國 立 交 通 大 學

資訊管理研究所

碩 士 論 文

應用引文分析和社群網路分析於供應鏈管理之研究

The Study of Supply Chain Management Using

Co-citation Analysis and Social Network Analysis

研 究 生: 彭志祺

指導教授: 楊 千博士

應用引文分析和社群網路分析於供應鏈管理之研究

The Study of Supply Chain Management Using

Co-citation Analysis and Social Network Analysis

研 究 生:彭 志 祺 Student: Jhih-Ci Peng

指導教授:楊 千 Advisor: Chyan Yang

國立交通大學 資訊管理研究所

碩士論文

A Thesis

Submitted to Institute of Information Management College of Management

National Chiao Tung University in Partial Fulfillment of the Requirements

for the Degree of Master of Science

in

Information Management June 2008

Hsinchu, Taiwan, the Republic of China

I

用引文分析和社群網路分析於供應鏈管理之研究

學生: 彭志祺 指導教授: 楊千 博士

交通大學 資訊管理研究所 碩士班

中文摘要

在全球競爭環境的新時代,因為現今企業最重要的典範轉移為單一企業不在被視為 唯一性及不變性的,而是應該被視為供應鏈的體系,所以供應鏈管理在企業環境中扮演 很重要的角色,由於供應鏈管理它是相當新且廣泛的概念,很多研究者從很多學科裡分 析文獻並探討供應鏈概念是如何的演進、改變和定義。 在這一個研究中,藉由實證性分析研究,我們使用共引用分析及社群網路分析方 法,探索供應鏈管理的主題及文件兩者之間的關係,並找出最密切相關的連結,我們希 望藉由此研究的初步結果,可以幫忙專家們更容易了解供應鏈的主要趨勢、理解智慧架 構和動向,以及找出供應鏈管理和其他領域之間的關係,並且快速的找出經典文獻。 關鍵字: 供應鏈管理、共引用分析、社群網路分析II

The Study of Supply Chain Management Using Co-citation Analysis and Social

Network Analysis

Student: Jhih-Ci Peng Advisor: Dr. Chyan Yang

Institute of Information Management

National Chiao Tung University

Abstract

In this era of global competitive environment, Supply Chain Management (SCM) plays an important role in the environment of an enterprise because the most important significant paradigm shifts of modern business environment that individual business no longer consider as unique and immutable, but rather must be seen as supply chain. Due to SCM, it is a relatively new extensive concept that many researchers analyze the literature from multiple disciplines by seeing how the supply chain concept has evolved and changed and defined.

In this study, by using empirical experiment, we use co-citation method and social network analysis to discover the most closely related links between sets of subjects or documents of SCM. Based on our research results that we hope to help specialists easily realize the main trends, understand of intellectual structure and movement in the SCM and in other areas, and locate relevant papers efficiently.

III

誌謝

入寶山豈可空手而歸,在這兩年的碩士生涯中,不管在專業知識的學習上、待人接 物處事、自我省思及突破等等,都讓我有所增長,也讓我更認識自己。 首先我要感謝我的指導教授楊千老師,在自由的學術風氣下,讓我勇於嘗試不同領 域的學術研究,培養了獨立思考及解決問題的能力,在老師身上不只讓我學習到做研究 應具備的態度,從老師的身教、言教上,啟迪了我更多觀點及想法,在論文口試期間, 感謝論文口試委員劉敦仁老師與傅振華老師撥冗閱讀本論文,給予此篇論文寶貴建議與 指導,使得本研究內容更為完備,特此感謝。 感謝研究室博士班耿杰學長兩年來的照顧與指導,在論文上給了我很多寶貴的指導 意見及建議,使得內容更為充實完善,感謝實驗室的芳萍學姊、意鈞學長、建良學長、 娜娜、錦梅、士原、瑋屏、士弘與耿瑜,陪伴我這段研究生涯,並適時的給予我鼓勵與 打氣,實驗室成員的凝聚力讓我有勇氣堅持下去,並且順利完成這篇論文。 最後我要感謝我的父母及哥哥在背後的支持與鼓勵,過去種種的回憶,令我難以忘 懷,我會銘記於心,並以此論文向曾經指導、幫助或參予的朋友們獻上最誠摯的謝意。 彭志祺 謹誌 國立交通大學資訊管理研究所 中華民國九十七年六月IV

Contents

誌謝 ...III Contents ...IV List of Tables ... V List of Figures...VI 1. Introduction ... 1 1.1 Research Background ... 1 1.2 Research Purpose... 2 1.3 Research Process ... 3 2. Literature Review ... 52.1 Supply Chain Management ... 5

2.2 Conceptual Framework of SCM... 9

3. Research Methodology and Proposed Method... 13

3.1 Research Methodology ... 13

3.1.1 Bibliographic and Co-citation ... 13

3.1.2 Social Network Analysis ... 16

3.2 Proposed Method... 18 3.2.1 Objective... 18 3.2.2 Build a Matrix... 18 3.2.3 Research Method ... 20 4. Experiment Result ... 21 4.1 Data Collection ... 21 4.1.1 Selection of Documents... 21

4.1.2 Retrieval of Co-citation Data... 22

4.1.3 Central Core papers ... 22

4.2 Results and discussion ... 26

5. Conclusion and Future Works ... 38

5.1 Conclusion ... 38

5.2 Future works ... 40

V

List of Tables

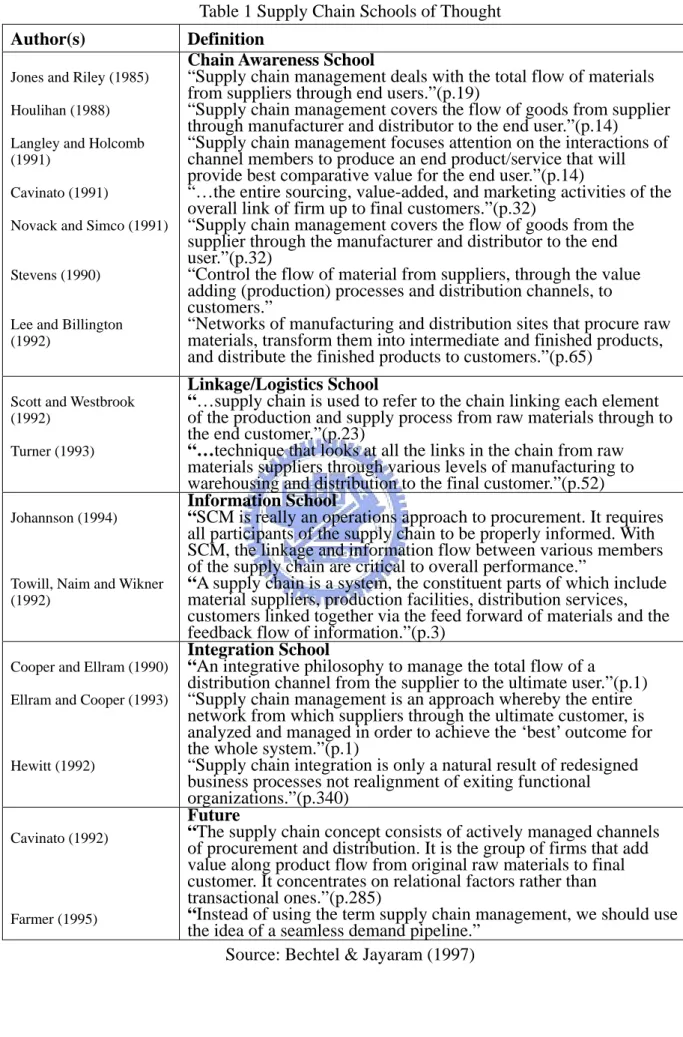

Table 1 Supply Chain Schools of Thought ... 7

Table 2 Definitions of Supply Chain Management ... 8

Table 3 Key Components of Supply chain Management ... 12

Table 4 Core paper list with assigned numbers ... 23

Table 5 Factor analysis with factor loadings at 0.40 or higher... 30

VI

List of Figures

Figure 1 Research Process... 4

Figure 2 Activities and firms in a supply chain. ... 6

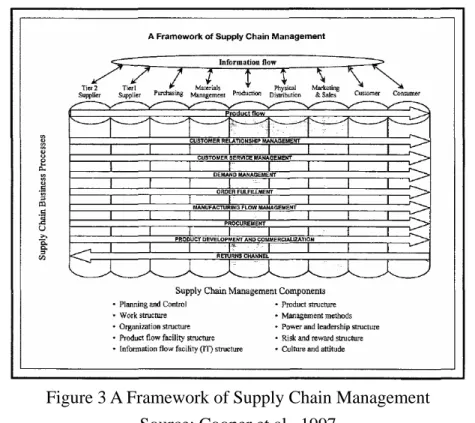

Figure 3 A Framework of Supply Chain Management... 9

Figure 4 Elements in the Framework of Supply Chain Management ... 10

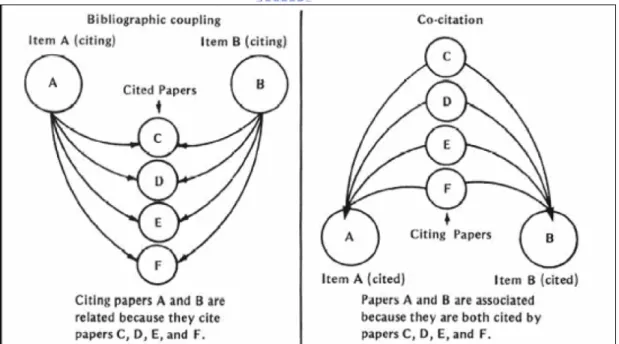

Figure 5 Bibliographic Coupling vs. Co-Citation ... 13

Figure 6 Table Schema ... 19

Figure 7 Getting co-citation number process ... 19

Figure 8 Research Method... 20

Figure 9 Papers of Social network analysis... 27

Figure 10 Principal component of Social network ... 28

Figure 11 Co-citation Matrix... 29

Figure 12 Factors of Social network ... 35

1

1. Introduction

1.1 Research Background

In this era of global competitive environment, in order to deal with competitive pressure and market globalization, firms need to develop supply chains which can quickly respond to customer service, increasing levels of service and flexibility in terms of delivery, minimize the cost, and improve communication among supply chain companies (Lancioni, Smith, & Oliva, 2000). Over the past decade, Supply Chain Management (SCM) has played an important role in the environment of an enterprise because the most important significant paradigm shifts of modern business environment is that individual business no longer consider as unique and immutable, but rather must be seen as organic and ever changing interdependent organisms. Strictly speaking, the supply chain is not a chain of businesses with one-to-one, business-to-business relationships, but a network of multiple businesses and relationships (Bechtel & Jayaram, 1997).

Due to SCM, it is a relatively new extensive concept that still lacks a clear definition. Many researchers analyze the literature from multiple disciplines by seeing how the supply chain concept has evolved and changed and defined (Bechtel & Jayaram, 1997; Croom, Romano, & Giannakis, 2000; Mentzer et al., 2001; Tan, 2001). However, at present, about SCM research works, there is still no systematic way to analyze the trends and relationships among papers, and help specialists realize the main trends, understand of intellectual structure and movement in the sciences and in other areas easily.

2

1.2 Research Purpose

The purpose of this study is to define the coupling of SCM document references cited in our research works. The analysis of the references of documents can be used to study the research fronts (Price, 1965). By using an actual example from the SCM documents, we could explore its relationship to other citation measures for identifying relationships. The more the two documents are cited together, the closer the relationship is between them, as perceived by the citing subjects, and the closer they would appear in the graphic rendering of groups of documents(White & Griffith, 1981) .

The goal of this thesis seeks to fulfill three objectives. First, we try to realize the main trends in Supply Chain Management. We apply the co-citation method to make an objective and empirical study. By using co-citation method, we can separate every sub-area in SCM topic. Second, we discuss SCM-related papers, trying to identify every sub-area and the relationships among the papers, and then recommend classic or highly influential papers in the field. We hope this work will help researchers better understand SCM issues and develop new theories and applications. Third, social network theory provides a conceptual framework and methodology for examining SCM documents group connection (Ennett & Bauman, 1993). UCINET 6.0 is a software package of social network analysis. Besides individual document network centralities provide insight into the individual’s location in the network (Orgnet.com). We use it to analyze SCM core papers in order to find out the inter-relationships among the papers.

The present study uses the SCM topic as the unit of sets documents of core papers that we collect from Google scholar search engine (http://scholar.google.com). By using an empirical experiment, we would discover the most closely related links between sets of subjects or documents of SCM.

3

1.3 Research Process

The research process (Figure 1) has six sequent steps:

1. Topic Selection: In this work, Supply Chain Management was selected as our research topic.

2. Paper Collection: Google scholar was used as our search engine tool to collect papers from the internet.

3. Social network analysis: UCINET6.0 program was carried on Social Network analysis. From the results of running social network, we would find the strong degree papers.

4. Core papers Selection: Furthermore, the papers, which we selected as core paper, must satisfy the threshold of citation number that we defined. Then, by using our program, we would build the raw co-citation frequency matrix.

5. Statistical analysis: SPSS program was carried on Factor analysis, which permitted us to derive subfields from the co-citation matrix (McCain, 1990). And, STATISCA program was carried on Multidimensional Scaling, which was a data reduction procedure that allowed us to generate a map using similarities (or dissimilarities) between objects (Wilkinson, 1998).

6. Discussion and conclusion: According step5 experiment result, we discussed the relationships between these papers and authors. Then, base on that discussion, we would draw some conclusions.

Topic Selection

4

Paper Collection

Figure 1 Research Process Core papers Selection

Social network analysis

Statistical analysis

5

2. Literature Review

2.1 Supply Chain Management

Forrester (1958) introduced a theory of distribution management that recognized the integrated nature of organizational relationships. “Management is on the verge of a major breakthrough in understanding how industrial company success depends on the interactions between the flows of information, materials, money, manpower and capital equipment. The way these five flow systems interlock to amplify one another and to cause change and fluctuation will form the basis for anticipating the effects of decisions, policies, organizational forms, and investment choices“ (Forrester, 1958).

Christopher (1999) proposes a supply chain (SC) as “SC is a network of organizations that are involved, through upstream and downstream linkages in the different processes and activities that produce value in the form of products and services in the hand of the ultimate consumer”.

It would be defined as integrated process of a supply chain, wherein a number of various business entities such as suppliers, manufacturers, distributors, and retailers…. They work together in an effort to (1) acquire raw materials, (2) extract raw materials or minerals from the earth, through the manufacturers, wholesalers, retailers, and the end user (see Figure 1), and (3) deliver these final products to retailers. Traditionally, this supply chain can be characterized by a forward flow of materials and a backward flow of information (Beamon, 1998; New & Payne, 1995).

Figure 2 Activities and firms in a supply chain. Source: New & Payne (1995)

The term “Supply Chain Management (SCM)”, which makes it began in 1982, is relative new in the literature. It is defined as “an integrative philosophy to manage the total flow of a distribution channel from the supplier to the ultimate user” (Oliver & Webber, 1992), and is an entire process that must be viewed as one system (Lummus & Vokurka, 1999). Many researchers analyze the literature from multiple disciplines and try to define the supply chain management such as Bechtel & Jayaram (1997) emerges Supply Chain Schools of Thought (see Table 1), and Mentzer et al. (2001) classify three categories: a management philosophy, implementation of a management philosophy, and a set of management processes (see Table 2). Besides, the Global Supply Chain Forum (ref. GSCF) defines the SCM as “Supply chain management is the integration of key business processes from end user through original suppliers that provides products, services, and information that adds value for customers and other stakeholders”.

7

Table 1 Supply Chain Schools of Thought

Author(s) Definition

Jones and Riley (1985) Houlihan (1988) Langley and Holcomb (1991)

Cavinato (1991)

Novack and Simco (1991)

Stevens (1990)

Lee and Billington (1992)

Chain Awareness School

“Supply chain management deals with the total flow of materials from suppliers through end users.”(p.19)

“Supply chain management covers the flow of goods from supplier through manufacturer and distributor to the end user.”(p.14)

“Supply chain management focuses attention on the interactions of channel members to produce an end product/service that will provide best comparative value for the end user.”(p.14)

“…the entire sourcing, value-added, and marketing activities of the overall link of firm up to final customers.”(p.32)

“Supply chain management covers the flow of goods from the supplier through the manufacturer and distributor to the end user.”(p.32)

“Control the flow of material from suppliers, through the value adding (production) processes and distribution channels, to customers.”

“Networks of manufacturing and distribution sites that procure raw materials, transform them into intermediate and finished products, and distribute the finished products to customers.”(p.65)

Scott and Westbrook (1992)

Turner (1993)

Linkage/Logistics School

“…supply chain is used to refer to the chain linking each element

of the production and supply process from raw materials through to the end customer.”(p.23)

“…technique that looks at all the links in the chain from raw

materials suppliers through various levels of manufacturing to warehousing and distribution to the final customer.”(p.52)

Johannson (1994)

Towill, Naim and Wikner (1992)

Information School

“SCM is really an operations approach to procurement. It requires

all participants of the supply chain to be properly informed. With SCM, the linkage and information flow between various members of the supply chain are critical to overall performance.”

“A supply chain is a system, the constituent parts of which include

material suppliers, production facilities, distribution services, customers linked together via the feed forward of materials and the feedback flow of information.”(p.3)

Cooper and Ellram (1990) Ellram and Cooper (1993)

Hewitt (1992)

Integration School

“An integrative philosophy to manage the total flow of a

distribution channel from the supplier to the ultimate user.”(p.1) “Supply chain management is an approach whereby the entire network from which suppliers through the ultimate customer, is analyzed and managed in order to achieve the ‘best’ outcome for the whole system.”(p.1)

“Supply chain integration is only a natural result of redesigned business processes not realignment of exiting functional organizations.”(p.340)

Cavinato (1992)

Farmer (1995)

Future

“The supply chain concept consists of actively managed channels

of procurement and distribution. It is the group of firms that add value along product flow from original raw materials to final customer. It concentrates on relational factors rather than transactional ones.”(p.285)

“Instead of using the term supply chain management, we should use

the idea of a seamless demand pipeline.” Source: Bechtel & Jayaram (1997)

Table 2 Definitions of Supply Chain Management

Monczka, Trent, and Handfield (1998)

SCM requires traditionally separate materials functions to report to an executive responsible for coordinating the entire materials process, and also requires joint relationships with suppliers across multiple tiers. SCM is a concept, “whose primary objective is to integrate and manage the sourcing, flow, and control of materials using a total systems perspective across multiple functions and multiple tiers of suppliers.”

La Londe and Masters (1994)

Supply chain strategy includes:”… two or more firms in a supply chain entering into a long-term agreement; … the development of trust and commitment to the relationship; … the integration of logistics activities involving the sharing of demand and sales data; … the potential for a shift in the locus of control of the logistics process.”

Stevens (1989) “The objective of managing the supply chain is to synchronize the requirements of the customer with the flow of materials from suppliers in order to effect a balance between what are often seen as conflicting goals of high customer service, low inventory management, and low unit cost.”

Houlihan (1988) Differences between supply chain management and classical materials and manufacturing control: (1) The supply chain is viewed as a single process. Responsibility for the various segments in the chain is not fragmented and relegated to functional areas such as manufacturing, purchasing, distribution, and sales. (2) Supply chain management calls for, and in the end depends on, strategic decision making. “Supply” is a shared objective of practically every function in the chain and is of particular strategic significance because of its impact on overall costs and market share. (3) Supply chain management calls for a different perspective on inventories which are used as a balancing mechanism of last, not first, resort. (4) A new approach to systems is required-integration rather than interfacing.”

Jones and Riley (1985)

“Supply chain management deals with the total flow of materials from suppliers through end users…”

Cooper et al. (1997)

Supply chain management is “… an integrative philosophy to manage the total flow of distribution channel from supplier to the ultimate user.”

Source: Mentzer et al. (2001)

2.2 Conceptual Framework of SCM

Cooper et al. (1997) depicts a simplified supply chain network structure, the information and product flows. Each firm in the supply chain will have its own set of functional silos that must be related to each key supply chain process (see Figure 3). As described in Figure3, the Global Supply Chain Forum (ref. GSCF) identifies eight key processes that make up the core of supply chain management: (1) Customer Relationship Management, (2) Customer Service Management, (3) Demand Management, (4) Order Fulfillment, (5) Manufacturing Flow Management, (6) Procurement, (7) Product Development and Commercialization and (8) Returns.

Figure 3 A Framework of Supply Chain Management Source: Cooper et al., 1997

Cooper et al. (1997) proposed a conceptual SCM framework, which encompasses three major and closely inter-related elements, which are business process, management components, and supply chain structure (Figure 3). (1) Business processes are the activities that produce a specific output of value to the customer. (2) The management components are the managerial variables by which the business processes are integrated and managed across the supply chain. (3) The supply chain structure is the network of members and the links

between members of the supply chain. They believe that these common management components play critical and fundamental roles for successful SCM because management components are to be integrated and managed for each process link (Cooper, Lambert, & Pagh, 1997; Lambert, Cooper, & Pagh, 1998).

Business Process

Supply Chain Management

10

Figure 4 Elements in the Framework of Supply Chain Management Source: Cooper et al., 1997

Cooper et al. (1997) presents components suggested in the supply chain literature (see Table 3), and these components span a range from strategic to operational, physical flow to information flow, tangible structures to organizational structures and cultures. From the conceptual framework of SCM, we find some part researchers who research in strategic perspective of SCM such as Tan (2001) merges the modern ear strategic approach to operations, materials, and logistics management, and the researchers discuss the role of “lean” (Leanness means developing a value stream to eliminate all waste, including time, and to enable a level schedule) and “agile” (Agility means using market knowledge and a virtual corporation to exploit profitable opportunities in a volatile marketplace) that how to create cost-effective supply chains (Christopher & Towill, 2001; Naylor, Naim, & Berry, 1999)

Supply Chain Structure Management

11

Lee et al. (1997), (2004) they analyze and discuss four sources of the bullwhip effect in supply chain management: (1) demand signal processing, (2) rationing game, (3) order batching, and (4) price variations.

Gunasekaran et al. (2001) develop a framework for measuring the strategic, tactical and operational level performance in a supply chain.

Ballou et al. (2000) focus on the problems in managing inter-organizationally, and Davis (1993) presents the methodology to manage the supply chains more successfully.

The present paper analyzes the theory’s heterogeneity by using co-citation and social network to identify the sub-areas of SCM fields.

Table 3 Key Components of Supply chain Management

12

A Supply Chain Management Perspective

A Business Process Reengineering Perspective

Houlihan (1985):

z Planning and control structure z Product flow facility structure z Information flow(IT-structure) z Values and attitudes

z Organizational culture z Management methods Stevens (1989)

z Process (work) structure z Planning and control structure z Product flow facility structure z Information flow (IT-structure) z Organization structure

z Management methods

z Power and leadership structure Cooper & Ellram (1990 & 1993): z Process (work) structure z Planning and control structure z Product flow facility structure z Information flow (IT-structure) z Risk and reward structure z Leadership structure z Corporate philosophies

Hammer & Champy(1993): z Process (work) structure z Organization (job) structure z Values and attitudes

z Management and evaluation structure

Andrews & Stalick(1993): z Process (work) structure z Organization structure z Technology structure z Reward structure z Measurement system z Management methods z Organizational culture z Political power

z Individual belief systems Hewitt (1994):

z Process (work) structure z Information flow (IT-structure) z Decision authority

MIT-model by Towers (1994): z Process (work) structure

z Organization and skill structure z Technology structure

z Values and behavior

z Management philosophies and decision structure

3. Research Methodology and Proposed Method

3.1 Research Methodology

3.1.1 Bibliographic and Co-citation

Figure 4 shows the essential different methodologies between Bibliographic coupling and Co-citation. When different authors cite one or more papers in common, papers are classified as bibliographically coupling. On the other hand, co-citation analysis is based primarily on identifying pairs of highly-cited papers. Bibliographic coupling, which is retrospective, is a fixed and permanent relationship, whereas co-citation, which is essentially a forward-looking perspective, changes as the interests and intellectual patterns of the field change (Garfield, 2001; Small, 1973).

Figure 5 Bibliographic Coupling vs. Co-Citation Source: Garfield E, 2001

Bibliographic Co-citation, which is a popular similarity measure used to establish a subject similarity between two items, has been used by a variety of researchers to establish relationships among documents. If item A and B of earlier literature are both cited by later literature, they could be said to be related to one another, even though they do not directly

14

refer to each other. If item A and B are both cited by many other items, then they would have a stronger relationship. The more items they are cited, the stronger relationship between them (Martins B. Class Co-citation).

The Co-citation method is defined as the frequency with which two documents or authors are cited together by the later literature in the same work. The aim of the Co-citation is to identify groups of closely related documents which can be considered as belonging to the same “research front” (Small, 1973). The co-citation is an objective, powerful and widely used methodology to study the structure of scientific disciplines and main trends for the researchers. In general, two items are considered as being co-citation when they appear together in the same reference list of a subsequent article (Zhao, 2006).

Author co-citation analysis (ACA), which moved the unit of analysis from co-cited documents to co-cited oeuvres, began at Drexel University in 1979. Oeuvres that called by French is a body of writing by a personal, and not the person himself (Dictionary). Based on co-citation frequencies of association between authors, ACA could be able to reveal pattern. It makes a prospective methodology for understanding the evolution of an academic discipline (White & McCain, 1998). To analyze the intellectual structure of science studies that ACA has been widely used in bibliometric technique as an analytical method. It is also used by researchers to investigate various phenomena, apply to identify authors from the same or similar research fields (He & Cheung Hui, 2002). To use ACA methodology, many researchers have already addressed the development (Culnan, 1986; He & Cheung Hui, 2002; White, 1990, 2003a, 2003b). It might contribute to the understanding of intellectual structure in the sciences and possibly in other areas to the extent that those areas rely on serial publications (White & Griffith, 1981).

15

In order to study the intellectual structure of this research field and infer to some characteristics of the corresponding scientific community, ACA researchers can use co-citation counts as similarity measures, which represent the proximity between authors. When we get the result of co-citation between authors, we can obtain the Pearson correlation, and use multivariate techniques and multidimensional scaling to analyze the data (White & Griffith, 1981; White & McCain, 1998).

In our study, there are two reasons for using a bibliometrical method: the first is to present a complete picture of the theory, and the second is to be objective, and then we can adopt the co-citation methodology to carry on empirical analysis of Supply Chain Management.

16

3.1.2 Social Network Analysis

A social network is a collection of people, each of whom is acquainted with some subset of the others. Such a network can be represented as a set of points (or vertices) denoting people, joined in pairs by lines (or edges) denoting acquaintance (Newman, 2001).Social network analysis (SNA) seeks to examine relationships ranging from single user, two-person ties, and small groups to the entire community network. Social network analysis approach can help to uncover the roles and importance of members in a community to understand the nature of a social network (Garton, Haythornthwaite, & Wellman, 1997).

A lot of work with social networks is primarily descriptive and/or exploratory, rather than confirmatory hypothesis testing. SNA focuses on using quantitative measurement to study the interaction among the members to profile the structure of the community and its members (Hanneman, 2001). Social network researchers measure network activity for a node by using the concept of degree where how many direct links between two or more nodes. The relationship between the centralities of all nodes can reveal much about the overall network structure (Orgnet.com). The definition of hub is a node in a graph with a high degree. Sometimes a node is connected to every other node in the graph. K-core is used to identify the strong ties in a network or community, and it is a set of nodes in a graph that each node in the set is connected to at least k other nodes in the set (ref. Graph theory). The more ties an actor has then, the more power they (may) have (Swan, 2001).

Social networks have been the subject of both empirical and theoretical study in the social sciences for at least 50 years. Stanley Milgram conducted a famous early empirical study of the structure of social networks (Newman, 2001). At present, social network analysts use two kinds of tools from mathematics to represent information about patterns of ties among social actors: graphs and matrices. It usually provides both a visual and a mathematical analysis of human relationships.

17

The theory of SNA emphasizes patterns of relationships among individuals and interprets the behavior of individuals in reference to their positions within social networks. A primary task of social network analysis is to use the international patterns among individuals to identify clusters or cliques within a network of individuals (Ennett & Bauman, 1993). A sub-graph that forms a clique is considered interesting because the high interconnectedness of the nodes suggests that the sub-graph forms an important structure.

18

3.2 Proposed Method

3.2.1 Objective

To address the issue of finding the core papers and sub-areas of the SCM, the data analysis was carried out by means of an exploratory factory analysis approach as this was customary in statistics. The quantitative data analysis was performed. Therefore, the social network analysis, factor analysis and multidimensional scaling were to do an empirical experiment. First, social network analysis was used to provide information about the interconnectedness of the papers due to the structure of the whole graph. In social network, an important focus is on the analysis of local structures to determine important actors and groups in the network (ref. Graph theory). Second, according to the first step result, we selected the core papers whose cited number is larger than 50 times to build a Co-citation matrix. Factors analysis which describes the internal structure of the covariance and correlation matrices concerned permits us to derive subfields from the co-citation matrix. It seeks to study correlations among a number of interrelated variables and to group them into a few highly descriptive factors (Lawley & Maxwell, 1962). Lastly, Multidimensional scaling (MDS), which is a data reduction procedure, would allow us to visualize the conceptual distance between various intellectual strands of research.

3.2.2 Build a Matrix

We selected core papers and assigned numbers to identify each of them. Then, in order to process data of papers, we created two database tables as in Figure Chien-Liang, 2007). The first one was “citation” table in which contained three attributes: (1) “Serial”, which was the primary key, represented the serial numbers of the supply chain management core papers; (2) “paperserial”, cited one of the core papers, and represented the serial numbers of papers; (3) “subserial”, which had value the same as “Serial”. And, the second one was “subpapers” table which contained two attributes: (1) “Serial” attribute, which was a foreign key of

“citation” table, represented a serial number of papers which cited core papers. (2) “Data” attribute stored the metadata about papers in the “citation” table.

19

Source: Chien-Liang Chen, 2007

For example, we had two core papers, P1, P2 and two groups of citing papers which cited P1 and P2, respectively

Figure 6 Table Schema

. In order to find identical citing papers between two groups, we followed the steps described in Figure 7. First, we set the value of co-citation number to zero. Then for each identical citing paper found, we increased co-citation number by one. Finally, we would get the result of co-citation number.

Figure 7 Getting co-citation number process End loop no yes P1 P2 Cite P1 papers (loop) Find r identical pape Cite P2 papers Plus 1 to the co-citation number Get R Citation Subpapers Serial Serial Data paperserial subserial esult

20

3.2.3 Research Metho

The research method of this study is described in Figure 8. The steps of co-citation methodology is followed by White and Griffith in their published paper (White & Griffith, 1981), then we use social network analysis to find the core papers of SCM.

Figure 8 Research Method

d

Threshold >=50

Google Scholar

Paper Collection (Core papers Selection)

Co-Citation Matrix Experiment result Papers are not enough SCM Research Topic UCINET6.0 Social network STATISTICA (MDS) SPSS Factor Analysis Correlation matrix 1. Rotated varimax

2. Total variance Explained 1. K-core (Clique)

21

4. Experiment Result

uthors of papers

urce documents in Google scholar altogether to bers of these

papers were between 10 to 1308 times. In order to cover all the development within SCM field and to find the core papers of SCM, there are no strict and fast rules, but the subjectivity inherence in the selection of SCM docum nts should be limited on their significant

contributions to the field. We selected all pape CM, and collected as

ny as core papers as possible.

4.1.1 Selection of Documents

In this study by running social network analysis latter, a list of 48 papers (see Table 4, involved three books, which were [v37] [v38] [v39]) was determined to be the core papers in our dataset and others were eliminated. Then, we found out the 48 source articles which had a total of 14478 citations, and the number of citati s between 50 to 1308 times in Google scholar. All of data (number f citations per paper) were downloaded from

Google Scholar on May 10th, 2008. Th mpirical study involved 48 core

papers. In order to cover all the developments m a

core as large as possible and selected core data of a theory or discipline is a critical stage in

The list of SCM documents’ result is shown in T itle” means the paper ame, the “Count of Citation” means how many papers have already cited itself and the “No.” is just the variable name for our rese

4.1 Data Collection

Data were collected primarily by means of a cited number, year and a

from the Google scholar search engine (http://scholar.google.com). We had collected 178

so be our dataset. The cited num

e

rs which had related to S ma

ons of these papers wa o

e research on an e

within the theory, our objective was to for

the process.

able 4. The “T n

22

4.1.2 Retrieval of Co-cit

The citation counts of

hain” or “Supply Chain Management” as the keyword/subject to deter

4.1.3 Central Core papers

documents during the factor ng.

ation Data

SCM documents were collected from the Google scholar search engine. We used “Supply C

mine which documents were the most cited fellows. It was difficulty to determine a core paper dataset. Once this core set of SCM documents was identified, it was necessary to limit search terms to avoid retrieving misty subjects.

The core papers allow a delimitation of the area under study on the basis that a scientific paper can be included when it cites one or more such source papers (Acedo, Barroso, & Galan, 2006). The most widely used criterion is the number of cites of papers, therefore, we take the most significant works representing the study field to be the core

analysis and multidimensional scali

In this study, because of SCM being a field over the past decades, so we primarily collected data by means of a cited number, year and authors of papers. Some part core papers belong to Science Citation Index (SCI) or Social Sciences Citation Index (SSCI). The core papers represent assemblies’ documents which share SCM subject, theory, or common methodology and describe current investigation. In addition, by using co-citation method, the more coherent and integrated discipline or sub-areas of SCM is the more scientific community determined.

23

r list with assigned numbers

No.

citations (2007)

Table 4 Core pape

Title Count of Impact Factor

v01 Supply Chain Management: A Strategic Perspective (Bechtel & Jayaram, 239 -- 1997)

v02 Supply Chain Management: More Than a New Name for Logistics 531 --

v03 Supply Chain Redesign (Hewitt, 1994) 76 --

v04 Characteristics of Supply Chain Management and Purchasing and Logistics Strategy (Cooper & Ellram (Cooper et al., 1997)

the Implications for

, 1993) 259 --

Supply Chain Management : Implementation Issues and Research

er, 2000) 387 --

v06

e Supply Chain: The Impact of n (Chen, Drezner, Ryan, & Simchi-Levi, 2000)

468 1.931

v11

An empirical investigation into supply chain management: A perspective

of Information Sharing in a Two-Level Supply Chain (Lee, So,

0) 438 1.931

v18 Supply chain partnerships: Opportunities for operations research (Maloni

& Benton, 1997) 234 1.096

v19 The four roles of supply chain management in construction (Vrijhoef &

Koskela, 2000) 106 --

v20 Supply chain postponement and speculation strategies: How to choose the

right strategy (Pagh & Cooper, 1998) 152 --

v21 Performance measures and metrics in a supply chain environment

(Gunasekaran, Patel, & Tirtiroglu, 2001) 227 1.054 v22 The Agile Supply Chain Competing in Volatile Markets (Christopher,

2000) 233 0.911

v05

Opportunities (Lambert & Coop

Issues in Supply Chain Management (Lambert & Cooper, 2000) 443 0.911 v07 The Role of the Internet in Supply Chain Management(Lancioni et al.,

2000) 172 0.911

v08 The Bullwhip Effect in Supply Chains (Lee, Padmanabhan, & Whang,

1997) 934 0.849

v09 Information Distortion in a Supply Chain: The Bullwhip Effect (Lee,

Padmanabhan, & Whang, 2004) 1308 1.931

v10

Quantifying the Bullwhip Effect in a Simpl Forecasting, Lead Times, and Informatio

Supply chain design and analysis: Models and methods (Beamon, 1998) 380 0.995 v12

on partnerships (Spekman, Kamauff Jr, & Myhr, 1998) 237 -- v13 Defining supply chain management (Mentzer et al., 2001) 249 --

v14 A framework of supply chain management literature (Tan, 2001) 200 -- v15 Defining supply chain management: a historical perspective and practical

guidelines (Lummus & Vokurka, 1999) 132 --

v16 Supply Chain Inventory Management and the Value of Shared Information

(Cachon & Fisher, 2000) 448 1.931

v17 The Value & Tang, 200

24

No. Title Count of Impact Factor citations (2007)

v23 An integrated model for the design of agile supply chains (Christopher &

Towill, 2001) 121 --

v24 etoric and reality of supply chain integration (Fawcett & Magnan, 86 -- v25 will revolutionize supply chain logistics (Bowersox, 113 --

0.911 1.435

Supply chain management in theory and practice: a passing fad or a

v32 96 --

v33 management processes (Croxton, Garcia-Dastugue, 76 -- v34 427 0.849

v35 Squaring lean supply with supply chain management (Lamming, 1996) 142 1.054

v36 Supply-Chain Management: The Industrial Organisation Perspective 192 -- v37 WHAT IS THE RIGHT SUPPLY CHAIN FOR YOUR PRODUCT? 905 --

v38 nt: Strategies for Reducing Cost 670 --

v39 616 --

v40 anagement: an analytical framework for critical literature 220 -- v41 nagement: Relationships, Chains and Networks (Harland, 282 1.534

v42 408 --

v43 gration on operating performance 54 --

v44 277 --

v45 chain migration from lean and functional to agile and customized

(Christopher & Towill, 2000) 148 0.913

The rh 2002)

Ten mega-trends that Closs, & Stank, 2000)

v26 New Managerial Challenges from Supply Chain Opportunities (Ballou,

Gilbert, & Mukherjee, 2000) 122

v27 Special research focus on supply chain linkages: Challenges for design and

management in the 21st century (Mabert & Venkataramanan, 1998) 113 v28

fundamental change? (Chandra & Kumar, 2000) 81 --

v29 Causal linkages in supply chain management: An exploratory study of

North American manufacturing firms (Narasimhan & Jayaram, 1998) 111 1.435 v30 Power, value and supply chain management (Cox, 1999) 129 0.913

v31 Leagility: Integrating the lean and agile manufacturing paradigms in the

total supply chain (Naylor et al., 1999) 249 0.995 A Total Cost/Value Model for Supply Chain Competitiveness (Cavinato,

1992)

The supply chain Lambert, & Rogers, 2001)

Effective supply chain management (Davis, 1993)

(Ellram, 1991) (Fisher, 2003)

Logistics and Supply Chain Manageme and Improving Service (Christopher, 1999)

Introduction to supply chain management (Handfield & Nichols, 1999) Supply chain m

review (Croom et al., 2000) Supply Chain Ma

1996)

Integrating the supply chain (Stevens, 1989) The impact of supply chain inte (Armistead & Mapes, 1993)

International supply chain management (Houlihan, 1985) Supply

25

( No. Title Count of

citations

Impact Factor 2007)

v46 Supply chain management and advanced planning––basics, overview and

challenges (Stadtler, 2005) 71 1.096

v47 Information sharing in a supply chain (Lee & Whang, 2000) 323 0.356

) 2.054 v48 The nature of interfirm partnering in supply chain management (Mentzer,

26

Results and discussio

of ial netw sing

pa lar "ego e) is "embedded" (connected to) its "neighborhood" (the actors that are connected to ego, and their connections to one another) and to the larger graph (Hanneman, 2001).

To illustrate, figure 9 depicts the papers of k-core analysis of social network. Subgroup can be identified by the measurements of component. So we can focus on the subgroup and the number of citations of papers. To use K-core function of UCINET 6.0 program would run to form the different color subgroup of social community.

On the left side, paper number 54, 74, 95, 157, 170 and 178 have no relationship with other members of the social network community. Other papers form the social network community of SCM. We could regard the strong relationship of papers which are inside the blue round shape as the hub.

4.2

n

UCINET 6.0 is a good helpful tool to deal with the complexity soc ork. U colors and shapes is a useful ways to convey information about what “type” of actor each node is. A good drawing can also help us to better understand how a rticu " (nod

Figure 9 Papers of Social network analysis

28

UCINET 6.0 can use a node shape to deal with the complexity of social network. By using UCINET 6.0, we could find out the part in which each node has cited number larger than 50 times. As described in Figure 10, 48 nodes were surrounded by a blue round.

From the 48 core papers above, we built a ro (see Figure 11). Then,

we transformed the co-citation matrix in atrix. However, we could

not find the weak relationships among papers.

w co-citation Matrix to a Pearson correlation m

Figure 11 Co-citation Matrix

Table 5 shows the results of the factorial analysis with varimax rotation which has the advantage of showing the loads on more than one factor and expresses the importance of the variables loading on a given factor. We rank the factor loadings on papers with a 0.40 minimum cutoff point. Six factors are extracted, and they explain 74.464% of total variance. The first factor accounts for 43.404% of the variance and the second for 10.583%. The other results are 9.008% (factor 3), 5.735% (factor 4), 2.931% (factor 5) and 2.803% (factor 6).

29 29

30

Table 5 Factor analysis with factor loadings at 0.40 or higher

No. Authors Year Factor

1 Factor 2 Factor 3 Factor 4 Factor 5 Factor 6 v 13 Mentzer et al. 2001 .900

v 04 Cooper & Ellram 1992 .897 v 01 Bechtel & Jayaram 1997 .883

v 36 Ellram 1991 .867

v 03 Hewitt 1994 .866

v 39 Handfield & Nichols 1999 .850 v 05 Lambert & Cooper 2000 .842

v 32 Cavinato 1992 .839

v 12 Spekman, Kamauff Jr, & Myhr 1998 .838 v 33 Croxton,Garcia-Dastugue, Lambert, &

Rogers 2001 .836

v 06 Lambert & Cooper 2000 .835 v 26 Ballou, Gilbert, & Mukherjee 2000 .829

v 14 Tan 2001 .817

v 15 Lummus & Vokurka 1999 .806

v 38 Christopher 1999 .778

v 27 Mabert & Venkataramanan 1998 .760

v 07 Lancioni et al. 2000 .753

v 02 Cooper, Lambert, & Pagh 1997 .724

v 11 Beamon 1998 .705 .401

v 19 Vrijhoef & Koskela 2000 .700

v 21 Gunasekaran, Patel, & Tirtiroglu 2001 .696 .426

v 35 Lamming 1996 .688

v 28 Chandra & Kumar 2000 .680

v 24 Fawcett & Magnan 2002 .680 .460

v 34 Davis 1993 .636 .456

v 29 Narasimhan & Jayaram 1998 .625

v 25 Bowersox, Closs, & Stank 2000 .554

v 30 Cox 1999 .534 .444

v 10 Chen, Drezner, Ryan, & Sim .879

v 17 Lee, So, & Tang 3

v 1

v 08 Lee, Padmanabhan, & Whang 1997 .793

v 47 Lee & Whang 2000 .632 .427

v 43 Armistead & Mapes 1993 .733

v 4 Christopher & Towill 2000 .530 .678 v 40 Croom, Romano, & Giannakis 2000 .608

v 46 Stadtler 2005 .601

chi-Levi 2000

2000 .84

6 Cachon & Fisher 2000 .840

v 09 Lee, Padmanabhan, & Whang 2004 .730

v 18 Maloni & Benton 1997 .511 .575

v 20 Pagh & Cooper 1998 .856

v 23 Christopher & Towill 2001 .826

v 31 Naylor, Naim, & Berry 1999 .814

v 22 Christopher 2000 .764

v 44 Houlihan 1985 .884

v 48 Mentzer, Min, & Zacharia 2000 .868 5

31 v 42 Stevens .880 v 41 Harland 37 Fisher . 1989 1996 2003 .441 .771 v .462 667

In T , Factor 1 is the best primary factor, and the factor name is “Effective managed fra o pective of SCM”. It includes 28 core papers. Many kinds of topics are covered in this factor. 28 core papers are divided to five groups.

e des papers [v13], [v15] and [v39], and it introduces and defines the

su c

e rs [v1], [v4], [v14], [v30], [v33] and [v37] (overlaps in the

Fa 6 perspective as C er & Ellram (1993) [v4] focus on

purchasing and logistics strategy, Tan (2001) reviews the literature to mer e the modern ear of

a i opera , ma and logistics ma ent, and

Croxton et al. (2001) [v33] provide strategic and operational descriptions of ea h of the eight supply chain processes.

e d group of papers [v2], [v5], [v6], [v11], [v18] (overlaps in the Factor 2), [v26], [v27], [v28], [v32] and [v35] proposes the concept, theory, model, and guidance for business

lea e issues to m ke a decision

an nage the SCM well.

e apers [v3], [v7], [v21], [v25] and [v34] focus on the effective and

eff c ewitt (1994) [v3] propo pply chain redesign pro e the process

eff c ness. Lancioni et al. (2000) [v7] discuss how the internet is

be s major components of supply chains. Bowersox et al. (2000) [v21]

indicate the ten mega-trends which would ly substantial change in logistics practices able 5

mew rk & strategic pers

Th first group inclu pply hain management.

Th second group of pape

ctor ) focuses on strategic such oop

g

holist c and strategic approach to tions terials, nagem

c

Th thir

ders and managers to overcom of challenges, and hope them a d ma

Th fourth group of p

icien y issues. H ses su to im v

icien y and process effective ing u ed in managing the

32

am s hain partners as they strug o establish efficient, effective, and relevant product/service solutions for end-customer. Gunasekaran et al. (2001) [v21] and Davis (1993) [v34] address the performance measures in supply chain.

do not share a common voice and have moved slowly to bridge the gaps that separate them. Vrijhoef & Koskela (2000) [v19

ir proposed conceptual framework to investigate the key causal linkages in SCM by using structural equation modeling techniques.

effect in a supply chain. Chen et al. (2000) [v10] propose two factors which are demand forecasting and order lead time in their model, and assume them to cause the bullwhip effect. And they demonstrate that the bullwhip effect can be reduced, but not completely eliminated. Information system technology can now work a tight coordination between supply chain partners. The researches of [v16], [v17], [v18] and [v47] are all about information sharing. Information technique, such as Electronic Data Interchange (EDI) and Vend

ong upply c gle t

Other group of papers [v12], [v19], [v24] and [v29] is about empirical analysis. For instance, Spekman et al. (1998) [v12] indicate that buyers and sellers

] identify that SCM has four specific roles in construction, and Narasimhan & Jayaram(1998) [v29] test the

The Factor 2 “Information sharing issue in SCM” covers 7 papers [v8], [v9], [v10] [v16], [v17], [v18] and [v47], and another paper [v11] (locates in the Factor 2). The big reason for causing “bullwhip effect” is information distortion. The issue is related to bullwhip effect papers which are [v8], [v9], and [v10] papers. Lee et al. (1997) [v8], (2004) [v9] discuss the phenomenon of bullwhip

or-Managed-Inventory (VMI), plays an important role in SCM for sharing information. Cachon & Fisher (2000) [v16] hope to improve increasing delivery frequency by reducing shipment batch sizes, and Lee et al. (2000) [v17] hope to provide significant inventory reduction and cost savings to the manufacturer, Beamon (1998) [v11] provides a focused review of literature in multi-stage supply chain modeling, and it addresses the demand

33

v20], [v22], [v23] and [v31] papers, and other papers [v21], [v24], [v30] and [v34] which is primarily located in the Facto

ding supply chains from a strategic as well as from an operational perspective. Papers [v21] and [v34] propose a framework for m

distortion and variance amplification issues of supply chain modeling.

The Factor 3 “Agile and lean SCM’s strategies” includes [

r1. Pagh & Cooper (1998) [20] identify a framework for selecting postponement and speculation strategies to achieve delivery of products in a timely and cost-effective manner. Christopher (2000) [v22] suggests that the key to survive in these changed conditions is through “agility”, in particular, by the creation of responsive supply chains. Christopher et al. (2001) [v23] and Naylor et al. (1999) [v31] indicate the role of “lean” and “agile” into supply chains. Cox (1999) [v30] indicates a case which makes for understan

easuring the performance of supply chain management. Christopher & Towill (2000) [v45] propose a cyclic migratory model which describes the PC supply chain attributes during its evolution from traditional to its present customized “leagile” operation. As have described from above statements, according to the business adopting different strategic of SCM would result different performance for managing the supply chain management.

The Factor 4 “Integrated evolution of SCM” owns 6 papers which are [v40], [v43], [v44], [v45], [v46] and [v48]. Croom et al. (2000) [v40] recognize that developments in SCM require multi-disciplinarity. Armistead & Mapes (1993) [v43] investigate the contribution of new manufacturing techniques and approaches to increase integration across the value chain on manufacturing performance. Houlihan (1985) [44] describes the approaches how to manage change in international chains. Christopher & Towill (2000) [v45] encourage “supply chain migration from lean and functional to agile and customized”. Stadtler (2005)[v46] points out interdisciplinary research incorporating computer science, accounting and

34

solution capabilities. Mentzer et al. (2000) [48] provides an inclusive “partnering” phenomenon with the environm

y of functional products and responsive supply of innovative product).

organizational theory, etc., for their great progress in modeling and

ental pressures, antecedents, orientation and consequences of strategic and operational partnering for vertical relationships within retail supply chains.

The Factor 5 “Collaborative Supply Chain” involves papers: [v41] and [v42], and paper [v47] which locates in the Factor 2. Harland (1996) [v41] summarizes the system approach that how to manage relationships, chains and networks in SCM. Stevens (1989)[v42] points out involving some degree of collaboration to solve bottlenecks in the supply chain, and overcome bumps in demand or supply. Lee & Whang (2000) [v47] describe the types of information shared because it is a basic enabler for supply chain partners to work in tight coordination.

Finally, the Factor 6 is “Choosing right supply chain”. Fisher (2003) [v37] indicates the cause of plaguing problems, which many supply chains is a mismatch between the type of product (they are either primarily functional or primarily innovative) and the type of supply chain (they are efficient suppl

35

or 4 has paper [v40], Factor 5 has papers [v41] and [v42], and Factor 6 has paper [v37].

Table 6 Factor Topics

In Figure 12, by using social network analysis, we could group each factor inside a blue round shape. In total 178 papers, we measure the importance of each paper in the social network by using degree criterion, then for each factor encloses the papers whose degree is larger than or equal to 70 inside a green circle. We consider them maybe play important roles in the SCM. Factor 1 has papers [v2], [v5], [v6], [v12], [v13], [v14], [v38] and [v39]. Factor 2 has papers [v8] and [v9], Fact

Figure 12 Factors of Social network Factor 1: Effective managed framework & strategic

perspective of SCM

Factor 2: Information sharing issues in SCM Factor 3: Agile and lean SCM’s strategies Factor 4: Integrated evolution of SCM Factor 5: Collaborative Supply Chain Factor 6: Choosing right supply chain

Factor 1 Factor 6 Factor 3 Factor 5 Factor 4 Factor 2

36

After comparing the results of Figure 12 and Figure 13, we found that the papers [v2], [v5], [v6], [v8], [v9], [v13], [v14], [v37], [v38] and [v39] are in the red round shape in the center of Figure 13. Furthermore, by double checking the results of high importance of papers, we could find these main trends papers which play important roles in SCM field ([v12] and [v40] are excluded). However, others papers [v41] and [v42] have high importance in minor trends papers.

In Figure 13, Factor 1 locates in quadrant II, III, IV, Factor 2 locates quadrant I, Factor3 locates in IV, Factor 4 and Factor 5 locate in quadrant I and IV and Factor6 locates in III. Factor 1, Factor 3 and Factor 6 are about “effective framework or strategic perspective of SCM”, and the topics of SCM of Factor 4, Factor 5 are related to “integration and collaboration of SCM”. Therefore, we learn that Factor 2 plays as a bridge between the group1 (includes Factor1, Factor3 and Factor 6) and group2 (includes Factor 4 and Factor 5). From the above result, we could see the critical role of information sharing issues in the inter-relationships between a company and its collaborative participants, and the intra-relationships among the divisions in a company.

The multidimensional analysis provides a graphic vision of the different trends. In Figure 13, the y-axis shows the division between “The framework and strategic perspective of SCM” trends and “Information sharing & Integration of SCM” trends. We name the “Information sharing & Integration of SCM” in which there are three kinds of factors (which are Factor 2 “Information sharing issues in SCM”, Factor 4 “Integrated evolution of SCM”, and Factor 5 “Collaborative Supply Chain”) in the right-hand side. Then we name the “The framework and strategic perspective of SCM” in which also has other three kinds of factors (which are Factor 1 “Effective managed framework & strategic perspective of SCM”, Factor 3 “Agile and lean SCM’s strategies” and Factor 6 “Choosing right supply chain”) in the left-hand side.

37

Figure 13 Multidimensional Scaling

Factor 2 Factor 4

Factor 6 Factor 5

Factor 1

38

5.1 Conclusion

l structure and movement in the SCM and in other areas. According to this study experiment results, we can find the three findings which are w

S map to

5. Conclusion and Future Works

The study combines exploratory factor analysis and social network analysis for SCM to carry an empirical study. We hope that based on our research results to help specialists easily realize the main trends, understand of intellectua

orth summarizing below:

First, by using social network analysis and the threshold of the cited number defined, we found the core papers of SCM field to do factor analysis. The factor analysis extracted six factors, which are “Effective managed framework & strategic perspective of SCM”, “Information sharing issues in SCM”, “Agile and lean SCM’s strategies”, “Integrated evolution of SCM”, “Collaborative Supply Chain” and “Choosing right supply chain”. We recognized the main trends were factor 1, factor 2, factor 3 and factor 4, and the minor trends were factor 5 and factor 6.

Second, comparing results from factor analysis and social network analysis, we leant the variable numbers of paper [v2], [v5], [v6], [v8], [v9], [v13], [v14], [v37], [v38] and [v39] had higher importance of main trends papers in SCM fields. While others papers [v41] and [v42] had high importance in minor trends papers. Based on these papers, the specialists would extend the topic and discuss the issues of SCM

Lastly, by multidimensional analysis (MDS) providing a graphic vision of the different trends, we saw that y-axis made a clear division between “The framework and strategic perspective of SCM” trends in the left-hand side and “Information sharing & Integration of SCM” trends in the right-hand-side. We could also match these papers with the MD

se

39

1 nd group 2 (which are Factor 4 and Factor 5).

Researchers might benefit from for their future studies. However, this

ly the first exciting step. earch iously required.

e which quadrant they belonged to and the topics they related to. In addition, the other worth point was that “information sharing issues” played a critical bridge between the group (which are Factor1, Factor 3 and Factor 6) a

these findings

40

5.2 Future w

tions in our research, yet they also points out new possibilities for future research.

, and the result of Social network analysis maybe have more findings.

3. To

orks

There are some limita

1. To collect more papers: This method of investigation is not without problems, but it still lacks enough sample core papers to do analyze, in the future research, we can collect more sample papers of SCM fields to do an experiment. Maybe the larger the pool of core papers, then the more reliable the results is

2. To use other search terms about SCM: In our study we only use two search terms which are “Supply Chain” and “Supply Chain management”. The title of our all core papers has Supply Chain or Supply chain management keywords. In addition, many other papers might use other search terms as related to SCM fields, and they do not use our search terms to be keywords. In the future research, we can investigate more search terms to find more core papers of SCM field in order to make a precise exploratory analysis.

expand other criterions to measure the relationships of papers in SCM: In this work, we use degree criterion of Social network analysis to measure the relationships among the papers. For the future work, we could add others criterions such as density, closeness and betweenness to measure the network, group and the individual/node position status related to other nodes (Hanneman, 2001).

41

ion and main trends. Strategic Management Journal, 27(7), 621-636.

Armistead, C. G., & Mapes, J. (1993). The impact of supply chain integration on operating

from Supply Chain Opportunities. Industrial Marketing Management, 29(1), 7-18.

Beamon, B. M. (1998). Supply chain design and analysis: Models and methods. International

Journal of Production Economics, 55(3), 281-294.

Bechtel, C., & Jayaram, J. (1997). Supply Chain Management: A Strategic Perspective.

International Journal of Logistics Management, 8(1), 15-34.

Bowersox, D. J., Closs, D. J., & Stank, T. P. (2000). Ten mega-trends that will revolutionize supply chain logistics. Journal of Business Logistics, 21(2), 1-16.

Cachon, G. P., & Fisher, M. (2000). Supply Chain Inventory Management and the Value of Shared Information. Management Science, 46(8), 1032-1048.

Cavinato, J. L. (1992). A total cost/value model for supply chain competitiveness. Journal of

Business Logistics, 13(2), 285-301.

Chandra, C., & Kumar, S. (2000). Supply chain management in theory and practice: a passing fad or a fundamental change? Industrial Management and Data Systems, 100(3), 100-113.

Chen, F., Drezner, Z., Ryan, J. K., & Simchi-Levi, D. (2000). Quantifying the Bullwhip Effect in a Simple Supply Chain: The Impact of Forecasting, Lead Times, and Information.

Management Science, 46(3), 436-443.

Christopher, M. (1999). Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service. International Journal of Logistics Research and

Applications, 2(1), 103-103.

Christopher, M. (2000). The Agile Supply Chain Competing in Volatile Markets. Industrial

Marketing Management, 29(1), 37-44.

Christopher, M., & Towill, D. (2001). An integrated model for the design of agile supply chains. Management, 31(4).

Christopher, M., & Towill, D. R. (2000). Supply chain migration from lean and functional to agile and customised. Supply Chain Management: An International Journal, 5(4), 206-213.

Cooper, M. C., & Ellram, L. M. (1993). Characteristics of Supply Chain Management and the Implications for Purchasing and Logistics Strategy. International Journal of Logistics

Management, 4(2), 13-24.

6. References

Acedo, F. J., Barroso, C., & Galan, J. L. (2006). The resource-based theory: Disseminat

performance. Logistics Information Management, 6(4), 9-14.

42

, D. M., & Pagh, J. D. (1997). Supply Chain Management: More Than r Logistics. International Journal of Logistics Management, 8(1),

Cox, A. (1999). Power, value and supply chain management. Supply Chain Management: An

ernational Journal, 4(4), 167-175.

Croom, S., Romano, P., & Giannakis, M. (2000). Supply chain management: an analytical

Management, 6(1), 67-83.

13-36.

82: A Co-Citation Analysis. Management Science, 32(2), 156-172.

Davis, T. (1993). Effective supply chain management. Sloan Management Review, 34(4), 35-46.

13-22.

Fawcett, S. E., & Magnan, G. M. (2002). The rhetoric and reality of supply chain integration.

LY CHAIN FOR YOUR PRODUCT?

Operations Management: Critical Perspectives on Business and Management, 105(1),

16.

Garfield, E. (2001). From bibliographic coupling to co-citation analysis via algorithmic

Garton, L., Haythornthwaite, C., & Wellman, B. (1997). Studying Online Social Networks.

iated Communication, 3(1).

Gunasekaran, A., Patel, C., & Tirtiroglu, E. (2001). Performance measures and metrics in a supply chain environment. International Journal of Operations & Production

Management, 21(1/2), 71-87.

Handfield, R. B., & Nichols, E. L. (1999). Introduction to supply chain management: Prentice Hall Upper Saddle River, NJ.

Hanneman, R. A. (2001). Introduction to Social Network Methods. URL: URL: http://faculty

Cooper, M. C., Lambert a New Name fo 1-14.

Int

framework for critical literature review. European Journal of Purchasing and Supply

Croxton, K. L., Garcia-Dastugue, S. J., Lambert, D. M., & Rogers, D. S. (2001). The Supply Chain Management Processes. International Journal of Logistics Management, 12(2),

Culnan, M. J. (1986). The Intellectual Development of Management Information Systems, 1972-19

Ellram, L. M. (1991). Supply chain management: the industrial organization perspective.

International Journal of Physical Distribution and Logistics Management, 21(1),

Ennett, S. T., & Bauman, K. E. (1993). Peer group structure and adolescent cigarette smoking: a social network analysis. Journal of Health and Social Behavior, 34(3), 226-236.

Management, 32(5), 339-361.

Fisher, M. L. (2003). WHAT IS THE RIGHT SUPP

Forrester, J. W. (1958). Industrial Dynamics: A Major Breakthrough for Decision Makers.

Harvard Business Review, 36(4), 37-66.

historio-bibliography. speech deliveredat DrexelUniversity, Philadelphia, PA,

November, 27.

Journal of Computer-Med