, Taipei, 10617,

1. Introduction 21

Local buckling can cause significant strength and stiffness degradation in steel member response 22

during an earthquake. Maximum values for the slenderness ratios of unstiffened and stiffened 23

elements of wide flange sections (i.e. b/2tf for flanges and h/tw for webs, where bf and h are flange 24

width and web height, respectively, and tf and tw are flange and web thicknesses, respectively) are 25

specified in the AISC specifications [1]. When ductility is important, e.g. in earthquake 26

applications, the maximum slenderness ratios are specified in the AISC seismic provisions [2] for 27

members classified as highly ductile or moderately ductile. The current slenderness limits are 28

derived from early analytical and experimental research on beams under monotonic loading [3-6]. 29

30

Information on the effect of cyclic loading on the slenderness limits is rather rare in the literature 31

and is typically inferred from member level response. Richards and Uang [7] studied the effect of 32

flange slenderness ratio on the cyclic rotation capacity of links using finite element models. Their 33

results suggested that the existing limiting slenderness ratios for link flanges could be relaxed. 34

Newell and Uang [8] conducted cyclic tests of W14 columns subjected to axial forces combined 35

with large drift loading. The stocky webs of W14 columns were found to stabilize the flange and 36

contribute to the observed large deformation capacity of the studied sections. Cheng et al. [9] tested 37

nine H-shaped beam-columns with large slenderness ratios and concluded that the effect of 38

flange/web slenderness ratios and axial force ratios should be considered mutually because of their 39

strong dependence upon each other. The computational study performed by Elkady and Lignos 40

[10] indicated that current limiting ratios for highly ductile members are not adequate for columns 41

subjected to a constant axial load of 0.2Py or more, where Py is the axial yield strength of the cross 42

section. Fogarty and El-Tawil [11], Fogarty et al. [12] and Wu et al. [13] reached similar 43

conclusions and proposed revised highly ductile limits for deep columns. 44

45

The intent of this paper is to address the paucity of experimental data on the effect of flange local 46

buckling (FLB) and develop a deeper understanding of the effect of the FLB slenderness on the 47

cyclic response of steel wide flange sections. To this end, nineteen half-scale T-section specimens 48

are subjected to monotonic axial compression and cyclic axial loading. The test configuration and 49

axial loading protocols are carefully chosen and developed to replicate the seismic demands 50

imposed on beam flanges and column flanges in their plastic hinge regions. The specimens cover 51

a wide range of flange slenderness ratios and allow for the study of the effect of web restraint on 52

flange local buckling behavior. A computational study is performed to further investigate the effect 53

of local slenderness ratios on the cyclic behavior of column flanges. The peak strength and strength 54

degradation rates observed from the test and simulations are compared and used to evaluate current 55

seismic provisions for local instability of steel members. 56

57

2. Finite Element Model Development and Validation 58

The finite element models employed in this work are created and analyzed using the commercial 59

software, Hypermesh [14] and LS-DYNA [15], respectively. The models are discretized using 4-60

node fully integrated shell elements (ELFORM 16) based on the formulation published by 61

Engelmann et al. [16] with a mesh size of 25.4 mm, which is also employed in Fogarty and El-62

Tawil [11]. The mesh density is kept constant in all models to avoid mesh size dependency. A 63

combined isotropic/kinematic hardening material model (MAT_153) developed by Huang and 64

Mahin [17] is assigned to the shell elements. The hardening moduli and model parameters are 65

calibrated to the true stress-true strain model proposed by Arasaratnam et al. [18] using nominal 66

properties of A992 steel. Initial imperfections in the T-section members used herein are obtained 67

by applying the first buckling mode as a geometric perturbation. Calibration studies showed that 68

the results match the test data best when the maximum amplitude of the applied perturbation 69

geometry is the plate width divided by 500. For example, for a flange with a width of 152.4 mm, 70

the magnitude of its imperfection is 0.305 mm. The modeling approach has been extensively 71

validated in previous work by the authors, e.g. in Fogarty and El-Tawil [11], Fogarty et al. [12] 72

and Wu et al. [19]. Additional validation studies using the experimental data obtained in this work 73

are discussed later on in the paper. 74

75

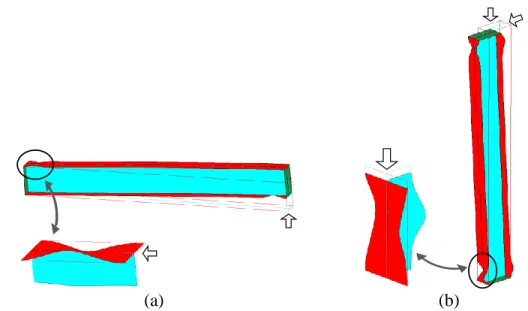

3. Rationale for T-Section Test Specimens 76

Under seismic loading, structural members of a special moment frame (SMF), such as beams and 77

columns, are subjected to either cyclic bending moment or combined cyclic axial force and 78

bending moment in their plastic hinge regions. The premise of this paper is that the seismic 79

demands on flanges in the plastic hinge region can be approximated as cyclic axial deformation 80

demands for wide flange beams and columns, as shown in Fig. 1. Therefore, rather than testing a 81

complete structural component or subassemblage, a short T-section column with fixed ends can 82

be tested under cyclic axial loading instead. This assumption substantially simplifies the study of 83

inelastic cyclic FLB because a hydraulic axial load frame can be used instead of a more 84

comprehensive and complicated setup needed to test a structural member or sub-assembly under 85

cyclic loading. 86

87

(a) (b) 88

Fig. 1. Flange deformed shape in plastic hinge region of (a) wide flange beams under cyclic 89

bending moment and (b) wide flange columns under combined cyclic axial force and bending 90

moment. 91

92

To ensure that the proposed T-section members realistically represent their full section 93

counterparts, the web portion of the T must be adequately long to impose the same level of flange 94

restraint achieved in the original section. Detailed finite element studies of W24 sections are 95

conducted to determine a reasonable web length. The axial deformation history of the flange in the 96

plastic hinge region, whose length is the same as the section depth as usually assumed [20], is 97

extracted and applied to its counterpart T-section member. The responses of the T-section member 98

and the corresponding portion in the full member are compared in terms of overall deformed shape 99

and the force versus deformation history. The studies suggest that a web length equal to one third 100

of the full section depth results in a meaningful representation of the overall section’s behavior. 101

102

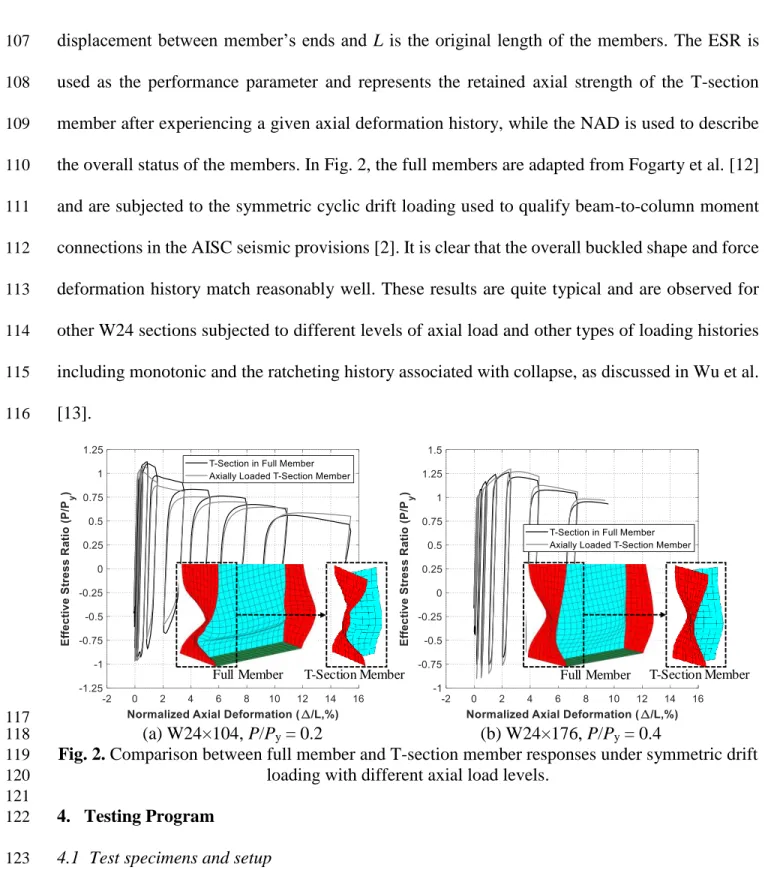

Fig. 2 shows comparisons between the full and T-section member responses for two different W24 103

sections under different levels of axial loading. Here, the effective stress ratio (ESR) is defined as 104

the axial strength normalized by the yield strength of the cross-section, i.e. P/Py, and the 105

normalized axial deformation (NAD) is calculated by Δ/L, where Δ is the relative axial 106

displacement between member’s ends and L is the original length of the members. The ESR is 107

used as the performance parameter and represents the retained axial strength of the T-section 108

member after experiencing a given axial deformation history, while the NAD is used to describe 109

the overall status of the members. In Fig. 2, the full members are adapted from Fogarty et al. [12] 110

and are subjected to the symmetric cyclic drift loading used to qualify beam-to-column moment 111

connections in the AISC seismic provisions [2]. It is clear that the overall buckled shape and force 112

deformation history match reasonably well. These results are quite typical and are observed for 113

other W24 sections subjected to different levels of axial load and other types of loading histories 114

including monotonic and the ratcheting history associated with collapse, as discussed in Wu et al. 115

[13]. 116

117

(a) W24×104, P/Py = 0.2 (b) W24×176, P/Py = 0.4 118

Fig. 2. Comparison between full member and T-section member responses under symmetric drift 119

loading with different axial load levels. 120

121

4. Testing Program 122

4.1 Test specimens and setup 123

Nineteen half-scale T-section specimens with a depth of 305 mm were selected to represent the 124

behavior of a W24 section, which is commonly used for beams and columns in the current design 125

T-Section Member

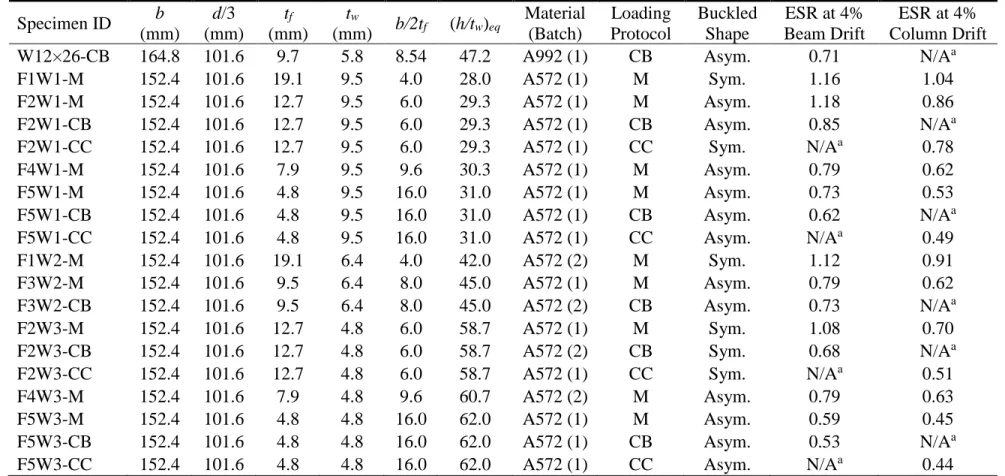

Table 1. Test matrix. 126 Specimen ID b (mm) d/3 (mm) tf (mm) tw (mm) b/2tf (h/tw)eq Material (Batch) Loading Protocol Buckled Shape ESR at 4% Beam Drift ESR at 4% Column Drift

W12×26-CB 164.8 101.6 9.7 5.8 8.54 47.2 A992 (1) CB Asym. 0.71 N/Aa

F1W1-M 152.4 101.6 19.1 9.5 4.0 28.0 A572 (1) M Sym. 1.16 1.04

F2W1-M 152.4 101.6 12.7 9.5 6.0 29.3 A572 (1) M Asym. 1.18 0.86

F2W1-CB 152.4 101.6 12.7 9.5 6.0 29.3 A572 (1) CB Asym. 0.85 N/Aa

F2W1-CC 152.4 101.6 12.7 9.5 6.0 29.3 A572 (1) CC Sym. N/Aa 0.78

F4W1-M 152.4 101.6 7.9 9.5 9.6 30.3 A572 (1) M Asym. 0.79 0.62

F5W1-M 152.4 101.6 4.8 9.5 16.0 31.0 A572 (1) M Asym. 0.73 0.53

F5W1-CB 152.4 101.6 4.8 9.5 16.0 31.0 A572 (1) CB Asym. 0.62 N/Aa

F5W1-CC 152.4 101.6 4.8 9.5 16.0 31.0 A572 (1) CC Asym. N/Aa 0.49

F1W2-M 152.4 101.6 19.1 6.4 4.0 42.0 A572 (2) M Sym. 1.12 0.91

F3W2-M 152.4 101.6 9.5 6.4 8.0 45.0 A572 (1) M Asym. 0.79 0.62

F3W2-CB 152.4 101.6 9.5 6.4 8.0 45.0 A572 (2) CB Asym. 0.73 N/Aa

F2W3-M 152.4 101.6 12.7 4.8 6.0 58.7 A572 (1) M Sym. 1.08 0.70

F2W3-CB 152.4 101.6 12.7 4.8 6.0 58.7 A572 (2) CB Sym. 0.68 N/Aa

F2W3-CC 152.4 101.6 12.7 4.8 6.0 58.7 A572 (1) CC Sym. N/Aa 0.51

F4W3-M 152.4 101.6 7.9 4.8 9.6 60.7 A572 (2) M Asym. 0.79 0.63

F5W3-M 152.4 101.6 4.8 4.8 16.0 62.0 A572 (1) M Asym. 0.59 0.45

F5W3-CB 152.4 101.6 4.8 4.8 16.0 62.0 A572 (1) CB Asym. 0.53 N/Aa

F5W3-CC 152.4 101.6 4.8 4.8 16.0 62.0 A572 (1) CC Asym. N/Aa 0.44

aNot available because the loading protocol is intended to approximate the seismic demands on flanges in beams (columns). 127

128 129

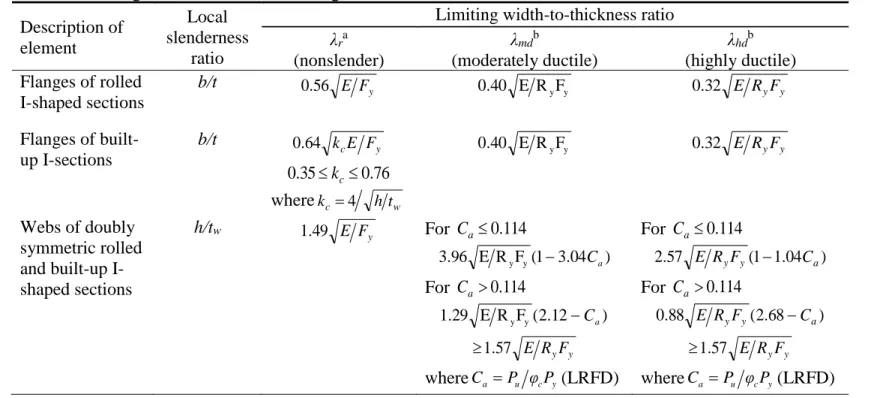

Table 2. Limiting slenderness ratios for flanges and webs. 130 Description of element Local slenderness ratio

Limiting width-to-thickness ratio λra (nonslender) λmdb (moderately ductile) λhdb (highly ductile) Flanges of rolled I-shaped sections b/t y F E 56 . 0 0.40 E RyFy 0.32 E RyFy Flanges of built-up I-sections b/t y cE F k 64 . 0 76 . 0 35 . 0 kc wherekc =4 h tw y yF R E 40 . 0 0.32 E RyFy Webs of doubly symmetric rolled and built-up I-shaped sections h/tw y F E 49 . 1 For Ca 0.114 ) 04 . 3 1 ( F R E 96 . 3 y y − Ca For Ca 0.114 ) 12 . 2 ( F R E 29 . 1 y y −Ca y yF R E 57 . 1 whereC =a Pu φcPy(LRFD) For Ca 0.114 ) 04 . 1 1 ( 57 . 2 E RyFy − Ca For Ca 0.114 ) 68 . 2 ( 88 . 0 E RyFy −Ca y yF R E 57 . 1 whereC =a Pu φcPy(LRFD) aAISC [1] 131 bAISC [2] 132

of special moment frames. The experimental parameters are flange and equivalent web slenderness 133

ratios, i.e. b/2tf and (h/tw)eq. The parameter (h/tw)eq is the web slenderness ratio of the full W24 134

section, where the depth is three times that of the T-section member. Changing (h/tw)eq changes 135

the amount of web restraint applied to the flanges. To achieve control over the slenderness ratios, 136

built-up sections were preferred over cutting T-sections from an existing W-sections. The effect 137

of residual stress due to the welding between the web and flange is considered insignificant as the 138

specimens undergo large plastic deformations. To confirm that the test results from built-up T-139

section specimens are transferable to WT-section members, a WT-section specimen cut from a W-140

section member with similar slenderness ratios to one of the built-up T-section specimens is also 141

studied. 142

143

Five flange thicknesses and three web thicknesses are selected to cover a range of local slenderness 144

ratios. The employed built-up T-section specimens are listed in Table 1, where F1 and W1 145

represent the thickest flange and web used in the test, respectively, and F5 and W3 represent the 146

thinnest ones. The local slenderness ratios of the specimens are shown in Fig. 3 along with the 147

code-specified limiting ratios for highly ductile (λhd), moderately ductile (λmd), and non-slender 148

(λr) elements, as listed in Table 2. According to AISC [1][2], highly/moderately ductile members 149

are “intended to withstand significant plastic rotation of 0.04/0.02 rad or more” during the design 150

earthquake, and non-slender sections are “cross sections possessing plate components where local 151

buckling in the elastic range will not occur”. Note that only non-slender limits for built-up sections 152

consider the effect of web slenderness ratio on flange capacity by using the kc factor, where kc is 153

the buckling coefficient for unstiffened elements and is calculated as 4 √ℎ 𝑡⁄ ⁄ 𝑤. 154

The built-up T-section and WT-section specimens were made of ASTM A572 Gr. 50 steel and 156

A992 steel, respectively. The steel was ordered in two batches, and two coupons were taken from 157

each plate in each batch and tested in accordance with ASTM E8 [21]. Table 3 summarizes the 158

average material properties of the two coupons from each batch of material. 159

160

Fig. 3. Local slenderness ratios of specimens along with code-specified limiting ratios for highly 161

ductile (λhd), moderately ductile (λmd), and non-slender (λr) elements. WT: WT sections. BU: 162

built-up section 163

164

Table 3. Results of Tensile Coupon Tests. 165 Material t (mm) Batch 1 Batch 2 Fy (MPa) Fu (MPa) Elongation (%) Fy (MPa) Fu (MPa) Elongation (%) A992 9.65 357 470 39.8 381 481 49.9 5.84 360 475 35.6 400 487 42.0 A572 19.1 357 506 36.2 380 540 - 12.7 380 460 40.5 407 464 36.9 9.53 414 469 41.7 401 465 54.9 7.94 440 484 31.3 471 537 42.3 6.35 425 470 27.6 365 448 48.3 4.76 408 513 29.2 368 496 36.9 166

The specimens are tested using the setup shown in Fig. 4. The web plate is welded to the flange 167

plate using a 2-sided fillet weld to form the built-up specimens. The specimens are then welded to 168

fixture plates that are bolted to the fixed loading heads of a 2.22 MN uniaxial hydraulic load frame. 169

Axial loading is applied in displacement control. The applied axial load is directly measured by a 170

load cell, while the axial displacement is measured by an optical tracking system with the markers 171

located at the center and four edges of the fixture plates. The five measured relative axial 172

displacements were averaged to obtain only the deformation in the specimen. 173

174

Fig. 4. Test setup. 175

176

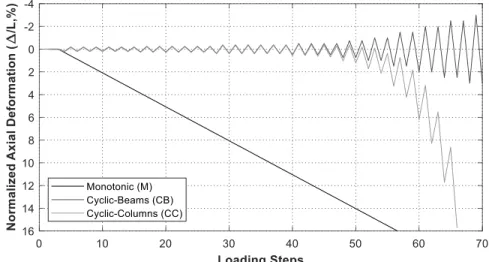

4.2 Loading schemes 177

Three different loading protocols are employed in the experiment: (1) monotonic axial 178

compression (designated M); (2) cyclic axial loading that is intended to approximate the seismic 179

demands on flanges in beams (designated CB); and (3) cyclic axial loading intended to 180

approximate the seismic demands on flanges in columns (designated CC). The monotonic loading 181

scheme is used to obtain the buckling and post-buckling capacity of the cross-section without 182

cyclic degradation. The cyclic loading schemes reflect the axial demands on beams and columns 183

under the symmetric cyclic drift loading specified in the AISC seismic provisions [2]. 184

It is assumed that the overall strain distribution across the cross-section of a beam is linear about 186

the neutral axis and that the neutral axis location does not fluctuate with cyclic loading. For a 187

plastic hinge rotation, θ, the flange is subjected to an axial deformation Δ=dθ/2 in the plastic hinge 188

region, where d is the section depth. Assuming that the plastic hinge length is d [20], then the 189

flange is subjected to a NAD = Δ/L = dθ/2d= θ/2 in the plastic hinge region. As a result, the NAD 190

protocol applied to the T-section member, i.e. the CB protocol, is half the beam rotation specified 191

in the beam-column connection qualification protocol. For example, NAD = 2% when a beam 192

achieves 4% plastic rotation, a limit commonly associated with highly ductile response. The 193

resulting CB protocol is shown in Fig. 5. 194

195

The existence of axial force in columns increases the severity of web local buckling in column 196

members and causes the columns to shorten under cyclic loading. To take this into account, the 197

CC protocol is developed using finite element simulations of deep column specimens 1L 198

(W24×176), 2L (W24×131), and 3L (W24×104) tested in Ozkula et al. [22] and subjected to 199

symmetric cyclic drift loading. The three columns specimens are subjected to a constant axial load 200

of 0.18Py. The computed axial demand histories are averaged and smoothed to get the CC loading 201

protocol shown in Fig. 5. The NAD corresponding to a column drift of 4% in the selected CC 202

protocol is 8.3%. Although this protocol is specific to certain column sizes (similar to those 203

considered in this research) and may not be applicable to other columns, it reflects the flange 204

behavior commonly seen in experimental column tests. 205

The loading rate for monotonic loading (M protocol) is 1.52 mm/min. Faster rates of 3.05 mm/min 207

for small deformations and 12.2 mm/min for 4% NAD or larger are used for the cyclic loading 208

tests (the CB and CC protocols) to reduce test duration to a reasonable time. 209

210

Fig. 5. Employed loading schemes. 211

5. Experimental Results 212

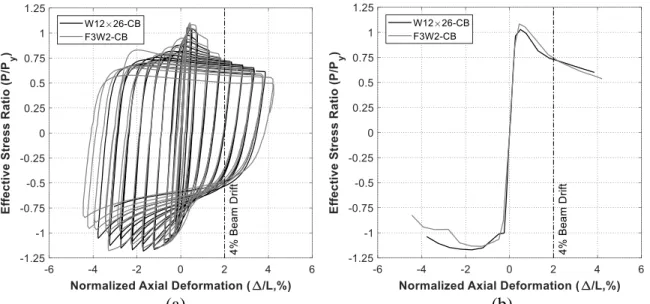

5.1 Comparison between WT-Section and T-Section Specimens 213

Fig. 6 shows a comparison between the hysteresis responses and backbone curves of a WT-section 214

(W12×26) and a T-section (F3W2) specimen with similar slenderness ratios subjected to the CB 215

loading protocol. Except for the sudden drop in the backbone curve under tension due to a lapse 216

of applying axial displacement, Fig. 6 clearly shows that both specimens yield generally similar 217

responses in terms of peak load, post-buckling strength, post-peak degradation rate and hysteresis 218

under cyclic loading. This comparison provides confidence in the use of built-up sections in this 219

study and suggests that the findings also can be applied to W-sections. 220

221

(a) (b) 222

Fig. 6. Comparison of (a) hysteresis responses and (b) backbone curves for Wsection and T-223

section specimens with similar slenderness ratios under the CB protocol 224

225

5.2 FLB Modes 226

The specimens subjected to both monotonic and cyclic loading exhibit two distinct buckled shapes, 227

asymmetric and symmetric FLB, as shown in Fig. 7(a, d) and (b, e), respectively. The buckling 228

mode of each specimen is documented in Table 1. Most of the specimens exhibit asymmetric 229

buckling behavior, where the flange and web interact with each other and experience local 230

buckling simultaneously. The test data indicates that specimens that have comparable flange and 231

web slendernesses are more likely to experience asymmetric buckling. 232

233

A few specimens with a very stocky flange and a slender web, e.g. Specimen F1W2 with b/2tf of 234

4.0 and (h/tw)eq of 42.0, buckle in a symmetric mode, i.e. both half flanges bend together in the 235

direction of the plane of the web, as shown in Fig. 7(b). In this case, the flange itself suffers from 236

weak-axis flexural buckling because the restraint provided by the web is relatively minimal and 237

not able to alter the flange buckling mode. Within the studied range of slenderness ratios, only the 238

specimens with b/2tf ≤ 6 are susceptible to this mode. 239

The asymmetric buckling behavior is commonly seen in plastic hinge zones of deep columns 240

subjected to combined axial and lateral loading [22][23], lending credence to the premise of this 241

paper, i.e. the T-section specimens can replicate certain flange buckling responses and be used to 242

study the flange behavior in plastic hinge regions under large lateral displacements. The symmetric 243

buckling behavior has also been seen in previous tests [24], but with slight flange-web junction 244

displacement and in columns with the extreme combination of a stocky flange and a very stocky 245

web, e.g. W14×176 with b/2tf = 5.97 and h/tw = 13.7. 246 247 248 (a) (b) (c) 249 250 (d) (e) (f) 251

Fig. 7. Asymmetric local buckling in (a) Specimen F4W3-M and (d) Specimen F3W2-M; 252

symmetric local buckling in (b) Specimen F1W2-M and (e) Specimen F2W1-CC; and fracture in 253

(c) Specimen F2W1-CB and (f) Specimen F2W3-CB. 254

Fracture

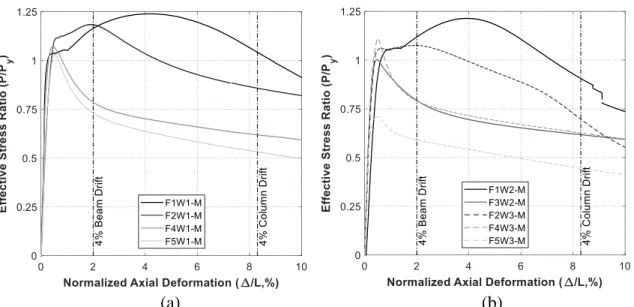

5.3 Response under Monotonic Loading 255

The nine specimens under monotonic loading are compressed to 10% NAD and ESR is computed 256

using the material yield strength obtained from the coupon tests listed in Table 3. The ESR versus 257

NAD curves of the nine T-section specimens are plotted in Fig. 8, where specimens with the same 258

flange thickness are plotted in the same color, while the specimens with the same web thickness 259

are plotted in the same line style. 260

261

By comparing the curves of the specimens with a web thickness of 9.5 mm, i.e. W1 specimens 262

plotted as solid curves, it is clear that the smaller the b/2tf, the higher the buckling and post-263

buckling strength. For example, specimen F1W1-M’s peak strength reaches 1.24Py (b/2tf = 4.0), 264

meanwhile as b/2tf increases, the buckling strength drops to 1.18Py, 1.07Py, and 1.02Py for F2W1-265

M, F4W1-M, and F5W1-M, respectively. All four W1 specimens can reach Py even though F5W1-266

M has a b/2tf = 16.0, which is larger than λr = 13.5. The better than expected performance results 267

from the fixed end condition, which causes a full buckling wavelength that is commonly seen in 268

experiments and simulations [13, 24], unlike the pinned end conditions conservatively assumed in 269

the AISC specification [1]. In terms of post-buckling capacity, λhd works well for identifying the 270

sections with superior ductility. Specimens with a b/2tf lower than λhd = 7.35, i.e. F1W1-M and 271

F2W1-M, maintain a large post-buckling capacity of at least Py until 8.9% and 4.5% NAD, 272

respectively, which are much higher than NAD = 2% that corresponds to 4% beam drift. On the 273

other hand, F4W1-M and F5W1-M that have a b/2tf larger than λhd exhibit rapid strength 274

degradation after reaching the peak values and can only maintain Py up to NADs of 0.8% and 0.7%, 275

respectively. 276

277

(a) (b) 278

Fig. 8. Effective stress ratio-normalized axial deformation curves of specimens under monotonic 279

axial compression: (a) W1 specimens; (b) W2 and W3 specimens 280

281

The effect of equivalent web slenderness ratio, (h/tw)eq, on flange behavior is not significant when 282

b/2tf is smaller than 10 as can be seen from the comparison of specimens F1W1-M, F2W1-M, and 283

F4W1-M to their counterparts with slenderer webs, i.e. F1W2-M, F2W3-M, and F4W3-M. For 284

specimens with slender flanges, e.g. F5W1-M and F5W3-M, the effect of (h/tw)eq is significant 285

because the slender flange negatively interacts with the slender web. As shown in Fig. 8, while 286

Specimen F5W1-M has a peak strength of 1.02Py, F5W3-M reaches an axial capacity of only 0.7Py. 287

Overall, for flanges under monotonic compression, the λr and λhd limits in current seismic 288

provisions seem to be reasonable. 289

290

5.4 Effects of Cyclic Loading 291

The resulting relationship between ESR and NAD of the specimens under the three applied loading 292

protocols are plotted together in Fig. 9. Positive and negative NAD represent compression and 293

tension, respectively, to be consistent with Fig. 8. 294

Although the difference in peak compression strength between specimens under the M and CB 296

protocol is not significant, the degradation rate of post-buckling compression strength of the 297

specimens subjected to CB demands is considerably faster than their monotonic counterparts. For 298

example, as shown in Fig. 9(c), while Specimen F2W1-M maintains an axial capacity of at least 299

Py up to 4.5% NAD, Specimen F2W1-CB can only sustain Py to 1.5% NAD and quickly degrades 300

to 0.85Py at 2% NAD, suggesting that moment capacity of beams satisfying the λhd limits starts to 301

degrade after reaching 3% drift. The effect is even more pronounced for Specimen F2W3-CB. 302

These results suggest that the web restraint has a large impact on the rate of degradation with 303

continued cycling to large NAD levels. The strength degradation rates for specimens with high 304

b/2tf, e.g. specimen F5W1-CB and F5W3-CB, are comparable to their monotonic counterparts 305

before 2% NAD. After reaching 2% NAD, the rate of degradation is much faster. For example, the 306

post-buckling strength of both specimens under the CB protocol is 0.51Py and 0.44Py at 3% NAD, 307

respectively, compared to 0.67Py and 0.57Py, respectively, under monotonic loading. 308

309

Degradation of tensile strength occurs with cyclic loading, but the rate is substantially smaller than 310

that under compression. Tensile degradation generally begins during the 1.5% or 2% NAD cycles. 311

Specimens typically fail when the tensile strength drops to 0.8Py. Failure occurs due to fracture, 312

as marked by red circles in Fig. 9. One key characteristic that slenderness ratios influence is the 313

recovery of the tensile strength after unloading from compression. Specifically, more tensile strain 314

is required to stretch out the buckled shape and recover tensile strength for specimens that have 315

higher b/2tf and (h/tw)eq, i.e. experience more severe local buckling. For example, during the 2% 316

NAD cycle, Specimen F2W1-CB can reach 0.8Py at 0.7% NAD, but Specimen F5W3-CB has to 317

be pulled to -1.3% NAD (tension side) to recover the same level of tensile strength, as shown by 318

the red (thicker) lines in Fig. 9(c) and (b). 319

320

Although specimens under the CB protocol have the same buckled shape as the ones under the M 321

protocol, they eventually failed by ultra-low-cycle fatigue under tension. As shown in Fig. 7(c), 322

for Specimen F2W1-CB, fracture initiates at midpoints along the outer edges of the flange and 323

web, where the highest strain level occurs due to the buckling behavior. Because of the connection 324

between strain level and buckling behavior, fracture occurs earlier for specimens with larger b/2tf 325

and (h/tw)eq due to buckling during earlier cycles. For example, fracture occurs during the 3.5% 326

NAD cycle for Specimen F5W3-CB and is delayed to the 4.5% and 5.5% NAD cycles for 327

Specimens F5W1-CB and F2W1-CB, respectively. One exception is that Specimen F2W3-CB 328

suffers from earlier fracture at the midpoint along the flange-web connection during the 3% NAD 329

cycle due to symmetric buckling behavior, as shown in Fig. 7(f), suggesting that buckling mode 330

also has an influence on fracture behavior. Although ultra-low-cycle fatigue is the eventual failure 331

mode for all specimens, severe strength degradation under compression occurred much earlier and 332

therefore is a design concern. 333

334

The responses of the four specimens under the CC protocol are shown in Fig. 9. The backbone 335

curves of the F5 specimens are almost identical to the responses of their monotonic counterparts. 336

The F2 specimens under the CC protocol, unlike their monotonic counterparts, buckle in a 337

symmetric mode and have a lower backbone curve. From Fig. 9 it can be seen that all specimens 338

under the CC protocol experience much less tensile plastic strain than specimens under the CB 339

protocol, allowing the specimens to deform to greater NADs without succumbing to ductile 340

fracture. Nevertheless, the ESR of the specimens under the CC protocol at the 8.3% NAD that 341

corresponds to 4% column drift is lower than that of the specimens under the CB protocol at the 342

2% NAD that corresponds to 4% beam drift, as can be observed from Fig. 9. For example, the ESR 343

of F2W1-CC at the 8.3% NAD and F2W1-CB at the 2% NAD is 0.78 and 0.85, respectively. These 344

lower ESRs may greatly degrade column capacity and require further investigation. 345 346 347 (a) (b) 348 349 (c) (d) 350

Fig. 9. Comparison of axial force ratio-axial strain curves between different loading schemes for 351

Specimen (a) F5W1; (b) F5W3; (c) F2W1; and (d) F2W3. 352

6. Finite Element Simulations 354

Computational simulation is used to expand the parameter space and gain greater insight into the 355

effects of FLB on member capacity. 356

357

6.1 Validation 358

In addition to the validation effort discussed earlier in the paper, the modeling approach is further 359

validated using the experimental data presented in Section 5. Due to limited space, only a 360

comparison of responses of Specimen F3W2-M and F5W1-CC are shown in Fig. 10. The measured 361

specimen dimensions and material properties obtained from tensile coupon tests in Table 3 are 362

used in the finite element simulation. The peak strength, post-buckling strength, cyclic strength 363

degradation rate obtained from the simulation match well with those measured during the physical 364

testing and provide additional confidence that the employed modeling techniques can generate 365 reasonable behavior. 366 367 (a) (b) 368

Fig. 10. Comparison of responses between experimental and simulation results for Specimen (a) 369

F3W2-M and (b) F5W1-CC. 370

6.2 Section Selection and Performance Parameter 372

To study the effect of slenderness ratio on cyclic capacity of column flanges, finite element models 373

of T-sections with b = 152.4 mm, d/3 = 101.6 mm, and b/2tf and (h/tw)eq ranging from 6 to 16 and 374

24 to 56, respectively, are created using the modeling approach described in Section 2. The values 375

of b and d are the same as the tested specimens, and the range of slenderness ratios is selected to 376

cover most commercial standard W-section sections. The T-section models are axially loaded 377

according to the CC protocol to further study the lower ESRs observed from these specimens. 378

379

In all simulation cases, ESR is used to track cross-section capacity at different column drift levels. 380

As noted earlier, column drift levels are gauged from detailed finite element analysis of entire 381

columns. Fig. 11 shows the results of a T-section where b/2tf = 6 and (h/tw)eq = 32. The ESR is 382

0.94, 0.83, 0.76 and 0.69 at column drift levels of 1%, 2%, 3%, and 4%. 383

384

385

Fig. 11. The effective stress ratio (ESR) corresponding to different column drifts for the T-386

section with b/2tf = 6 and (h/tw)eq = 32 under the CC protocol. 387

6.3 Simulation Results 389

All T-sections buckle in the asymmetric mode with the ESRs plotted in Fig. 12 against b/2tf for 390

column drift levels of 1% through 4% for different values of (h/tw)eq. It is clear that (h/tw)eq has a 391

negative effect on ESR. While the negative effect is significant when the drift level is small, 1%, 392

it diminishes as both (h/tw)eq and drift level decrease in value. The effect also diminishes as the 393

value of b/2tf decreases. The above results further confirm the trend observed from the tests: the 394

effect of (h/tw)eq is significant only on post-buckling strength at small strain levels when the flange 395

is slender. An important observation from Fig. 12(d) is that the ESR curves tend to cluster together 396

at drift levels in excess of 2%, suggesting that it is reasonably accurate to ignore the effect of 397

(h/tw)eq on λhd limits for the flanges. 398

399

Fig. 12 also shows that both b/2tf and drift level adversely affect ESR. For example, for T-sections 400

with (h/tw)eq = 56, the ESR corresponding to 1% drift decreases from 0.92 to 0.61 when b/2tf 401

increases from 6 to 16. ESR drops significantly as the column drift increases to 4%, where its range 402

decreases from 0.92 - 0.61 to 0.70 - 0.50 for b/2tf ranging from 6 to 16. Through a regression 403

analysis, the effect of b/2tf and drift level on ESR can be quantified by the following bilinear 404

equation with b/2tf = 8 as a transition point: 405 𝐸𝑆𝑅 = (0.0575 − 0.422𝐷𝑅) (23.3 − 𝑏 2𝑡𝑓 ) for 6 ≤ 𝑏 2𝑡𝑓 ≤ 8 𝐸𝑆𝑅 = (0.0205 − 0.15𝐷𝑅) (51 − 𝑏 2𝑡𝑓 ) for 8 < 𝑏 2𝑡𝑓 ≤ 16 (1)

where DR is the column drift ratio, e.g. 0.04 rad for the cases in Fig. 12(d). Equation (1) is plotted 406

as the solid black line in Fig. 12 and portrays the negative effect of both b/2tf and drift level on 407

ESR. Another observation is that the degradation of ESR with drift level could be substantial. 408

According to Equation (1), when b/2tf=λhd, ESR drops from 0.78 to 0.65 (17% decrease) as DR 409 increases from 2% to 4%. 410 411 412 (a) (b) 413 414 (c) (d) 415

Fig. 12. Effective stress ratio (ESR) of T-sections at column DR of (a) 1%; (b) 2%; (c) 3% and 416

(d) 4%. 417

418

7. Comparison with Current AISC Seismic Provisions 419

All specimens with b/2tf and (h/tw)eq smaller than λr have a buckling strength larger than Py under 420

all loading schemes. Even when b/2tf exceeds λr, e.g. F5W1 specimens, a peak strength of at least 421

Py is still achieved. While not shown in this paper, the computational study also supports this 422

finding. As a result, the current λr limit is considered adequate for flanges in beams and columns 423

under the monotonic and cyclic loading schemes considered in this work. 424

425

From the experimental results, it is also clear that λhd is reasonable under monotonic loading. This 426

assessment is based on the observed good post-buckling responses exhibited by monotonically 427

loaded specimens with F1 and F2 flanges. The same can be said for specimens subjected to cyclic 428

axial loading for demands under the CB protocol. The degradation in tensile strength is much 429

milder than the post-buckling degradation seen under compression, which combined, will likely 430

allow most available cross-sections to carry at least 80% of their plastic moment capacity up to 431

4% rotation. Therefore, current limits on λhd for flanges appear to provide appropriate highly 432

ductile behavior for beams under cyclic loading. 433

434

Specimen F2W1-CC, which has a b/2tf smaller than the current λhd limit, exhibits an ESR of 0.78Py 435

at a NAD corresponding to 4% column drift. Equation (1) indicates that ESR reaches 0.65 at the 436

highly ductile slenderness limit. The evidence in this paper suggests that, barring other failure 437

modes such as global instability, a W24 column with slenderness characteristics similar to those 438

considered would be able “to withstand significant plastic rotation of 0.04 rad or more” per current 439

design philosophy and still support a substantial axial load. However, the key question of whether 440

the moment or axial capacities have been degraded too much by cyclic FLB is not addressed in 441

current seismic provisions. Unlike beams, where current seismic design provisions require that the 442

moment capacity be at least 80% of the plastic capacity at 4% drift, columns have no such 443

requirement. The research in this paper points out the need for more precise performance 444

requirements for columns. 445

446

8. Conclusions 447

The effect of cyclic FLB on the capacity of structural members in special moment frames was 448

experimentally and computationally investigated in this study. Nineteen half-scale T-section 449

specimens were axially loaded to represent the flange/web subassembly in the plastic hinge region 450

of a wide flange section under combined axial and flexural loading. The specimens were selected 451

to cover a wide range of slenderness ratios and subjected to three different loading schemes. The 452

loading schemes included monotonic compression, meant to obtain the flange capacity without 453

cyclic degradation, and two cyclic axial loading histories, one that reflected the axial demands on 454

beam flanges and another for column flanges under cyclic drift loading. To further study the cyclic 455

behavior of column flanges and justify the observation from the test results, a parametric 456

computational study with different slenderness ratios was performed. The effect of slenderness 457

ratios on column compression capacity due to flange strength degradation was then evaluated. 458

459

The test results showed that most T-section specimens could reach a peak strength of Py regardless 460

of the value of b/2tf, but b/2tf substantially influenced post-buckling behavior. Under monotonic 461

loading, the current value for λhd for a flange was shown to be a boundary between large buckling 462

capacity and rapid degradation after reaching peak strength. The effect of (h/tw)eq, on the other 463

hand, was shown to be secondary and became significant only when both b/2tf and (h/tw)eq were 464

large and negatively interacted with each other. 465

Specimens under the CB loading protocol exhibited much more severe compressive strength 467

degradation than the monotonic protocol. Depending on a specimen’s b/2tf, the compressive 468

strength dropped to as low as 0.53 Py at deformation levels that corresponded to 4% beam rotation. 469

The tensile strength had a much milder degradation rate than the compressive strength. However, 470

the required tensile strain for recovery of tensile strength after unloading from compression 471

depended on the slenderness ratio due to the effort of stretching out the buckled shape. 472

473

The backbone curves of specimens under CC loading were much higher than those for specimens 474

under CB loading and were quite close to the responses under M loading. This result was attributed 475

to the smaller tensile plastic strain demands and led to a milder cyclic degradation rate under 476

compression. Nevertheless, the degradation at higher drift levels could be substantial and could 477

compromise the axial and flexural capacities of the columns. 478

479

The experimental and computational data was used to evaluate the current AISC seismic 480

provisions. It was shown that the current λr limit is adequate for flanges in beams and columns 481

under the monotonic and cyclic loading schemes considered in this work. It was also shown that 482

λhd is reasonable for members under monotonic loading and CB loading, which is representative 483

of the demands seen in beams. The conclusion for λhd and λmd under CC loading, representative of 484

the demands seen in columns, was not definitive because the performance expectations of the 485

AISC seismic provisions are not as explicit as they are for beams. The research outlined in this 486

paper provides useful input to refine current specifications to address this issue. 487

The evaluation in this paper is only valid for the specific wide flange section sizes, loading 489

protocols and range of parameters studied. Although this research points out specific drawbacks 490

in the current AISC seismic provisions, additional research is needed to broaden the results and 491

draw comprehensive conclusions that warrant specification changes. 492

493

Acknowledgements 494

This work was supported by the University of Michigan and US NSF grant number ACI-1638186. 495

Any opinions, findings, conclusions, and recommendations expressed in this paper are those of the 496

authors and do not necessarily reflect the views of the sponsor. 497

498

References 499

[1] ANSI/AISC 360-16 Specification for Structural Steel Buildings. Chicago, IL: American 500

Institute for Steel Construction; 2016. 501

[2] ANSI/AISC 341-16 Seismic Provisions for Structural Steel Buildings. Chicago, IL: American 502

Institute for Steel Construction; 2016. 503

[3] Sawyer HA. Post-Elastic Behavior of Wide-Flange Steel Beams. Journal of the Structural 504

Division ASCE 1961; 87 (ST8): 43–71. 505

[4] Lay MG. Some Studies of Flange Local Buckling in Wide-Flange Shapes. Journal of the 506

Structural Division ASCE 1965; 91(6): 94-116. 507

[5] Bansal JP. The Lateral Instability of Continuous Steel Beams. CESRL Dissertation No. 71-1. 508

Austin, TX: University of Texas; 1971. 509

[6] Kemp AR. Factors Affecting the Rotation Capacity of Plastically Designed Members. Struct 510

Eng 1986; 64B(2): 28-35. 511

[7] Richards PW, Uang C-M. Effect of flange width-thickness ratio on eccentrically braced frames 512

link cyclic rotation capacity. J Struct Eng ASCE 2005; 131(10): 1546–1552. 513

[8] Newell JD, Uang C-M. Cyclic behavior of steel wide-flange columns subjected to large drift.” J 514

Struct Eng ASCE 2008; 134(8):1334-1342. 515

[9] Cheng X, Chen Y, Nethercot DA. Experimental study on H-shaped steel beam-columns with 516

large width-thickness ratios under cyclic bending about weak-axis. Eng Struct 2013; 49: 264-517

274. 518

[10] Elkady A, Lignos DG. Analytical investigation of the cyclic behavior and plastic hinge 519

formation in deep wide-flange steel beam-columns. Bull Earthquake Eng. 2015; 13: 1097-520

1118. 521

[11] Fogarty J, El-Tawil S. Collapse resistance of steel columns under combined axial and lateral 522

loading. J Struct Eng ASCE 2015; 142(1): 04015091. 523

[12] Fogarty J, Wu T.-Y., El-Tawil S. Collapse Response and Design of Deep Steel Columns 524

Subjected to Lateral Displacement. J Struct Eng ASCE 2017; 143(9): 04017130 525

[13] Wu T-Y, El-Tawil S, McCormick J. Highly ductile limits for deep steel columns. J Struct Eng 526

ASCE 2018; 144(4): 04018016. 527

[14] Altair Computing. Hypermesh Version 12.0. Troy, MI: Altair Engineering Inc.; 2013. 528

[15] Hallquist J. LS-DYNA. Livermore, CA: Livermore Software Technology Corp; 2013. 529

[16] Engelmann BE, Whirley RG, Goudreau GL. A simple shell element formulation for large-530

scale elastoplastic analysis. In: Noor AK, Belytschko T, and Simo JC, editors. Analytical and 531

computational models of shells. New York: ASME, New York; 1989. 532

[17] Huang Y, Mahin SA. Simulating the inelastic seismic behavior of steel braced frames 533

including the effects of low-cycle fatigue. Rep. No. PEER 2010/104. Berkeley, CA: Pacific 534

Earthquake Engineering Research Center, Univ. of California at Berkeley; 2010. 535

[18] Arasaratnam P, Sivakumaran KS, Tait MJ. True stress-true strain models for structural steel 536

elements. ISRN Civ Eng 2011. http://dx.doi.org/10.5402/2011/656401 537

[19] Wu T-Y, El-Tawil S, McCormick J. Seismic collapse response of steel moment frames with 538

deep columns. J Struct Eng ASCE 2018; 144(9): 04018145. 539

[20] MacRae GA, Carr AJ, Walpole WR. The seismic response of steel frames. Research Rep. No. 540

90-6. New Zealand: Dept. of Civil Engineering, Univ. of Canterbury; 1990. 541

[21] ASTM E8/E8M-15a Standard test methods for tension testing of metallic materials. West 542

Conshohocken, PA: ASTM; 2015. 543

[22] Ozkula G, Harris J, Uang C-M. Observations from cyclic tests on deep, wide- beam-column 544

columns. AISC Eng. J. 2017; 54(1): 45–61. 545

[23] Elkady A, Lignos DG. Full-Scale Testing of Deep Wide-Flange Steel Columns under 546

Multiaxis Cyclic Loading: Loading Sequence, Boundary Effects, and Lateral Stability Bracing 547

Force Demands. J Struct Eng ASCE 2017; 144(2): 04017189. 548

[24] Ozkula G, Harris J, Uang C-M. Classifying Cyclic Buckling Modes of Steel Wide-Flange 549

Columns under Cyclic Loading. Structures Congress 2017: 155-167. 550