A stage approach for industrial technology development and

implementation—the case of Taiwan’s computer industry

Pao-Long Chang

a,*, Chiung-Wen Hsu

b, Chien-Tzu Tsai

a,caInstitute of Management Science, National Chiao Tung University, 4F, 114 Chung-Hsiao W. Road, Sec. 1, Taipei, Taiwan, ROC bIndustrial Technology Research Institute (ITRI), Chutung, Hsinchu, Taiwan, ROC

cDept. of Industrial Engineering and Management, MingHsin Institute of Technology, 1 Hsin-Hsing Road, Hsin-Fong, Hsinchu, Taiwan, ROC Received 21 March 1998; received in revised form 4 July 1998; accepted 3 September 1998

Abstract

The objective of this paper is to study how government-supported R&D institutes cooperate with the industrial sector to assist industrial technology development in developing countries. By investigating the case of the computer industry in Taiwan, the authors suggest a stage approach for industrial technology development. This approach emphasizes the implementation of technology, that is, R&D institutes should help industry to truly absorb and apply technology to improve their products or services to upgrade their overall industrial competitiveness. For developing countries, the key problems of industrial technology development are not only gaining technology but also implementing that technology in their own industrial context. This paper suggests that R&D institutes should closely coordinate with industry during the R&D procedures to make different technology implementation strategies at different developmental stages. The approach is based on three stages which respectively represent industrial technology capabilities at weak, medium or strong levels. Five strategies are discussed. To link the implementation strategies and the R&D procedures there are three critical factors to consider: commercialization capability; market timing; and industrial technology requirements. This approach shows how R&D institutes can effectively help industrial technology to develop step-by-step, thus upgrading techno-logical capability and fostering overall industrial growth.1999 Elsevier Science Ltd. All rights reserved.

Keywords: Government-supported R&D institutes; Industrial technology development; Industrial technology implementation; Computer industry

1. Introduction

Technological development is a major agent of indus-trial development (Kim and Dahiman, 1992). For developing countries, it is important that technology can be developed and used effectively for industrial develop-ment, especially for countries with few natural resources and relatively small domestic markets, like Taiwan. In fact, the economic growth and international competi-tiveness Taiwan has gained over the past few decades has mostly depended on technological development (IMD, 1997).

However, technology R&D is risky and needs much capital and time (Lee, 1991; Roessner et al., 1992; Schechter, 1982). Governments of some countries have been helping their industries to develop technology. In

* Corresponding author. Tel.: ⫹ 2314-6537; fax: ⫹ 886-2-2361-1162; e-mail: changpl@ms16.hinet.net

0166-4972/99/$ - see front matter1999 Elsevier Science Ltd. All rights reserved. PII: S 0 1 6 6 - 4 9 7 2 ( 9 8 ) 0 0 1 1 1 - 4

Taiwan, the domestic industries are mainly composed of small and medium-sized companies. Their R&D scales are relatively small compared to those of developed countries. Industry itself can hardly carry the entire responsibility of technological development (Choi, 1988; Rothwell and Zegveld, 1982). Taiwan’s government has employed a strategy to support non-profit R&D institutes to develop technology and then disseminate the results to industry. The mission of the government-supported R&D institutes is to aid industrial growth via technologi-cal development (MEA, 1989).

In such a context, how can government-supported R& D institutes cooperate with industry effectively? How can R&D institutes realize which kinds of technology are truly required by industry? How can R&D institutes develop and disseminate these technologies efficiently? How can industry absorb and apply the technology to foster their business? How can such cooperation really sustain technological upgrading and promote industrial growth? All these questions need to be considered.

Although many studies have discussed R&D manage-ment and technology transfer for single organizations, fewer studies have examined the interaction between R& D institutes and industry from a long-term view of devel-opment for an entire industry.

This article attempts to explore the above questions and take advantage of the successful experience of Tai-wan’s computer industry to formulate a suggestive approach for industrial technology development.

Computers and the related information industry now form the largest export industry in Taiwan. Begun in the early 1970s, this field at first had only a few businesses assembling or copying others’ products. In 1978, the First National Science and Technology Conference set the small computer system as the key technology to be developed for the foundation of a larger high-tech indus-try. According to national policy, the government-sup-ported Industrial Technology Research Institute (ITRI) in 1979 started to implement the Technological Develop-ment Project for the Computer Industry and many pro-jects have since followed. After two decades, the tech-nology development has fostered fast-paced industrial growth. Taiwan now has a world-class computer indus-try, with production volume behind only the US and Japan. Moreover, the industry enjoys more than 50% of the world market share for monitor, motherboard, key-board, mouse, video card, sound card and scanner sales (III, 1997).

There are many factors behind the success of Tai-wan’s computer industry. In addition to domestic manu-facturers’ efforts, international technology transfers, foreign investments and foreign purchases have all played roles in developing Taiwan’s computer industry. Multi-national corporations such as IBM, HP and Philips came to Taiwan in the 1960s and 1970s to set up affili-ates. They brought not only commodities but also tech-nology to Taiwan and helped the electronics industry to flourish. HP equipment helped many Taiwan engineers to carry out their work and research. HP also transferred technology such as its twelve-layer PCB to Taiwan. A program of software engineering institute, jointly set up by IBM and the Taiwan Institute for Information Indus-try in 1972, was also a notable case of software tech-nology transfer and professional training. Taiwan Philips contributed much in monitor production and semicond-uctor investment in the late 1980s. Meanwhile, OEM of electronic components, computers and peripherals from such international big firms as DEC, Compaq and Dell, gave Taiwan manufacturers much space to grow.

However, in addition to industrial initiatives, govern-ment policy is also a critical prerequisite for leading to successful industry and this article shall concentrated on the perspective of government-supported R&D insti-tutes. This case study focuses on the interactive experi-ence of Taiwan’s computer industry and the largest government-supported R&D institute, ITRI, to find a

feasible and helpful way for R&D institutes to foster industrial technology capability from backward origins to global competitiveness. The term Industrial

Tech-nology Development is used to mean this kind of

tech-nology R&D aimed at industrial establishment and growth.

By studying the development of the computer industry in Taiwan from 1978 to 1996, this paper proposes the strategies used by ITRI for industrial technology devel-opment and highlights the underlying concepts and fac-tors that made the technology implementation more suc-cessful. The results of this case study have helped the authors to construct a stage approach for industrial tech-nology development and implementation. The following sections first elaborate on the approach and then describe the 20 year history of the computer industry in Taiwan and demonstrate actual incidences that cross-refer to the stage approach. The final section summarizes the case illustration and the implications for both the industry and the R&D institutes.

2. Stage approach for industrial technology development and implementation

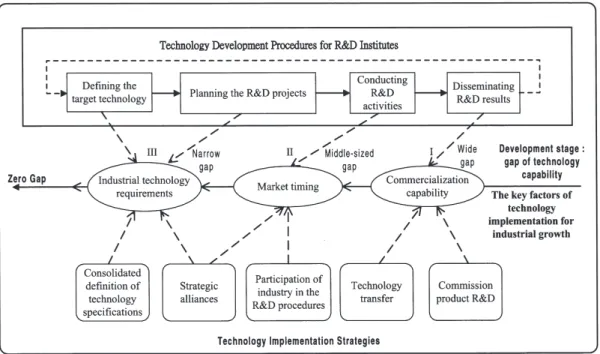

The stage approach is shown in Fig. 1 and has three major parts: the technology development procedures of R&D institutes; the key factors of technology implemen-tation for industrial growth; and the technology implementation strategies employed by R&D institutes. These major parts are integrated by the underlying con-cepts of growing technology capability (Sharif, 1997; Yin, 1992). There are three stages found in the growth path of industrial technology development based on the gap between Taiwan’s technology capability and that of leading countries, which can be classified as: far behind; immediately following; and nearly catching-up. Various technology implementation strategies are suggested for R&D institutes depending on the stage that the industry is currently in. R&D institutes should choose the adequate strategies at the appropriate phases in order to help industry catch the key factors for industrial growth. The R&D procedures and the implementation strategies are thus linked conceptually by the key factors.

2.1. The technology development procedures for R&D institutes

The technological R&D conducted by government-supported institutes is aimed at improving the level of industrial technology capability and at helping to estab-lish a developing industry (Barry and Loveless, 1987; MEA, 1989). Hence, its R&D activities can be logically sequenced by first selecting what technology the industry actually needs, and then developing it to the level that the industry can accept and assimilate (Chang et al.,

Fig. 1. Stage approach of industrial technology development and implementation.

1993). Therefore, the entire R&D procedure includes four phases: defining the target technology; planning the R&D projects; conducting R&D activities; and dissemi-nating R&D results (Harvey, 1984; Hayes and Wheel-wright, 1988; Shama, 1992). These are the four spaces in the upper part of Fig. 1. Below is a summary of the activities and objectives of each phase.

1. Defining the target technology. The R&D institute should first conduct policy analysis, market surveys, technological forecasting, as well as assess the tech-nological needs and capabilities of industry in order to define the target technology to be developed in accordance with the requirements of industrial growth.

2. Planning the R&D projects. Based on the target tech-nology needed by industry, the R&D institute should next decide about the detailed specification of the related technology or products. It should then analyze its own research capabilities and resources in order to select the way to acquire the technology, either through local development or overseas transfer. Finally, the R&D institute has to propose concrete plans about the projects’ cost-benefits, schedules and personnel requirements.

3. Conducting R&D activities. With a proper control of project costs and schedules, the R&D institute should work on technology research and product develop-ment. This can be done independently or by coop-erating with foreign enterprises for technology intro-duction and transfer.

4. Disseminating R&D results. The R&D results should finally be disseminated to industry by implementing

local technology transfer projects, providing techno-logical information, industrial field services, person-nel training, etc. The R&D institute should also help industry to incorporate the disseminated technology into manufacturing or commercial applications. The above four-phase procedure is a conceptually logi-cal sequence. This procedure is suggested to be flexibly managed according to the concept of integrative cyclic and linear technology innovation process (Betz, 1993). In prac-tice, there are three points worth noting. First, different R&D projects may emphasize different phases, according to the requirements of industry at that time. For example, there is a project of ITRI called Industrial Technology Information Service, which is aimed at phase 4. Second, the term ‘R&D’ used here has a broad meaning. R&D may or may not include basic or applied research or technology creation. The R&D institute may just introduce the exist-ing foreign technology and concentrate on developexist-ing it or readying it for industrial exploitation. Third, the R&D institute should match its R&D procedure with appropriate strategies to meet its goal-effective industrial technology development and implementation. Both technological and industrial contexts should be considered and different stra-tegies are suitable for different development stages. The next section discusses the distinctions of the stages and the critical factors for industrial growth in each stage.

2.2. Key factors of technology implementation for industrial growth

For developing countries, industrial technology devel-opment is, in fact, a process of acquiring technology

capabilities to bridge the gap behind more developed countries (Kim and Dahiman, 1992; Sharif, 1997). In addition to acquiring the advanced technology, applying the technology to finished products or services can really heighten industrial competitiveness. So-called

tech-nology implementation refers to industries being able to

absorb and use these new technologies, the key that determines the success of the entire technology develop-ment and effectively shortens the distance between the local industry and those of developed countries. Many factors may affect technology implementation, but this suggested approach focuses on the critical factors of each stage during the development process. The devel-opment status of each stage and the accordant key factors are given below.

2.2.1. Stage 1

During the early founding days, industrial technology lags by a huge margin. Industry alone cannot catch up with foreign advanced technology. The R&D institute may, at this point, introduce some mature technology to local firms and help them apply the technology to commercial products. At this stage, only the technology that can help the firms penetrate the market will let the industry keep growing. Industry must build up such capabilities to transform the introduced technology into commercial benefits. This key factor may be called

com-mercialization capability (Chang et al., 1993; Spann et

al., 1993).

2.2.2. Stage 2

As manufacturers gradually establish their technologi-cal foundation, efforts are concentrated on narrowing the gap behind the developed countries. Industry needs to quickly adapt to technological change to sustain and pro-mote its position in international markets (Porter, 1985). The focus of this stage for the R&D institute is to reinforce and speed up R&D efficiency to let industries seize market opportunities. This factor is called market

timing. 2.2.3. Stage 3

As the industry’s technological competence begins to accumulate, the critical factor is to forecast market-directed technology trends and to clearly define the tech-nology requirements for industrial growth (Chang et al., 1997). The R&D institute can help industry not only to follow foreign technology but the institute can also do local R&D so that the industrial technology development can keep up with advancing technology. This key factor is called meeting industrial technology requirements.

Considering these factors, the R&D process of the research institutes can meet the technology requirements of industry and help the manufacturers to commercialize the technology on time. The above-stated factors high-light the key points to be focused on at each stage in the

technology development trajectory. These are the three ovals found at the center of Fig. 1.

2.3. Technology implementation strategies

A practical, feasible set of strategies should be used to guide the R&D process so that technology develop-ment may agree with the above-stated factors of tech-nology implementation. By helping industry to catch these three factors, the R&D institute can truly foster effective industrial technology development and help bridge the technological gap stage by stage. There are five strategies suggested to link the key factors of each stage for technology implementation. These five stra-tegies are given in squares in the lower part of Fig. 1.

At stage 1, commercialization capability, there are two adequate strategies for R&D institutes. One strategy is to exploit local technology transfer which emphasizes the dissemination phase of the R&D procedures. The specific methods include technology concession, tech-nology data transfer, establishing spin-off companies, personnel transfer, etc. (Autio and Laamanen, 1995; Dorf, 1988; Mogavero and Shane, 1982; Winebrake, 1992). Another strategy is to receive further specified

product development commissions from companies that

have even poorer R&D facilities. From product develop-ment commissions, R&D institutes can not only help the manufacturers to get commercialized products but also can aid them to gradually build up their own capabilities via personnel training and on-the-spot technology assist-ance.

At stage 2, the important goal for the R&D institute is to help industry get technology more quickly in order to keep up with market timing. International strategic

alliance (Devlin and Bleackley, 1988; Ohame, 1989;

Sounder and Nassor, 1990; Yuan and Wan, 1995) is an effective strategy to quickly acquire foreign technology. Patent licensing and joint R&D ventures greatly reduce R&D time. Another method is to speed up the tech-nology assimilation for local industry. The R&D institute may employ the strategy of manufacturers’ participation in the R&D actions. This strategy is feasible because manufacturers already have the technological basis from the experience of the prior stage. This strategy allows manufacturers to absorb the technology as early as poss-ible and shorten the time needed for local technology transfer. Moreover, this can upgrade industrial tech-nology capability as manufacturers will have more opportunities to learn.

At stage 3, selecting the right technology to develop is critical for industrial growth. The strategy that may be used for this purpose is the consolidated definition of

technology specifications by the manufacturers’

partici-pation with the R&D institute. Thus, the R&D institute can select and plan R&D projects that meet industrial requirements, thereby gaining firms’ support. The

method can be done by using information service com-mittees of industry, pre-R&D technology transfer con-tracts, etc.

The basic concept of the suggested approach lies in the capability of the industries to effectively reduce the technical gap, in stages, through good management of the three key factors. For this purpose, R&D institutes are suggested to apply proper technology implemen-tation strategies in stages to guide the practical R&D procedure. The next section uses Taiwan’s computer industry as an actual illustration.

3. Case study: the industrial technology development of Taiwan’s computer industry

3.1. Background

After the invention of the first vacuum tube computer in 1946, the development of computer science and appli-cation of semi-conductor technology accelerated the development of computer technology. However, most technology developed at that time was capital-poured for medium-sized and large computers.

This continued until 1971, when Intel introduced the first micro-processor. The computer market of the 1970s possessed relatively small capital investments, had a small operational scale and had scattered markets, but this micro-computer field gradually grew. This growth gave Taiwan an opportunity to enter the computer indus-try. Taiwan’s electronics industry at that time was mainly composed of assembly plants. In 1977, the Chuan-Ya Company’s development of the EDU-80 com-puterized learning-aid product marked the birth of Tai-wan’s computer industry. In January 1978, the Republic of China’s Executive Yuan held a Science and Tech-nology Conference which set the government’s goal to develop and promote small computer systems in Taiwan for the long-term development of a domestic elec-tronics industry.

Under this policy, the government-supported non-pro-fit R&D institute, the Industrial Technology Research Institute (ITRI), started to carry out the Technology Development Project for the computer industry. In the following two decades, this industry has shown a notable three-stage growth trajectory, with time spans divided by significant turning points. The first turning point was 1984, when Taiwan developed its own IBM-PC compat-ible products. The second came in 1990 when Taiwan made its 486PC and notebook PC at nearly the same time as the developed countries and began to upgrade to workstation computer technology. Details are given below.

3.2. Stage 1, getting started: 1978–1984

Taiwan’s computer industry in this early period was composed of small, scattered firms. In the late 1970s, manufacturers were caught between the shadow of an Apple computer imitation ban and the video game clamp down conducted by the ROC Ministry of Education. Manufacturers searched for new products and markets to survive. During this period, following long-term policy goals, ITRI targeted the micro-computer field and imported some foreign technology to establish its own R&D facilities and systems. Meanwhile, through joint research with foreign scholars and personnel training programs, ITRI built up a solid infrastructure for com-puter technology development, including comcom-puter pro-duct-design and manufacturing technology. Experiments were conducted from basic product levels (4-bit and 8-bit micro-processors) to higher levels (16-8-bit products). Software technology was likewise developed, resulting in products like operating system CROS-86 and com-piler and emulator ASEM-86. Furthermore, ITRI sent representatives to the American Wang Computer Co. for training and a transfer of system production technology. In 1981, an experimental factory was established to enhance production engineering.

This period also happened to be the time when IBM opened the production of its PC-compatible computers. Taiwan’s manufacturers took advantage of the opport-unity at hand (IBM opening its market) and the support available (R&D at ITRI) and jumped into the micro-computer market. However, the technological capabili-ties of the manufacturers during this period did not allow them to do their own R&D. Thus, ITRI turned over its products and production technology to the manufacturers (e.g. transfer of the Z80 computer CMC-100 technology to Hong-yu Co. in 1982). Such a local technology

trans-fer strategy allowed manufacturers to effectively use

ITRI’s technological foundation to develop their own commercial products. At the same time, some manufac-turers also commissioned product R&D to ITRI. In 1983, ITRI was able to assist five computer manufacturers, including ACER, with R&D for the IBM compatible PC-XT and in 1984 for the technology upgrade to PC-AT. In these examples from 1978 to 1984, ITRI undertook the foundational works of initial technology develop-ment. It shared the R&D costs and gave the industry a good basis to take-off with good products at competitive prices, thus letting manufacturers establish their

com-mercialization capability. Together with the investments

and OEM of leading foreign companies, like IBM and HP, Taiwan’s manufacturers gained footholds in the glo-bal market.

3.3. Stage 2, rapid growth: 1984–1990

After getting started, Taiwan’s computer industry had to speed up its pace to cope with the competition.

Although the low-priced compatible products were able to penetrate the market, manufacturers had to upgrade their products’ quality and production time to enhance further growth.

In this context, ITRI then supported the industry’s development in two directions. First, ITRI developed com-puter hardware technology and the technology for testing, quality control (QC) and high-quality production. Second, ITRI promoted the development of PC-related technology including computer peripheral products, software tech-nology, and IC technology. Both developments were aimed at helping manufacturers grab market opportunities to launch better products. To implement the technology, ITRI used the participating strategy to let manufacturers join in the R&D procedures.

3.3.1. Development of computer hardware and technology for testing and production

ITRI put up the first EMI test laboratory in Taiwan, offered FCC test services, and helped factories conduct material inspections and specification verifications. This solved the difficulties that manufacturers encountered when sending new R&D products abroad for examination and helped the manufacturers save both money and time when launching new products. ITRI also researched and promoted the use of SMT technology and established high-quality PCB technology to upgrade the level of pro-duction. Manufacturers assisted by ITRI included Tatung, Acer, Sampo, Mitac, Copam, and others. Such technology enhanced the production of PC motherboards and by 1996 Taiwan enjoyed 74% of world motherboard market (III, 1997).

As for computer hardware technology development, notable results were found from the Four-year Project of System Product Designing Technology carried out by ITRI. Because manufacturers had gained some technology capability from the module designing experience in the prior stage, ITRI took the strategy that manufacturers par-ticipated in this project to jointly conduct R&D activities. The industry thus shortened the time to absorb the tech-nology and accelerated new product development. By 1985, at the introduction of PC-AT compatible products, Taiwan manufacturers had shortened the time gap behind developed countries from 25 months in 1983 to only 13 months. At the launch of the 386-AT in 1986, Taiwan’s technology was only behind by 2 months. By 1989, Tai-wan was able to launch its 486 PC at the same time as developed countries. By pursuing a strategy of

manufac-turers’ participation in R&D activities, the

government-supported institute helped industry to effectively catch up to market timing.

3.3.2. Development of PC-related technology

During this stage of integrated computer system tech-nology development, the chip-set IC became the new trend in the design technology of micro-processors and

their key components. In 1985 ITRI participated in a project to establish the government-supported Chip Implementation Center to help manufacturers establish their IC design technology. UMC, Taiwan’s first private-sector IC manufacturer, was a spin-off from ITRI and commenced mass production in 1982. ITRI also helped to found the first pure IC foundry in the world, TSMC, in 1987. Taiwan’s computer industry thus linked the key technology with its upstream IC industry. Besides, software programming skills also played an important role in the production of a complete computer system product. Based on the software development experience in the first stage, ITRI came up with the personal com-puter BIOS, various types of operating systems, as well as compiler and interface software programs. Further-more, ITRI also deepened its R&D for PC peripheral products such as printers and scanners. At this stage, manufacturers possessed excellent production capability and were thus able to take advantage of capitalizing on such downstream industries. These products were gradu-ally welcomed in the international market. For example, with the contribution of many famous firms like Umax and Microtek, Taiwan’s scanners held 52% of the market share by 1996 (III, 1997).

These developments let the computer industry inte-grate both the upstream technology of key components and the downstream technology of applications and per-ipherals, thus speeding up its product marketing as an entire competitive system.

3.4. Stage 3, reaching maturity: 1990–1996

Taiwan had earned an important position in the world PC market by stage 2. It then faced two new challenges regarding upgrading of industrial technology: (1) vertical upgrade of product capacity; and (2) extension and expansion of product lines.

3.4.1. Vertical upgrade of product capacity

Faced with this challenge, industry had to consider the development of workstation computers. Manufacturers and ITRI jointly decided on the critical technology requirements of this direction and searched for partners to form strategic alliances of technology development. Thus, ITRI went to the leading manufacturer in the inter-national market, Sun Microsystems, to negotiate the mat-ter of patent licensing and royalties. Domestic manufac-turers also participated in evaluating the viability of this deal. In 1989, Tatung, Datatech, Twinhead, and ITRI signed an international joint production agreement with Sun. Sun transferred the source code and object code technology to ITRI and ITRI then sub-licensed the tech-nology to local manufacturers. Sun received royalty pay-ments for the units produced in Taiwan. The technology introduced by this international strategic alliance let Tai-wan manufacturers launch their first workstations by

1990. In 1993, at the introduction of the SPARC Classic compatible products, the industry was only behind Sun Microsystems by 2.5 months.

By this alliance strategy, the key technology for indus-trial development had been jointly defined and R&D time had been effectively shortened. The success of this technology development strategy was due to the tech-nology importation channels and experience established during the first two stages. Another more important fac-tor was the fact that the manufacturers were able to clearly specify the target technology required for product commercialization and they already possessed enough technology capacity to realize technology absorption and new product development.

Another example of alliance strategy was the Taiwan New PC Product Development Alliance (TNPC), jointly established by ITRI and the Electric and Electronics Manufacturers Association in 1993. TNPC was more than just an alliance of thirty or so domestic manufac-turers; it was also able to attract well-known foreign enterprises such as IBM, Motorola, National Semicond-uctor Co. and Phillips. TNPC developed a PowerPC prototype in six months. This alliance strategy was able to raise the PC product technology in Taiwan to the same level as in advanced countries.

3.4.2. Extension and expansion of product lines

There were three significant developments in this direction: multi-media computers; portable computers; and communication technology.

3.4.2.1. Multi-media computers Taiwan’s computer industry possessed an excellent environment for the pro-duction of IC components, motherboards and computer peripherals like monitor, mouse and scanner. Hence, the industry was able to effect a smooth transition into the production of multi-media computers. As for helping the industry upgrade such technology, ITRI developed a var-iety of applications and drivers for graphics, image pro-cesses and laser printers through its 4 year project during this stage.

As for programming computer system software pack-ages, both the manufacturers and the government auth-orities sensed the need for professionalism and indus-trialization. Hence, in 1992, the Software Technology Park was established, a tangible form of policy assist-ance and support. Its presence made the environment for Taiwan’s computer industry more complete and well-rounded.

ITRI also developed the high-speed and high-density IC packing technology, thus improving the SMT layout application and engineering analysis ability. More than 10 manufacturers benefitted from these technology developments, including Copam, Microtek, Atop and Umax.

3.4.2.2. Portable computers When the US introduced the concept of portable computers, Taiwan manufac-turers started to draft and set the product standards and specifications for the notebook PC, based on the wealth of PC production technology the industry already pos-sessed. A joint planning session was held in June of 1990, which involved ITRI, the Electrical Equipment Manufacturers Association, and 46 manufacturers, including Lunghwa and Universal.

This consolidated definition of technology

specifi-cation strategy was jointly implemented by ITRI and the

manufacturers. Taiwan’s notebook PCs were leading those of developed countries launched in 1990. ITRI’s technology support and the consolidated strategy helped industry to effectively grab the information and tech-nology requirements of new market trends. By then, the manufacturers’ production capability and the OEM orders together fostered Taiwan’s notebook PC sub-industry. So, by 1991, Taiwan was able to ship 500 000 notebook PCs around the world. In 1996, Taiwan made 32% of the world production volume for notebook PCs (III, 1997).

3.4.2.3. Communication technology Due to the popu-larity of internet systems that integrate computers, com-munications and consumer electronics (3C technology), ITRI established the Computer and Communication Lab-oratory (CCL) in 1990.

This institute implemented R&D programs for a var-iety of computer systems and communication techno-logies. The Wireless Digital Advancement Program that ITRI jointly accomplished with seven manufacturing companies was completed in 1996. In 1995, ITRI’s tech-nology team approached D-Link and GVC, manufac-turers with network technology and production capacity, for a cooperative venture into the network-information market. ITRI also entered into a joint investment cooperation with a computer industry leader, Acer; this led to the establishment of a computer-communication professional company, Lienchi Technology Co. ITRI expects that, once more, it might help industry meet the 3C wave of technology competition through manufac-turers’ consolidation and strategic alliances.

The objective of the industrial technology develop-ment at this stage was to strengthen the ability to forecast future technological trends and predict market demands to make the right products at the right time. During this same period, the industry was able to participate in set-ting specifications for technology requirements with the R&D institutes (ITRI). Industry was also able to foster its product technology through international strategic alliances, thus greatly narrowing the gap separating them from the developed countries. The computer industry became well-rounded by adding relevant industries such as the IC, network communication, computer peripheral and software industries. All this growth has given

Tai-wan an important position in the international market. By 1996, the industry, the third-largest in the world, pro-duced US$16.4 billion worth of goods, and had a growth rate of 21% (III, 1997). Many forces in both the private and public sectors helped shape Taiwan’s computer industry of today, and government-supported R&D insti-tutes played a definite role in helping industrial tech-nology development and implementation via appropriate strategies and procedures.

4. Summary

Industrial growth depends on upgrading technological capability. Among the many prerequisites for a success-ful industry, this study explored specifically how the public sector can assist. A government-supported R&D institute may contribute to industrial technology devel-opment. However, the task is not only to develop tech-nology for the industry but also to help implement it. The basic objective is to help bridge the industrial nology gap behind the advanced countries. For tech-nology to be effectively implemented into industry, R& D institutes must consider the actual context of industrial development in order to apply the right strategy at the right time. R&D institutes should have R&D activities meet the real needs of manufacturers and the actual capabilities of the industry so as to truly catalyze the development of the industry. Based on a long-term view, the suggested stage approach stresses the need to coordi-nate R&D procedure with implementation strategies. This perspective emphasizes the importance of a close reciprocal relationship between the technological devel-opment by R&D institutes and industrial develdevel-opment.

In the early developmental stage, when the industrial technology is still very backward, the R&D institute may choose strategic technologies to develop and, by tech-nology transfer, may disseminate the techtech-nology to the industry. The key problem concerning manufacturers in this stage is commercialization capability. The R&D institute may use a strategy of product R&D com-missioning to help manufacturers and share its know-how to improve firms’ capabilities. The R&D institute should take most responsibility for the R&D activities as it builds a foundation for industrial technology devel-opment. The institute’s jobs include setting up channels for introducing foreign technology, training technology personnel, and establishing laboratories and experi-mental factories. It plays the roles of both instructor and infrastructure builder.

In pace with the growing experience and sophisti-cation of the technology possessed by the industry, the technological gap may be narrowed. Manufacturers need more than just technology to make products, they need to get it quickly so that they can meet market timing in this competitive world. The R&D institute can use the

strategy of manufacturers’ participation in R&D activi-ties to speed up this technology dissemination. Likewise, improving production technology is important in speed-ing up the manufacturspeed-ing process. The R&D institute may support quality control and testing work. Moreover, international strategic alliances can be helpful in acquir-ing advanced technology quickly.

As the manufacturers’ technical capability upgrades and the industry gradually matures, the development of both upstream and downstream industries becomes criti-cal for the continuous prosperity of the industry. The R& D institute has to then foster the related industries. At the same time, manufacturers should improve their market-oriented product R&D to satisfy users’ requirements. International alliances can meet this purpose as well. The R&D institute can become a joint partner with the manu-facturers to define the specification of the target tech-nology and develop it together.

The course of industrial technology development goes stage by stage and the mission of the R&D institute focuses on implementing technology to assist the indus-trial sector. It is not for the long-term replacement of R&D departments. The role of the R&D institute has to shift from a coaching role to one of consultant and assist-ant. This gives the manufacturers room for self-develop-ment and growth so the industry may effectively benefit from technology development in the long-term.

In the case of Taiwan’s computer industry interacting with ITRI, some failures have of course occurred. For example, ITRI’s HDTV project still has had no effect on the industrialization of this technology. ITRI conduc-ted the HDTV project by specifying a new standard dif-ferent from that of advanced countries. Such a task, how-ever, was somewhat beyond ITRI’s capabilities. For instance, technology implementation was not well con-sidered at that time (no transmission station was set up and there was little market for HDTV). Such a failure justifies the key point of this stage approach—R&D institutes should develop technology that meets the needs and capabilities of the industry so it can be truly implemented. The HDTV project tried to outpace the advanced countries and thus broke the step-by-step pace of narrowing the technological gap.

Currently Taiwan has the world’s third-largest com-puter industry. Still, many challenges loom. However, the stage approach of industrial technology development emphasizes the actual implementation of technology and may provide a valuable lesson for government-supported R&D institutes and industries as they seek effective tech-nology development.

References

Autio, E., Laamanen, T., 1995. Measurement and evaluation of tech-nology transfer: review of techtech-nology transfer mechanisms and indicators. Int. J. Technology Management 10 (7/8), 643–664.

Barry, B., Loveless, S., 1987. Sector, context and performance: a com-parison of industrial and government research unites. Adminis-tration and Policy 19 (2), 197–235.

Betz, F., 1993. Strategic Technology Management. McGraw-Hill, Inc., New York.

Chang, P.-L., Shih, C., Hsu, C.-W., 1993. Taiwan’s approach to tech-nological change: the case of integrated circuit design. Technology Analysis and Strategic Management 5 (2), 173–177.

Chang, P.-L., Hsu, C.-W., Lung, S.S.C., 1997. The forecast model for the technology needs of Taiwan high-tech industries, working paper. Institute of Management Science, National Chiao-Tung University. Choi, H.S., 1988. Science and Technology policies for industrialization

of developing countries. Technological Forecasting and Social Change 36, 209–215.

Devlin, G., Bleackley, M., 1988. Strategic alliance—guidelines for success. Long Range Planning 21 (5), 18–23.

Dorf, R.C., 1988. Models for technology transfer from university and research laboratories. In: Proc. 1st J. Technology Management, Interscience Enterprises, pp. 302–312.

Harvey, M.G., 1984. Application of technology life cycles to tech-nology transfer. The Jorunal of Business Strategy 5 (2), 51–58. Hayes, R.H., Wheelwright, S.C., 1988. Matching process technology

with product/market requirement. In: Tushman. M.L., Moore, W.L. (Eds.), Readings in the Management of Innovation, 2nd edn. Ball-inger, pp. 417–443.

Institute for Information Industry (III), 1997. Information Industry Yearbook, Taiwan, ROC.

International Institute for Management Development (IMD), 1997. World Competitiveness Yearbook.

Kim, L., Dahiman, C.J., 1992. Technology policy for industrialization: an integrative framework and Korea’s experience. Research Policy 21, 437–452.

Lee, C.O., 1991. Stages of economic development and technology policy: the experience of Korea. Science and Public Policy 18 (4), 219–224. Ministry of Economic Affairs, Taiwan, ROC, (MEA), 1989. Ministry of Economic Affairs, Government-Supported R&D Project Man-agement Manual.

Mogavero, L.N., Shane, R.S., 1982. Technology Transfer and Inno-vation. Marcel Dekker, New York.

Ohame, K., 1989. The global logical of strategic alliances. Harvard Business Review March–April, 143–154.

Porter, M.E., 1985. Technology and competitive strategy. In: Competi-tive Advantage: Creating and Sustaining Superior Performance, Chapter 5. Free Press, New York.

Roessner, J.D., Porter, A.L., Xu, H., 1992. National capacities to absorb and institutionalize external science and technology. Tech-nology Analysis and Strategic Management 4 (2), 99–113. Rothwell, R., Zegveld, W., 1982. Small and medium-sized

manufactur-ing enterprises and technological innovation: the role of govern-ment. In: Rothwell, R., Zegveld, W. (Eds.), Industrial Innovation and Public Policy. Frances Printer, London, pp. 176–205. Schechter, J., 1982. Technology transfer to developing countries using

an applied research and development institute. In: Mogavero, L.N., Shane, XX (Eds.), Technology Transfer and Innovation. Marcel Dekker, New York, pp. 65–70.

Shama, A., 1992. Guns to butter: technology-transfer strategies in the National Laboratories. Technology Transfer 18–24.

Sharif, M.N., 1997. Technology strategy in developing counties: evolv-ing from comparative to competitive advantage. Int. J. Technology Management 14 (2/3/4), 309–343.

Sounder, W.E., Nassor, S., 1990. Managing R&D consortia for success. Research Technology Management September–October 44–50. Spann, M.S., Adams, M., Souder, W.E., 1993. Improving federal

tech-nology commercialization: some recommendations from a field study. Technology Transfer 18 (3/4), 63–74.

Winebrake, J.J., 1992. A study of technology-transfer mechanisms for federally funded R&D. Technology Transfer 17 (4), 54–61. Yin, J.E., 1992. Technological capabilities as determinants of the

suc-cess of technology transfer project. Technological Forecasting and Social Change 42, 17–29.

Yuan, B., Wan, M.-Y., 1995. The influential factors for the effective-ness of international strategic alliances of high-tech industry in Tai-wan. Int. J. Technology Management 10(7/8).

Pao-Long Chang received a bachelor’s degree

in Mathematics in 1971 from Fu Jen University, Taiwan, and an MS degree in Mathematics in 1975 from the State University of New York at Albany. He received his Ph.D. from the Univer-sity of Washington in 1980. At present, he is a Professor at the Institute of Management Science, National Chiao Tung University. His research focuses on technology management and decision sciences. His work has been pub-lished in journals such as Journal of the

ational Research Society, Computers and Oper-ations Research, Energy Policy, Energy Systems and Policy, Journal of Environmental Management, Technology Analysis and Strategic Manage-ment, Total Quality ManageManage-ment, Technovation, International Journal of Project Management, and International Journal of Technology Manage-ment.

Chiung-Wen Hsu was born in 1959 in Taiwan.

She received a bachelor’s degree in Industrial Management from National Taiwan Institute of Technology in 1983 and an MS degree in Man-agement Science in 1985 from National Chiao Tung University. In 1985, she joined the Indus-trial Technology Research Institute’s (ITRI) Offices of Planning, where she currently works as a researcher. In 1989 she entered the Ph.D. program in Management at National Chiao Tung University. She received her Ph.D. in 1994; most of her research has been in the area of tech-nology transfers, project management, and industrial techtech-nology policy.

Chien-Tzu Tsai is a lecturer of the Department

of Industrial Engineering and Management, MingHsin Institute of Technology, Taiwan. She received a bachelor’s degree in Electronic Engineering in 1986 and an MS degree in Man-agement Science in 1989 from National Chiao Tung University, Taiwan. In 1994 she entered the Ph.D. program in Technology Management at the Institute of Management Science, National Chiao Tung University. Her research to date focuses on technology management and infor-mation management.