Sputtered Cr and Reactively Sputtered CrN Serving as

Barrier Layers Against Copper Diffusion

Jui-Chang Chuang,* Shuo-Lun Tu, and Mao-Chieh Chen**

Department of Electronics Engineering and the Institute of Electronics, National Chiao-Tung University, Hsinchu 300, Taiwan

ABSTRACT

The barrier capabilitr of sputter deposited Cr and reactively sputter deposited CrN films against Cu diffusion in a structure of Cu/barrier/p n junction diodes was investigated by means of t1ermal annealing at elevated temperatures in conjunction with electrical measurements and material analysis. For a 500 A thick barrier layer, the barrier capability of a pure Cr layer was limited to temperatures up to 500°C, while CrN films sputter deposited in a gas mixture of Ar and N2 showed improved barrier capabilities. With Ar/N2 flow rates of 24/6 to 24/12 standard cubic centimeters er minute, the deposited CrN films possessed a much improved barrier capability. In particular, the Cu/CrNr (24/9)/p n junction diodes were capable of sustaining 30 mm of thermal anneal at temperatures up to 700°C without degradation of the diodes' electrical characteristics. The failure of Cu/Cr/p*n and Cu/CrN/pn junction diodes under extreme thermal treat-ment was presumed to arise from two mechanisms: grain boundary diffusion for lightly nitrogen doped CrNr and pure Cr barriers, and localized defect (microcrack) diffusion for excessively nitrogen doped CrN, barriers.

lnfroduction

Withthe continuing progress of integrated circuit tech-nology, the requirement to increase device density necessi-tates the improvement of multilevel metallizations."2 As

the linewidth of aluminum (Al) interconnects is scaled

down to deep submicrometer dimensions, the electrical re-sistivities of Al and its alloys are no longer low enough to reduce the interconnect propagation delay.3 The Al inter-connection line also suffers from earlier electromigration

failure under high current density.4-6 Furthermore, hillocks form on Al films at processing temperatures as low as

300°C, and cause interlevel (as well as intralevel) shorting by penetrating through the dielectric layers that separate neighboring interconnect lines.7

Copper (Cu) has been extensively studied as a potential substitute for Al and Al alloys in multilevel metallization

of semiconductor devices and integrated circuits.1'2 Copper

metallization for multilevel interconnects has many advan-tages, such as high melting point,8'9 high electromigration

resistance,'° low electrical resistivity,1'8 and thus low

inter-connect RC time delay, low reaction tendency with com-monly used diffusion barrier materials,"8'° and, probably, overall back-end process simplicity. However, there are a number of difficulties associated with the application of Cu in silicon-based integrated circuits, for example, poor

ad-hesion to dielectric layers,1 difficulty in dry etching,3'1' easy

diffusion in silicon and Si03, deep level trap in silicon, and formation of Cu silicides at low temperatures. All of these drawbacks have detrimental effects on the device reliabili-ty'2-'7 Therefore, the use of barrier layers between Cu and Si as well as Cu and Si02 becomes essential to the success-ful use of Cu in integrated circuit applications.

A large number of barrier layers have been studied.'7 Among them, refractory metals (Cr, Nb, Ti, Mo, W, and Ta)

and their nitrides have been investigated as diffusion

bar-riers because of their high melting points, high thermal

stability, good adhesion to dielectrics, and good electrical

conductivity.'72' Chromium (Cr) and its nitride (CrN)

films are widely used as scratch and corrosion passivation

layers in field application.22'23 Nonetheless, little work has

been reported regarding the properties of Cr-related thin films that serve as diffusion barriers in Cu metallization

systems. In this work, Cu/Cu/n-Si and Cu/CrNjn-Si

structures were investigated with respect to the barrier capability of the sputtered Cr and reactively sputtered

CrN films against Cu diffusion.

*ElectrochemicalSociety Student Member, ** ElectrochemicalSociety Active Member,

Experimental

For this study, Cu/Cr/pn and Cu/CrNr/pn junction

diodes were fabricated from n-type, (100) oriented, 4 in.

diam Si wafers with a nominal resistivity of 1-7 (1 cm.

After a standard RCA cleaning,24 5000 A Si02 was ther-mally grown in a pyrogenic steam atmosphere at 1050°C. Square active regions with areas ranging from 100 x100

to 1000 X 1000 p.m were defined by the conventional pho-tolithographic method. Then a 250 A screen oxide was

thermally grown in dry oxygen atmosphere at 900°C. The

pn junctions were formed by BF2 implantation at an energy of 40 keV to a dose of 3 X i0' cm2 followed by thermal annealing in a N2 atmosphere at 900°C for 30 mm. The screen oxide was then removed using a dilute HF

solu-tion. The junction made by this process was estimated to be 0.25-0.30 p.m. The wafers were loaded into a sputtering

system immediately following the screening oxide

re-moval. A 500 A, Cr or CrN barrier layer was sputter

de-posited, followed by another deposition of 2000 A Cu over-layer without breaking the vacuum. The Cr film was

sputter deposited using a pure Cr target (99.9999% purity) in Ar atmosphere, while the CrNr layers were deposited by reactive sputtering using the same Cr target in a gas mix-ture of Ar and N3 with various flow rates. The base pres-sure of the sputtering chamber was 2 X iO Ton, and films were sputtered at a pressure of 7.6 mTorr. For the purpose of easy identification, the CrN films deposited with vari-ous flow rates of Ar and N3 are designated as CrN (a/b) hereafter, where a and b stand for Ar and N2 flow rates in standard cubic centimeters per minute (sccm), respective-ly, in the sputtering gas mixture. After the deposition of the Cu overlayer, the Cu/Cr as well as the Cu/CrN dual layers were patterned using the lift-off method.

The Cu/barrier/pn samples were thermally annealed in a furnace for 30 mm at temperatures ranging from 400 to 800°C in a N3 atmosphere. At the end of the thermal treat-ment, samples were retained in the furnace with N2 flush-ing until the temperature was below 200°C; then samples were removed from the furnace. Reverse bias leakage cur-rents were measured at a reverse bias of 5 V for the sam-ples with various junction areas. Typically, for each case, eighteen randomly chosen diodes were measured using an HP4145B semiconductor parameter analyzer.

Unpatterned samples of Cr/Si, CrNJSi, Cu/Cr/Si, and Cu/CrN/Si structures processed in the same process run were also prepared for material analysis. Sheet resistance was measured using a four-point probe on the unpatterned samples. The phase composition was identified by X-ray diffraction (XRD) analysis. Scanning electron microscopy 4290 J. Electrochem. Soc., Vol. 145, No. 12, December 1998 The Electrochemical Society, Inc.

(SEM) was used to investigate the surface morphology and

the cross section of the samples. The nitrogen content

(atomic concentration, designated as N atom %) in the as-deposited CrN film was obtained by Auger electron spec-troscopy (AES) analysis.

Resultsand Discussion

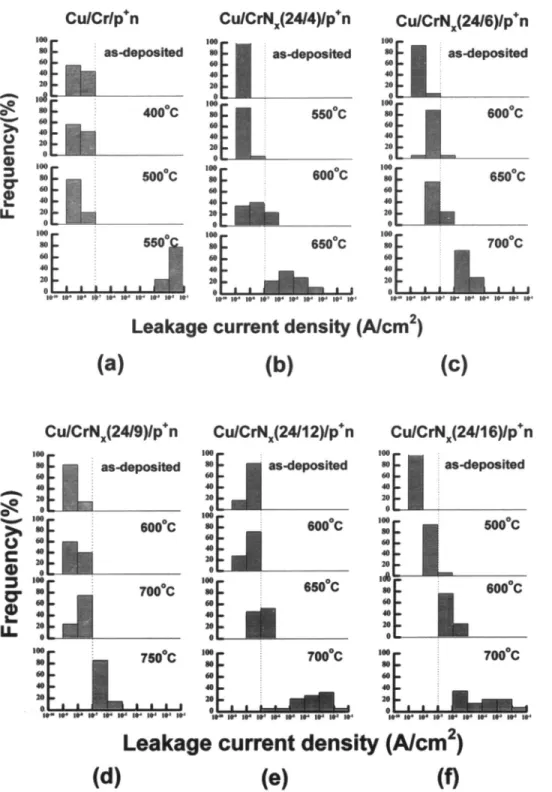

Thermal stability of Cu/barrier/pn junction diodes.— Figure 1 shows the statistical distributions of reverse bias (5 V) leakage current densities for the Cu/Cr (500 A)/pn junction diodes as well as for the Cu/CrNr(500 A)/pn junc-tion diodes annealed at various temperatures. In this study,

we defined a leakage current density larger than 1 X i0

A/cm2 as a failure. The Cu/Cr/pin junction diodes (Fig. la)

were able to sustain a 30 mm thermal treatment up to

500°C without causing degradation; however, annealing at

550°C resulted in severe degradation. For the

Cu/CrN(24/4)/pn junction diodes (Fig. ib), diode degra-dation after annealing at temperatures above 600°C was

observed, showing an at least 50°C improvement of the

thermal stability over the Cu/Cr/pn diodes. Further im-provement was observed for the Cu/CrN,/24/6)/pn and

Cu/CrNr(24/12)/pn junction diodes (Fig. ic and e), which

were able to sustain the thermal treatment up to 600°C. The

best resu1t was observed for the Cu/CrN(24/9)/p*n junc-tion diodes (Fig. id), which remained stable at

tempera-tures up to 700°C. This is an improvement of 200°C as com-pared to the Cu/Cr/pn junction diodes. However, the thermal stability of Cu/CrN(24/16)/pn diodes (Fig. if) showed only slight improvement over that of Cu/Cr/pn

diodes.

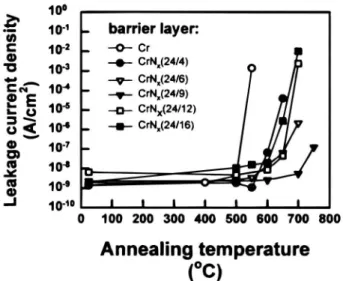

Average values of leakage current density vs. annealing

temperature for all the Cu/CrN/pn junction diodes are

summarized in Fig. 2. The results indicate that the thermal stability of Cu/Cr/pn junction diodes can be substantial-ly improved by using reactivesubstantial-ly sputtered CrN films with appropriate nitrogen contents in a sputtering gas mixture of Ar and N2 instead of a pure Cr barrier layer.

Leakage current density (AIcm2)

(e)

CuICr!pn

Cu!CrN(24I4)!pn

CuICrN(24I6ypn

1I0 ILL

iL LL

600°C':

650°C650°C

:

700°C—

. i

r_L_L._L_IlII__L._L_J

I.- I.' ii' is' is' is' is. is. I,- 10. is is. II- is• I. is is'

I

I

(a)

(b)

(c)

Leakage current density (A/cm2)

Cu!CrN(24I9)Ipn

Cu!CrN(24I1 2)/pn

CuICrN(24I1 6pn

-I.

as-depositedj

asdeposited as-depositedFig. 1. Statistical distributions

of reverse bias (5 V) leakage

current density for the

Cu/barn-er/pn 'unction diodes having

500 A thick barrier layers

annealed at various tempera-hires for 30 mm: (a) Cu/Cr/pn,

(b) Cu/CrN,(24/4)/pn, (c) Cu / Cr N ,( 24 / 6)/ p (d) Cu/CrN.(24/9)/pn, (e) Cu/CrN.(24/12)/pn, and (f) Cu/CrN(24/ 1 6)/pn. IN N N N 20 IN N SI a 20

i.

N N*

20 C ISO N N N 20 ISO 00 60 40 20 IN N N 40 20 Kc

600°C 700°CLL2

':

I

600°C 650°C 700°C (i

I.LL11

LL

IN 700°C NII- iI is. is' is' is• is' is' is' is'

(d)

is- is. is. is. is' is. is. is. is. is.

C

0

-C0

0

-JPhysicalproperties of Cr and CrN films deposited on an Si substrate—Figure 3 shows the nitrogen content (N atom

%) of various as-deposited CrN films. It reveals the

creasing trend of N atom % in the CrNr films with the in-crease of nitrogen volume fractions (N2/Ar + N2) in the

sputtering gas mixture. Nonetheless, N atom % eventually

reached a saturated value of about 40 atorn %.Figure 4 shows the surface morphology of the 2000 A thick as-de-posited Cr and various CrNr films on Si substrates. The Cr

film (Fig. 4a) revealed a slightly granular surface, while the

CrN films revealed granular surfaces with various grain sizes and roughness (Fig. 4b-d). Also, microcracks were clearly observable on the surface of the CrN(24/l6) film (Fig. 4d), which was sputtered in a gas mixture with a high content of nitrogen (flow rate 16 sccm). Figure 5 shows XRD spectra for the as-deposited and thermally annealed Cr and various CrN films deposited on Si substrates. For the as-deposited samples (Fig. 5a), the Cr/Si sample

exhib-ited a strong Cr(ll0) preferred orientation as well as a

weak diffraction peak corresponding to the Cr oxide, pre-sumably due to air exposure of the samples before taking

the XRD analysis, because Cr is inherently an oxygen

absorber.8'9 For the CrNJSi samples, the Cr nitride (CrN) phase appeared, and the intensity of the diffraction peak became stronger with increasing nitrogen content in the sputtering gas mixture. The CrNr(24/4)/Si (not shown) and CrN(24/6)/Si samples revealed similar XRD spectra, i.e., neither Cr nor CrN diffraction peaks were observed. The

CrN(24/9)/Si sample revealed a polycrystalline CrN phase ________

Fig. 3. N atom % of as-deposited CrN, films vs. N2 volume frac-tion in the sputtering gas mixture as determined by AES.

barrier layer: —0—Cr —•— CrN,(24/4) —ç-- CrN(24/6) —-- CrN(24/9) —.0.- CrN(24I12) -— CrN,(24/16) 100 10.1 102 iO-10-s

10

10-' 10-i 10-' 10-' 10.10 0 100 200 300 400 500 600 700 800Annealing temperature

(°C)

Fig.2. Average reverse bias leakage current density vs.

anneal-ing temperature for various Cu/barrier/pn junction diodes.

of (111) and (200) orientations. The CrN(24/l2) and

CrNr(24/16) (not shown) samples showed similar spectra, in which only CrN(1 11) X-ray reflections were found. For the thermally annealed samples (Fig. 5b), the XRD spectrashowed basically the same nitride phase detected in the

corresponding as-deposited samples. However, a silicide (CrSi2) phase appeared on the Cr/Si sample annealed at

(a)

(b)

(c)

(d)

z

60 50 40 30 20 10 0 0 10 20 2500A 30 40 50N2 volume fraction (%)

Fig. 4. SEM micrographs showing the surface morphology of

as-deposited Cr and CrN, films: (a) Cr, (b) CrN(24/6), (c) CrN(24/9), and (d) CrN(24/ 16).

J. Electrochem. Soc., Vol. 145, No. 12, December 1998 The Electrochemical Society, Inc.

(a)

0.8 JC,NA2A45IJcflJlllO)

30 35 40 45 50 55 60 65

29 (degree) CiSI4)10) CS,)112) IOOt,c,)sl30 35 40 45 50 55 60 65

20 (degree)Fig. 5. XRD spectra for (a) as-deposited and (b) thermally

annealed Cr/Si and various CrN/Si samples.

temperaturesof 600°C and above. Figure 6 shows the resis-tivity of CrN films vs. nitrogen volume fraction in the sputtering gas mixture, showing an N-shaped variation.

Figure 7showsthe deposition rate of CrN films for vari-ous sputtering powers vs. nitrogen volume fraction in the sputtering gas mixture. As was expected, higher sputtering powers resulted in higher deposition rates. Furthermore, higher volume fractions of nitrogen in the sputtering gas mixture resulted in lower deposition rates.

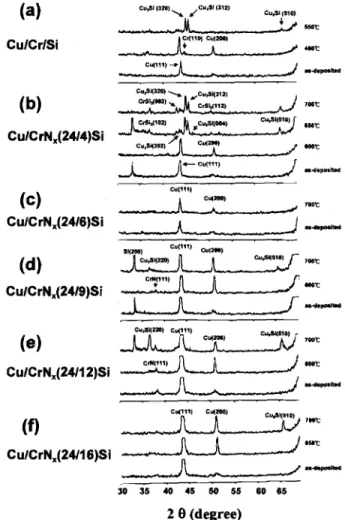

Thermal annealing of Cu/Cr/Si and Cu/CrNJSi

struc-tures.—XRD spectra of as-deposited and thermally

annealed Cu/Cr/Si and Cu/CrNJSi samples having 500 Athick barrier films are illustrated in Fig. 8. For the

as-deposited samples, the phase composition of the Cr and CrN films remained unchanged as compared with the cor-responding samples without a Cu overlayer. In addition, there were no obvious differences between the spectra of as-deposited and the corresponding low temperature

nealed samples. Figure 9 shows sheet resistance vs. an-nealing temperature for various Cu/CrN/Si samples.

After annealing at a temperature of 400°C, all samples re-vealed a slight decrease of sheet resistance, presumably due to the healing of sputter induced defects and the crys-tallization of the Cr and CrN, films.1"125 For the Cu/Cr/Si sample, sheet resistance revealed a drastic increase after

0 10 20 30 40 50

N2 Volume fraction (%)

Fig. 6. Resistivity of as-deposited CrN0 films vs. N2 volume

frac-tion in the sputtering gas mixture. Criftill) Cttl.(24112))5I

.2

co

0'—'

a

0

a

(b)

0.7 0.6 0.5 0.4 0.3 0.2 0.1 o 260w o 200w A 160w V 100w450w

C.tl(111) 5M20) 4 Citl(200) 0,01)220)bit.

Cfl442V1))S1 -- bOOt. C01424(ipS( 0 10 20 30 40 0.N2

Volume fraction (%)

Fig. 7. Deposition rate of CrN,, films vs. N2 volume fraction in the

sputtering gas mixture for various sputtering powers.

annealing at 500°C, and the XRD analysis showed the

appearance of Cu3Si phase after annealing at tempera-tures as low as 550°C, but showed no appearance of Cr sili-cide phase (Fig. 8a). For the Cu/CrN(24/4)/Si sample,

Cu3Si and CrSi2 were observed after annealing at 650°C

(Fig. 8b) and the sheet resistance also showed a drastic increase (Fig. 9a). For the samples with Cr or CrNr(24/4) as

a barrier layer, the results of the electrical measurements (Fig. 1 and 9) and the XRD analysis(Fig. 8) consistently

show that the formation of high resistive Cu silicide2°

stand for the failure of the diffusion harriet For the

sam-(a)

Co,SI (320) ._, Cu.5) (312)00.51(110) j..., soot Cu/CriSi ..-____::L::/L__._....__0..___..___....1 a

(b)

Co.3l(320) _.Co,50312) TOOt3I2)jflt

Cu/CrN5(2414)Si(c)

Cu/CrN0(24!6)Si(d)

CuICrN5(24!9)Si(e)

C*)11l) -region 3 - region 2I

9

C

S

>0 'is to to a, 8x103 7x103 6x103 SxlO' 4x103 3x10 Cr 24/6 I I I Co)lll) 0.12W) lootflj

________—

C..5I)22O) 00)111)Cu/CrN5(24/12)Si

_nA_J____.) .oOt

AJ _i —

00)111) 0i4000)

o'UJlO)

CuICrN5(24/16)Si _.__0____a ___k_________J

—

30 35 40 45 50 55 60 65

20 (degree)

Fig.8.XRDspectra for the as-deposited as well as the

therm-ally annealed Cu/barrier/Si samples: (a) Cu/Cr/Si, (b) Cu/ CrN,j24/4)/Si, (c) Cu/CrN5(24/6)/Si, (d) Cu/CrNJ24/9)/Si, (e)

I 0

w

C10

E Io

—0

a) .C 1OFig. 9. Sheet resistance vs. annealing temperature for various Cu/barrier/Si samples.

pieswith a barrier layer of CrN films deposited with a

higher nitrogen content in the sputtering gas mixture

(Ar/N2 flow ratio less than 24/6), Cu suicide was also de-tected by XRD analysis at and above the temperatures of the observation of electrical failure (Fig. 1, 8, and 9d-f); however, no Cr silicide phase was observed. The samples with CrN(24/9), CrN(24/12), and CrN(24/16) barrier

lay-ers showed only a moderate increase of the sheet resist-ance after annealing at temperatures above 600°C; this in-dicated that the interaction between Cu and Si substrates was not sensitively detectable by sheet resistance

meas-urement and XRD analysis, but was serious enough to

detrimentally increase the junction leakage current.

Fig-ure 10 shows SEM micrographs for the Cu/Cr/Si and Cu/CrNJSi samples annealed at elevated temperatures;

formation of Cu silicide can be clearly observed. After an-nealing at high temperatures, tetragonal92628 Cu3Si was observed. Deformed and ruptured films due to the stress induced by the volume change of suicide formation were easily observed for the Cu/Cr/Si sample annealed at 600°C

(Fig. lOa and b) and the Cu/CrN(2 4/4)/Si sample annealed

at 650°C (Fig. bc); they were also observed for the

Cu/CrN(24/6)/Si sample annealed at 800°C (Fig. lOd) and the Cu/CrN(24/9)/Si sample annealed at 750°C (Fig. be),though they were found in fewer numbers. For the

Cu/CrN(24//16)/Si sample that revealed microcracks in

the as-deposited CrN film (Fig. 4d), thermal annealing

resulted in porosity of the Cu overlayer (Fig. lOf),

presum-ably resulting from the fast inward diffusion of Cu

through the microcracks.2°Discussion.—In Fig. 5, it was observed that the sputtered

Cr film revealed a Cr(110) preferred orientation, which

remained stable after annealing at temperatures up to

500°C. For the reactively sputtered CrNr films, diffraction peaks of CrN phase appeared and the intensity of the peaks increased with the nitrogen content in the sputtering gas

Fig. 10. SEM micrographs

showing the surface morpholo-gy and cross-sectional view for the thermally annealed

Cu/bar-rier/Si samples: (a) and (b) Cu/Cr/Si at 600°C, (c) Cu/CrN(24/4)/Si at 650°C, (d) Cu/CrN(24/6)/Si at 800°C, (e) Cu/CrN(24/9)/Si at 750°C, and (0 Cu/CrN(24/16)/Si at 650°C. 0 100 200 300 400 500 600 700 800

Annealing temperature (°C)

mixture. In addition, the CrN phase with the (111)

pre-ferred orientation was detected for the samples of

CrN(24/12) and CrN(24/l6). Because all the CrN1 films were reactively sputtered using the same conditions except the Ar/N2 flow rates, we assume that the nitrogen content in the sputtering gas mixture should be responsible for the orientation preference.

For the CrN films deposited with low nitrogen flow

rates, the incorporated nitrogen did not react with the sput-tered Cr; instead, the nitrogen tended to collect in the grain boundaries of the deposited Cr films. As a consequence of lattice deformation, the resistivity of the Cr films increased with the increase of nitrogen content. This is designated as

region 1 for the N-shaped curve shown in Fig. 6. Eventually,

the crystalline structure of the Cr film was destroyed and

the XRDdatashowed a nearly amorphous spectrum, which

revealed no distinguishable diffraction peak after annealing at temperatures up to 600°C. As the nitrogen content in the

sputtering gas mixture was increased, the chemical reaction

of Cr and nitrogen increased, resulting in the formation of

Cr nitride, and thus decreasing resistivity (region 2 of

Fig. 6). The XRD data were similar to that shown in Fig. 5 for the sample of CrN(24/6)/Si, which revealed very weak

but still distinguishable diffraction peaks of CrN after

annealing at 600°C. As the nitrogen content in the

sputter-ing gas mixture was further increased, a portion of the

incorporated nitrogen turned to decorate grain boundaries of the polycrystalline Cr nitride in addition to increase the

N atom % in the deposited films; thus, resistivity of the film

increased again. However, we assume that there is a com-peting sputter deposition/etching process in the sputtering chamber. The nitrogen in the reactive sputtering process served as a reactant for the formation of Cr nitride and also

supported the N2 plasma, which would sputter etch the deposited Cr nitride film. When the nitrogen flow rate in the

sputtering gas mixture was increased to a notable amount, the rates of sputter etching and sputter deposition became

comparable.25'3° Thus, we observed the ceasing of the increasing trend of N atom % (Fig. 3), the decrease of depo-sition rates irrespective of the depodepo-sition power (Fig. 7), and

the increase of surface damages of the films. Eventually, as

the nitrogen flow rate was increased to an excessive amount (e.g., an N2 flow rate of 16 sccm), microcracks (Fig. 4d) were

created in the films that resulted in a drastic increase of

re-sistivity, as shown in region 3 of Fig. 6.

Thermodynamic data31 suggest that Cr nitrides are more stable than Cr silicides at room temperature but silicides

are more stable at elevated temperatures., The results

shown in Fig. Sb indicate that interaction between Cr and

the nitrogen in N2 atmosphere as well as between Cr and the

silicon in Si substrate occurred at 600°C of the Cr/Si sam-ples, while there was no interaction between CrN and the

Si substrate at temperatures up to 800°C for the CrN/Si

samples. For the reactively sputter deposited CrN films on Si substrate, Cr nitride was formed during the sputter

depo-sition process, and the formation of Cr silicide was deterred

by the presence of Cr nitride.

There are two possible types of Cu diffusion paths in the

Cr-based barrier layers. First, for the Cr and CrN films

deposited with low nitrogen content in the sputtering gas

mixture (N2 flow rates below 6 sccm), Cu diffuses to the Si

substrate through the barrier layers along the grain

bound-aries which are deficient in nitrogen decoration. Second, for

the CrN films deposited with high nitrogen content in the

sputtering gas mixture (N2 flow rates above 12 sccm),

local-ized defects, such as microcracks, provide fast diffusion paths for Cu diffusion. Cu can diffuse to the Si substrate by way of these diffusion paths and deteriorate the electrical

characteristics of the pn junction diodes,1247 and form localized Cu3Si grains as shown in Fig. 10. As the grains of

Cu3Si grew, the volume difference between Cu and its

sili-cide resulted in the deformation of the Cu overlayer and the

protrusion of Cu2Si through the Cu overlayer as well as the intrusion of Cu3Si grains into the underlying Si substrate.

Presumably, the roles of the nitrogen are to collect at the grain boundaries of the as-deposited barrier layers and to

form Cr nitrides. For the CrN,, films deposited with low nitrogen content in the sputtering gas mixture, there was not enough nitrogen incorporation and a Cr nitride phase was not detected. For the CrN films deposited with high nitrogen content in the sputtering gas mixture, the nitrogen

content in the CrN films was increased and CrN was

detected. The abundant supply of nitrogen not oniy formed Cr nitride but also blocked the grain boundaries of the Cr nitride; thus, it should possess a superior barrier capability.

However, CrN films deposited with very high nitrogen con-tent in the sputtering gas mixture (e.g., N2 flow rate of

16 sccm) possessed sputter-induced defects such as

miro-cracks. Therefore, the defect-related failure took dominance

and the electrical characteristics of the pn junction diodes tended to deteriorate with increasing annealing tempera-ture. For the CrN films deposited with medium nitrogen content in the sputtering gas mixture (N2 flow rates from 6 to 12 sccm), failure would occur due to both mechanisms.

Moreover, the barrier capability of CrN films deposited

with nitrogen flow rate of 9 sccm (i.e., the CrN(24/9) film) was the best among all the Cr nitride films investigated.

Conclusion

Thiswork investigated the barrier capability of sputter deposited Cr and reactively sputter deposited Cr14,, films against Cu diffusion in a structure of Cu/barrier/pn junc-tion diodes. The CrN,, films deposited in a sputtering gas mixture of Ar and N2 with Ar/N2 flow ratios from 24/6 to

24/12 were found to possess efficient barrier capability. For

a 500 A thick layei we found that the Cu/CrN,,(24/9)/pn junction diodes were capable of sustaining 30 mm of ther-mal annealing at temperatures up to 700°C without degra-dation to the diodes' electrical characteristics. The dorre-sponding thermal stability of junction diodes using a pure

Cr barrier layer was found to be 500°C. The failure of

Cu/CrN,,/pn junction diodes under extreme thermal treat-ment was presumed to be arising from two mechanisms:

grain boundary diffusion for the lightly nitrogen doped CrN,, including the Cr barriers, and localized defect

(micro-crack) diffusion for the excessively nitrogen doped CrN,, barriers.

Acknowledgment

The authors wish to thank the Semiconductor Research Center of National Chiao-Thng University for providing excellent processing environment. This work was support-ed by the National Science Council, ROC, under contract

no. NSC-86-2215-E-009-040.

Manuscript submitted March 10, 1998; revised manu-script received August 10, 1998.

National Chiao-Tung University assisted in meeting the publication costs of this article.

REFERENCES

1. See, for example, MRSBull.,18 (1993); 19 (1994);

de-voted to the topic of copper metallization for

micro-electronics.

2. K. P Rodell, E. G. Colgan, and C. K. Hu, in Mater Res.

Soc. Symp. Proc., 337, P Murarka, A. Katz, K. N. Th,

and K. Maex, Editors, p. 59, MRS, Pittsburgh, PA

(1994).

3. C. K. Hu, B. Luther, F B. Kaufman, J. Hummel, C.

Uzoh, and D. J. Pearson, ThinSolidFilms, 262, 84

(1995).

4. K. N. Th, J.Vac. Sci. Technol., A,2, 216 (1984).

S. J. K. Howard, J. F White, and P 5. Ho, J. Appl. Phys.,

49, 4083 (1978).

6. C. K. Hu, Thin Solid Films, 260, 124 (1995).

7. S. Wolf and R. N. Tauber, Silicon Processing for the VLSIEra,Vol. 1, Editor; p. 269, Lattice Press, Sunset

Beach, CA (1986).

8. CRC Handbook of Chemistry and Physics, 73rd ed.,

D. R. Lide, Editor, Section 12, CRC Press, Inc., Boca Raton, FL (1992).

9. Binary Alloy PhaseDiagrams,2nd ed., P B. Massalski,

Editor; pp. 1266, 1293, 1304, 1333, 1446, ASM

Inter-national, Materials Park, OH (1990).

10. 5. Shingubara, K. Fujiki, A. Sano, H. Sakaue, and Y.

J. C. Coburn, J. E. Sanchez, Jr., K. P. Rodbell, and

W. F Filter, Editors, p. 441, MRS, Pittsburgh, PA (1994).

11. Y. Igarashi, T. Yamanobe, and T. Ito, Thin Solid Films, 262, 124 (1995).

12. J. D. McBrayer, B. M. Swanson, and T. W Sigmon, J. Electrochem. Soc., 133,1242(1986).

13. Y. Shacham-Diamand, A. Dedhia, D. Hoffstettei and

W. G. Oldham, J. Elect rochem. Soc., 140, 2427 (1993).

14. D. Gupta in Mater Res. Soc. Symp. Proc., S. P. Murar-ka, A. Katz, K. N. Tu, and K. Maex, Editors, p. 209,

MRS, Pittsburgh, PA (1994).

15. G. Raghavan, C. Chiang, P. B. Anders, S. M. Tzeng, R. Villasol, G. Bai, M. Bohr, and D. B. Fraser, Thin Solid Films, 262, 168 (1995).

16. VLSI Technology, 2nd ed., S. M. Sze, Editor, p. 309,

McGraw-Hill, Singapore (1988).

17. 5. Q. Wang, S. Suther, C. Hoeflich, and B. J. Burrow, J. Appi. Phys., 73, 2301 (1993).

18. C. A. Chang, J. Appl. Phys., 67, 6184 (1990).

19. D. Y. Shih, C. A. Chang, J. Paraszczak, S. Nunes, and J. Cataldo, J. Appl. Phys., 70, 3052 (1991).

20. H. Ono, T. Nakano, and T. Ohta, Appl. Phys. Lett., 64,

1511 (1994).

21. L. C. Lane, T. C. Nason, G. R. Yang, T. M. Lu, and H.

Bakhru, J. Appl. Phys., 69, 6719 (1991).

22. F. Cosset, G. Contoux, A. Celerier, and J. Machet, Surf. Coat. Technol., 79, 25 (1996).

23. C. Friedrich, G. Berg, E. Broszeit, and K. H. Kloos,

Surf. Coat. Technol., 74-75, 279 (1995).

24. W. Kern and D. A. Puotinen, RCA Rev., 31,187(1970).

25. J. C. Chuang and M. C. Chen, Thin Solid Films, 322,

213 (1998).

26. C. S. Liu and L. J. Chen, J. Appl. Phys., 74, 3611 (1993).

27. C. S. Liu and L. J. Chen, Thin Solid Films, 262, 187

(1995).

28. C. S. Liu and L. J. Chen, J. Appl. Phys., 75, 2370 (1994).

29. B. E. Reed-Hill, Physical Metallurgy Principles, 2nd

ed., p. 386, Van Nostrand, New York (1972).

30. J. C. Chuang and M. C. Chen, J. Electrochem. Soc., 145, 3170(1998).

31. E. A. Brandes, in Smithells Metals Reference Book, 6th

ed., p. 8, Robert Hartnoll Ltd., Bodmin, Cornwall,

England (1983).

Application of a Semi-insulating Amorphous Hydrogenated

Silicon Nifride Film as a Resistive Field Shield and Its

Reliability

K. Matsuzaki,*,0 1. Horasawa,b G. Tada,c and M. Saga"

°Fuji Electric Corporate Research and Development, Limited, Advanced Device Technology Laboratory, Matsumoto City, Japan 390

bFujj Electric Company, Limited, Matsumoto Factory, IC Fabrication Department, Matsumoto City, Japan 390 °Fuji Electric Company, Limited, Matsumoto Factory, Semiconductor Device Research and Development Center,

Matsumoto City, Japan 390

dFuji Electric Corporate Research and Development, Limited, Yokosuka City, Japan 240

ABSTRACT

In order to develop reliable high voltage integrated circuits (HVICs), the characteristics of semi-insulating plasma-deposited amorphous silicon nitride (a-SiN:H) films as resistive field shields, are examined, the reliability of their appli-cation to HVICs are studied. The surfaces of these semi-insulating films were unstable, and it was concluded that these films must be covered with a final passivation film such as an insulating plasma-deposited a-SiN:H film. The transverse electrical conduction mechanism of these films is briefly discussed.

Infroduction

Ingeneral, high voltage integrated circuits (HVICs) using planar technology employ shallow junctions and alternative means to control the electric field near the surface of a

semiconductor. The depletion layer can be controlled and the breakdown voltage can be improved by using a field plate, a resistive field shield, an equipotential ring, etc."2 The use of semi-insulating polycrystalline silicon (SIPOS) as a resistive field shield has been developed,3" but its use has been limited.6-8 Because a resistive field shield was needed and the problems encountered with SIPOS must be

avoided, Osenbach et al. developed Si-rich

plasma-deposit-ed amorphous silicon nitride hydrogen alloys (a-SiN:H) as

resistive field shields.7 In this paper, we study the reliability of HVICs using such semi-insulating a-SiN:H films.

Experimental

Chemical vapor deposition of a-SiN:H films—A

VDS-5000 plasma chemical vapor deposition (CVD) system

(JPEL Co.) was used for the deposition of a-SiN:H films. This system was operated at 50 kHz, 1 kW radio frequen-cy (rf) power, and 320°C. The pressure of deposition and the flow of Ar carrier gas were kept at 53 Pa and 1.5

stan-dard liters per minute (slm), respectively. The gas flow

*ElectrochemicalSociety Active Member,

ratio R = SiH4/(SiH4+ NH3)was variable. Insulating and

semi-insulating a-SiN:H films were deposited at R =0.15

and R = 0.70—0.77,respectively. The substrates were 4 in.

diam, (100)-polished silicon wafers.

HVIC device structure using semi-insulating a-SiN:H films.—The schematic structure of the device is shown in

Fig. 1. The substrates were 4 in. diam, (100)-polished, p-type (p =100—150tI cm) silicon wafers. N-well (p '—10

l

cm, X '—6p.m), P-base (p "-0.511 cm, X —2p.m), P-offset(p —10l cm, X -'-1.5p.m), gate oxide (t0 =25nm),

poly-Si gate electrodes, and source-drain regions were

succes-sively formed in the substrates. The field region lying

between source and drain region was covered with

local-ized oxidation of silicon (LOCOS) (t0,, =0.7p.m),

phospho-silicate glass (PSG) SiO, (tpsG =1p.m), and finally a semi-insulating a-SiN:H film (ts,N =1p.m, R =0.76typically) as

a resistive field shield. The length of the field region was

"70 p.m. The breakdown voltage of this HVIC was

designed to be over 700 V.

Measurements.—The thickness of the film was deter-mined by a laser-based ellipsometer. The density of the film was calculated using the mass determined by measur-ing the sample weight before and after deposition, and the volume of the film. The transmission infrared spectrum of the film was taken with Fourier transform infrared (FTIR)