Case Studies

Identification of Pollution Source of Cadmium in Soil

Application of Material Flow Analysis and A Case Study in Taiwan

Li-Teh Lu1, I-Cheng Chang2*, Teng-Yuan Hsiao3, Yue-Hwa Yu1 and Hwong-Wen Ma11Graduate Institute of Environmental Engineering, National Taiwan University, No. 71, Chou-Shan Road, Taipei, Taiwan 106 2Nan Kai Institute of Technology, Department of Information Management, Assistant Professor, Zhongzheng Rd., No. 568,

542 Caotun Town, Nantou County, Taiwan

3Department of Tourism Industry, Jin-Wen Institute of Technology, No. 99, Ann-Chon Road, Taipei County, Taiwan 231

* Corresponding author (d2507002@gmail.com)

through the route of wastewater in Cd flow analysis were five factories, Coin, Jili, Taiwan Dye, Guangzheng and Mingguan, and they were all categorized as stearate Cd industries; (5) the typical source of the Cd pollution in soil in Changhua County through the pollution route of wastewater should be the metal surfacing process industries.

Conclusions. This study proved that MFA can be a good tool for identifying Cd flow as well as for recognizing the crux of the problem concerning incidents of Cd pollution. This study led to the conclusion that the causal relationship between farmland pollution caused by Cd and stearate Cd factories in Taiwan seemed quite close by way of MFA methodology. In addition, this study also found that the wastewater discharged from a single metal surfacing process factory will not cause remarkable farmland pollution. However, the wastewater simultaneously discharged from a group of pollution factories can result in a significant pollution incident.

Recommendations and Outlook. This case study is only a small contribution to the understanding of the toxic material flow related to Cd in the environment. This study recommends that Taiwanese governmental authorities should not deal with prob-lems on an ad hoc basis, but should instead deal with Cd pollu-tion problems overall employing control measures. Finally, the more accurate information or data we can collect, the more reliable results we can identify. Therefore, the quality and quan-tity of related data used in this MFA model should be closely scrutinized in order to ensure the most correct and comprehen-sive investigation on the toxic material flow.

Keywords: Cadmium (Cd); Cd pollution in soil; farmland Cd pol-lution; heavy metals; Life Cycle Assessment (LCA); Material Flow Analysis (MFA); metal surfacing processes; stearate Cd factory DOI: http://dx.doi.org/10.1065/espr2005.08.278

Abstract

Background. Since the 1970s, at least 200 hectares (ha) of farm-land has been polluted by the heavy metal cadmium (Cd). Con-sequently, the Cd pollution has led to contaminate the rice pro-duction and caused acute social panic. According to the recent investigation results performed by the Taiwan Environmental Protection Administration (TEPA), it is indicated that most of the Cd pollution incidents in Taiwan resulted from the waste-water discharge of stearate Cd factories. To prevent the Cd pol-lution incidents from spreading, the TEPA has either forced these factories to close down or assisted them in improving their pro-duction processes since the 1980s. Unfortunately, accidental in-cidents of Cd pollution still emerge in an endless stream, despite the strict governmental controls placed on these questionable factories. Whether this pollution has resulted from undetected or hidden pollution sources stemming from two decades ago or comes from some new source, will be an outstanding issue. There-fore, this study attempts to identify the pollution sources of Cd in soil in Taiwan as well as to find the solution to the above-mentioned, outstanding issue by way of a methodology termed Material Flow Analysis (MFA).

Methodology. The MFA has proved to be a useful tool on pro-viding quantitative information of the flow of substances through an economic to an environmental system. Based upon the sup-ply-and-demand theory of MFA, researchers have successfully conducted an overview of the use of materials in many indus-tries, the construction industry being one of these. Therefore, this study tries to establish a set of analytical processes by way of MFA for identifying the pollution source of Cd in soil in Taiwan. In addition, the spirit of Life Cycle Assessment (LCA) technique was also employed to identify the materials, and prod-ucts should be ignored as a crucial pollution source in this study. Results and Discussion. According to the MFA methodology applied in this study and on the basis of related studies per-formed by Taiwanese governmental authorities, we arrive at the following analysis results: (1) the total amount of Cd from the economic perspective of material and product flow was approxi-mately 441.2 tons; (2) the wastewater directly discharged into irrigation water can be concluded to be the major pollution route of Cd in farmland soil in Taiwan; (3) material plastic stabilizer (cadmium oxide, CdO), Zn-Pd compounds and Cu compounds should be the crucial pollution sources to contaminate environ-ment through the route of wastewater in Cd flow analysis; (4) the crucial pollution sources to contaminate environment

Introduction

The heavy metal element cadmium (Cd), an odorless and whitish silver metal, has a strong bio-accumulative tendency. Due to its chemical characteristics, which are similar to the heavy metal Zinc (Zn), Cd is easily absorbed into human, plant, and animal tissues [1]. Furthermore, Cd is toxic to all organisms and can enter the human body in many different ways. When Cd or its related compounds are absorbed into the human body, they may cause some or all of the follow-ing symptoms such as salivation, difficulty in breathfollow-ing, nausea, vomiting, abdominal pain, anemia, kidney failure, and diarrhea. Moreover, when Cd dust or smoke is inhaled,

it may cause dryness of the throat, headache, chest pain, coughing, increased uneasiness, and bronchial complications. According to the reference [2], it is indicated that Cd also held an extremely negative influence on the metabolic sys-tems of organisms. In addition, the reference [3] indicated that Cd might cause kidney malfunction or death at levels of 200 mg/kg in the kidney. In 1969, for example, the Itai-itai disease caused the death of 64 people in the Jintsu Val-ley of Toyama Prefecture, Japan [4].

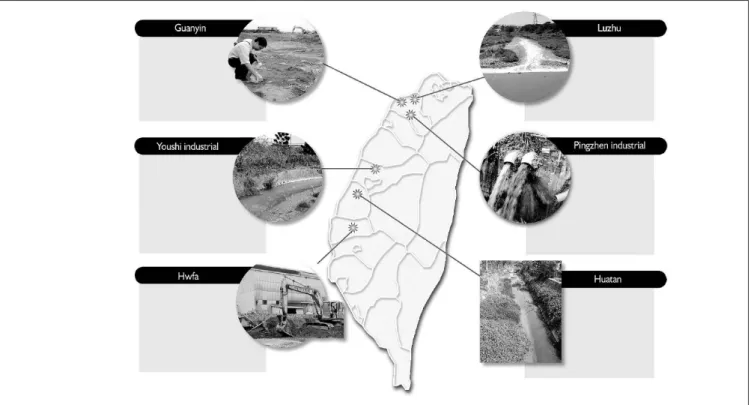

In 1979, several incidents of Cd pollution in soil simultane-ously occurred in Taiwan. The Coin and Jili chemical facto-ries located at Guanyin and Luzhu in Taoyuan County, for example, discharged wastewater containing Cd from the stea-rate Cd production process in one of the most typical cases. The wastewater was directly discharged into irrigation ditches, and ultimately caused approximately 100 ha of farm-lands to fail during the pollution period. To prevent Cd pol-lution in soil incidents from spreading, the Taiwan Environ-mental Protection Administration (TEPA) has either forced

these questionable factories to close down or assisted them in improving their production processes since the 1980s. Unfortunately, accidental incidents of Cd pollution still emerge in an endless stream despite the strict governmental controls placed on these questionable factories. Rice pro-duction or farmlands contaminated by Cd, for example, were found at Huatan in Chsnghua County in 1990, Pingzhen industrial park in Taoyuan County in 1994, and Youshi in-dustrial park in Taichung county in 2001. Fig. 1 indicates the sites of farmlands contaminated by Cd in Taiwan. In addition, Table 1 [5] shows the details of farmlands con-taminated by Cd indicated in Fig. 1, such as pollution source, pollution route, area polluted, and pollution outcome. Cd is frequently found in some production processes that contain the heavy metals Zn, copper (Cu), and lead (Pb). Undoubtedly, the metal surfacing process industries are re-garded as potential sources to discharge Cd into the envi-ronment. For example, Zn-Pb-plating and Cu-plating indus-tries can be regarded as pollution sources of Cd in soil. To

Farmland pollution site a Pollution source a (Factory)

Pollution route a Pollution area (ha) a Pollution outcome a

Guanyin (in Tao Yuan County) Guan-yin chemical Wastewater discharge 17 Cadmium rice Luzhu (in Tao Yuan County) Jili chemical Wastewater discharge 83 Cadmium rice Hwfa (in Yunlin County) Taiwan Dye Wastewater discharge 1 Cadmium rice Pingzhen industrial park (in Tao Yuan County) Uncertain sources Wastewater discharge 1.6 Cadmium farmland Huatan (in Changhua County) Uncertain sources Wastewater discharge 1 Cadmium rice Youshi industrial park (in Taichung County) Uncertain sources Wastewater discharge 0.41 Cadmium rice

a from [5]

Table 1: The details and sites of farmlands in Taiwan contaminated by cadmium

identify, investigate and discuss the pollution sources of Cd in soil as well as to recognize the crux of the problem con-cerning accidental incidents of Cd pollution, this study tries to employ a methodology termed Material Flow Analysis (MFA) in order to implement the purpose of this study, and MFA has proved to be a useful tool on providing quantita-tive information of the flow of substances through econom-ics to environment system.

1 Methodology

As industrial economies developed, the heart of the envi-ronmental challenge comes from the continual flow of goods and services to satisfy the need for housing, food, energy, transport, and recreation by members of society.

The 'Material Flow Analysis (MFA)' methodology can iden-tify the amounts of materials, as classes or individual sub-stances, that enter the economy through market transactions, accumulate in capital stock such as housing and automo-biles, or exit to the environment during the commercial life cycle from extraction to processing, to manufacturing, to use, to disposal or recycling. Fig. 2 shows the relationships between flows of material inputs and outputs, and the inter-action phases of the material life cycle [6].

MFA is an analytical tool that provides quantitative infor-mation on the flows of goods and substances through an economic to an environmental system [7–8]. This informa-tion derived from an MFA system can be used to develop more holistic policies on material management in order to better utilize materials and to more efficiently reduce fluxes to the environment. It has been applied to toxic heavy met-als such as Cd and Pb, to valuable metmet-als such as Cu, to nutrients such as Phosphorus (P), and to organic substances such as CFCs [9], to model the concrete from construction and demolition waste in Taiwan [10], and to examine the technical and economic considerations for a robust concrete recycling system [11–12].

MFA indicators can be combined with ambient and other measures to enable governmental managers to set more in-clusive targets and better identify the effectiveness of envi-ronmental policies. At the operational level, more detailed accounts can help identify the most effective points for policy intervention to increase the efficiency of the flow of mate-rials and reduce the dispersion of hazardous matemate-rials to the environment. For example, MFAs support indicators of resource productivity that allow comparisons between dif-ferent phases of the life cycle for the same material flow (e.g. ratios of production waste to production, or outputs to uses) or between different flows (e.g. feed crops and meat production). These indicators offer insight into how the eco-nomic activity relates to the flow of materials into the envi-ronment [13]. Between the 1970s and the mid-1990s, for example, the amount of residues recovered from lumber production rose 24%, indicating the increased flow of the residues to paper manufacture and energy recovery [14]. Different materials management strategies can be designed and tested by MFA to compare the flows to the environ-ment, or against some acceptance criteria for environmen-tal loading. A major advantage of the MFA methodology is that it accounts for stocks of Cd in the anthroposphere and can be used to predict future flows to the environment un-der different material management scenarios.

The methodology is initially quite resource intensive, but with the establishment of databases of goods and material concentrations in various goods, and with a development of understanding of the partitioning of materials through proc-esses, the methodology becomes more economically avail-able. This study on the concentration of Cd in raw material and goods has largely been undertaken. The major task to be carried out in Taiwan is to determine the flow of Cd containing goods through related processes.

The pre-task of applying MFA is to determine the study scope, system boundary, and material. Therefore, the analysis and calculation procedure of MFA can be

marized using the following four items and is illustrated in

Fig. 3 [15].

(1) Input of the material to processes of a study system. (2) Summation of stocks of the material in processes of the

study system.

(3) Output of material from anthropogenic processes to out-side environment.

(4) Use of input/output analysis results on material manage-ment issue.

Consequently, any strategies of the material management can be discussed through the results of an MFA system. For example, the life cycle of material and related control poli-cies can be studied and drawn up through the change of quantity of material in an MFA system. To prevent the Cd pollution incidents from spreading, the TEPA has either forced these factories to close down or assisted them in im-proving their production processes since the 1980s. Unfor-tunately, accidental incidents of Cd pollution still emerge in an endless stream despite the strict governmental controls placed on these questionable factories. Whether this pollu-tion has resulted from undetected or hidden pollupollu-tion sources from 20 years ago or comes from some new source will be an outstanding issue. Therefore, this study attempts to iden-tify the pollution sources of Cd in soil in Taiwan as well as to find the solution to the above-mentioned, outstanding issue by way of the methodology termed MFA.

2 Data Sources and Constraint

Owing to the deficiency of some environmental and eco-nomic database, this study was based on data collected from the Taiwanese governmental data sources between 1981 and 2002, such as the area contaminated by Cd and wastewater flow rate as well as its quality, the amount of Cd used in pro-duction processes, etc. In addition, the underground or un-licensed factories were ignored in this study and some as-sumption data used in this study all has been stated clearly.

3 Results and Discussion

3.1 Results of the Cd flow analysis from the perspective of economic system

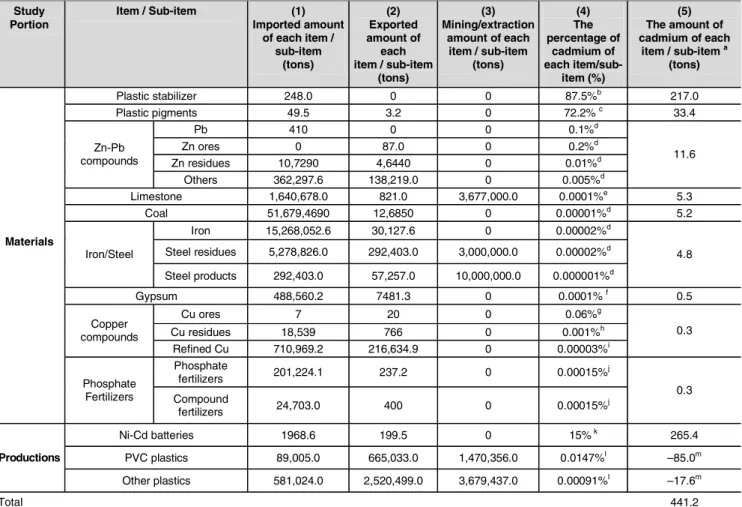

The analysis direction and the quantity of the Cd flow in Taiwan can be performed from two main portions in this study, i.e. the material phase and the product phase. Based on the available import/export and mining/extraction data collected from Taiwanese governmental data sources, plas-tic stabilizer (cadmium oxide, CdO), plasplas-tic pigments, zinc-lead (Zn-Pb) compounds, limestone, coal, iron and steel, gypsum, Cu compounds, and phosphate fertilizers consist of the material phase of Cd flow in this study. Aside from nickel-cadmium (Ni-Cd) batteries, polyvinyl chloride (PVC) plastics, and other plastics consist of the product phase of Cd flow in this study. This study summarized the detailed calculation procedure and data sources concerning the

mentioned materials and product flow in Table 2 [16–24]. Eventually, Table 2 indicates that the total amount of Cd from the economic perspective of material and product flow is approximately 441.2 tons.

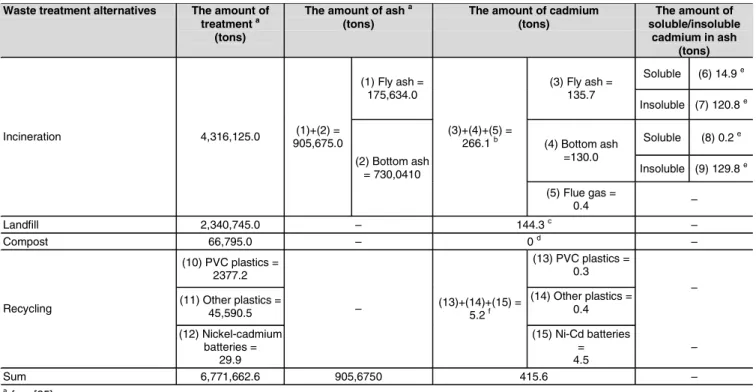

According to the statistics of the TEPA [25], it is indicated that the total amount of solid waste treatment (incinera-tion, landfill and compost) in Taiwan was approximately 6,723,665 tons in 2002. It is also indicated that approxi-mately 64.2% of the garbage was treated by the incinera-tion mode, 34.8% was treated by the incineraincinera-tion landfill mode, and only 1% was treated by the compost mode. In addition, the statistics of TEPA [24] indicated that the total recycling amount of plastics (PVC plastics and other plas-tics) in Taiwan was approximately 45,967.7 tons; the total recycling amount of Ni-Cd batteries in Taiwan was approxi-mately 29.9 tons. The incineration ash was divided into two major categories in this study, namely fly ash and bottom ash. According to the statistics of TEPA [26], it indicated that the average amount of the heavy metal Cd in fly ash was

ap-proximately 773 mg/kg, and the average amount of the heavy metal Cd in bottom ash was approximately 178 mg/kg. In addition, the statistics of TEPA [26] indicated that the portion of the amount of fly ash to the amount of ash pro-duced by the incinerators was approximately 50.96%, the proportion of the amount of bottom ash to the amount of ash produced by the incinerators was approximately 48.91%, and the proportion of the amount of airborne emission in flue gas to the amount of ash produced by the incinerators was approximately 0.14%. According to reference [27], it is indicated that the average amount of soluble Cd in fly ash is approximately 4.25 mg/L by way of the 'Toxicity charac-teristic leaching procedure (TCLP),' and the average amount of soluble Cd in bottom ash is approximately 0.01 mg/L. According to above-mentioned statistics/data, this study summarized the detailed calculation procedure and data sources concerning Cd flow analysis of Taiwanese Munici-pal Solid Waste (MSW) treatment alternatives in 2002 as shown in Table 3. Study Portion Item / Sub-item (1) Imported amount of each item / sub-item (tons) (2) Exported amount of each item / sub-item (tons) (3) Mining/extraction amount of each item / sub-item (tons) (4) The percentage of cadmium of each item/sub-item (%) (5) The amount of cadmium of each item / sub-item a (tons) Plastic stabilizer 248.0 0 0 87.5%b 217.0 Plastic pigments 49.5 3.2 0 72.2% c 33.4 Pb 410 0 0 0.1%d Zn ores 0 87.0 0 0.2%d Zn residues 10,7290 4,6440 0 0.01%d Zn-Pb compounds Others 362,297.6 138,219.0 0 0.005%d 11.6 Limestone 1,640,678.0 821.0 3,677,000.0 0.0001%e 5.3 Coal 51,679,4690 12,6850 0 0.00001%d 5.2 Iron 15,268,052.6 30,127.6 0 0.00002%d Steel residues 5,278,826.0 292,403.0 3,000,000.0 0.00002%d Iron/Steel Steel products 292,403.0 57,257.0 10,000,000.0 0.000001%d 4.8 Gypsum 488,560.2 7481.3 0 0.0001% f 0.5 Cu ores 7 20 0 0.06%g Cu residues 18,539 766 0 0.001%h Copper compounds Refined Cu 710,969.2 216,634.9 0 0.00003%i 0.3 Phosphate fertilizers 201,224.1 237.2 0 0.00015% j Materials Phosphate Fertilizers Compound fertilizers 24,703.0 400 0 0.00015% j 0.3 Ni-Cd batteries 1968.6 199.5 0 15% k 265.4 PVC plastics 89,005.0 665,033.0 1,470,356.0 0.0147%l –85.0m Productions Other plastics 581,024.0 2,520,499.0 3,679,437.0 0.00091%l –17.6m Total 441.2

a column(5)=[column(1)-column(2)+column(3)]×column(4); imported amount=column(1)×column(4); Exported amount=column(2)×column(4);

Mining/Extraction amount= column(3)×column(4)

b This study presumes the plastic stabilizer is in form of cadmium oxide (CdO) compound. Consequently, the percentage of cadmium of CdO is 87.5ˁ c from [16]; d from [17]; e from [18]; f from[19]; g from [20]; h from [21]; i from [22]

j The TEPA standard level of cadmium is 1.5 mg/kg k

from [23]; l from [24]

m

The exported amount of cadmium is larger than the imported amount of cadmium in Taiwan

Table 3 indicates that the amount of Cd from the fly and bottom ash of incinerators in Taiwan in 2002 is approxi-mately 266.1 tons, the amount of Cd from landfills is ap-proximately 144.3 tons, the amount of Cd from flue gas is approximately 0.4 tons, and the amount of Cd from plastic and Ni-Cd battery recycling is approximately 5.2 tons. In addition, Table 3 also indicates that the amount of soluble Cd in fly ash is approximately 14.9 tons, and the amount of soluble Cd in bottom ash is approximately 0.2 tons. Here,

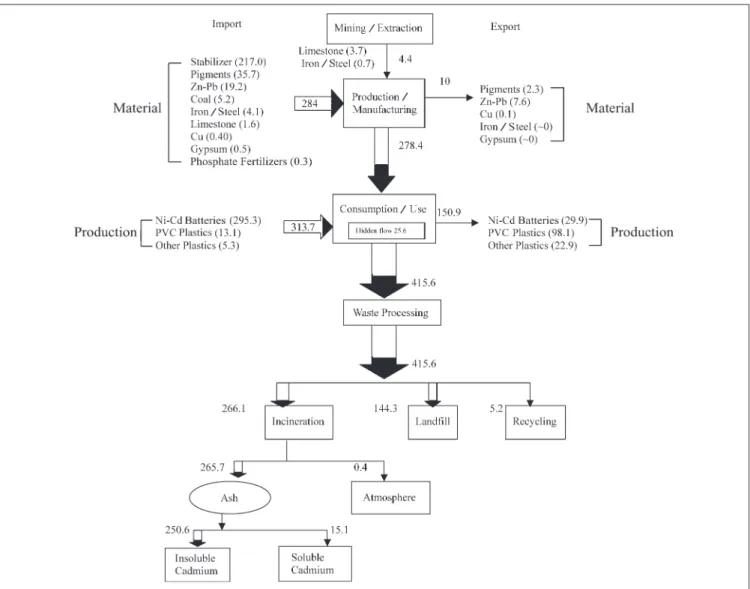

Fig. 4 shows the calculation results of Table 2 and Table 3. 3.2 The dominant pollution route of Cd in farmland soil

in Taiwan

It is widely recognized that (1) the heavy metal Cd contami-nation through air pollution or irrigation water, (2) the use of fertilizer containing Cd, and (3) the original heavy metal Cd existing in the soil are regarded as three principal pollu-tion sources of Cd in farmland soil in Taiwan. According to the statistics of TEPA [28], it is indicated that the propor-tion of the amount of Cd pollupropor-tion from the source of sedi-ment of the ditches and irrigation water to other sources was approximately 93%. Additionally, some pollution sources studies on Jili, Coin, and Taiwan Dye factories per-formed by the TEPA [29], also found that contaminated ir-rigation water and canal sediment were strongly correlated to the Cd contamination in the farmland soil in Taiwan. Consequently, wastewater directly discharged into irrigation

water can be concluded to be the major pollution route of Cd in farmland soil in Taiwan. It was also observed in the preceding Table 1 that wastewater was the dominant pollu-tion route of Cd in farmland soil in Taiwan.

3.3 Ignorable materials and products on identifying the crucial pollution source through the route of wastewater in Cd flow analysis

According to the results of the preceding sub-section 3.1 and 3.2, this study attempted to tabulate the materials and products to be ignored as a crucial pollution source to envi-ronment in Cd flow analysis through an Life Cycle Assess-ment (LCA) technique, such as the process of Cd mining/ extraction, production/manufacturing and consumption/use. All analysis results and discussions are enumerated and shown in Table 4.

Table 4 indicates that (1) owing to the Cd flow in the proc-ess of mining/extraction concerning material limestone, iron and steel will not contaminate environment through the pollution route of wastewater, and they can be ignored as a crucial pollution source to environment in this study; (2) due to the fact that Cd component is retained in the prod-ucts, or contaminates the environment through the route of air, or is discarded as a solid waste and is buried in a landfill, the Cd flow in the process of production/manufacturing concerning materials pigments, limestone, gypsum and coal can be ignored as a crucial pollution source to the

environ-Waste treatment alternatives The amount of treatment a

(tons)

The amount of ash a (tons)

The amount of cadmium (tons) The amount of soluble/insoluble cadmium in ash (tons) Soluble (6) 14.9 e (1) Fly ash = 175,634.0 (3) Fly ash = 135.7 Insoluble (7) 120.8 e Soluble (8) 0.2 e (4) Bottom ash =130.0 Insoluble (9) 129.8 e Incineration 4,316,125.0 (1)+(2) = 905,675.0 (2) Bottom ash = 730,0410 (3)+(4)+(5) = 266.1 b (5) Flue gas = 0.4 – Landfill 2,340,745.0 – 144.3 c – Compost 66,795.0 – 0 d – (10) PVC plastics = 2377.2 (13) PVC plastics = 0.3 (11) Other plastics = 45,590.5 (14) Other plastics = 0.4 – Recycling (12) Nickel-cadmium batteries = 29.9 – (13)+(14)+(15) = 5.2 f (15) Ni-Cd batteries = 4.5 – Sum 6,771,662.6 905,6750 415.6 – a from[25] b

(3)=(1) × (mg of cadmium in unit kilogram of fly ash: 773 mg/Kg, from [26])×10–6; (4)=(2) × (mg of cadmium in unit kilogram of bottom ash: 178 mg/Kg, from [26])×10–6; (5)=(3)×50.96%÷0.14%, from [26]

c

Cadmium amount in landfills= Treatment amount of landfill × (mg of cadmium in unit kilogram of treatment amount of landfill: 61.65 mg/kg, from [26]) × 10–9

d

The garbage in compost does not contain plastics and nickel-cadmium batteries. Consequently, the cadmium in this study was presumed to be zero

e

(6)=(3)×2(liters)×(The TCLP soluble cadmium of the fly ash:4.25 mg/L, from [27])÷100(gram)×10–5; (7)=(3)-(6); (8)=(4)×2(liters)×(The TCLP soluble cadmium of the bottom ash: 0.01 mg/L, from [27])÷100(gram)×10–5˗(9)=(4)-(8)

f (13)=(10)×0.0147% , from [24]; (14)=(11)×0.00091% , from[24]; (15)=(12)×15%, from [23]

Fig. 4: The cadmium material flow in Taiwan from the perspective of an economic system in 2002 (tons)

ment in this study; (3) due to production, Ni-Cd batteries are all imported from other countries and are usually buried in a landfill after being discarded. In addition, the Cd ponents are retained stably in Ni-Cd batteries, the Cd com-ponents will not leach out easily and cause environmental problems through the route of wastewater, and the Cd flow in the process of consumption/ use concerning the produc-tion of Ni-Cd batteries can be ignored as a crucial polluproduc-tion source to the environment in this study; (4) due to the fact that the Cd components are retained stably in the produc-tion of PVC plastics and other plastics buried in a landfill after being discarded, Cd component will not leach out eas-ily and cause environmental problems through the route of wastewater, and the Cd flow in the process of consumption/ use concerning the production of PVC plastics and other plastics can also be ignored as a crucial pollution source to the environment in this study. In addition, according to the studies performed by the Environmental Protection Bureau of Hsinchu (EPBH), it has been indicated that there were no Cd leaching out-incidents to be found in the body of water near the Nanliao landfill that has been operating for more than 3 decades, as well as the Jin Shui landfill that has been

operating for more than 1 decade. Besides, the study results also indicate the concentration of Cd in the soil near the above-mentioned landfills was both under the standard level [30]; (5) the Cd flow in the process of production/manufac-turing concerning material iron and steel, and phosphate fertilizers can also be ignored as a crucial pollution source to the environment in this study, and they have been clearly discussed in Table 4.

3.4 The crucial pollution source to contaminate the environment through the pollution route of wastewater in Cd flow analysis

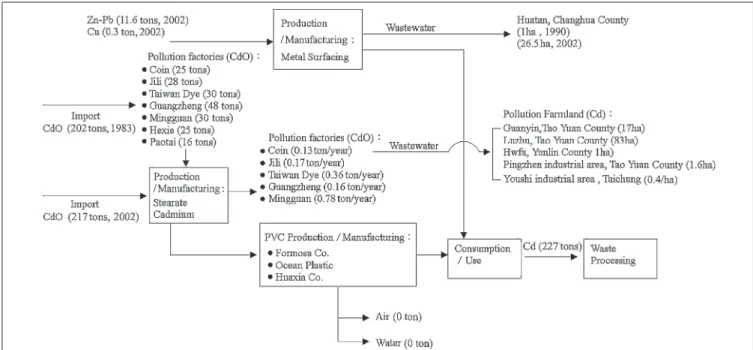

According to the results of the preceding sub-sections 3.1 and 3.2, this study eventually summarized through a LCA technique that material plastic stabilizer (cadmium oxide, CdO), Zn-Pd compounds and Cu compounds should be the crucial pollution sources to contaminate the environment through the route of wastewater in Cd flow analysis in Tai-wan in 2002. It was also observed in the preceding Table 1 that the Cd pollution incidents resulted from the wastewater discharge of these industries.

3.5 The relationship between the Cd pollution in soil and the stearate Cd factories in Taiwan

Stearate Cd is one stabilizer used in plastics, and is mainly used to inhibit decomposition caused by light and heat during the production process. Besides, it is especially important in the production of PVC products. Generally, there are two methods to produce stearate Cd. The first method is termed direct melting which is known as the dry method. This method directly heats up the CdO and stearate. The stearate Cd is produced without using water. Consequently, no wastewater is discharged. The second method is termed the wet method. The Cd is melted in nitrate or sulfurate, and then compounded with stearate to become stearate Cd. The wet processing

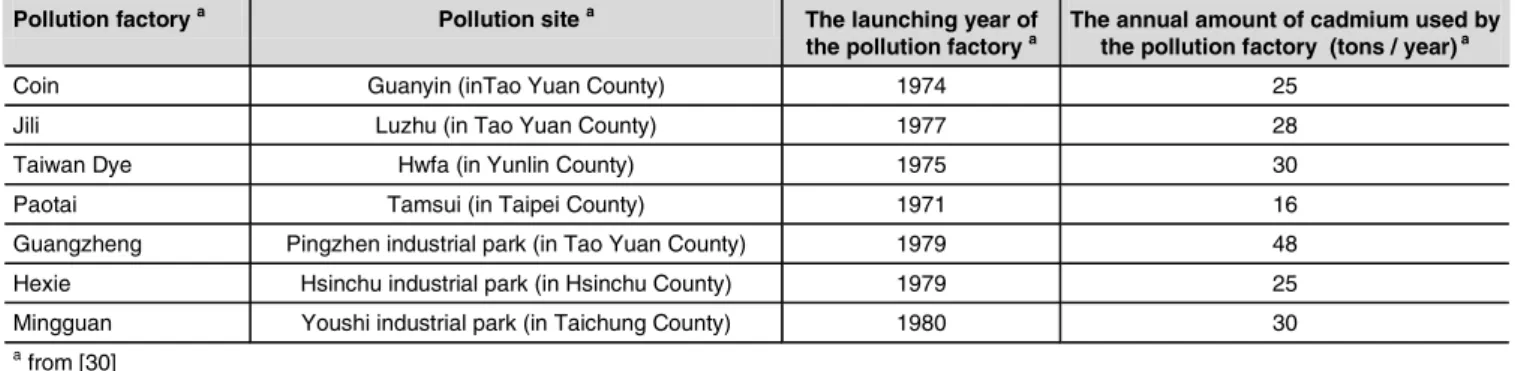

method not only consumes water during production, but also needs to be further washed and dehydrated. This leads to wastewater containing Cd, which causes Cd pollution when discharging. According to studies performed by the Taiwan Water Pollution Control Institute (TWPCI), they were found among the seven factories (Coin, Jili , Taiwan Dye, Paotai, Guangzheng, Hexie, and Mingguan Chemical) which were regarded as questionable pollution sources of Cd, and they were all categorized as stearate Cd industries. The annual amount of Cd consumed by the seven factories is approxi-mately 202 tons, which represented more than 90% of the total amount of imported Cd [31]. Table 5 shows the details of the above-mentioned seven questionable factories.

Life cycle (Process)

Material/production The amount of material /production

(tons)

The amount of cadmium of material /production

(tons)

Analysis results and discussion

Limestone 3.7 Ignored in this study Mining/

Extraction Iron/Steel 0.7 Ignored in this study

The cadmium flow in the process of mining/extraction concerning material limestone,

iron and steel will not contaminate environment through the route of wastewater. Pigments 33.4 Ignored in this study The cadmium component is retained in the

products, and it will not contaminate environment through the route of wastewater. Limestone 1.6 Ignored in this study The cadmium component is retained in the

products, and it will not contaminate environment through the route of wastewater. Coal 5.2 Ignored in this study The cadmium flow in fly and bottom ash was

discarded as solid waste and buried in a landfill, and it will not contaminate environment through the

route of wastewater.

Iron/Steel 4.1 Ignored in this study These sources of cadmium flow are located in southern Taiwan (Kaoshung). It is impossible for these sources

to cause cadmium pollution in central Taiwan. Gypsum 0.5 Ignored in this study The cadmium component is retained in the

products, and it will not contaminate environment through the route of wastewater. Production/

Manufacturing

Phosphate Fertilizers

0.3 Ignored in this study Owing to phosphate fertilizers are used in northern, central, southern, and eastern Taiwan. Consequently, it is impossible for phosphate fertilizers to cause cadmium pollution only on a

designated area such as central Taiwan. Ni-Cd Batteries 265.4 Ignored in this study

PVC Plastics –85.0 a Ignored in this study Consumption/

Use Other Plastics –17.6 a Ignored in this study

The cadmium component is retailed stably in production Ni-Cd batteries, PVC plastics, and other

plastics, or is buried in a landfill after being discarded. Therefore, cadmium flow will not leach out easily and cause environmental contamination

problems through the route of wastewater.

a

The exported amount of cadmium is larger than the imported amount of cadmium in Taiwan

Table 4: The ignorable materials and products on identifying the crucial pollution source through the pollution route of wastewater in cadmium flow analysis

Pollution factory a Pollution site a

The launching year of the pollution factory a

The annual amount of cadmium used by the pollution factory (tons / year) a

Coin Guanyin (inTao Yuan County) 1974 25 Jili Luzhu (in Tao Yuan County) 1977 28 Taiwan Dye Hwfa (in Yunlin County) 1975 30 Paotai Tamsui (in Taipei County) 1971 16 Guangzheng Pingzhen industrial park (in Tao Yuan County) 1979 48 Hexie Hsinchu industrial park (in Hsinchu County) 1979 25 Mingguan Youshi industrial park (in Taichung County) 1980 30

a

from [30]

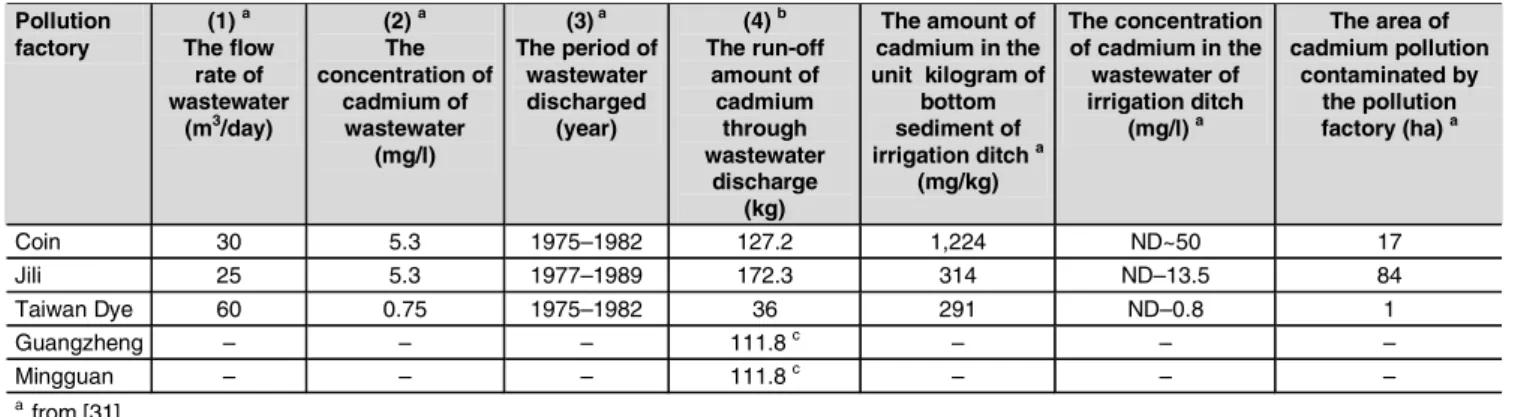

Based on the available data of wastewater discharge, this study could only select five factories (Coin, Jili, Taiwan Dye, Guangzheng and Mingguan) from the above-mentioned seven questionable factories, and summarized the details of calculation concerning the run-off amount of Cd in Table 6. Furthermore, if we assume that the topsoil depth in a pollu-tion site contaminated by Cd is 15 cm on the basis of the concentration standard level of Cd in soil (5 mg/kg), one hectare of farmland will then hold approximately 13.5 kg Cd in soil. Therefore, if we discharge 13.5 kg of Cd into a farmland, then it will result in one hectare of farmland con-taminated by Cd. It was also observed in the preceding Ta-ble 6, for example, that Coin discharged 127.2 kg (super-large as compared with 13.5 kg) of Cd and eventually resulted in 17 ha of farmland contaminated by Cd. Clearly, the above-mentioned, five pollution factories (Coin, Jili, Taiwan Dye, Guangzheng and Mingguan) all used Cd in their production processes. Judging from this study, we concluded that the cru-cial pollution sources to contaminate the environment through the route of wastewater in Cd flow analysis were the Coin, Jili, Taiwan Dye, Guangzheng and Mingguan factories.

3.6 The relationship between the Cd pollution in soil and the metal surfacing process factories in a case study County-Changhua

A small amount of heavy metals, for example Cd, are gener-ally obtained as by-products from the process of mining/ extraction or metal surfacing process industries. Clearly, the Cd is a by-product in the process of Zn mining/extraction. Therefore, when discussing the flow of Cd by way of MFA, we not only should examine the metals containing Cd, but also should take the production of Zn compounds and other metals having Cd as by-products into consideration [32]. As mentioned previously, as well as on the basis of the re-sults derived from MFA methodology in this study, the metal surfacing process industries will undoubtedly cause Cd pol-lution. In the preceding sub-section, we merely tried to fo-cus our study issue on the relationship between the Cd pol-lution in soil and the stearate Cd factories in Taiwan. Therefore, we neglected considering other metal surfacing process industries, which produce of Zn, Pb, and Cu

com-pounds having Cd as by-products and which can conse-quently cause Cd pollution in soil. However, we placed the above-mentioned study issue in this sub-section and a typi-cal Cd pollution incident in case study County-Changhua County was discussed here. According to reference [28], it is indicated that there were 2209 metal surfacing process factories to be categorized as Cd pollution sources in soil in Taiwan in 2002. In addition, it also indicated that the an-nual run-off amount of Cd discharged from the 2209 facto-ries through pollution route of wastewater was approxi-mately 119.91 kg/year. Therefore, this study estimated that the annual run-off amount of Cd discharged from 498 metal surfacing factories located in Changhua County was approxi-mately 26.9 kg (26.9=119.9 × 498÷2209).

Eventually, this study integrated the results of this section into

Fig. 5. Fig. 5 shows the Cd flow relationships among Zn-Pb

compounds, Cu compounds, and stearate Cd factories.

4 Conclusions and Recommendations

Since the 1970s, at least 200 ha of farmland has been pol-luted by the heavy metal Cd in Taiwan. The above-men-tioned crisis has caused some rice production contaminated by Cd and acute social panic. According to the studies per-formed by the TEPA, it has been indicated that the main crucial pollution source of Cd in soil in Taiwan was from the wastewater discharge of metal surfacing process indus-tries. To prevent the Cd pollution incidents from spreading, the TEPA has either forced these factories to close down or assisted them to improve their production processes since the 1980s. Unfortunately, accidental incidents of Cd pollution still emerge in an endless stream despite the strict governmental controls placed on these questionable factories during the sub-sequent two decades. Whether this pollution has resulted from undetected or hidden pollution sources from 2 decades ago or comes from some new source will be an outstanding issue. Therefore, this study attempts to identify the potential crucial pollution source of Cd in soil in Taiwan and find the solution to the outstanding issue by way of MFA, and these results lead to the following conclusions:

1. MFA methodology can clearly identify the flow of toxic material in an environmental and economic system.

Con-Pollution factory (1) a The flow rate of wastewater (m3/day) (2) a The concentration of cadmium of wastewater (mg/l) (3) a The period of wastewater discharged (year) (4) b The run-off amount of cadmium through wastewater discharge (kg) The amount of cadmium in the unit kilogram of bottom sediment of irrigation ditch a (mg/kg) The concentration of cadmium in the wastewater of irrigation ditch (mg/l) a The area of cadmium pollution contaminated by the pollution factory (ha) a Coin 30 5.3 1975–1982 127.2 1,224 ND~50 17 Jili 25 5.3 1977–1989 172.3 314 ND–13.5 84 Taiwan Dye 60 0.75 1975–1982 36 291 ND–0.8 1 Guangzheng – – – 111.8 c – – – Mingguan – – – 111.8 c – – – a from [31] b

column(4)=column(1)×column(2)×column(3); The average annual operational days in column (3) are presumed 100 days/year in this study, from [31]

c

Owing to the statistics are not available from Taiwanese governmental data sources, the data value is estimated on the basis of the average of Coin, Jili, and Taiwan Dye

sequently, this study employed MFA as a useful imple-mentation to identify pollution sources of Cd in soil in Taiwan.

2. According to the MFA methodology applied in this study and on the basis of related studies performed by Tai-wanese governmental authorities, this study led to the conclusion that the causal relationship between farm-land pollution and stearate Cd factories in Taiwan seemed quite close by way of MFA methodology.

3. In the past years, owing to the over-development of pet-rochemical industries in Taiwan, as well as the mass pro-duction on PVC using stearate as stabilizers, and disre-gard of the removal of heavy metal Cd in their wastewater treatment facilities, the farmlands near the petrochemi-cal industries, such as Jili, Coin, Taiwan Dye, Guang-Zheng, Ming-guang, have been critically polluted by the heavy metal Cd.

4. According to the MFA methodology applied in this study and on the basis of related studies performed by the Tai-wanese governmental authorities, this study led to the conclusion that the typical source of the Cd pollution source in soil in Changhua County through the pollu-tion route of wastewater should be the metal surfacing process industries.

5. This study also found that the wastewater discharged from a single metal surfacing process factory will not cause remarkable farmland pollution. However, the wastewater simultaneously discharged from a group of pollution factories can result in a significant pollution incident. Therefore, this study recommends that Taiwan-ese governmental authorities should not deal with prob-lems on an ad hoc basis, but should instead deal with Cd pollution problems as an overall control measure. 6. This case study is only a small contribution to the

under-standing of the toxic material flow related to Cd in an

Fig. 5: The cadmium flow relationships among Zn-Pb compounds, Cu compounds and stearate Cd factories

environmental and economic system. Furthermore, the more accurate information or data we can collect, the more reliable results we can identify. Therefore, the qual-ity and quantqual-ity of related data used in this MFA model should be closely scrutinized in order to ensure the most correct and comprehensive investigation on the toxic material flow.

Acknowledgments. The authors would like to thank the Taiwan

Envi-ronment Protection Administration (TEPA) for financially supporting this research under Contract No. EPA-91-H103-02-214.

References

[1] van der Voet E, van Egmond L, Kleijn R, Huppe G (1994): Cadmium in the European Community: A Policy-Oriented Analysis. Waste Management and Research 12, 507–526 [2] Doyle JJ (1977): Effect of low levels of dietary cadmium in

animal review. Journal of Environment Quality 6, 111–116 [3] Fassett DW (1980): Cadmium. In: Waldron HA (ed), Metals in

the Environment. Academic Press, London, pp 61–110 [4] Friberg L, Piscator M, Nordberg GF, Kjellstorm T (1974):

Cad-mium in the Environment. CRC Press, Cleveland

[5] Taiwan Environmental Protection Administration (TEPA) (2000): The report of soil heavy metal in Taiwan (in Chinese) [6] Wernick IK, Irwin FH (2004): Material Flow Accounts: A Tool

for Making Environmental Policy. The World Resources Insti-tute, Washington DC, USA

[7] Bauer G, Deistler M, Gleiß A, Glenck E, Matyus T (1997): Identification of Material Flow Systems. Env Sci Pollut Res 4 (2) 105–112

[8] Deistler M, Matyus T, Bauer G, Gleiß A, Glenck E, Lampert C (1998): Identification of Material Flow Systems: Extensions and Case Study. Env Sci Pollut Res 5 (4) 245–258

[9] Brunner PH, Rechberger H (2004): Practical Handbook of Material Flow Analysis. Lewis Publishers

[10] Hsiao TY, Huang YT, Yu YH, Wernick IK (2002): Modeling Materials Flows of Waste Concrete from Construction and Demo-lition Wastes in Taiwan. Resources Policy 28/1–2, 39–47

[11] Kelly T (1998): Crushed Cement Concrete Substitution for Con-struction Aggregates: A Materials Flow Analysis. Washington, DC, United States Geological Survey Circular No. 1177 [12] Wilburn DR, Goonan TG (1998): Aggregates from Natural and

Recycled Sources Economic Assessments for Construction Ap-plications: A Materials Flow Analysis. Washington, DC, United States Geological Survey Circular No. 1176

[13] Templet PH (1995): The Positive Relationship Between Jobs, Environment, and Pollution: An Empirical Analysis. Spectrum, Spring issue, pp 37–49

[14] Wernick IK, Paul E, Waggoner, Jesse HA (1998): Searching for Leverage to Conserve Forests: The Industrial Ecology of Wood Products in the US. Journal of Industrial Ecology 1 (3) 125–145 [15] Baccini P, Brunner PH (1991): Metabolism of the

Anthropo-sphere. Springer Verlag, Berlin

[16] Tamaddon F, Hogland W (1993): Review of Cadmium in Plas-tic Waste in Sweden. Waste Management and Research 11, 287–295

[17] Suphaphat K, David W, Stephen M (2002): Use of Information from Material Flux Analysis for Human Health Risk Assessment at Regional Scales: Cadmium as a case study in Australia. The Third Australia Conference on Life Cycle Assessment, Australia [18] Mantell CL (1975): Solid wastes: Origin, collection, process-ing and disposal developments in plant and soil sciences. Wiley-Interscience, New York, USA

[19] Senn A, Milham P (2000): Managing cadmium in vegetables. 1st edn., NSW Agriculture

[20] Stigliani WM, Anderberg S (1994): Industrial metabolism at the regional level: The Rhine Basin. In: Ayres RU, Simonis UE (eds), Industrial Metabolism: Restructuring for Sustainable De-velopment. UN University Press, Tokyo-New York-Paris [21] WMC Resource Ltd. (2002): Available on <http://www.wmc.

com.au/>

[22] Woodcock JT, Hamilton JK (eds) (1993): Australasian Insti-tute of Mining and Metallurgy. Monograph Series, 19, The Sir Maurice Mawby Memorial Volume, 2nd edn., Australia [23] Bundesamt Fur Umwelt Wald und Landschaft (1997):

Cadmi-um-Stofffluss Analyse. BUWAL, Switzerland

[24] Taiwan Environmental Protection Administration (TEPA) (2002): Material-Flow Analysis on the Non-Ferrous Metals in Taiwan % Cadmium as an Example. EPA-91-H103-02-214 (in Chinese)

[25] TEPA (Taiwan Environmental Protection Administration) (eds) (2003a): Environmental Protection Statistics of Taiwan. Taipei Taiwan, R.O.C. (in Chinese)

[26] TEPA (Taiwan Environmental Protection Administration) (eds) (2003b): Investigation of Heavy Metals in Incinerator Fly Ash and Bottom Ash. Taipei Taiwan, R.O.C. (in Chinese) [27] Wang KS, Chiang KY (1996): Metal Leachability and Species

Analysis of MSW Incinerator Ashes. 12th International Con-ference on Solid Waste Technology and Management, Phila-delphia, USA, pp 17–20

[28] Taiwan Environmental Protection Administration (TEPA) (2001): The heavy metal investigation project of the irrigation ditch water and sediment in Taiwan. EPA-90-G103-02-228 (in Chinese)

[29] Taiwan Water Pollution Control Institute (TWPCI) (1983): The investigation of polluted farmland by Cd and Pb wastewater [30] Environmental Protection Bureau of Hsinchu (EPBH) (1999):

Investigation of Industrial Park Soil and Underground Water Quality Pollution

[31] Taiwan Water Pollution Control Institute (TWPCI) (1980): The investigation report of toxic substance (in Chinese)

[32] Graedel TE, Allenby BR (1995): Industrial Ecology, Prentice Hall

Received: June 21st, 2004 Accepted: August 5th, 2005

OnlineFirst: August 6th, 2005

Env Sci Pollut Res 4 (2) 105–112 (1997)

and, in special cases, they are optimal, i.e. they have minimal vari-ance. In the second part of the paper, we present a real world ap-plication of the methods proposed: Section 3, in a certain sense, is introductory for the application. The results of data accounting for the metabolism of phosphorus in a region of Upper Austria are de-scribed here. Data accounting methods and various aspects of data uncertainty are discussed. Section 4 is concerned with the math-ematical modeling of the phosphorus system mentioned above. The linear static approach is used for the following purposes: (i) data reconciliation and estimation of unmeasured flows and transfer co-efficients, (ii) choice of control strategies on the basis of control analysis and (iii) to get some hints concerning the improvement of the accounting strategy for phosphorus in this specific region. The case study relates to a real world application and is therefore of some complexity. Nevertheless, it may serve as a demonstration example for the practitioner.

Identification of Material Flow Systems − Extensions and Case Study

Andreas Gleiß1, Thomas Matyus1, Gerd Bauer1, Manfred Deistler1*, Emmanuel Glenck2, Christoph Lampert3

1Institute for Econometrics, Operations Research and System Theory, Division for Econometrics and System Theory,

University of Technology, Argentinierstraße 8, 1040 Vienna, Austria

2Data Organisation-Consulting, Bauer & Glenck OEG, Steckhovengasse 23/19,1130 Vienna, Austria

3Institute for Water Quality and Waste Management, Department for Waste Management, University of Technology, Karlsplatz 13,

1040 Vienna, Austria

* Corresponding author (deistler@e119ws1.tuwien.ac.at) This paper consists of two main parts: In the first part (Section 2), a mathematical analysis of material flow systems is given. To be more precise, the problems of model description, data reconcilia-tion using e.g. mass balances, identificareconcilia-tion of subsystems and simulation are dealt with for the linear, static case. Main emphasis is put on data driven modeling by considering the material flow analysis (MFA) problem as a particularly structured system-identi-fication problem. The results obtained generalize those described in a previous paper (BAUER et al. 1997) in particular, by taking into account the information contained in noisy measurements of transfer coefficients, by further extending origins analysi (developed by VAN DER VOET et al. 1995) and by introducing control analysis as a new instrument for policy simulation. Compared to traditional ap-proaches in MFA, information about the whole system is used here to generate estimates for the flows and transfer coefficients in a systematic way. The estimates satisfy the mass balance principle

![Fig. 2: The material flows and the life cycle of materials (from [6])](https://thumb-ap.123doks.com/thumbv2/9libinfo/8776073.213964/3.892.66.830.798.1070/fig-material-flows-life-cycle-materials.webp)

![Fig. 3: The flow chart of an anthropogenic material flow system comprises goods and processes (from [15])](https://thumb-ap.123doks.com/thumbv2/9libinfo/8776073.213964/4.892.77.826.100.572/fig-flow-chart-anthropogenic-material-comprises-goods-processes.webp)