ContentslistsavailableatSciVerseScienceDirect

Precision

Engineering

jou rn a l h o m e pa g e :w w w . e l s e v i e r . c o m / l o c a t e / p r e c i s i o n

Technical

note

Development

of

a

new

apparatus

for

ultrasonic

vibration-assisted

glass

hot

embossing

process

Jung-Chung

Hung

a,

Yen-Pin

Tsai

b,

Chinghua

Hung

b,∗aDepartmentofMechanicalEngineering,NationalChin-YiUniversityofTechnology,No.35,Lane215,Section1,Chung-ShanRoad,TaipingCity,Taichung,41170,Taiwan

bDepartmentofMechanicalEngineering,NationalChiaoTungUniversity,No.1001,TaHsuehRoad,Hsinchu30010,Taiwan

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received18February2012

Receivedinrevisedform2May2012

Accepted12June2012

Available online 10 July 2012 Keywords:

Ultrasonicvibration

Glasshotembossing

a

b

s

t

r

a

c

t

Anewapparatusforanultrasonicvibration-assistedglasshotembossingprocesshasbeendeveloped.The upperdieconstitutestheultrasonicvibratingdevice,andacoolerisprovidedtoprotectthetransducer fromthehighoperatingtemperatures.Anultrasonichornoriginallydesignedforuseatroomtemperature wasmodifiedtoensurecorrectoperationofultrasonicvibratingdeviceforhightemperatureuse.Because theloadcellislocatedinsideavacuumchamber,thedetectionoftheforceappliedtotheglassduringthe formingprocessisnotsignificantlyimpactedbyexternalforces,andthus,apreciseforcehistoryofthe formingglasscanbeobtained.Flathotembossingexperimentswereperformedtoinvestigatetheeffectof ultrasonicvibrationontheamountofforcerequiredduringforming,andFresnelstructurehotembossing experimentswerethenconductedtoinvestigatetheimprovementinmoldingaccuracygainedthrough ultrasonicvibration.Theexperimentalresultsaretakentovalidatethemanufacturingpotentialofthe developedapparatusandtheimprovementinformabilityachievedbyapplyingultrasonicvibration.

© 2012 Elsevier Inc. All rights reserved.

1. Introduction

Opticalglasshotembossingiscrucialforthemassproduction ofopticalelements.Inthisprocess,theglassisfirstlyheatedabove a specific temperature, then embossed using molds with well-machinedsphericalorasphericalsurfacesandreplicatestheshapes ofthesurfaces,andfinallycooledtoroomtemperaturetoformthe finalproduct.Theabilitytoproducelargenumbersofprecise repli-casmakesglasshotembossingtechnologyanidealchoiceforthe fabricationofopticalelements[1–4].

Thistechniquewasrecentlyextendedtothemanufactureof opticalelementswithcomplexstructures.Saotome[5]useda sil-iconmoldtomakeV-groovesonK-PSK100andK-PG375optical glassandfoundthattheglassexhibitedsufficient microformabil-ityforuseinmicro-ornano-formingprocesses.Yi[6]fabricated a diffractiveoptical element made ofglass using a fused silica moldandK-PG325glass,whichisnotedforitslowtransition tem-perature(Tg).Theresultsproposedglassmoldingasaneffective alternativemanufacturingmethodforhigh-quality,low-cost opti-calcomponents.

Although the industry will eventually adopt hot embossing for the production of glass optical elements, several problems mustbesolved.First,theglassdoesnotreadilyfillthe microcav-itiesofcomplexmolds,thusloweringthequalityoftheresulting

∗ Correspondingauthor.Tel.:+88635712121x55160;fax:+88635720634.

E-mailaddress:chhung@mail.nctu.edu.tw(C.Hung).

opticalelements.Thecostofproducingthemoldsisalsohigh,and themoldscanbedamagedunderexcessiveloadswithinsufficient moldingtemperatures. Loadcanbereducedby raisingmolding temperatures,butthismeanslongerheatingtimesanddecreased productionefficiency.Thelife-spanofthemoldsisalsoshortened byhighertemperatureheatingandcoolingcycles.

To increase formability in the hot embossing of polymers, ultrasonic vibration has proven effective [7,8]; however, there is a concern that glassmay break ifdirectly subjected tosuch vibrations.Thisproblemcanbeavoidedbyraisingthemolding tem-peraturewellabovetheTgoftheglass.That,however,changesthe materialpropertiesoftheultrasonichornandshiftsitsresonant fre-quency,causingamismatchwiththefrequencygenerator.Another problemisthat,topreventoxidation,theglasshotembossing pro-cessmustbeperformedinavacuumornitrogen-richenvironment, either of which is difficulttoincorporate intoan experimental apparatus.Thechoiceofmoldmaterialisalsorestrictedbecause whatevermaterialisusedmustnotonlyresisthighworking tem-peraturesbutalsoendurethealternatingmechanicalstressesof ultrasonic vibration.Hence, seldomworks have focused onthe ultrasonicvibration-assistedglasshotembossingprocess.

Thepreliminaryresultsofoneexperimentwiththeultrasonic vibrationtechniquerevealedthatvibrationimprovedthe forma-bility of V-grooveand Fresnel structures onglass material [9]. However,theabilityoftheexperimentalapparatustomeasurethe forcesappliedwasaffectedbyseveralproblems.First,theloadcell wasinstalledoutsidethevacuumchamberatthebottomofthe movingdiecausingthedietobepulledbythevacuumduringthe

0141-6359/$–seefrontmatter © 2012 Elsevier Inc. All rights reserved.

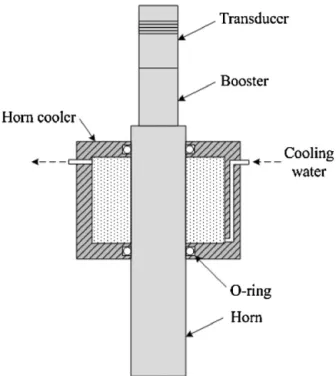

Fig.1.Apparatusfortheultrasonicvibration-assistedglasshotembossingprocess.

formingprocess.Second,theO-ringsealsbetweenthemovingdie andthevacuumchamberappliedanadditionalshrinkageforceon themovingdie.Becauseoftheseexternalforces,theapparatuswas unabletomonitortheappliedforcespreciselyenoughtoobtain aforcehistoryfor glassdeformation,resultingwitha compres-siontesterthatcouldnotadequatelyregulatetheembossingforce. Inaddition,theinfraredheaterswereinstalledinsidethevacuum chamber,wherethehighworkingtemperaturerenderedthem eas-ilybroken.InthedesignproposedbyFukuyama[10],theloadcell ishousedintheformingchamber,andthepressurefluctuationsin theformingchamberhavelittleeffectontheoutputoftheloadcell. Forthisstudy,anewapparatusforultrasonicvibration-assisted glasshotembossingwasbuilttoaddressthesedifficulties.Inthis design,theultrasonicvibratingdeviceisbuiltintotheupperdie. Inaddition,theloadcellislocatedinside thevacuumchamber toenhance the accuracyof force detection during theforming process.Twotypesofexperimentswereconductedwiththis appa-ratus.First, flathot embossing experiments wereperformedto investigatetheimpactofultrasonicvibrationonmoldingforces. Second,Fresnel structurehotembossingexperimentswere per-formedundera differentultrasonic frequencycompared tothe previousstudytoassessthemanufacturingpotentialofthe appa-ratusandtovalidatetheenhancedformabilitypossiblethroughthe useofultrasonicvibration.

2. Experimentalapparatus

Fig.1showsthenewhotembossingapparatusdevelopedfor thisstudy.Aheatingfurnaceandanultrasonicvibratingdeviceare

Table1

Specificationsofmoldingapparatusdevelopedforthisstudy.

Maximummoldtemperature 600◦C

Maximumvacuum 2×10−1Torr

Displacementaccuracy 4m

Drivingresource Servomotor

Maximumload 50kN

Ultrasonicfrequency 35kHz±500Hz

Ultrasonicpower 900W

Ultrasonicvibrationamplitudeonboosterin25◦ 3m

attachedtoacompressiontester.Theheatingfurnaceheatsboth

themoldsandtheglassspecimensandprovidesavacuum

environ-mentfortheembossingprocess.Thecompressiontestercontrols

theembossingdisplacementwithfeedbacksignalsfromanoptical

encoderandaloadcell.Vibrationsareappliedtotheglass

speci-menbyanultrasonicvibratingdevicebuiltintotheupperdieof

thefurnace.Table1liststhespecificationsforthisapparatus.

2.1. Theheatingfurnace

Fig.2showsacross-sectionaldiagramoftheheatingfurnace.A quartztubeisintegratedintothevacuumchamberwall.In conjunc-tionwiththemovingflatbedofthecompressiontester,thelower diemovesinandoutofthisquartztubetoloadtheglass speci-men,embossit,andunloadtheproduct.Infraredheaterssurround thequartztubeoutsidethechamberwall,andtheinfraredlight penetratesthroughthequartztoheatthemoldsandthespecimen inside.

Thelowerdiecontainsaloadcell,whichiscooledbyalower coolertopreventfrombeingdamagedbythehighworking temper-aturesinthechamber.Theloadcell(LW-20100,Interface,Inc.)has acompensatedtemperaturerangeof16–71◦C,butbecauseits tem-peratureduringtheglasshotembossingprocessdoesnotexceed 35◦C, sensorcalibrationsforelevatedtemperaturesaredeemed unnecessary.Theloadcellisdonutshaped,withthecentral tun-nelaccommodatingthepipesforthewatercirculatinginthelower coolerandthevacuumpumpingforthechamber.Duringthe form-ingprocess,theloadcellisinsidethevacuumchamber.Theforce

Fig.3.Designofhorncoolerforultrasonicvibratingdevice.

appliedcanthereforebedetectedfreeofexternalforces,enabling apreciseforcehistoryfortheformingglass.

Theinfraredheatersareplacedoutsidethevacuumchamberto increasetheirlifetimes.Aframewiththecirculatedcoolingwater supportssixheatersinasemi-circlethatsurroundsthechamber inthreelayers.Themaximumpoweroftheseheatersis7.8kW. Duringtheembossingprocess,thezoneinsidethequartztubeis pumpedtoformavacuum,andradiationfromtheheaterspasses throughthequartztubetothemoldsandglassspecimeninside thechamber.Theoutputpoweroftheheatersissuppliedbyan SCRandiscontrolledbyaUP150programtemperaturecontroller (YokogawaElectricCo.)thatreceivesfeedbacksignalsfroma K-typethermocoupleinstalledintothemold.

2.2. Ultrasonicvibratingdevice

Theultrasonicvibratingdeviceis designedtoworkproperly at35kHz.Thefrequencygenerator(KingUltrasonicCo.)issetto operatewithautomaticfrequencytrackingat35kHz±500Hz.For thermalprotection,ahorncoolerismountedoutsidetheultrasonic horn,asshowninFig.3.O-ringsplacedbetweentheultrasonichorn andthehorncoolertoformawatersealdonotsignificantlyaffect theabilityoftheultrasonicdevicetovibrate.

Theultrasonichornwasoriginallydesignedforuseatroom tem-peratureandhadadiameterof40mmandalengthof209mm.In theglasshotembossingprocess,however,thematerialproperties ofthehornareaffectedbythehighertemperatures,causingthe res-onantfrequencyofthevibratingdevicetoshiftbeyondthetracking rangeofthefrequencygenerator.Therefore,basedonthe compen-sationmethodproposedin[9],thelengthoftheultrasonichornwas reducedto202.5mm,andthemaximumworkingtemperatureof theultrasonicvibratingdevicewasraisedfrom150◦Cto450◦Cto accommodatethemoldingtemperaturesusedintheprocess.

3. Experiment 3.1. Procedure

Fig.4showstheexperimentalprocedure,whichprogressedas follows:(1) theglassandmoldsweresimultaneouslyheatedto themoldingtemperature(approximately20–40◦CaboveTg);(2) themold began embossing theglass at a preliminaryspeed of 0.1mm/mintoensurethatthetemperaturesonthecontact sur-faces of themolds and theglass were identical; (3) when the embossing displacement reached0.1mm,the embossing speed wasincreasedto1.5mm/min;(4)whentheembossing displace-mentreached1.5mm,ultrasonicvibrationwasapplied;(5)when theembossingdisplacementreached2mm,ultrasonicvibration ceasedandbothstageswereheldattheirfinalpositionsfor30s; and(6)theglasswasreleasedfromthemoldsandlefttocoolto roomtemperature.

K-PSK-100(SumitaOpticalGlass,Inc.)glasswith7mmin diam-eterand6.5mminheightwasusedinthisstudy.Accordingtothe manufacturer’sreport,theTgand theyieldingpoint(At)of the batchofglasswere398◦Cand426◦C,respectively.

3.2. Flathotembossing

Stainless AISI304 molds were used for theflat hot emboss-ingexperimentswiththemoldingsurfacespolished,asshownin Fig.5. Flatmolds wereusedin both theupperand lowerdies. Table2liststheexperimentalparameters,and Fig.6shows the force–displacementcurves. CurvesP1,P4, andP8 representthe resultsfortheconventionalglasshotembossingprocessatthree moldingtemperatures.Thedatashowthatwhenthemolding tem-perature was increased,less force wasrequired to emboss the glass.Whentheultrasonicvibrationwasapplied,therequiredforce droppedrapidlywhilethedisplacementcontinuedtoincrease.At thefinaldisplacementof2mm,anincreaseinforcereductionwas observedasthemoldingtemperaturedecreased.

Fig.5.Flatmold.

Table2

Parametersforflathotembossingexperiments.

No. Applyultrasonic vibration

Lowermold

temperature(◦C) Uppertemperaturemold(◦C)

P1 No 420 427 P2 Yes 420 428 P3 Yes 420 427 P4 No 425 432 P5 Yes 425 432 P6 Yes 425 433 P7 Yes 425 432 P8 No 430 435 P9 Yes 430 434 P10 Yes 430 434

Fig.6.Force–displacementresultsforflathotembossingexperiments.

Fig.8.Fresnelmold.

3.3. Fresnelstructurehotembossing

TheFresnelmoldswereformedbyelectroformingNiCoona

speciallydesignedFresnelstructure,whichwasmachinedby

ultra-precisionmachiningonNi.TheFresnelmoldswerecoatedwith

PtIrtopreventtheglassfromadheringtothemoldsduringthehot

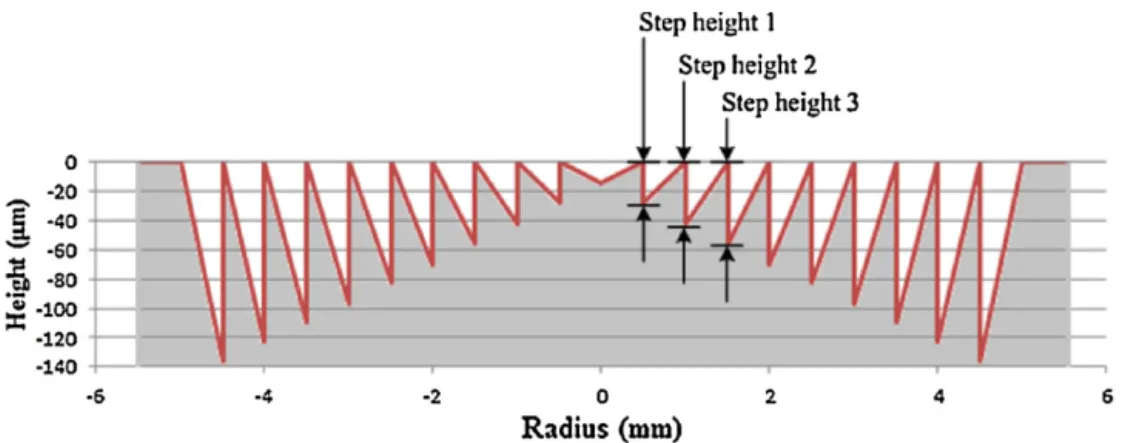

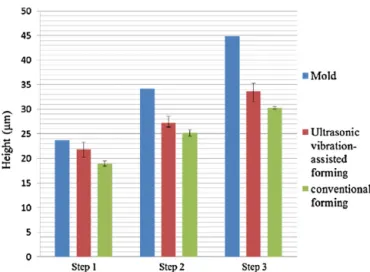

embossingprocess.Fig.7showsthedesigndimensionsandFig.8

showstheactualFresnelmold.InFig.7,severalstepheightsare defined,andthemeasurementsforthesestepheightsweretaken fromthemoldandthemoldedglassaftertheembossingprocess wascomplete.Inthehotembossingprocess,theFresnelmoldwas fixedtothelowerdie,andaflatmoldsimilartothatusedinthe flathotembossingexperimentwasmountedtotheupperdie.The moldingtemperatureswere431◦C and435◦Cintheupperand lowermolds,respectively.Fig.9showsanexampleofthemolded glass.

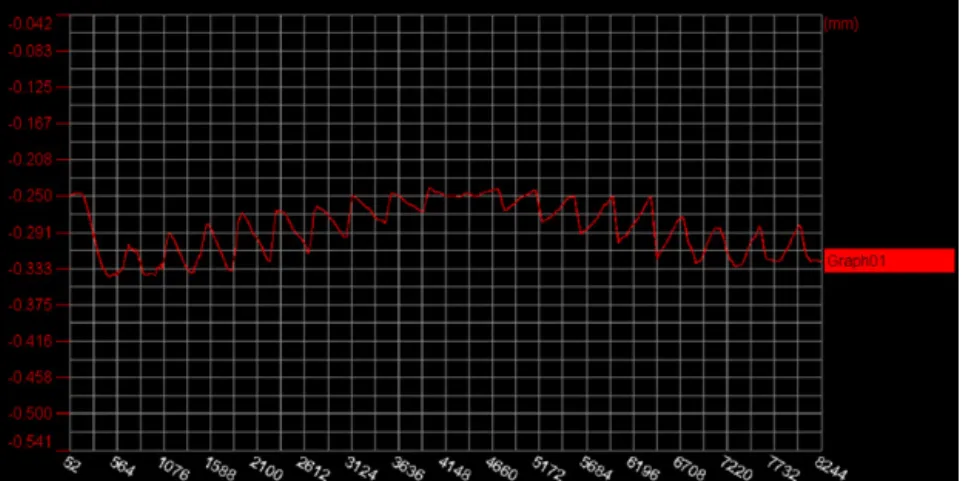

TheFresnelstructuresweremeasuredusinganapparatus con-sistingofaLK-H020laserdisplacementsensor(KEYENCECo.)and aservolinearactuator(ANIMATICSCo.),asshowninFig.10.Fig.11 showsthemeasurementresultsfortheFresnelmold,andFig.12 showsanexampleofthemeasurementsforthemoldedglass.Each pieceofmoldedglasswasscannedcross-directionally,sothatevery stepoftheFresnelstructureyieldedfourmeasuredvalues.Thestep heightswererecordedastheaverageofthesevalues.Fig.13shows thethreeinnerstepheightsofthemoldandthemoldedglass.These datashowsthattheheightsfortheultrasonicvibration-assisted hotembossingprocessarehigherthanthosefortheconventional processwithoutultrasonicvibration.

Fig.9.MoldedFresnelstructure.

4. Discussion

Theapparatusdevelopedforthisstudyovercamethedifficulty ofacquiringaccurateforcedatainavacuumenvironment,whichis criticalformonitoringproductqualityduringtheglasshot emboss-ingprocess.Thenewapparatuscanyieldprecisemeasurementsof theforcehistoryoftheglassduringformingandgenerateaccurate materialpropertiesofglass.Furthermore,thecompressiontester allowsforgreatercontroloftheappliedforcethaninearlierdesigns, andtherefore,productqualityisimproved.

Acoolingsystemisnecessarytopreventdamagetothe trans-ducercausedbythehightemperature,buttheadditionalmassof acoolerindirectcontactwiththeultrasonichornwoulddampen thevibrationsandchangetheresonantfrequencyoftheultrasonic

Fig.10.Apparatusforstructuralmeasurements.

vibratingdevice.Hence,thedesignedcoolerdoesnotcontactthe ultrasonichorndirectly,andO-ringsareadoptedtosealthe cool-ingwatersurroundingthehorn.Thissystemdeliverscoolingwater tothehornsurfacewithinsignificantchangesintheresonant fre-quency.

In the flat hot embossing experiments, ultrasonic vibration significantlyreducedtheforcerequired.Thismaybebecause ultra-sonicvibrationsraisedthelocaltemperaturebetweenthemolds and theglass,thussoftening theglass tothepointwhere flow conditions werecomparable tothoseobserved athigher mold-ingtemperaturesintheconventionalhotembossingprocess.With lowerrequiredmoldingtemperatures,heatingtimeisshortened,

Fig.11.MeasurementresultsfortheFresnelmold.

Fig.13.Measuredstepheightsofmoldandmoldedglass.

andefficiencyisimproved.Inaddition,embossingforcesare low-ered,reducingwearonthemoldsandextendingmoldlife.

IntheFresnelstructurehotembossingexperiments,ultrasonic vibrationenhancedthestepheightsofthemoldedFresnel struc-turesbyfurthersofteningtheglassandfacilitatingitsflowinginto themoldcavities.

5. Conclusion

Thisstudysuccessfullydemonstratedtheeffectivenessofanew apparatus designed for use in the ultrasonic vibration-assisted glasshotembossingprocess.A quartztubeisincorporatedinto thevacuumchamberwall.Infraredheaterssurroundthequartz tubeoutsidethechamber,andradiationfromtheheaterspenetrate throughthequartztubetoheatthemoldsandtheglassspecimen insidethechamber.The loadcellis insidethelowerdieand is protectedbyacoolingsystem.Becausetheloadcellisinsidethe vacuumchamberduringtheformingprocess,theeffectsof exter-nalforcesarenegligible;thus,theloadcellobtainsapreciseforce historyfortheformingglass.Theultrasonicvibratingdeviceisin

theupperdie,andacoolerprotectsthetransducerfromhigh tem-peratures.Anultrasonichornoriginallydesignedforuseatroom temperaturewasmodifiedtoensureproperfunctionatthehigh temperaturesrequiredbythehotembossingprocess.

Withthisapparatus,flathotembossingexperimentswere per-formedtoinvestigatetheeffectofultrasonicvibration.Theresult showthatformingforcesdroprapidlyasultrasonicvibrationis applied,thusindicatingthattheglassissoftened.Fresnelstructure hotembossingexperimentswerealsoconductedwiththesame apparatus,andthestepheightsofthemoldedglassstructureswere enhancedbyofultrasonicvibration.Theseresultsaretakento val-idatethemanufacturingpotentialofthedevelopedapparatusand confirmthatultrasonicvibrationimproveformabilityinglasshot embossing.

References

[1]Meden-PielingerGAA,VandeHeuvelJHP.Precisionpressedoptical

compo-nentsmadeofglassandglasssuitablemodeling,USPatent4,391,915(1983).

[2]TaniguchiY.Moldformoldingopticalelement.USPatent5,855,641(1999).

[3] FirestoneGC,JainA,YiAY.Precisionlaboratoryapparatusforhigh

temper-aturecompressionmoldingofglasslenses.ReviewofScientificInstruments

2005;76:063101,http://dx.doi.org/10.1063/1.1921367.

[4]Yi AY, Huang C, Klocke F, Brecher C, Pongs G, Winterschladen M,

et al. Development of a compression molding processfor three

dimen-sional tailored free-form glass optics. Applied Optics 2006;45:6511–8,

http://dx.doi.org/10.1364/AO.45.006511.

[5]SaotomeY.Microformabilityofopticalglassesforprecisionmolding.Journal

ofMaterialsProcessingTechnology2003;140:379–84.

[6] YiAY,ChenY,KlockeF,PongsG,DemmerA,GrewellD,etal.Ahighvolume

precisioncompressionmoldingprocessofglassdiffractiveopticsbyuseofa

micromachinedfusedsilicawafermoldandlowTgopticalglass.Journalof

MicromechanicsandMicroengineering2006;16:2000–5.

[7] MekaruM,NoguchiT,GotoH,TakahashiM.Effectofapplyingultrasonic

vibration in thermal nanoimprint lithography.Microsystem Technologies

2008;14:1325–33,http://dx.doi.org/10.1143/JJAP.46.6355.

[8] Lee CH, Jung PG, Lee SM, Park SH, Shin BS, Kim JH, et al.

Replica-tion of polyethylene nanomicro hierarchical structures using ultrasonic

forming.JournalofMicromechanicsandMicroengineering2010;20:035018,

http://dx.doi.org/10.1088/0960-1317/20/3/035018.

[9]TsaiYP,HungJC,YinLC,HungC.Ultrasonicvibration-assistedopticalglasshot

embossingprocess.InternationalJournalofAdvancedManufacturing

Technol-ogy2012;60:1207,http://dx.doi.org/10.1007/s00170-011-3669-8.

[10]FukuyamaS,FujiwaraS,SugiuraY.Pressformingmachineforglass.USPatent