國 立 交 通 大 學

運 輸 科 技 與 管 理 學 系

博 士 論 文

反應規模經濟與需求波動之供應鏈網路設計

Supply Chain Network Design in Response to Scale Economies

and Demand Fluctuations

研 究 生:李慧潔

指導教授:許巧鶯 教授

反應規模經濟與需求波動之供應鏈網路設計

Supply Chain Network Design in Response to Scale Economies

and Demand Fluctuations

研 究 生:李慧潔

Student: Hui-Chieh Li

指導教授:許巧鶯 Advisor:

Dr.

Chaug-Ing

Hsu

國立交通大學

運輸科技與管理學系

博士論文

A DISSERTATION

Submitted to Department of Transportation Technology and Management

College of Management

National Chiao Tung University

in Partial Fullfillment of the Requirements

for the Degree of

DOCTOR OF PHILOSOPHY

in

Transportation Technology and Management

June 2006

Hsinchu, Taiwan, Republic of China

Supply Chain Network Design in Response to Scale

Economies and Demand Fluctuations

Student: Hui-Chieh Li Advisor: Dr. Chaug-Ing Hsu Department of Transportation Technology and Management

National Chiao Tung University

ABSTRACT

The extremely complexity of designing a supply chain network is due to the need for the configuration to adhere to customer demands, and manufacturer’s capacity and production must treat demand fluctuations. In supply chain network design phases, manufacturers merely use average estimated demand patterns, where peak and off-peak periods are covered. However, the uncertainty surrounding input parameters complicates the network design. A flexible supply chain network design that could better respond to demand fluctuations is more appropriate for operational planning. Regarding delivery strategies, the goal is to reduce logistics costs and satisfy customer needs. The assumption of constant demand is highly controversial, since demand varies with time, space and consumer socioeconomic characteristics. Serving all customers without considering the above causes high logistics cost and low customer satisfaction, thus a reduced profit.

This study aims to investigate the supply chain network design problems in response to economies of scale and demand fluctuations. A series of models are formulated to systematically investigate the problems and analyze manufacturers’ decisions on how much and how often material/product to purchase/transport among/to suppliers/customers as well as the optimal capacity and production amount for multiple plants with economies of scale in an uncertain environment. According to the issues of significance, the dissertation is divided into five distinct parts. The first part formulates an integrated plant capacity and production model, which aims to investigate how economies of scale, customer demand levels and investment conditions in different locations influence the supply chain network design. The second part focuses on evaluating the reliability of the network design from the first part on condition that abnormal demand fluctuations occur. Two mathematical programming models are further developed to determine the optimal adjustment decisions regarding production

reallocation among plant under different fluctuating demand. In the third part, the network design model is extended to include the inbound and outbound dispatching decisions with shipping economies in the supply chain. Then, the network is narrowed down to two echelons, such as plants and customers in the forth part, to focus on the logistics issues in the supply chain network. The demand-supply interaction models, which optimize a delivery service strategy, are developed as they cope with time and spatial dependent demand, demand-supply interaction. Moreover, the impacts of demand-supply interaction on the optimal capacity and production allocation among the manufacturing plants are also investigated. Furthermore, in the fifth part of the dissertation, this study focuses on the end consumer shopping behavior and employs Internet shopping as the study object. The impacts of consumer characteristics on the optimal delivery service problems are emphasized. Specifically, in addition to the determination of the optimal number and duration of service cycles by exploring demand-supply interaction and time-dependent consumer demand, this part also investigates how variations in consumer socioeconomic, temporal and spatial distributions influence consumer demand and, thereby, profit.

A series of case studies are performed to demonstrate the applications of the study. The results show the benefits in terms of cost savings brought by centralized production are larger than the increased transportation cost as a result of decentralization. The results also show performing an adjustment in response to demand expansion benefits the manufacturer in way that total production cost is reduced and revenue loss is avoided, which outweigh the additional costs. The results also show the total monthly material/product flows between two locations impacts more than their distance does on the optimal shipping frequency. The results also imply for two locations that are distant apart; there must be a large economical shipment size or less frequent shipment. The results show that without considering demand-supply interaction, the manufacturer typically pursues minimized logistics cost by assuming inelastic customer demand and applying less delivery service cycles. However, this strategy overestimates customer demand and yields higher production cost, leading to a reduced profit. In sum, the results of the study provide a reference for the manufacturer in the decision making procedures of network planning with economies of scale and demand fluctuations, as they cope with related benefits and costs.

ACKNOWLEDGEMENT

此刻終於能體會陳之藩所說,「要感謝的人太多了,那就謝天吧!」。論文得以完成, 順利拿到博士學位,並非個人能獨力完成。首先感謝恩師 許巧鶯老師多年的指導與教誨, 從觀念、態度、思考之啟迪、獨立研究之培養、邏輯推導至學術價值之定位、個人潛力之 激發與提升,均蒙恩師指導。恩師嚴謹治學、處事的態度,更令學生由衷佩服。除學術與 學業外,恩師在生活上對我也諸多關心。師恩浩浩,永銘於心。 感謝論文口試暨審查委員中央大學顏上堯教授、成功大學林正章教授、本校馮正民教 授、張新立教授,於口試與審查期間撥冗細審,並給予寶貴意見與殷切指正,使本論文更 加完善。此外,亦感謝系上陳光華老師、吳水威老師、任維廉老師、卓訓榮老師、韓復華 老師、張新立老師、謝尚行老師、高 凱老師、吳宗修老師、王晉元老師、黃寬丞老師、 郭秀貴老師、林貴璽老師、李明山老師,於課業上的指導與生活上的關心,僅致上由衷的 謝意,其中特別要感謝高老師,感謝老師給學生機會擔任長達七年的經濟學助教,且給予 百分之百的信任,更感謝老師平日對我的照顧與關心,當面臨困惑抉擇時,老師總是不吝 提供意見或予以幫助,儼然是我另一個慈父。系上可愛美麗又做事認真的助理秀蔭與幸榮 除提供行政支援外,更提供了許多生活上寶貴的意見與經驗分享,謝謝你們的幫助與友 情。國科會於研究經費的補助以及扶輪社獎助學金,僅此一併敬謝。 研究室學長姐裕弘、淑娉、清成、幼屏、惠如、敏玲、志青、俊勳、惠存與慶彰,感 謝你們的經驗傳承與教導,碩士班同學佩憓、雅妮與美珠,感謝你們在求學與研究上相互 砥礪與切磋,學弟妹素妙、哲彰、乃嘉、聖峰、一民、鵬先、乃文、偉哲、心玫、剛伯、 耀慶、憲宏、易呈、姵青、舜輔、錦昌、立弘、維真、維婷,感謝你們的陪伴,謝謝你們, 沒有各位同門的相伴,研究生活一定枯燥又乏味,還有可愛又脾氣好的佳紋,感謝你的幫 忙與包容,其他系上的學弟妹們,謝謝你們的關心,與我共同分享歡樂。還有我最好的朋 友國婷與佩憓,感謝你們對我的關心,在失意時安慰我、快樂時與我一起分享,知道有人 永遠跟自己站在同一邊,支持、關心著自己的感覺真好,你們使我的人生更精彩與完整。 我以誠摯與感恩的心,感謝我親愛的父母與哥哥、妹妹,感謝爸爸與媽媽含辛茹苦的 養育之恩,對我用心的栽培與全心全意的付出,為人處事的言教與身教,哥哥、妹妹的關 懷與鼓勵,還有舅舅、阿姨們的疼愛與照顧,希望我的表現沒有讓你們失望,還要感謝親 愛的富加,謝謝你一路相伴、全心支持與付出。 最後,感謝天真老師對我心性的啟發,希望徒兒能夠更精進、讓智慧顯現,成為上帝 的使者。李慧潔

2006 年七月於新竹交大CONTENTS

ABSTRACT ... i

ACKNOWLEDGEMENT ... iii

CONTENTS ... iv

LIST OF TABLES ... vii

LIST OF FIGURES ... xi

CHAPTER 1 Introduction...1

1.1 Motivations and background... 1

1.2 Research objectives ... 7

1.3 Research scope and approaches ...11

1.4 Dissertation framework... 20

CHAPTER 2 Literature review...27

2.1 Supply chain management related issues... 27

2.2 Supply chain network design models ... 35

2.3 Logistics and transportation issues in supply chain ... 41

2.4 Internet shopping and physical distribution problems... 47

2.5 MIP formulations ... 52

2.6 Summary... 54

CHAPTER 3 An integrated plant capacity and production model with economies of scales ...57

3.1 Introduction to the problem... 57

3.2 Model formulation... 61

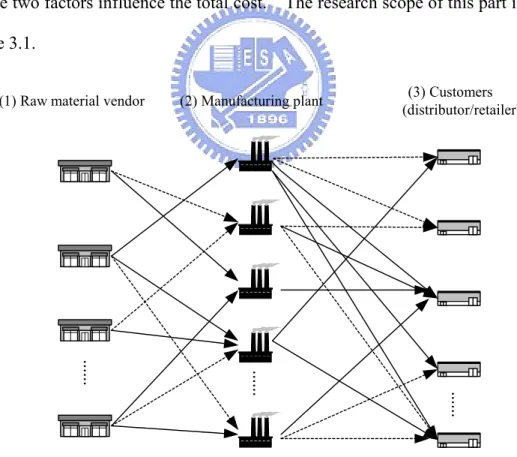

3.2.1 A supply chain network ... 62

3.2.2 Cost functions... 65

3.3 Algorithm... 74

3.3.1 Initial solution (INIT) ... 75

3.4 Case study ... 79

3.5 Summary... 95

CHAPTER 4 Reliability evaluation and adjustment for supply chain network design with demand fluctuations...98

4.1 Introduction to the problem... 99

4.2 Reliability evaluation methods... 101

4.3 Supply chain network adjustment model... 106

4.3.1 Customer demand expansion... 107

4.3.2 Customer demand shrinkage ...112

4.4 Case study ...115

4.5 Summary... 132

CHAPTER 5 Incorporating dispatching decisions into supply chain network design with production and shipping economies ...136

5.1 Introduction to the problem... 136

5.2 Model formulation... 138

5.3 Algorithm... 148

5.3.1 Initial solution (INIT) ... 148

5.3.2 Simulated annealing (SA)... 150

5.4 Case study ... 152

5.5 Summary... 163

CHAPTER 6 Optimal delivery service strategy for high-tech product manufacturers with time and spatial dependent demand ...166

6.1 Introduction to the problem... 166

6.2 Model formulations ... 169

6.2.1 Discriminating service strategy ... 170

6.2.2 Uniform service strategy ... 180

6.3 Case study ... 182

6.4 Summary... 196

CHAPTER 7 Optimal delivery service strategy for Internet shopping with time-dependent consumer demand ...198

7.2 Consumer demand for Internet store goods... 201

7.2.1 Individual characteristics... 201

7.2.2 Variations in ordering time of consumer goods and locations... 206

7.3 Mathematical programming models for the optimal service cycles... 209

7.3.1 Logistics cost functions for discriminating service strategy ... 209

7.3.2 Logistics cost functions for uniform service strategy... 212

7.3.3 Formulation of the optimal problem... 213

7.4 Case study ... 215

7.5 Summary... 232

Chapter 8 Conclusions ...235

8.1 Research summary ... 235

8.2 Extensions for future research... 244

Reference ...247

GLOSSARY OF SYMBOLS ...256

VITA ...265

PUBLICATION ...266

A. Journal Papers... 266

LIST OF TABLES

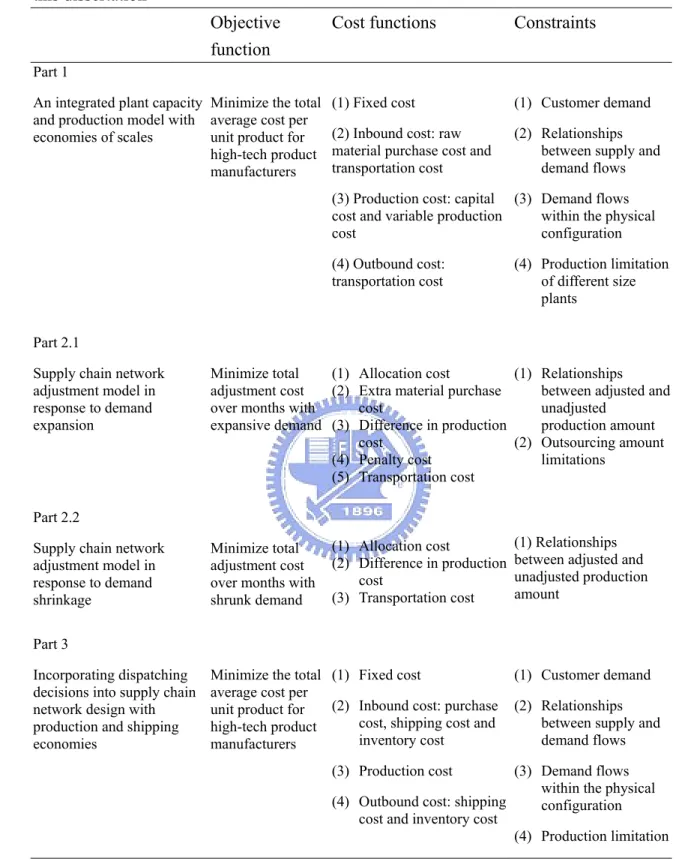

Table 1.1 The objectives functions, costs and constraints considered in different parts of this dissertation...16

Table 1.1 (continued)...17

Table 1.2 The decision variables with respect to the mathematical programming models developed in different parts ...18

Table 1.2 (continued)...19

Table 2.1 Main issues, features and results in literature on supply chain management related issues...34

Table 2.2 Main issues, features and results in literature on supply chain network design models...40

Table 2.3 Main issues, features and results in literature on logistics issues in the supply chain ...46

Table 2.4 Main issues, features and results in literature on Internet shopping and physical distribution problems ...51

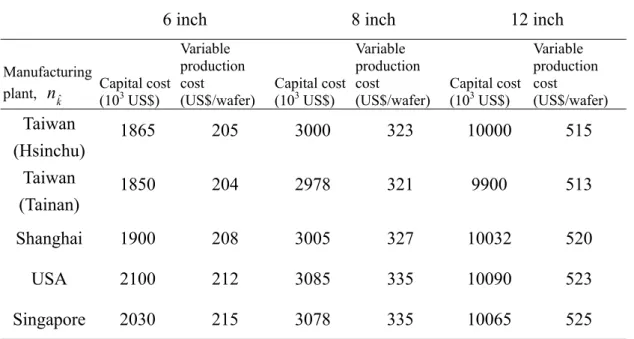

Table 3.1 The alternative sizes of FAB and base production parameters for manufacturing plants ...84

Table 3.2 The initial values of base procurement parameters ...84

Table 3.3(a) The transportation cost per kg between chemical source vendors and manufacturing plants ...85

Table 3.3(b) The transportation cost per kg between manufacturing plants and customers in six areas. ...85

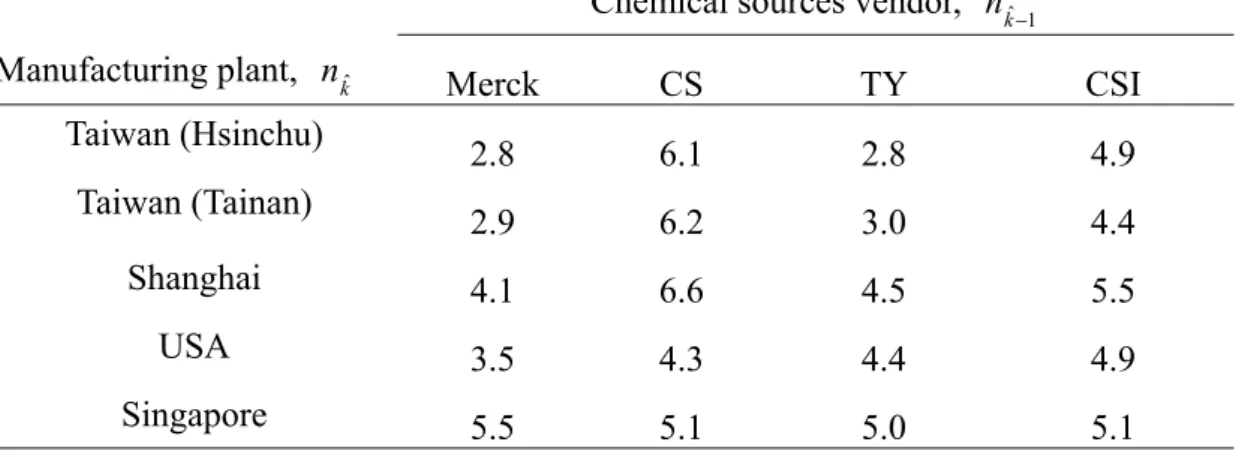

Table 3.4 The initial results of manufacturing plants ...88

Table 3.5 The initial results of the relationship between manufacturing plants and chemical source vendors...88

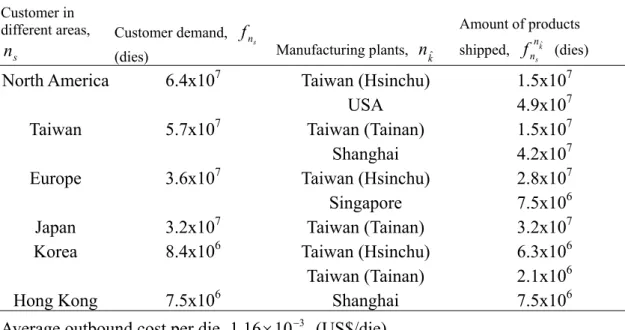

Table 3.6 The initial results of the relationship between manufacturing plants and customers in six areas...90

Table 3.7 The optimal size FABs and capacity utilization of manufacturing plants with different amounts of customer demand ...94

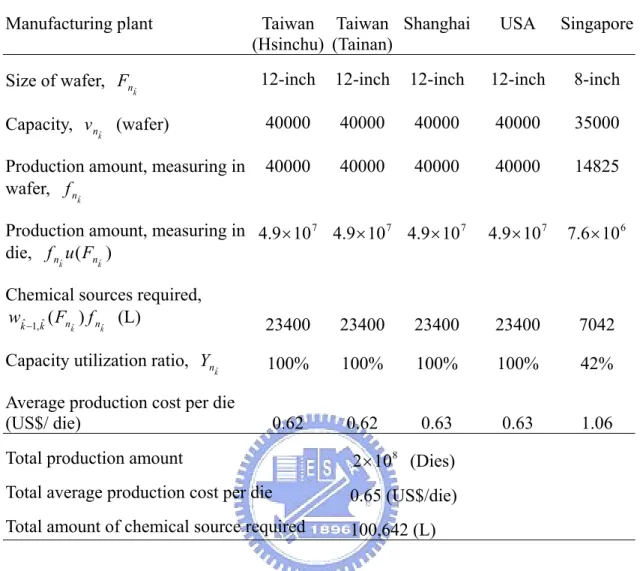

Table 4.1 Demand forecasts for five major customers in 2007 ...117

Table 4.2 The base production parameters for different-size FAB in different locations ...117

Table 4.3 Initial results of manufacturing plants and their relationship with customers in different locations ...118

Table 4.4 Hypothetical data regarding abnormal state on customers in China ...121

Table 4.5 Reliability of the manufacturing plants, given abnormal demand from China ...121

Table 4.6 The initial values of parameters in P2 ...123

Table 4.7 Initial proposed, expected and adjusted monthly flows, related costs and the results of adjust/do-nothing judgments in response to demand expansion ...124

Table 4.8 Hypothetical data regarding abnormal state on customers in North America ...129

Table 4.9 Reliability of the manufacturing plants, given abnormal demand from North America ...129

Table 4.10 The initial values of parameters in P3 ...131

Table 4.11 Initial proposed, expected and adjusted monthly flows, related costs and the results of judgments in response to demand shrinkage ...131

Table 5.1 Initial values of base shipping parameters...154

Table 5.2 Alternative sizes and base production parameters for manufacturing plants 154

Table 5.3 Initial results and optimal objective function values ...155

Table 5.4 Comparisons of results from models with and without considerations of distances and total monthly flow between two locations ...161

Table 5.5 Results for supplier-manufacturing plant under a low price strategy of suppliers in Japan ...161

Table 6.1 The initial values of base transportation parameters ...184

Table 6.2 The initial transportation time between locations of the manufacturing plants and customers ...184

Table 6.3 The alternative sizes and base production parameters for the manufacturing plants...184

Table 6.4 The initial results from models without considering the impact of demand-supply interaction on production decisions ...187

Table 6.5 The optimal dispatching dates of plants in serving different customers...190

Table 6.6 The revised results with considering the impact of demand-supply interaction on production decisions...192

Table 6.7 Comparisons of results from models with and without demand-supply interaction ...194

Table 7.1 The initial values of base demand and supply parameters...218

Table 7.2 The related data about study zones ...218

Table 7.3 Results and the optimal objective function value for discriminating and uniform service strategies...220

Table 7.4 Results and the optimal objective function value for discriminating and uniform service strategies under different values of base value of fixed transportation cost...224

Table 7.5 Results and the optimal objective function values for discriminating service strategy under different values of multiplier reflecting extra cost...224

Table 7.6 Results and the optimal objective function values without and with consideration of variations in consumers’ characteristics ...226

Table 7.7 Comparisons of results from models with and without consideration of temporal and spatial variations in consumer demand of Internet shopping. ...226

Table 7.8 Comparisons of results from models with and without demand-supply interaction ...231

LIST OF FIGURES

Figure 1.1 The research scope ...12

Figure 1.2 The framework of the dissertation ...23

Figure 1.3 The research process flowchart...26

Figure 3.1 The research scope of Chapter 3 ...57

Figure 3.2 The relationship of flows between nodes at the upper echelon and nodes at the lower echelon...63

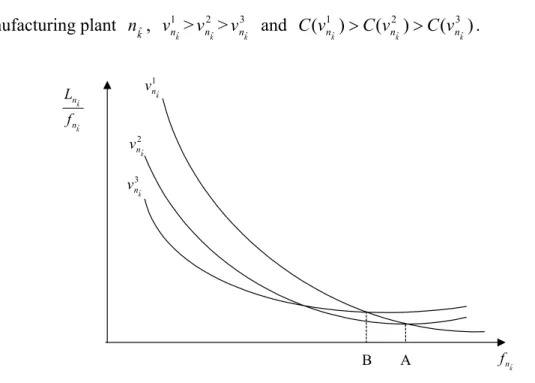

Figure 3.3 The relationship between the average production cost and the production amount ...68

Figure 3.4 Average production cost per die vs. production amount ...81

Figure 3.5 Average production cost per die vs. production amount in the USA ...90

Figure 4.1 The research scope of Chapter 4 ...99

Figure 4.2 The threshold of adjust/do-nothing judgments by comparing between unit-product outsourcing and penalty costs...126

Figure 4.3 The threshold of adjust/do-nothing judgments by comparing between duration of abnormal months and fixed allocation costs...126

Figure 5.1 The research scope of Chapter 5 ...136

Figure 5.2 Shipping frequency vs. monthly flow between two locations ...159

Figure 6.1 The research scope of Chapter 6 ...166

Figure 6.2 The profile of service cycles ...171

Figure 6.3 Time-dependent customer demands for notebooks from the five major customers during the study period...185

Figure 7.1 The research scope of Chapter 7 ...198

Figure 7.2 Inventory cost profile ...211

Figure 7.3(b) Total time-dependent consumer demand for goods over the entire study area ...219

Figure 7.4 Accumulated consumer demand for Internet store goods for discriminating service strategy ...219

Figure 7.5(a) Average logistics cost per item vs. the number of service cycles for discriminating service strategy ...221

Figure 7.5(b) Consumer demand for Internet store goods vs. the number of service cycles for discriminating service strategy ...221

Figure 7.5(c) Profit vs. the number of service cycles for discriminating service strategy ...221

CHAPTER 1

Introduction

The general field of interest in this dissertation is supply chain network design problems for high-tech product manufacturer in response to scale economies and demand fluctuations. This chapter presents an overview of the motivation, problem statement, research objectives and approaches, and illustrates the framework of this dissertation.

1.1 Motivations and background

Manufacturing industries are usually characterized with high capital cost, especially high-tech products. High capital costs are usually involved in the investment of capacity held by high-tech manufacturers, while there exists economies of scale that allows manufacturers with the large size capacity to operate more efficiently than those with the small size. Furthermore, increased specialization also requires increased transportation. As a result, the profits may shrink due to the geographical spread of their suppliers and customers, leading to a higher transportation cost. The extremely complexity of designing a supply chain network is due to the need for the configuration to adhere to customer demands, and manufacturer’s capacity and production must treat demand fluctuations. In supply chain network design phases, manufacturers merely use average estimated demand patterns, where peak and off-peak periods might be covered. However, the uncertainty surrounding input parameters complicates the network design. A flexible supply chain network design that could better respond to demand fluctuations is more appropriate for operational planning.

High-tech products manufacturing firms are characterized as having high capital costs due to the expense of sophisticated equipment, land acquisition, and plant and

warehouse construction. For example, semiconductor manufacturers spend almost a billion US dollars to construct an 8-inch wafer fabrication (FAB), and thirty billion US dollars for a 12-inch FAB. In addition, it costs more to produce one piece of 12-inch wafer than it does producing an 8-inch wafer. However, there is an advantage to a 12-inch FAB over an 8-inch FAB in terms of lower per-unit product production costs due the fact that the production is done on a larger scale, which further leads to a larger amount of final products.

The benefits brought by operating large-scale manufacturing plants shrink and production costs dramatically increase when the market demand is insufficient to realize scale economies and the capacity utilization is low. On the other hand, revenue loss arises and customer performance downgrades when supply does not match with high market demand. Strategic supply chain network design is a prerequisite for efficient tactical operations, and therefore has a long lasting impact on the manufacturers. The majority of supply chain network problems uses average estimated customer demand patterns for the manufacturers over planning years. Unfortunately, unexpected abnormal events occur and continue for a period of time, which further influence customer demand and affect network performance. The continued survival and effectiveness lie in manufacturers’ ability to respond promptly to environmental turbulence (Lloréns et al., 2005).

Regarding key-components purchase, manufacturers usually maintain their long-term contractual basis with particular suppliers, in which the total procurement meets the annual or monthly demands. To remain adaptable, the manufacturer has the flexibility of scheduling dispatching decisions, i.e. shipping frequency and shipment size to satisfy their contracted annual or monthly demands. To avoid large inventories on hand, the manufacturer may determine a more frequent shipment; however, this

results in a higher shipping cost due to shipping diseconomies. On the other hand, to take advantage of shipping economies, larger shipment sizes are encouraged. However, this may result in less frequent shipments for an equal total shipment amount, and consequently resulting in a high inventory cost. These inbound and outbound dispatching decisions involve the trade-off between inventory and shipping costs as a result of variations in the total amount of flows between two locations and their spatial distances. According to Daganzo (1991), some cost components may not be paid by the manufacture, e.g. the key-component shipping fee and the inventory cost of the final products at customers. However, an optimization without these costs tends to transfer the burden of the operation from the manufacturer to the customers and the suppliers, since their costs are not being considered. In other words, the customers and suppliers may be less willing to participate in the operation.

High-tech product demands from customers in various geographical regions can be also described as featured with time-dependent distribution. For example, peak demand likely occurs during Christmas holiday for most western markets, while customers from China might order more during the Chinese New Year. To prevent profit loss resulting from stockout, retailers (customers) often increase their inventory level, which leads to a high inventory cost. To solve this problem and improve customer service performance, transporting parts in frequent shipments of small lots is encouraged for the manufacturer. However, this strategy makes it expensive to serve and deliver product to customers whose distance are far away and the shipment size is not sufficient to achieve shipping economies. Serving all customers via the same service delivery strategy without considering variations in cumulative product amount during each service cycle and geographical spread among plants and customers causes high logistics cost under time-dependent customer demand. In addition, distribution

network combined with service delivery strategy has a dramatic influence on customer intention to purchase the manufacturer product, since it determines delay in receiving products. A trade-off relationship exists between logistics cost, given the sum of transportation cost and inventory cost, and customer demand for the manufacturer’s products, such that a low average logistics cost could be realized by a least delivery cycle but customer intention to purchase is reduced.

Regarding end consumers, the goal of delivery strategies is to reduce logistics costs and satisfy consumer needs. A crucial factor in optimizing a delivery service strategy is consumer demand. The assumption of constant demand is highly controversial, since in reality demand varies with time, space, and consumer socioeconomic characteristics. In addition to time-dependent consumer demand, consumer demand for retailers is also characterized by socioeconomic characteristics, and temporal and spatial variations. Even when served by the same service cycles, consumers with different characteristics perceive differently, which may further influence consumer demand for retailer goods and, thus, profit. In summary, how to determine an optimal delivery service strategy for retailers by considering demand-supply interaction, time-dependent consumer demand and consumer characteristics has become important.

There have been a lot of studies conducted from different perspective for the supply chain network design. The emphasized decision variables can be classified as facility selection, production/shipment quantities and supplier selections, etc. According to Chopra and Meindl (2004), a supply chain design problem comprises the decisions regarding the number and location of production facilities, the capacity at each facility, the assignment of each market region to one or more location and supplier selection, etc. The most emphasized area in supply chain network design modeling is to address the coordination of logistics operations and the design of effective production

and distribution systems (e.g. Jayaraman and Pirkul, 2001; Miranda and Garrido, 2004).

There is a large number of optimization based approaches that have been proposed for the design of supply chain networks (e.g. Arntzen et al., 1995; Jayaraman and Pirkul, 2001; Cohen and Moon, 1991). Others focused on addressing the coordination of logistics operations in terms of the design of effective production and distribution systems (e.g. Cohen and Lee, 1988; Vidal and Goetschalckx, 1997; Eskigun et al. 2005). Due to the fact that large-scale models have proven to be extremely difficult for solving optimality, most of the research focused on model improvements and algorithms to solve the developed models. Though such network designs can be seen as bases for short-run manufacturers’ operational references, the performance results of network designs, apart from demand fluctuations, were not evaluated yet.

The impacts of uncertainties on manufacturer efficiency have prompted a lot of studies to address stochastic parameters in supply chain planning phase. At the static and operational levels, there is a great deal of research developing production/inventory models that deal with various uncertain factors in the environment. The attention has been focused mostly on the probabilistic modeling of the customer demand side (e.g. Cachon and Fisher, 2000; Gavirneni et al., 1997; Gavirneni, 2002). Other studies dealt with supply uncertainties, such as machine breakdowns, strikes, shortages in material availability, etc. The majority of the research employed and modified economic order quantity (EOQ) formulas to include random variables reflecting different uncertainties (e.g. Hariga and Haouari, 1999; Wang and Gerchak, 1996). These studies have shown how the company’s performance is affected by uncertain environment and provided tools to tackle these uncertainties and ease these influences. The planning frame of these studies is focused on operational level, rather than strategic design from systematic perspectives.

Taking another approach, several studies have employed stochastic programming models to formulate optimization problems that involve uncertain input parameters (e.g. Santoso et al., 2005; Tsiakis et al., 2001). These studies focused mainly on providing efficient algorithms that solve the stochastic integer programming models and presenting computational results on supply chain network involving different number of nodes, arcs or products. However, abnormal states occur unexpectedly, resulting in severe demand fluctuations and affecting the performance of a well-design network within the abnormal state continues. Instead of reconstructing the whole network, it is important to propose adjustment method for the manufacturer so as to maintain overall global network design objectives. To summarize, few studies have combined supply chain network modeling and economy theory to formulate integrated models, as they cope with scale economies and demand fluctuations.

Numerous studies have addressed supplier selection issues in supply chain management. Some of them investigated the important factors for selecting suppliers by collecting data and by conducting hypothesis (e.g. Verma and Pullman, 1998; Jahnukaiene and Lahti, 1999). The important criteria include price, quality and delivery reliability, etc. Other studies focused on the quantification-factors and discussed the supplier selection problem as a cost-minimization formulation problem. Supplier selections also influence the design problem structure with additional factors such as geographical location of the suppliers and the manufacturing plants. There are few studies that consider the effects of spatial distance between suppliers and manufacturing plants in the optimal supplier selection process.

To sum up, several important issues in the field of supply chain network design deserve further investigation; however, these issues are rarely emphasized and theoretically formulated. This study aims to investigate the supply chain network

design problems in response to scale economies and demand fluctuations. A series models are formulated to systematically investigate the problems and analyze manufacturers’ decisions on how much and how often raw material/product to purchase/transport among/to suppliers/customers as well as the optimal capacity and the production amount for multiple plants in response to production and shipping economies in an uncertain environment. Furthermore, the scope of the study is downstream to the end users and aims at optimizing a delivery service strategy for retailers, i.e. Internet store operators, by considering time-dependent consumer demand, demand-supply interaction and consumer socioeconomic characteristics.

1.2 Research objectives

The overall goal of this dissertation is to develop a better understanding of the supply chain network problems and to make contributions in improving the performance of the network. Specifically, the purpose of this dissertation is to investigate the supply chain design problems for high-tech product manufacturers, as they capture the impacts of scale economies and demand fluctuations on the network. In view of this, a series of models are constructed in accordance with issues emphasized. According to the issues of significance, there are five distinct parts in this dissertation, which can be addressed as: integrated plant capacity and production model with economies of scales; incorporating dispatching decisions into supply chain design with production and shipping economies; reliability evaluation and adjustment for supply chain network design with demand fluctuations; and determining optimal delivery service strategies for supply chain network and Internet shopping with time-dependent demand. These five parts can be illustrated as follows.

In the first part of this dissertation, this study aims at investigating how economies of scale, customer demand level and investment conditions in different locations

influence the supply chain network design. This study also investigates how the capacity utilization as well as production amount in a short run and the capacity of multiple plants in the long run relates and those two factors influence the total cost. Note that the supply chain network design model developed in this part is the base of the dissertation. The models in the other parts are developed and extended from this network design model to tackle and deal with different issues in the supply chain network.

Following the results from the first part, the second part of this dissertation focuses on evaluating the reliability of the network design on the condition that abnormal demand fluctuations occur. To lessen the impacts of the abnormal demand on the manufacturer cost, this study further proposes adjustment procedures as they cope with different abnormal demand fluctuations. The decisions on performing an adjustment or do nothing are also investigated by comparing between the results if no adjustments are made and if adjustment are made during the duration of an abnormal state.

In the third part of this dissertation, this study extends the models developed in the first part to further include the inbound and outbound dispatching decisions with shipping economies in the supply chain. The impacts of different flow values, total material/product amount of flows between two locations as well as their spatial distance on the optimal shipping frequency and size are specially explored.

Then, the forth part of this dissertation turns the emphasis from the strategic level upon the static level. And the network is narrowed down to two echelons, such as manufacturing plants and customers in different locations, to focus on the logistics aspect in the supply chain network. The issue arises from time-dependent demand and wide spread between the manufacturing plants and customers in different locations. This part of the dissertation aims at investigating the delivery service problems for the

manufacturer by considering time-dependent demand and demand-supply interactions. In view of this, the demand-supply interaction models, which optimize a delivery service strategy for high-tech product manufacturer, are developed as they cope with time-dependent demand, demand-supply interaction and geographical spreads of plants and customers. Moreover, the impacts of demand-supply interaction on the optimal capacity and production allocation among the manufacturing plants are also investigated.

Furthermore, in the fifth part of the dissertation, this study focuses on the end consumer shopping behavior and employs Internet shopping as the study object. The impacts of consumer characteristics on the optimal delivery service problems are emphasized in this part. Specifically, in addition to the determination of the optimal number and duration of service cycles by exploring demand-supply interaction and time-dependent consumer demand, this part also investigates how variations in consumer socioeconomic, temporal and spatial distributions influence consumer demand and, thereby, profit.

Specifically, the objectives and contributions of this dissertation are addressed, respectively, as follows.

(1) This study constructs a nonlinear MIP model which attempts to minimize the average total cost per unit-product subject to constraints such as satisfying customer demand in various geographic regions, relationship between supply flows and demand flows within the physical configuration and the production limitation of different-size plants. A heuristic solution approach, based on the simulated annealing (SA), is also developed to solve the optimal problem. This study shows how economies of scale can be considered in solving the capacity and production problems. This study also shows the capacity utilization as well as production

allocation among the manufacturing plants in a short run and the size of capacity of multiple plants in a long run are related and those two factors influence the total cost.

(2) This study develops a series models to systematically investigate the supply chain design problems in response to production economies scale and demand fluctuations. A reliability evaluation method is developed in responding different demand fluctuations. The reliability in the study is defined, as the probability that initially proposed capacity of the manufacturing plant will operate effectively under demand fluctuations. This study further formulates supply chain network adjustment models with respect to demand expansion and shrinkage, as they cope with different fluctuant demands combined with various durations where the abnormal events continue. This study shows how the advantage and disadvantage brought by the adjustment can be carefully considered in advance when solving the network adjustment problems. This study also shows how the duration of an abnormal state and the related allocation costs influence the judgment on whether or not performing an adjustment.

(3) This study constructed a MIP model to incorporate the inbound and outbound dispatching decisions into a supply chain network design problem. This study also explores the impacts of different flow values, total amount of flows between two locations as well as their spatial distance on the optimal shipping frequency and size. Moreover, the impacts of the key-component price by suppliers, which are located at different distance to the plants, on the optimal supplier selection are also investigated.

(4) This study explores how to optimize not only decisions on the first part but also the delivery service strategy for the manufacturer in terms of service cycle frequency

and duration for different customers in various regions as well as their corresponding plant assignments in response to time and spatial dependent customer demand. Furthermore, the impacts of demand-supply interaction with on the optimal capacity and production of the manufacturing plants are investigated.

(5) This study develops a mathematical programming model that can determine the optimal number and duration of service cycles for Internet shopping by exploring demand-supply interaction and time-dependent consumer demand. In the demand side, this study formulates a consumer choice probability model for choosing between Internet and conventional shopping modes. Furthermore, this study investigates how consumer demand for goods from Internet stores influences logistics costs for Internet store operators by formulating average logistics cost for both uniform and discriminating service strategies. The optimal service strategy is also obtained by comparing profit between using discriminating and uniform service strategies.

1.3 Research scope and approaches

This study aims at developing a series supply chain network models for a high-tech product manufacturer who operates multiple plants at different regions. According to the specific issues emphasized in different parts, the planning frame of this dissertation includes strategic level and timeframe between tactic and operational levels. The research scope is shown as Figure 1.1.

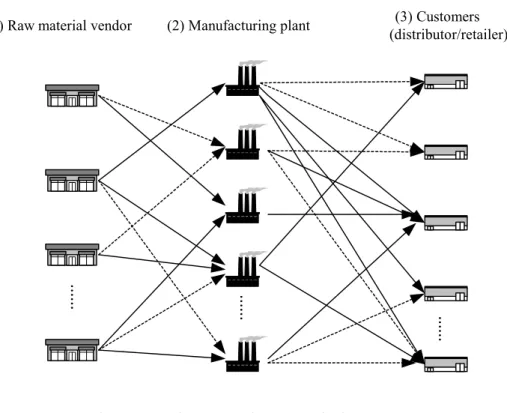

(1) Raw material vendor . . . . . .

(2) Manufacturing plant (distributor/retailer)(3) Customers (4) End user (consumer)

. . . . . . . . . . . .

The research approach with respect to different parts is described as follows. Following past literature in the field of supply chain network design problems, the first and third parts of this dissertation apply mixed integer programming (MIP) formulations and attempt to minimize the average total cost per unit product subject to constraints such as satisfying customer demand in various geographic regions, relationships between supply flows and demand flows within the physical configuration and the production limitation of different size plants. The average total cost per unit-product in the study is given by the sum of inbound, production and outbound cost and constructed, respectively by analytical approaches.

The second part devises a reliability evaluation method for the manufacturer in assessing how well the results of a supply chain network design perform under potential abnormal demand fluctuations. In the study, the capacity utilization is assumed to be the basic criterion for evaluating the reliability of the manufacturing plants under demand fluctuations. To lessen the impacts of the unreliable situations on the overall performance, this study investigates the advantage and disadvantage brought by the adjustment decisions under different fluctuant demand, by analytical approaches. Finally, this study develops the mathematical programming models and proposes adjustment procedures for the supply chain network for determining the optimal adjustment decisions, as they cope with different abnormal demand fluctuations. The judgment on performing an adjustment or do nothing is also investigated by comparing between the results if no adjustments are made and if adjustment are made during the duration of an abnormal state.

In the forth part of this dissertation, this study integrates the logistics aspect in the supply chain and customer demand analysis into one model, and aims at analyzing the impacts of service delivery strategy on customer choices and customer demands for the

manufacturer’s product with time and spatial dependent demand, and to incorporate demand-supply interaction into network design. The logistics cost, including transportation cost and inventory cost, are formulated by analytical approaches to tackle the impacts of time-dependent demand from various customers, service frequencies with respect to different customers and different assignments of manufacturing plants to customers on manufacturer total costs. This study further deals with dynamic and time-sensitive customer demand, and investigate how service cycle durations affects customer demand for manufacturer products. This study applies a binary logit model to determine customer choice probabilities for manufacturer products. The dependent variables include product prices and delay in receiving products from the manufacturer, where these factors are influenced by the manufacturer’s delivery service strategy. Furthermore, a nonlinear mixed integer programming model is formulated for determining the optimal number and duration of service cycles for different customers and the plants assignment decisions, by maximizing profit for the manufacturer subject to demand-supply equality.

In the fifth part of this dissertation, this study applies a binary logit model to determine consumer choice probabilities for both Internet and conventional shopping. The model further captures variations in consumer characteristics by employing consumer income distribution and individual logit model to estimate and aggregate the expected choice probability of choosing Internet shopping for all consumers. Then, the average logistics cost functions for discriminating service strategy is formulated by an analytical approach. Because of various numbers of orders accumulating during different service cycles during the entire study period, the average logistics cost during the study period is estimated using the weighting average method based on service cycle number and duration. Combing the choice probability function with the average

logistics cost function, this study further devises a mathematical programming model for determining the optimal number and duration of service cycles during the entire study period by considering the relationship between consumer demand and logistics costs and assuming that Internet store operators are seeking to maximize profit. Due to the complexity in solving a nonlinear programming problem, some approximate methods are required and the greedy algorithm is applied in this study due to its simple implementation and speed. The initial values, including the number and duration of service cycles, are randomly generated. Then the greedy algorithm is applied to obtain the best results for service duration for a specific number of service cycles. To verify this optimal solution, this study tests a variety of initial values for the duration of a specific number of service cycles. After several trials, the optimal duration for a specific number of service cycles can then be determined.

In sum, this dissertation applies network design modeling techniques, non-linear mixed integer programming formulation, disaggregate choice and demand forecast models to develop a series models on analyzing high-tech firms’ decision, such as the plant capacity and production allocation among the manufacturing plants, dispatching decisions, reliability evaluation and adjustment and delivery service strategies, as they cope with production and shipping economies, demand characteristics, demand-supply interaction in an uncertain environment. The objectives functions, costs and constraints considered in different parts of this dissertation are listed in Table 1.1. Moreover, the decision variables with respect to the mathematical programming models developed in different parts are shown in Table 1.2.

Table 1.1 The objectives functions, costs and constraints considered in different parts of this dissertation

Objective function

Cost functions Constraints

Part 1

An integrated plant capacity and production model with economies of scales

Minimize the total average cost per unit product for high-tech product manufacturers

(1) Fixed cost (2) Inbound cost: raw material purchase cost and transportation cost

(3) Production cost: capital cost and variable production cost

(4) Outbound cost: transportation cost

(1) Customer demand (2) Relationships

between supply and demand flows (3) Demand flows

within the physical configuration (4) Production limitation

of different size plants

Part 2.1

Supply chain network adjustment model in response to demand expansion

Part 2.2

Supply chain network adjustment model in response to demand shrinkage

Minimize total adjustment cost over months with expansive demand

Minimize total adjustment cost over months with shrunk demand

(1) Allocation cost (2) Extra material purchase

cost (3) Difference in production cost (4) Penalty cost (5) Transportation cost (1) Allocation cost (2) Difference in production cost (3) Transportation cost (1) Relationships between adjusted and unadjusted

production amount (2) Outsourcing amount

limitations

(1) Relationships between adjusted and unadjusted production amount

Part 3

Incorporating dispatching decisions into supply chain network design with production and shipping economies

Minimize the total average cost per unit product for high-tech product manufacturers

(1) Fixed cost

(2) Inbound cost: purchase cost, shipping cost and inventory cost

(3) Production cost (4) Outbound cost: shipping

cost and inventory cost

(1) Customer demand (2) Relationships

between supply and demand flows (3) Demand flows

within the physical configuration (4) Production limitation

Table 1.1 (continued)

Objective function

Cost functions Constraints

Part 4

Optimal delivery service strategy for high-tech product manufacturers with time-dependent demand

Maximize profit of the manufacturer throughout the entire study period

(1) Production cost (2) Logistics cost:

transportation cost and inventory cost

(1) Production limitation (2) Relationships

between the study period and service cycles

Part 5

Optimal delivery service strategy for Internet shopping with

time-dependent demand

Maximize profit of the Internet store operator

throughout the entire study period

(1) Transportation cost (2) Inventory cost

Relationships between the study period and service cycles

Table 1.2 The decision variables with respect to the mathematical programming models developed in different parts

Decision variables

Part 1

An integrated plant capacity and production model with economies of scales

(1) The capacity and production amount of the manufacturing plants

(2) The raw material amount from the vendors to the manufacturing plants

(3) Which manufacturing plants should produce how much production to serve customers in different regions

(4) The optimal capacity utilization of the manufacturing plants and the optimal number of active vendors

Part 2.1

Supply chain network adjustment model in response to demand expansion

Part 2.2

Supply chain network adjustment model in response to demand shrinkage

(1) Production reallocation among the manufacturing plants

(2) The optimal outsourcing firms as well as the outsourcing amount

(3) Whether or not performing an adjustment

(1) Production reallocation among the manufacturing plants

(2) Whether or not performing an adjustment Part 3

Incorporating dispatching decisions into supply chain network design with production and shipping economies

(1) The capacity and monthly production amount of the manufacturing plants

(2) The monthly procurement amount of key-component from suppliers to plants (3) Which manufacturing plants should produce

how much production to serve customers in different regions

(4) The average shipping frequency and shipment size between different combinations of

suppliers and plants and between those of plants to customers

Table 1.2 (continued)

Decision variables

Part 4

Optimal delivery service strategy for high-tech product manufacturers with time-dependent demand

(1) The optimal capacity and production amount of the manufacturing plants

(2) The optimal delivery service cycles and durations for the customers in different regions (3) The assignments of plants to customers during

each service cycle Part 5

Optimal delivery service strategy for Internet shopping with time-dependent demand

(1) The optimal delivery service cycles during the study period

(2) The time when the operator orders batch of each service cycle

(3) The number of items ordered in each batch ordering

1.4 Dissertation framework

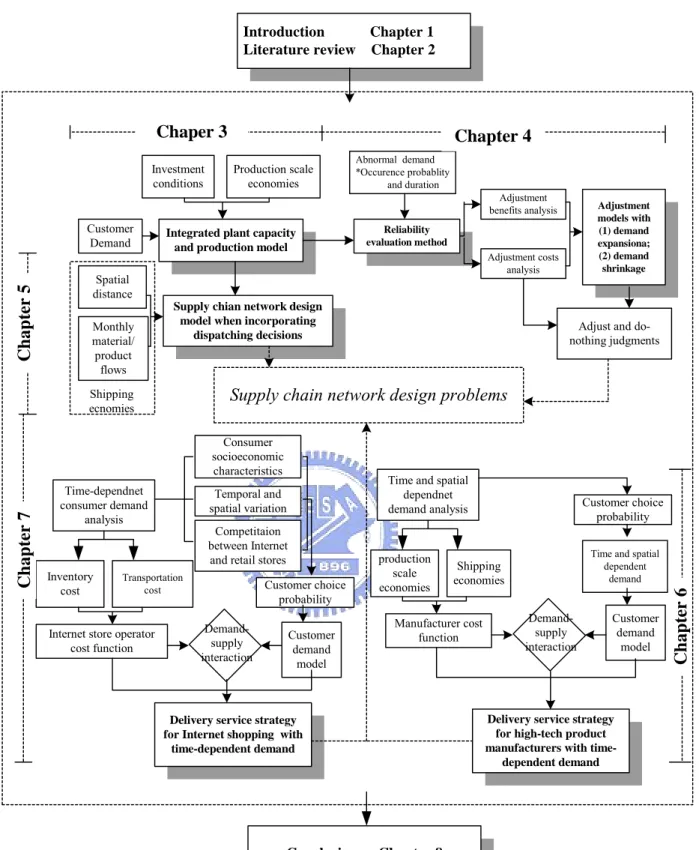

The framework and organization of this dissertation is shown in Figure 1.2. Figure 1.2 depicts the content and models of each part of this dissertation. Chapter 1 illustrates the overview of this dissertation in terms of motivations and background, objectives, spectrum and approach of the framework. Chapter 2 reviews literature in the relevant topics and distinguishes the study from past studies, in which the contributions of each part of this dissertation are also emphasized. Chapter 3 presents a basic supply chain network design model, where the decisions on plant capacity and production amount of the manufacturing plants are emphasized. In the model, how the demand from customers in different locations, investment conditions and scale economies influence the capacity and production allocation among the manufacturing plants are analyzed. The supply chain network design model is formulated as a MIP model, which attempts to minimize the average total cost per unit-product subject to constraints such as satisfying customer demand in various geographic regions, relationships between supply flows and demand flows within the physical configuration and the production limitation of different size plants.

Chapter 4 evaluates the performance of the results from Chapter 3 on condition that abnormal demand fluctuations occur. In accordance with the unreliable situations, the adjustment strategy is proposed, where the pro and con of the adjustment are analyzed by analytical approaches. Two mathematical programming models with respect to demand expansion and demand shrinkage are further developed to determine the optimal adjustment decisions, regarding production reallocations, manufacturing plants-customers reassignments and outsourcing firms selections, etc. The judgment on performing an adjustment or do nothing is also investigated by comparing between the results if no adjustments are made and if adjustment are made during the duration of

an abnormal state.

Chapter 5 focuses on investigating supply chain network design problems when incorporating inbound and outbound dispatching decisions by considering production and shipping economies. A MIP model is also formulated to determine not only decisions as Chapter 3 but also to determine the optimal shipping size and frequency between supply and demand by minimizing the sum of the average inbound, production and outbound costs. In the model, the impacts on the optimal shipping frequency and shipment size and resulting costs because of the geographical combinations of suppliers and manufacturing plants and the total monthly procurement/product amount between them are analyzed. Moreover, the impacts of the key-component price by suppliers, which are located at different distance to the manufacturing plants, on the optimal supplier selection are also investigated.

Chapters 6 and 7 focuses on the logistics issues with regard to delivery service strategies in the supply chain with time-dependent demand. Time and spatial dependent customer demand are first analyzed in Chapter 6. Then, this study formulates manufacturer cost functions as they cope with time and spatial dependent customer demand, where the impacts of production and transportation cost economies on total costs are also incorporated. The customer choice probability are formulated to capture the influences of delay in receiving products from the manufacturer, depended on the spatial distance and service cycles, and the product price charged by the manufacturer. The customer demand model is further estimated by aggregating time and spatial dependent customer demand. Combining with the customer demand function and the manufacturer cost function, a mathematical programming model is formulated for determining an optimal delivery service strategy in terms of the number and duration of service cycles for various customers and the assignments of the

manufacturing plants in serving these customers by taking demand-supply interaction into account. The demand-supply interactions on the delivery service strategy programming are discussed. Moreover, the impacts of demand-supply interaction on the determinations of capacity and production of the manufacturing plants are also investigated.

Turning the focus from the customers (retailers) into end users, Chapter 7 designs a consumer choice probability model for choosing between Internet and conventional shopping modes, by taking various factors into account. These factors include differences in consumer socioeconomic characteristics, temporal variations in ordering time of consumer goods, and spatial variations in consumer locations and competitions between Internet stores and retail stores in urban and non-urban areas. Moreover, total customer demand for Internet store goods during different service cycles are estimated by multiplying time-dependent consumer demand and the expected probability of selecting Internet shopping. Regarding the supply side, the logistics cost function, including transportation cost and inventory cost, is developed to analyze how consumer demand for goods influences logistics cost for Internet store operators. Combining with consumer choice model and operator logistic cost function, the optimal delivery service strategy problem is formulated as a mathematical programming model by maximizing operator profit during the study period.

Production scale economies Investment

conditions

Integrated plant capacity and production model

Customer Demand Chaper 3 Reliability evaluation method Abnormal demand *Occurence probablity and duration Adjustment models with (1) demand expansiona; (2) demand shrinkage Adjustment benefits analysis Adjustment costs analysis Chapter 4

Supply chian network design model when incorporating

dispatching decisions Spatial distance Monthly material/ product flows Shipping ecnomies

Time and spatial dependnet demand analysis production scale economies Shipping economies Manufacturer cost function Customer demand model Demand-supply interaction Customer choice probability

Time and spatial dependent

demand

Delivery service strategy for high-tech product manufacturers with

time-dependent demand

Ch

ap

ter 6

Adjust and do-nothing judgments

Supply chain network design problems

Time-dependnet consumer demand analysis Inventory cost Transportation cost

Internet store operator

cost function Customerdemand model Demand-supply interaction Customer choice probability

Delivery service strategy for Internet shopping with

time-dependent demand Consumer socioeconomic characteristics Temporal and spatial variation Competitaion between Internet

and retail stores

Ch ap ter 5 Ch ap ter 7 Introduction Chapter 1 Literature review Chapter 2

Conclusions Chapter 8

Figure 1.3 depicts the research processes and the steps can be expressed in detail as follows.

1. Define the research problems

According to the motivation and backgrounds, the research problems, issues, scope and objectives are first identified.

2. Literature review

To better understand the problems, this dissertation comprehensively reviews the existing literature in the relevant topics so as to understand the important factors when designing the supply chain network and when determining the optimal delivery service strategy, and to illuminate the contributions of this research.

3. Customer demand and manufacturer cost analysis

Next, customer demand characteristics are investigated. From long-term planning perspectives, events as well as important factors affecting customer demand are identified. Meanwhile, the derivative costs in serving customers are also investigated. These demand and supply analysis are the fundamentals of the model constructions.

4. Supply chain network design model

Based on the analysis in Step 3, the essential cost functions can be formulated. Employing the mixed integer programming models and related analytical techniques, this dissertation formulates a series of supply chain network design models, in which various topics are emphasized.

4.1 Reliability evaluation method

This dissertation further discusses how the performance of the manufacturing plants will be influenced by demand fluctuations by means of investigating the relationships between customer demand and production allocation. After some assumptions are made, this dissertation further formulates reliability evaluation method so as to evaluate the performance of the manufacturing plants on condition that an abnormal event occurs.

In view of how economies of scale and customer demand affect manufacturer costs, various adjustment methods in accordance with different fluctuant demand are proposed. Furthermore, the advantage and disadvantage of the proposed adjustment methods are also discussed by constructing analytical models.

4.3 Supply chain network adjustment model

The mathematical programming model is employed herein to determine the optimal adjustment decisions. And the judgment of do-nothing and adjustment is also done by comparing the objective functions under condition that if and if not an adjustment is performed.

5. Demand-supply interaction

The other major part of this dissertation aims at designing the optimal delivery service strategy under different pattern of fluctuant demand, i.e. time-dependent customer demand. Based on the analysis in Step 3, how the customer demand is affected by the service provided and the interrelationship between customer demand and manufacturer costs can be analyzed and developed by analytical approaches.

6. Mathematical programming model for the optimal delivery service strategy

The demand-supply interactions on the delivery service strategy programming are analyzed, by integrating supply and demand models and using an algorithm to solve the problem.

7. Case studies and sensitivity analysis

Case studies and sensitivity analysis are provided in each parts of this dissertation to illustrate the application of the models and to demonstrate the proposed models’ effectiveness.

8. Conclusions and suggestions

Finally, the summary, conclusions and the future studies of this dissertation are presented.

Define the research problems

Literature review

Customer demand and manufacturer cost analysis

Supply chain network desgin model Objectives

Contraints

Reliability evaluation method

Adjustment methods

Benefits and costs analysis

Supply chain network adjustment model Objectives

Constraints

Mathematical programming model for the optimal delivery service strategy Objectives

Constraints

Demand-supply interaction analysis

Case studies and sensitivity analysis

Conclusions and suggestions

CHAPTER 2

Literature review

This chapter reviews the literature on related areas including: 2.1 Supply chain management related issues; 2.2 Supply chain network design models; 2.3 Logistics and transportation issues in supply chain; 2.4 Internet shopping and physical distribution problems; 2.5 MIP formulations. Issues, theoretical methods and contributions of the relevant studies are discusses and summarized in this chapter. Furthermore, the contributions of the study are also clarified in Section 2.6.

2.1 Supply chain management related issues

Since the introduction of the term “supply chain management” (SCM) in 1982, it has received a lot of interests both in the literature and practice. According to Christopher (1998), a supply chain (SC) can be defined as a network of organizations that are involved, through upstream and downstream linkages in the different processes and activities that produce value in the form of products and services in the hand of the ultimate consumers. Therefore, supply chain management is the task of integrating materials, information and financial flows in order to fulfill customer demands with the aim of improving competitiveness of the SC as a whole (Stadtler, 2005). Furthermore, supply chain management can be viewed as logistics outside the firm to include customer and suppliers (Lamber and Cooper, 2000). The planning tasks can be classified to different levels depending on the time horizon, namely strategic, tactical and operational. The operational planning includes vehicle routing, scheduling, etc; the tactical planning involves the procurement, inventory and transportation system, etc; and the strategic planning includes the determinations of plant sites, the number of plants, etc. Specifically, the main determinations of strategic level include (1) the

number, location, capacity of manufacturing plants; (2) the active suppliers; (3) the amount of raw materials and products to produce and ship among suppliers, plants and customers, etc (Vidal and Goetschalckx, 1997). In practice, the short-term operational flexibility is directly related to the strategic decisions.

There exist different areas of literature associated with supply chain management, such as strategic management, logistics, relationships/partnerships, etc. Among those studies, a lot of studies have concerned about demand amplified, i.e. bullwhip effect in a supply chain, which can be described as the variability of orders increases from down stream to upstream (Simchi-Levi et al., 2000). This phenomenon makes supply chain planning difficult. Different ordering policies were considered and discussed to reduce the order variance. Geary et al. (2006) identified major causes of bullwhip and provided several principles to reduce bullwhip effect. A great deal of literature has investigated the impacts of different ordering policies on the order variability and the most mentioned policies are (s, S) ordering policy (e.g. Kelle and Milne, 1999). In addition to quantify bullwhip effect, some studies proposed different strategies to reduce bullwhip effect, such as accurate demand forecasts (e.g. Metters, 1997) and application of information flows technique (e.g. Cachon and Fisher, 2000). Bourland et al. (1996) exploited timely demand information (TDI) to reduce inventories. The results show that inventory-related benefits are sensitive to demand variability, the service level provided by suppliers, and the degree to which the order and production cycles are out of phase. Berman and Kim (2001) considered a problem of dynamic replenishment of parts in the supply chain consisting of single class of customers, company, and supplier. To sum up, the above literature can be classified as production-inventory models that involve uncertainties in the environment. The most attentions focused on the probabilistic modeling of the customer demand side. The timeframe of the literature

can be classified as operational planning in the supply chain management.

In another line of research, the economic order quantity (EOQ) or lot sizes decisions have been discussed extensively in the inventory control literature (e.g. Silver and Peterson, 1985; Wagner, 1980). Schniderjans and Cao (2000) and Fazel et al. (1998) presented an analytical model to evaluate and compare the total purchasing and inventory cost associated with just in time (JIT) and EOQ. The proposed model expanded the classical EOQ to include a quantity discount scheme. Other studies relaxed the assumption from deterministic demand to investigate the impacts of stochastic demand on the optimal ordering policy (e.g. Haneveld and Teunter, 1998). Other studies assumed a stochastic supply and discussed the optimal ordering policy with EOQ (e.g. Hariga and Haouari, 1999; Wang and Gerchak, 1996). Other studies have applied fuzzy theory to investigate the optimal ordering policy, such as Vujošević et al. (1996) assumed both inventory cost and ordering cost as two fuzzy variable and Roy and Maiti (1997) constructed a fuzzy EOQ model with time-dependent unit cost under limited storage capacity. In sum, past EOQ models are mainly based on the time frame, with the active suppliers being known and given.

There are still some studies aiming at reviewing literature about supply chain management. Croom et al. (2000) considered the bodies of literature associated with supply chain management and discussed the different perspectives adopted in different studies. Beamon (1998) provided a focused review of literature in multi-stage supply chain modeling. According to Beamon (1998), the four categories of modeling approach are (1) deterministic analytical models, in which the variables are known and specified, (2) stochastic analytical models, where at least one of the variables is unknown, and is assumed to follow a particular probability distribution, (3) economic models, and (4) simulation models.

The demand forecast methods and information flows technique have been demonstrated important factors influencing inventory cost and customer service performance in past literature. Most of the studies aimed at short-term demand uncertainty and the influencing on company’s operational efficiency. However, the extent to which the economic fluctuation influences the market demand of high-tech product is quite apparent. And the duration of different economic fluctuations during the planning year is quite different, which may further influences service quality and cost economies. Though some conventional statistical forecasting models can be applied to generate future customer demand, the fluctuations surrounding customer demand may affect accuracy of forecasted results.

In addition to apply accurate forecast methods, some studies aimed at investigate the relationship between supply side uncertainty and ordering policy. Whybark and William (1976) presented a framework for characterizing and studying the uncertainty which affect inventory level investment and service level performance in a material requirements planning (MRP) system. This study also showed how safety stock or safety lead time can be used for buffering a part against uncertainty. The results showed that under conditions of uncertainty in timing, safety lead time is the preferred technique, while safety stock is preferred under conditions of quantity uncertainty. Petrovic et al. (1998) represented supply chain fuzzy models and a corresponding simulator, developed to assist in decision making on operational supply chain control parameters in an uncertain environment. The objective in this study is to determine the stock levels and order quantities for each inventory in a supply chain during a finite time horizon to obtain an acceptable delivery performance at a reasonable total cost for the whole supply chain. Güllü et al. (1999) analyzed a periodic review, single-item inventory model under supply uncertainty. In the study, the uncertainty in supply was