行政院國家科學委員會補助專題研究計畫成果

報告

※※※※※※※※※※※※※※※※※※※※※※※※※

※ 遠距快速工程分析系統環境之研究 ※

※

Study on a Remote Quick CAE Environment

※

※※※※※※※※※※※※※※※※※※※※※※※※※

計畫類別:■個別型計畫 □整合型計畫

計畫編號:NSC 90-2212-E-151-010-

執行期間:2001 年 8 月 1 日至 2002 年 7 月 31 日

計畫主持人:高永洲 國立高雄應用科技大學 機械工程系

共同主持人:李榮顯 國立成功大學 機械工程系

計畫參與人員:

本成果報告包括以下應繳交之附件:

□赴國外出差或研習心得報告一份

□赴大陸地區出差或研習心得報告一份

□出席國際學術會議心得報告及發表之論文各一份

□國際合作研究計畫國外研究報告書一份

執行單位:國立高雄應用科技大學 機械工程系

中 華 民 國 九十一 年 七 月 三十一 日

行政院國家科學委員會專題研究計畫成果報告

遠距快速工程分析系統環境之研究

Study on a Remote Quick CAE Environment

計畫編號:NSC 90-2212-E-151-010

執行期限:2001 年 8 月 1 日至 2002 年 7 月 31 日

主持人:高永洲 國立高雄應用科技大學 機械工程系

共同主持人:李榮顯 國立成功大學 機械工程系

一、中文摘要 本 研 究 旨 在 研 發 一 能 透 過 網 際 網 路 (Internet) , 運 用 分 散 式 資 源 (Distributed resources),以建構一遠端電腦輔助工程分析 (Remote Quick CAE)應用系統之介面環境;此 一環境將提供座落於近端(local)之製程工程 師一智慧型軟體幫手與良善之跨平台使用者 介 面 (Platform independent user-friendly interface),協助該工程師應用遠端(remote)之 電腦輔助工程分析系統, 以輔助製程設計、 模具設計與製造活動之進行。 本研究的成果將能協助希望藉由引進電 腦輔助工程分析技術以提昇技術甚至轉型之 產業,例如金屬成形相關產業,對內改善製 程開發程序及方法,對外則可擴展成遠距協 同式金屬成形模具以及製程最佳化系統架 構,提供遠距協同式自動化運作環境,以因 應企業多點、多國化、核心設計與自動化製 造技術根留台灣之策略,進一步協助產業技 術升級與轉型。 本研究已經以金屬擠伸製程作為案例, 成功的建立一可以透過網際網路瀏覽器使用 的遠距三維擠伸模具曲面分析系統以驗證本 研究之概念以及研發出之系統的可行性。 關鍵詞:金屬成形、全球資訊網、遠距電腦 輔助工程分析、擠伸製程 AbstractThis article presents the development of a Web-based remote computer-aided engineering (CAE) system for geographically dispersed users to access a metal extrusion die design system at a

distance through network. A solid extrusion die surface optimization system developed by the authors was adopted to realize the developed system. The original user-interface of the adopted solid extrusion die surface optimization system was underlying a traditional single-user to single-computer framework where the system could only be used via direct and interactive input locally. With the synergy of Web-based technology, networking and computer technologies, this paper proposed a new algorithm to access the traditional interactive solid extrusion die surface optimization system remotely with least modification of the original program. This development eliminates the geographical barrier and also forms a platform-independent development because the developed system can be accessed through popular World-Wide Web (WWW) browsers such as Microsoft Internet Explorer and Netscape Communicator, etc.

Keywords : Metal forming, World-Wide Web, Remote CAE, Extrusion

二、Motive and Objective

The world has virtually become smaller since it has been networked with the advanced information technology such as the networking, computing and computer technologies. Global marketing and competition has thus become the norm among today’s multi-national enterprises. Therefore, the need in communication and interactive activities among geographically distributed engineers has become inevitable and very important to shorten

the time-to-market underlying the philosophy of collaborative concurrent engineering.

Computer-Supported Cooperated Work (CSCW) [1,2,3,4,5] has also been paid great attention since 1990’s and Web-based technology has enhanced its feasibility. It is also well known that a new era has gradually been formed in the 21st century where knowledge-intensive work is a norm towards so called knowledge economy. From the viewpoint of metal forming technology, the need for core technology that can be globally accessed and shared easily is emerging and demanding a remote rapid computer-aided engineering application to reduce the die design and development time.

Generally speaking, there are three methods to run a software program remotely: (1) to adopt remote application sharing software packages, (2) to extend the traditional interactive software to have dedicated networking capability so as to be accessed through network, and (3) to develop a platform-independent remote operation environment through common gateway interface (CGI) of Web server or equivalent environment. The easiest way to access a remote software program is through the first method where an application sharing software package can be installed separately on both the server side and the client side. This is suitable for legacy software and used normally between only two computers – the server computer that has the legacy software installed and the client computer that can access the server’s software. However, the load of networking on data transmission of the first method is normally very heavy resulting in unreliable accessibility through the publicly shared Internet. The second method needs to implement networking functionality into the software program that normally was old and developed without considering networking and inter-connectivity issues. Therefore, it needs a lot of efforts to rewrite existed software program for remote access. The third method provides an environment to access the remote software without the need to consider too much networking functionality in rewriting the original software program since the Web has already supported networking channel and

platform-independent user interface. The third method was adopted in this paper to extending an existed software program in solid metal extrusion die surface optimization.

The objective of this research was therefore focused on the development of a platform-independent user interface towards the use of a remote CAE software application, which will be illustrated in the following sections.

三、Realization of this study

Traditionally, there could have three modules [6] in extrusion die design processes: (1) die design parameters selection, (2) die surface analysis and optimization, and (3) die manufacturing. These modules were mostly applied through the sequential [7,8] operation based on single-user and single-location philosophy rather than concurrent [9,10,11] point of view. With the rapid growth on the number of multi-location enterprises, collaborative work has been paid more attention in these years forming strategic partners to enhance competitiveness. Therefore, these modules were extended in this paper to be in distributed mode and the second module can then be accessed through the worldwide web, as shown in Figure 1.

WWW Browsers (Client) (PC, Linux, etc.) WWW Server (Linux) C, C++ Storage Space Extusion Die Surface

Optmization (Module 2, Figure 1)

HTTP request

Server Response

Figure 1 Distributed remote extrusion die surface CAE through CGI

The common gateway interface (CGI) was adopted in this paper on the Web server side to extend an extrusion die surface optimization software program to be accessed remotely, as shown in Figure 2. This extrusion die surface optimization program was developed by the author [6] and can be used to calculate an optimized 3D extrusion die surface with circular die entrance shape changed to exit of planar shapes such as circular, elliptic and hexagon. The responded messages for the confirmation of the remote

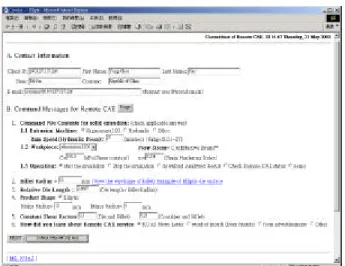

extrusion die surface design system is shown in Figure 3, therefore, users can have opportunity to make sure that proper parameters have been entered. A user can start the simulation for the die surface optimization processes with the mouse click in Figure 4; and once the optimization processes have been finished some messages will be responded, as shown in Figure 4, to notify users to access the information of the optimized die surface, as shown in Figure 5. The platform-independent JAVA applet was also adopted to develop the graphics display interface to show the wire-frame of the optimized extrusion die surface from circular entrance to elliptic exit, as shown in Figure 5; extrusion load and pressure an also be accessed as shown in Figure 6.

Figure 2 The CGI interface to access the remote CAE on extrusion die design

Figure 3 Confirmation of the entered parameters

Figure 4 Messages showing the extrusion die has been optimized and can be viewed

Figure 5 the wire frame of the optimized die surface and related information

Figure 6 the responded messages such as the extrusion pressures, etc.

四、Discussion and Conclusion

A remote CAE system on metal extrusion die surface design has been successfully developed and some preliminary result has been realized, as explained above. The CGI that is commonly supported by Web server has been adopted for this study and also have shown reasonable and successful achievement. The developed system can be accessed by more than one privileged geographically dispersed users remotely at the same time and optimized 3D extrusion die surface wireframe can be viewed through Java Applet

within the popular WWW browsers. Several networking media such as dial-up network, ADSL, Campus network and the Internet have been tested successfully. The significance of this development is in successfully extending traditional local metal forming CAE to be accessed globally. Future development will be focused on graphical user interface (GUI) for die surface and processes information such as velocity distribution contour, etc.

五、References

[1] ACM 1998, Proc. CSCW’98, Seattle, WA USA, 1998

[2] Connolly, John H. And Edmonds, Ernest A. (Eds.) 1994, CSCW and Artificial Intelligence, Springer-Verlag London Limited, ISBN 3-540-19816-4

[3] Feik, Dominic, “Computer Supported Cooperative Work: A Literature Survey”, Working Paper No. 3, The Union Research Centre on Office Technology (URCOT) July 1993, ISSN 1320-2537

[4] Greenberg, Saul 1991, “Computer-supported cooperative work and groupware: an introduction to the special issues”, Int. J. Man-Machine Studies, Vol. 34, pp. 133-141

[5] Feik, Dominic., “Computer Support Cooperative Work: A Literature Survey”, Working paper, 3, The Union Research Centre on Office Technology(URDOT), July 1993, ISSN 1320-2537

[6] [1] Kao, Y.C., Lin, Grier C.I. and He, Juan R. 1996, “Distributed Application of Die

Surface CAD/CAM for Forward Metal Extrusion”, in Proceedings of the International Workshop on Automotive Manufacturing Science and Technology, Jiao Tong University, Shanghai, China, 20-21 June, pp. 367-372

[7] Groover, Mikell P. 1987, Automation, Production Systems, and Computer Integrated Manufacturing, Prentice-Hall, Inc., ISBN 0-13-054610-0, Chap. 8-10

[8] Chen, Yuh-Min and Hsiao, Yun-Tau 1997, “A collaborative data management framework for concurrent product and process development”, in the Journal of Computer Integrated Manufacturing Systems, Vol. 10, No. 4, pp. 446-469

[9] Karinthi, R., V. Jaganna, V. Montan, J. Petro, R. Raman, and G. Trapp, “Promoting concurrent engineering through information sharing”, Proceedings of ASME Winter Annual Meeting, Anaheim, CA, November, 1992, pp. 8-13.

[10] Trapp, G., “Sharing Information: a CALS/CITIS, concurrent engineering and PDES/STEP synergy”. CERC Technical Report, CERT-TR-TM-91-011. Concurrent Engineering Research Center, West Virginia University

[11] Lee, R. S., Y. M. Chen, and C. Z. Lee, “Development of a Concurrent Mold Design System: A Knowledge Based Approach”, Computer Integrated Manufacturing System. Vol.10, No4, 1997, pp287-307.