Abrasion resistance design of sediment

sluicing tunnel in Taiwan: a case study

Chia-Han Lee, Shang-Shu Zhan, Shih-Hsien Chang, Shang-Yao Lien, andJen-Hung Chang

Abstract

Several cases of abrasion in hydraulic tunnels are collected including destroyed cases and resistance methods and materials at first. Then as an example of Zengwen Reservoir Sediment Sluicing Tunnel, illustrates the concept of basic design, laboratory and in-situ test, detail design, challenge of construction, inspection results after in-situ test and operation. The real abrasion condition was inspected in-situ. And the possible causes of abrasion was investigated finally. This abrasion resistance design can be a reference for other hydraulic tunnels in the future.

Keywords: reservoir sedimentation, sediment sluicing tunnel, abrasion resistance, tunnel inspection.

1 Introduction

The designed velocity of discharging is 18 to 30 m/sec in Zengwen Reservoir Sediment Sluicing Tunnel (ZRSST). So the abrasion resistance method and material are the one of the key issues. This paper will illustrate the abrasion resistance concept of basic design, laboratory and in-situ test, detail design, challenge of construction, inspection results after in-situ test and operation in this project.

2 Case study of abrasion resistance

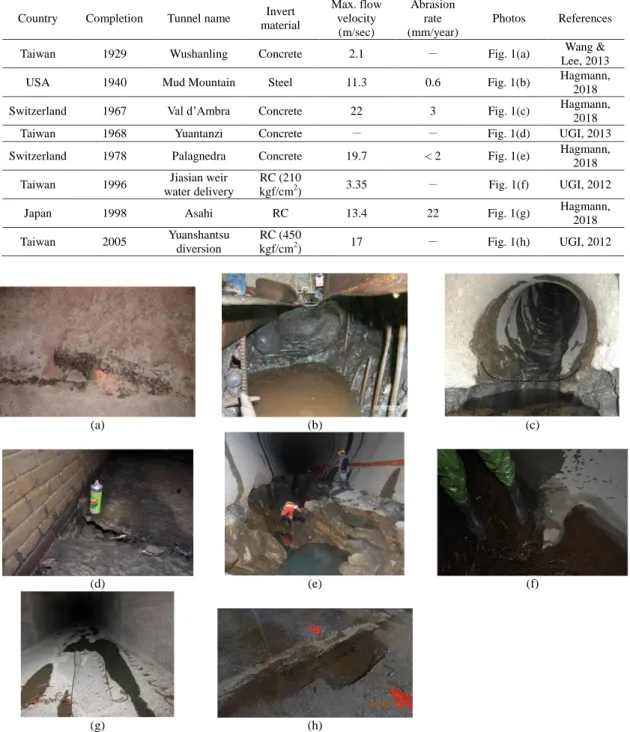

The actual cases of hydraulic tunnel invert abrasion are summarized in Table 1 and Figure 1. It is noted that whether the tunnel invert is made of such as bedrock, bricks, concrete, reinforced concrete, steel plates, etc., under the hydrological condition of high-speed water flow with mud or gravel, abrasion may be resulted on the invert, the lining construction joints, and the spots where the tunnel turns or changes its slope. Based on the above-mentioned domestic, international cases and related studies, abrasion resistance methods for hydraulic tunnel lining can be roughly divided into: (1) improving concrete strength; (2) increasing lining thickness; and (3) applying abrasion resistance material on the surface (means coating). Among them, abrasion resistance materials can be categorized into: (1) steel plates; (2) epoxy resins; (3) polyuria; (4) silica fume concrete; (5) fiber-reinforced concrete; (6) polymer mortar and so on. The real cases of applying abrasion resistance methods and materials are summarized in Table 2.

Table 1: Cases of invert abrasion in hydraulic tunnels.

Figure 1: Case photos of invert abrasion in hydraulic tunnels: (a) Wushanling tunnel (Wang & Lee, 2013); (b) Mud Mountain tunnel (USACE, 2016); (c) Val d’Ambra tunnel (Hagmann, 2018); (d) Yuantanzi tunnel (UGI, 2013); (e) Palagnedra tunnel (Auel & Sumi, 2016); (f) Jiasian weir water delivery tunnel (UGI, 2012); (g) Asahi tunnel (Hagmann, 2018); (h) Yuanshantsu diversion tunnel (UGI, 2012).

Country Completion Tunnel name Invert material Max. flow velocity (m/sec) Abrasion rate (mm/year) Photos References

Taiwan 1929 Wushanling Concrete 2.1 - Fig. 1(a) Wang & Lee, 2013 USA 1940 Mud Mountain Steel 11.3 0.6 Fig. 1(b) Hagmann, 2018 Switzerland 1967 Val d’Ambra Concrete 22 3 Fig. 1(c) Hagmann,

2018 Taiwan 1968 Yuantanzi Concrete - - Fig. 1(d) UGI, 2013 Switzerland 1978 Palagnedra Concrete 19.7 < 2 Fig. 1(e) Hagmann,

2018 Taiwan 1996 Jiasian weir

water delivery

RC (210

kgf/cm2) 3.35 - Fig. 1(f) UGI, 2012 Japan 1998 Asahi RC 13.4 22 Fig. 1(g) Hagmann,

2018 Taiwan 2005 Yuanshantsu diversion RC (450 kgf/cm2) 17 - Fig. 1(h) UGI, 2012 (a) (b) (c) (d) (e) (f) (g) (h)

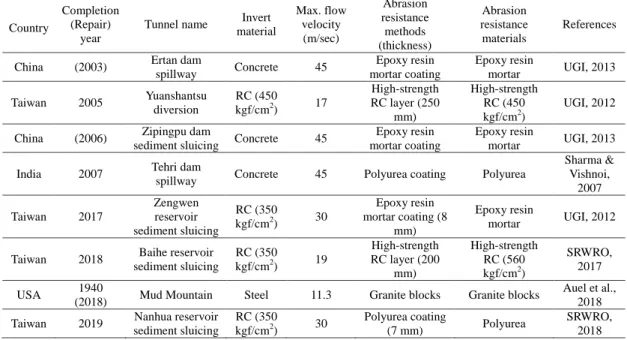

Table 2: Cases of invert abrasion resistance methods and materials in hydraulic tunnels.

3 Zengwen Reservoir Sediment Sluicing Tunnel project

3.1 Project overview

In 2009, Typhoon Morakot caused approximately 90 million cubic meters of sediment to enter the Zengwen Reservoir. The capacity of the Zengwen Reservoir was reduced to 491 million cubic meters. To ease the severe silting, the ZRSST project was launched in 2013 (Lee et al., 2016). Figure 2 presents the location of the ZRSST project. The tunnel is 1,235 m in length and located south of the earth dam of the reservoi. The designed flooding capability is 995 m3/s (Lai, 2017). The maximum overburden of the tunnel is approximately 250 m. The tunnel comprises five sections: (1) Intake section with an elephant-trunk shape pipe; (2) Inlet section; (3) Shaft and gate section, equipped with hydraulic facilities, including operational gate and maintenance gate; (4) Main tunnel section; (5) Outlet section, including plunge pool and stilling pool and tunnel outlet. (Lee et al., 2017). The ZRSST project was finished in the end of 2017.

Figure 2: The location of ZRSST project. Country

Completion (Repair)

year

Tunnel name Invert material Max. flow velocity (m/sec) Abrasion resistance methods (thickness) Abrasion resistance materials References

China (2003) Ertan dam

spillway Concrete 45 Epoxy resin mortar coating Epoxy resin mortar UGI, 2013 Taiwan 2005 Yuanshantsu diversion RC (450 kgf/cm2) 17 High-strength RC layer (250 mm) High-strength RC (450 kgf/cm2) UGI, 2012

China (2006) Zipingpu dam

sediment sluicing Concrete 45

Epoxy resin mortar coating

Epoxy resin

mortar UGI, 2013

India 2007 Tehri dam

spillway Concrete 45 Polyurea coating Polyurea

Sharma & Vishnoi, 2007 Taiwan 2017 Zengwen reservoir sediment sluicing RC (350 kgf/cm2) 30 Epoxy resin mortar coating (8 mm) Epoxy resin mortar UGI, 2012

Taiwan 2018 Baihe reservoir sediment sluicing RC (350 kgf/cm2) 19 High-strength RC layer (200 mm) High-strength RC (560 kgf/cm2) SRWRO, 2017 USA 1940

(2018) Mud Mountain Steel 11.3 Granite blocks Granite blocks

Auel et al., 2018 Taiwan 2019 Nanhua reservoir

sediment sluicing RC (350 kgf/cm2) 30 Polyurea coating (7 mm) Polyurea SRWRO, 2018 Zengwen Reservoir Intake PRO Dam Construction adit Power plant

Air addition tunnel

Zengwen river

3.2 Basic design of abrasion resistance

The flow velocity in the sediment sluicing tunnel is between 18-30 m/sec; therefore, the minimum thickness of the abrasion resistance material is 7 mm; and the area of abrasion resistance material implemented in each section should not be less than 90% of the design flow depth, while the height is between 2 and 10 m, as shown in Figure 3.

Figure 3: Basic design of the abrasion resistance layer for ZRSST project.

In addition, during the basic design stage, in order to avoid the designation of specific material which may cause difficulties in the performance of the turnkey project in the future, the abrasion resistance materials of this project are function and demand oriented to meet the following requirements: (1) abrasion resistance material performance: the abrasion resistance material should have been applied to the sediment discharge or sediment pump project with flow velocity of 18 m/sec or more; (2) the bonding strength between concrete and steel surface: the tensile strength of the bonding between concrete surface and steel surface should be greater than 30 kgf/cm2; (3) warranty requirements: the abrasion resistance project shall have a warranty of 5 years and up to 240 hours of operation. The thickness of the abrasion resistance layer during the warranty period shall not be less than 60% of the design thickness.

4 Tests, detailed design and construction

4.1 Laboratory and in-situ tests

After detailed evaluation by the contractor, the ZRSST project decided to use epoxy resin mortar as the abrasion resistance layer. The main material which is made up of

epoxy resin, hardener and fine aggregate (silica sand). The underwater abrasion resistance test mainly uses steel balls with different sizes to simulate the abrasion behavior of the abrasion resistance material under eddy current conditions. The abrasion resistance test under the impact of sand-containing water flow mainly involves the flushing of sand-containing water on the abrasion resistance materials at a flow velocity of about 12 m/s. In the abrasion resistance test under the impact of tubular sludge, the mud-containing water (20,000 ppm) with flow velocity of approximately 30 m/s was used to simulate the abrasion condition of the tunnel. (Liu, 2016)

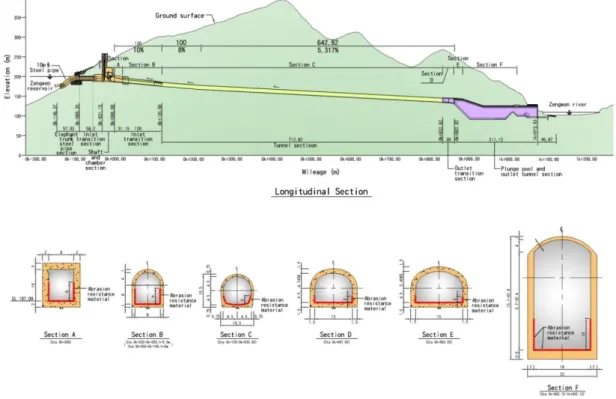

For the meso-scale in-situ tests, the concrete bottom plate and vertical wall were set up. The abrasion resistance mortar was prepared by mixing anti-abrasion epoxy resin A, B and quartz sand. The pull-out terminals were then installed on the concrete bottom plate and the vertical wall to carry out pull-out test according to ASTM D4541-02 specifications. The model size and the configuration of in-situ test are shown in Figure 4. The major failure modes can be categorized into: (1) terminal degumming failure; (2) bonding surface failure; (3) concrete failure. Overall, the bonding surface strength of the abrasion resistance material is mostly greater than 30 kgf/cm2 (KTI, 2016).

Figure 4: Configuration of the in-situ pull-out test.

4.2 Detailed design

Based on the small-scale laboratory test and the meso-scale in-situ test results, the designed coating thickness of abrasion resistance material is 8 mm, the designed tensile strength of the bonding surface between the abrasion resistance material and the substrate (steel or concrete lining) is 30 kgf/cm2. The design is to pre-embed steel sheet at the interface between the concrete lining and the abrasion resistance material and to measure its thickness by a film thickness meter (BES, 2016).

4.3 Construction

During the construction, the coated surface must be kept dry to effectively improve the bonding strength between interfaces. However, since the inlet section of the tunnel is adjacent to the reservoir area, leakage from the surrounding rock was encountered

during excavation. Most sections of the tunnel have adopted the water-stopping and the leakage-stopping techniques to keep the concrete lining surface dry, allowing the abrasion resistance material to be coated on the lining successfully. Nevertheless, few sections of the tunnel inlet are still affected by the leakage of surrounding rock caused by the high water level of the reservoir (Figure 5). After repeated pumping, water-stopping and surface-drying techniques, the abrasion resistance materials were successfully applied (BES, 2016).

According to the inspection results of the abrasion resistance material constructed for the ZRSST, the average tensile strength between the abrasion resistance material and the concrete lining or the steel is 61.6 kgf/cm2 or 98.6 kgf/cm2, respectively. The thickness of the abrasion resistance material for the entire tunnel is about 13.2 mm.

Figure 5: Water leakage of the lining during construction.

5 Operation and assessment

5.1 Trial run and operation

The ZRSST project was completed in November 2017, and the trial run with high-water level (EL.220 m or more) was carried out on August 20~21, 2018. Four sediment sluicing operations were conducted during the heavy rain period from August to September 2018. Figure 6 shows the relationship between the operation history of the tunnel, the regional daily rainfall and the reservoir water level.

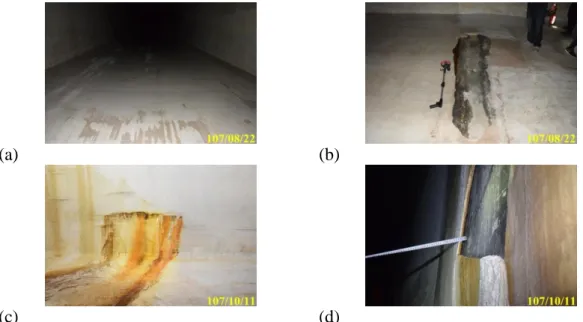

To understand the wearing condition of the abrasion resistance material after the trial run with water and the four sediment sluicing operations, in-situ inspections were carried out on August 22 and October 11, 2018. The inspection results show that the abrasion resistance material of invert has been worn down (Fig. 7a) and damaged (Fig. 7b). Moreover, water leakage (Fig. 7c) and spalling (Fig. 7d) phenomena were observed for the abrasion resistance material of the sidewall. The damaged abrasion resistance layer caused by the trial run with water and four sediment sluicing operations accounts for about 0.2% of the total abrasion resistance layer in the tunnel (UGI, 2018).

Figure 6: Relationship between reservoir level and daily rainfall during the period of trial run with water and four sediment sluicing operations.

(a) (b)

(c) (d)

Figure 7: Photographs showing abrasion and damage in-situ after trial run with water and four sediment sluicing operations.

5.2 Analysis and assessment

According to the in-situ inspection results, there are some concrete blocks remaining between the stilling basin and tetrapods of the outlet tunnel (Fig. 8). It is conjectured that such concrete blocks were piled near the inlet during the pouring of the underwater concrete in the elephant truck steel pipe section. Moreover, when the arc gate was raised from 60% to 100%, the increased flow rate may enhance the siphon effect, sucking the remaining concrete blocks into the sediment sluicing tunnel, which is then discharged together with the mud-containing water.

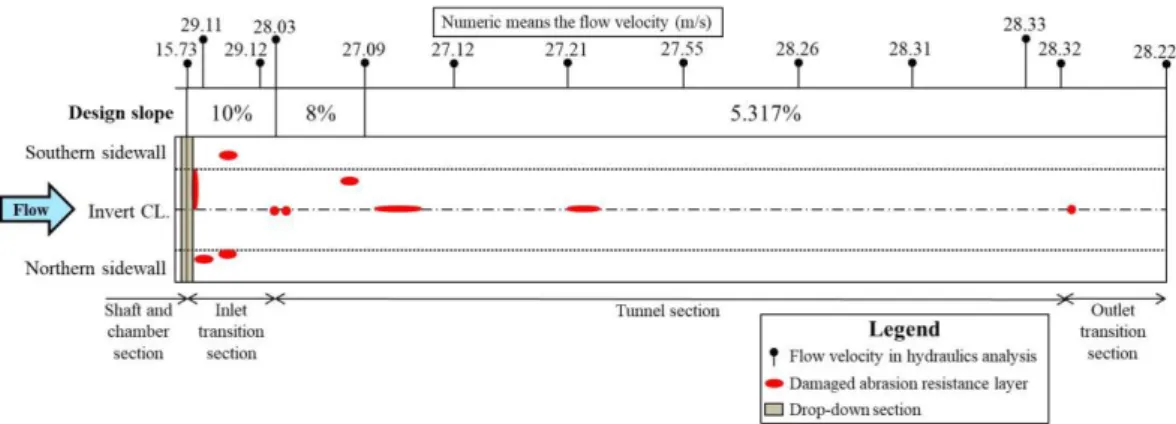

Figure 9 shows the relationship between the designed slope, flow velocity and damaged abrasion resistance layer of the ZRSST. The damaged abrasion resistance layer is concentrated in the inlet transition section and the front section of the tunnel section. The designed slopes of the two sections are 10% and 8%, respectively, which are the steepest sections from gate to plunge pool. In addition, there is a slope at the junction between the arc gate and the inlet transitional section. When the arc gate is opened, the high-speed muddy water containing concrete blocks will form a drop, which will increase the possibility of collision between the concrete blocks with the abrasion resistance layer, leading to damage.

On the other hand, during the period between the trial run with water and the four sediment sluicing operations, the in-situ inspection results showed water leakage and spalling phenomenon for the abrasion resistance layer on the sidewall of the inlet transition section. The heavy rain caused reservoir water level and groundwater level to rise, increasing the water pressure behind the concrete lining. In addition, during the excavation period, water leakage occurred due to the increased reservoir water level, which made the construction environment moist and weakened the bonding strength between the abrasion resistance material and the concrete lining. As a result, due to the increased reservoir water level and groundwater level, water leakage and spalling phenomenon was observed for the abrasion resistance layer on the sidewall.

Figure 8: Photographs of concrete blocks in the outlet after trial run with water.

Figure 9: Schematic diagram of designed slope, flow velocity in hydraulics analysis and damaged abrasion resistance layer.

6 Conclusions

ZRSST is the first hydraulic tunnel in Taiwan that uses epoxy resin mortar as the abrasion resistance material. The small-scale laboratory test, meso-scale in-situ test and large-scale in-situ construction inspection were conducted to completely understanding the abrasion resistance characteristics, tensile strength and layer thickness.

The in-situ inspection results show that the invert abrasion resistance layer of the ZRSST was damaged at the changing place of slope and flow velocity due to the impact of high mud-containing and concrete-containing water. Only partial abrasion was observed for the invert abrasion resistance layer. However, there was no significant difference in the abrasion resistance layer of the invert after four sediment sluicing operations. The water leakage and spalling phenomenon of the abrasion resistance layer on the sidewall is mainly caused by the heavy rain, leading to increased groundwater level and the increased moisture at the interface between the concrete lining and the abrasion resistance layer, which reduced the bonding strength.

It is recommended that the thickness of the abrasion resistance material should be measured annually by accurate measurement technique such as thickness meter, or LiDAR technique in the subsequent operation period.

References

Auel, C., Sumi, T. (2016). Abrasion Damage in Sediment Bypass Tunnels. 12th International Conference on Hydroscience & Engineering Hydro-Science & Engineering for Environmental Resilience, Tainan, Taiwan.

Auel et al. (2018). Rehabilitation of the Mud Mountain Bypass Tunnel Invert. Commission International Des Ggandes Barrages, Vienne, 51-71.

BES Engineering Co. (2016). Difference Description of Abrasion Resistance Coating Quality in Mirror Section. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese). Hagmann, M. (2018). Hydroabrasion by High-Speed Sediment-Laden Flows in Sediment Bypass

Tunnels. Doctoral Thesis, No. 24291, ETH Zurich, Switzerland.

Kuo Toong International Co., Ltd. (2016). Abrasion Resistance Project Constuction Plan of Zengwen Reservoir Sediment Sluicing Tunnel Project. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese).

Lai, C.H. (2017). Hydraulic desilting of reservoir in Taiwan. Proc. 2nd International Workshop on Sediment Bypass Tunnels, Japan, paper KN2: 1-11.

Lee et al. (2016). Rock Tunneling Applied to Steady Water Resources Supply in Taiwan: Challenges and Examples. Geotechnical Engineering Journal of the SEAGS & AGSSEA, 47(2): 1-6. Lee et al. (2017). Sediment-sluicing tunnel constructed neighboring to an existing earth dam with

innovative design, construction and monitoring technology, Proceedings of the World Tunnel Congress 2017, Norway, 1657-1663.

Liu, Y.W. (2016). Report on the Research Results of Engineering and Wearing Resistance of Kuohsin Technology Epoxy Resin Mortar. Kuo Hsin Technology Co., Ltd, Taiwan. (in Chinese). Sharma, S.C., Vishnoi, R.K. (2007). Application of Polyurea Coating on Concrete Lining of

Intermediate Level Outlet at Tehri Dam Project – A case Study. International Congress on River Basin Management, 733-745.

Southern Region Water Resources Office (2017). Detail Design Report of Baihe Reservoir Sediment Sluicing Tunnel Project. SRWRO, WRA, MOEA, Taiwan. (in Chinese)

Southern Region Water Resources Office (2018). Basic Design Report of Nanhua Reservoir Sediment Sluicing Tunnel Project. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese)

U.S. Army Corps of Engineers (2016). Mud Mountain Dam 9-Foot Tunnel Rearmoring, Enumclaw, WA - Construction Solicitation and Specifications, Phase 2 of 2. USACE, RFP No. W912DW-16-R-0006.

United Geotech, Inc. (2012). 2012 Inspection and Assessment Report of Yuanshantsu Flood Diversion Hydraulic Structures. The 10th River Management Office, WRA, MOEA, Taiwan. (in Chinese) United Geotech, Inc. (2012). Basic Design Report of Zengwen Reservoir Sediment Sluicing Tunnel

Project. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese)

United Geotech, Inc. (2012). Hydraulic Inspection and Safety Assessment Report of Jiasian Weir Transbasin Waterway. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese)

United Geotech, Inc. (2013). Inspection and Safety Sssessment Report of Water Conservancy Structures in Erren Waterway and Yuantanzi Tunnel. Farm Irrigation Association of Kaohsiung Taiwan. (in Chinese)

United Geotech, Inc. (2018). Safety Review before Use of Zengwen Reservoir Desilting Tunnel Project. Southern Region Water Resources Office, WRA, MOEA, Taiwan. (in Chinese). Wang, T.T., Lee, C.H. (2013). Life-cycle Design Considerations for Hydraulic Tunnels - Lessons

Learned from Inspection and Maintenance Cases. Journal of Performance of Constructed Facilities, 27(6): 796-806.

Authors

Chia-Han Lee (corresponding author) / Shang-Shu Zhan Email: ug513@mail.ugi.com.tw

United Geotech, Inc., Taiwan

Shih-Hsien Chang / Shang-Yao Lien

Southern Region Water Resources Office, WRA, MOEA, Taiwan

Jen-Hung Chang