行政院國家科學委員會專題研究計畫 成果報告

結合即時與物理化學分析方法研究電漿聚合薄膜並探討其 於生物材料領域之應用

研究成果報告(精簡版)

計 畫 類 別 : 個別型

計 畫 編 號 : NSC 96-2221-E-011-080-

執 行 期 間 : 96 年 08 月 01 日至 97 年 07 月 31 日 執 行 單 位 : 國立臺灣科技大學化學工程系

計 畫 主 持 人 : 王孟菊

報 告 附 件 : 出席國際會議研究心得報告及發表論文

處 理 方 式 : 本計畫涉及專利或其他智慧財產權,2 年後可公開查詢

中 華 民 國 97 年 10 月 10 日

行政院國家科學委員會專題研究計畫成果報告

結合即時與物理化學分析方法研究電漿聚合薄膜並探討其於生 物材料領域之應用

The investigations of plasma-polymerized thin films by integrating in-situ and physicochemical methods and their potential applications into biomaterials

計畫編號: NSC 96-2221-E-011-080

執行期限: 2007 年 08 月 01 日至 2008 年 07 月 31 日

主持人: 王孟菊 國立台灣科技大學化學工程系

計畫參與人員:張慶全(研究助理)、王淑玲(研究助理) 、 劉建宏(研究助理)

國立台灣科技大學化學工程系

1. 中文摘要

電漿聚合方法是在低溫情況下,利用 電漿增強系統聚合有機氣體的方法。利用 電漿聚合所製備的有機薄膜具有高度的交 連以及分枝性,和一般化學聚合方法所得 到的有機薄膜性質不同;同時,電漿聚合 之薄膜具有平坦不具孔洞;良好機械以及 化學等性質。

利用電漿製程製備薄膜的優點,包括 可沉積薄膜於不同的材料基質上、覆蓋面 積大且均勻、效率高、單一製程等。過去 研究電漿聚合薄膜的文獻,多專注於利用 電漿沉積製備新穎薄膜,並利用物理化學 方法分析薄膜之組成、薄膜表面型態、表 面能、以及其他實驗參數對於合成薄膜性 質之影響。基於實際使用時之儀器限制,

欲結合即時與物化分析對薄膜合成反應研 究具有相當的困難度。

本研究針對此問題,提出結合即時以 物理化學方法,研究電漿聚合過程中,各 參數對生成薄膜之影響。所研究的參數包 括施予電極之電壓、電壓頻率、單體分子

之種類與流量、沉積時間等。利用光學散 射光譜等即時分析方法,不僅能夠與物理 化學分析方法所得到的結果相互驗證,同 時能夠分析反應器中活性物質之強度以及 質量的演化。此研究有助於了解電漿聚合 反應機制之研究。為探討於生物材料表面 薄膜之研究,對於利用前述最適化之電漿 操作參數製備之薄膜,利用細胞附著以及 細胞活性等方法檢測生物相容性。

關鍵詞:電漿聚合、薄膜、界面現象、光 學散射光譜、石英晶體天平、生 物感測器。

Abstract

Plasma polymerization is an effective method to directly deposit ultra-thin film on substrates with advantageous properties such as good adhesion and biocompatibility. In this paper, the monomers containing amine groups with various unsaturated structures (propylamine, allylamine) are chosen to provide amine functionalities and to promote

biocompatibilities for the polymerized thin films. The deposition rates revealed by measuring the thickness of thin films are characterized by profilometer under various plasma conditions. FTIR and AFM are used to study the chemical structures and morphology of the deposited thin films. In order to examine the applicability of the deposited polymers for biosensors, the activities of the incorporated biomolecules on deposited thin films are analyzed. Chinese hamster ovary (CHO) cells are cultivated on the polymerized thin films. Both propylamine and allylamine polymerized thin films show enhanced cell viability than on glass slide substrates.

Keywords:

plasma polymerization, thin film, amine, cell viability, biosensor

2. Introduction

Plasma polymerization has demonstrated as a promising technique in preparing thin films for versatile applications in the fields of anticorrosive, electrical resistors, barrier coatings, immunosensors, and interfaces for biomaterials [1, 2]. The advantages of plasma polymerized thin films include pin-hole free, great homogeneity, mechanical, chemical, and adhesion properties [3]. Research works have been focused on investigating important parameters for polymerization such as the mode of power (continuous or pulsed) and structure of precursors [4, 5].

Considering the applications of plasma polymerized thin films in biomaterials, one of the critical requirements is the specific interaction between the thin films and biomolecules [6, 7]. Various monomers have

been chosen to prepare polymer thin films in order to provide nitrogen-containing functionalities which is believed to promote cell adhesion and proliferation [1, 8].

However, few works have been done on investigating the biocompatibility of plasma polymerized thin films.

In this work, in order to introduce amine-containing functionalities, saturated propylamine and double-bond containing allylamine are deposited by plasma onto glass substrate for the growth of CHO cells.

Physical-chemical analyses demonstrate that the plasma polymerization is a stable process to produce uniform thin films containing amine functions. The dissociation of unsaturated structure of allylamine can be clearly observed by FTIR characterizations.

The CHO cell viability is promoted by both precursors up to 1.3 folds. The correlations of current studies with the plasma operational parameters and the functionalities of thin films play important roles for the applications in medical and sensor fields.

3. Materials and methods

The precursors used for plasma polymerization, propylamine and allylamine (Sigma-Aldrich), are used without further purification. Figure 1 shows schematically the plasma configurations used in the present study. The plasma is composed by a reaction chamber, a radio-frequency generator, and vacuum systems. The precursors were introduced into the reaction chamber by a mass flow system. The gas flow was adjusted between 10-50 sccm depending on the conditions required for the polymerizations.

The total pressure was controlled from 50~10010

-3

Torr. For thin filmcharacterizations, the thickness was determined by Quartz Crystal Microbalance (QCM) and profilometer (Alpha-stepper).

The precursors resulted in thin films were deposited on KBr pellets for FTIR analyses.

The morphology of thin films was analyzed by a Digital Instruments Nanoscope III Atomic Force Microscopy (AFM) in tapping mode (Veeco Ltd.).

Chinese hamster ovary cells were kindly provided by Laboratory of Professor Wen-Chi Tseng (NTUST). The cells were cultivated in a humidified incubator with temperature (37C) and CO

2

(5%) control.All culture medium are purchased from Sigma: Dulbecco’s modified eagle medium (DMEM-high glucose) (56439C); Trypsin, lyophilized powder (T4799); EDTA(E6758);

Fetal Bovine Serum (F2442); Sodium bicarbonate (S5761); sodium pyruvate (P5280); and L-Glutamine (G8540). MTT tests were carried out to quantify the cell viability. The reduction of 3-(4,5-Dimethyl-2-thiazolyl)-2,5-diphenyl-2 H-tetrazolium bromide by active cells can form purple formazan crystals and the solution absorbance can then be analyzed by UV-Visible spectrometer (UV-550) at 554nm.

Figure 1. Plasma apparatus

4. Experiment results and discussion

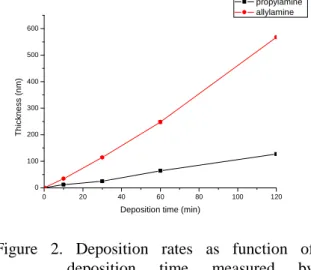

The thickness of plasma polymerized thin films measured by profilometer showed a linear relationship with the time of deposition for both propylamine and allylamine (Figure 2). This reveals that the plasma polymerization deposition is a stable process.

The deposition rates are 1.06 and 4.73 nm/min for propylamine and allylamine, respectively. The higher deposition rate for the double-bond containing allylamine was due to the transformation of unsaturated structure by high energy plasma state to facilitate the propagation of polymerization.

0 20 40 60 80 100 120

0 100 200 300 400 500 600

T h ic k n e s s (n m )

Deposition time (min)

propylamine allylamine

Figure 2. Deposition rates as function of deposition time measured by profilometer (Applied power: 50w;

Pressure : 100 mtor; flow rate : 10 sccm)

The in-situ analyses of plasma chamber provide the important information about evolution of reactive species, the formation of functional groups, and even the interactions between substrates and species in gas phase. This will facilitate the acquisition of the reaction mechanism. The OES spectra before the deposition can be shown as in Figure 3(a). Only the peaks of oxygen and argon can be observed. Once the polymerization was initiated, and complex processes of the formation of

nitrogen-oxygen binding can be identified (Figure 3b).

(a)

(b)

Figure3. The OES spectrum (a) before polymerization; (b) during plasma polymerization of propylamine

The chemical properties of deposited polymers were studied by Fourier Transform Infrared (FTIR) spectroscopy. The IR spectra were presented in Figure 4 to show the effects of the applied power on the chemical composition of the deposited thin films. For propylamine, the thickness of the deposited polymer is too thin to be analyzed by FITR due to the very low deposition rate under the applied power of 5W and 10W. For plasma polymerized propylamine thin film, FTIR spectra showed a wide absorption band at 3390-3360cm

-1

which is originated from the combination of primary amine, secondary amine and imine functions. The multiple absorption peaks between 2960-2880 and 1460-1380cm-1

are due to the methyl group stretches of aliphatic C-H components.. The peak at 1640cm-1

is present on the spectra of the polymer and it is associated with C=Calkenes or from N=N imine stretches. It is noticeable that, for propylamine deposited under 50W, a band at 2200cm

-1

can be observed. This specific band is associated with the stretching vibration of nitrile groups and it can not be found for propylamine deposition at 30W.3500 3000 2500 2000 1500 1000 500

(a) propylamine 30W (c) allylamine 5W

A b s o rb a n c e

Wavenumber (cm

-1) (f) allylamine 50W

(e) allylamine 30W

(d) allylamine 10W

(b) propylamine 50W

(Pressure : 100 mtorr, time : 1hr, flow rate : 10 sccm) Figure 4. FITR spectra for propylamine and

allylamine deposited on KBr pellets.

The effects of applied power can be observed more clearly by the IR spectra of polymerized allylamine. Higher applied power can increase the peak formation of nitrile and methyl functions. As shown in Figure 4c-4g, a clear formation of nitrile groups can be observed for the applied power up to 30W and it increased further for the applied power at 50W. Moreover, the absorption bands representing the vibration of methyl groups at range 2960-2880 cm

-1

and 1460-1380 cm-1

increased significantly as the applied power increased. This suggests that plasma polymerization resulted in the transformation of the unsaturated groups into saturated ones. At the same time, higher applied power can facilitate functionalization during polymerization processes.In order to study the surface morphology, the precursors were deposited on silicon

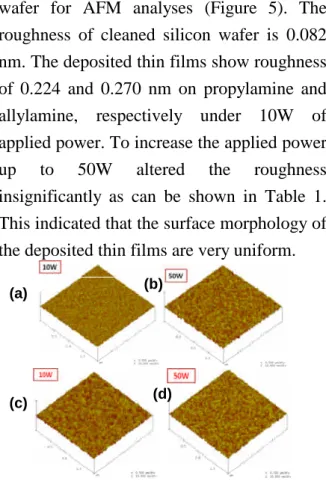

wafer for AFM analyses (Figure 5). The roughness of cleaned silicon wafer is 0.082 nm. The deposited thin films show roughness of 0.224 and 0.270 nm on propylamine and allylamine, respectively under 10W of applied power. To increase the applied power up to 50W altered the roughness insignificantly as can be shown in Table 1.

This indicated that the surface morphology of the deposited thin films are very uniform.

Figure 5. AFM analyses. surface morphology of plasma-polymerized propylamine (a)10W; (b) 50W; allylamine (c)10W;

(d) 50W.

Table .1. Roughness of plasma polymerized thin films Roughness

(nm) Applied power

Propylamine allylamine

Control(silicon wafer)

0.082

10W 0.224 0.270

50W 0.237 0.284

The cell viability of CHO cells were evaluated by measuring the metabolic activity of adhering cells by MTT-test. Cell proliferation was higher on plasma polymerization deposited thin films under mild applied power (10W). For polymerized propylamine thin films, the cell viability was about 1.3 folds higher than on the controlled glass slide substrates (Figure 6). Moreover,

the cell viability was 1.36 folds on the allylamine deposited thin films than on the glass substrate. Both propylamine and allylamine showed enhanced cell activities for CHO cells.

control propylamine allylamine

0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18

A b s o rb a n c e (a .u .)

Susbtrates

Figure 6. Cell viability tested by UV-visible analyses

Conclusion

Propylamine and allylamine were plasma polymerized on glass substrates to investigate their physical-chemical properties and the application potential for biosensors by examining the interactions between thin films and biomolecules. Both ex-situ physical chemical analyses and

in-situ

optical emission spectroscopy have been performed to monitor the polymerization processes.During the plasma polymerization process, the allylamine transformed C=C double bonds to methyl groups therefore resulted in much higher deposition rate comparing with propylamine. For higher applied power, the effect of polymerization became more important although the surfaces of thin films showed similar morphology for both precursors under various plasma operational parameters. For biocompatibility tests, both propylamine and allylamine induced thin films can enhance the CHO cell viability to up to 1.3 folds even under mild applied

(a)

(c)

(b)

(d) (d)

power for deposition (10W). More research works such as the density of amine functionalities provided by XPS analyses and various plasma operational parameters will be correlated to show the applicability of these plasma polymerized thin films for biosensors.

五、參考文獻

1. Altankov, G., Grinnell, F. and Groth, T., Journal of Biomedical Materials Research, 30, 385-391 (1996).

2. Banes, A.J., Apparatus for Applying Stress to Cell Cultures, US Patent Office, 4,839,280, US (1989).

3. Banes, A.J., Biocompatible polyorganosiloxane composition for cell culture apparatus, US Patent Office, 4,822,741, US (1989).

4. Barnes, D., Wolfe, R., Serrero, G., McClure, D.

and Sato, G., Journal of Supramolecular Structure, 14, 47-63 (1980).

5. Behnisch, J.; Hollander, A.; Zimmermann, H. J.

Appl. Polym. Sci., 49, 117, (1993).

6. Blau A, Weinl C, Mack J, Kienle S, Jung G, Ziegler C., J Neurosci Methods. 112(1), 65-73.

(2001)

7. Braut-Boucher, F., Pichon, J., Rat, P., Adolphe, M., Aubery, M. and Font, J., Journal of Immunological Methods, 178, 41-51 (1995).

8. Burrill, P.H., Bernardini, I., Kleinman, H.K. and Kretchmer, N., Journal of Supramolecular Structure, 16 (1981).

9. Carter, W.G., Rauvala, H. and Hakomori, S.-i., The Journal of Biological Chemistry, 88, 138-148 (1981).

10. d'Agostino, R. Plasma deposition, treatment;

and etching of polymers; Academic Press: San Diego, CA, (1990).

11. D'Agostino, R.; Cicala, G.; Creatore, M.; Favia, P.; Lammendola, R. Proc. 12 th ISPC, 355 (1999).

12. Degasne, I., Basle, M.F., Demais, V., Hure, G., Lesourd, M., Grolleau, B., Mercier, L. and Chappard, D., Calcified Tissue International, 64, 499-507 (1999).

13. Diener, A., Nebe, B., Luthen, F., Becker, P., Beck, U., Neumann, H.G. and Rychly, J., Biomaterials, 26, 383-392 (2005).

14. Dupont-Gillian, Ch; Adriaensen, Y.; Derclaye, P.;

Rouxhet, G.; Langmuir, 16, 8194.

15. Esty, A., Receptor-specific serum-free cell attachment using a highly stable engineered protein polymer., 44 (1991).

16. Favia, P.; Stendardo, M. V.; d'Agostino, R.

Plasmas Polym. 1996, 1, 91.

17. Ferreira, N. G.; Corat, E. J.; Trava-Airoldi, V. J.;

Leite, N. F. Diamond Relat. Mater, 9, 368 (2000).

18. Fodil-Bourahla, I., Drubaix, I. and Robert, L., Mechanisms of Ageing and Development, 106, 241-260 (1999).

19. France, R. M.; Short, R. D. Langmuir, 14, 4827 (1998).

20. Franz, D.; Hollenstein, M.; Hollenstein, C. Thin Solid Films, 379, 37(2000).

21. Garscadden, A.; Nagpal, R. Plasma Sources Sci.

Technol., 4, 268 (1995).

22. Gerenser, L. J. J. Adhesion Sci. Techol., 7, 1019 (1993).

23. Hersel U, Dahmen C, Kessler H. Biomaterials.

24(24):4385-415. (2003)

24. Hirohata, Y.; Tsuchiya, N.; Hino, T. Appl. Surf.

Sci., 612, 169-170 (2001).

25. Horbett, T.A. and Schway, M.B., Journal of Biomedical Materials Research, 22, 763-793 (1988).

26. Hsiue, G.-H., Lee, S.-D., Chang, P.C.-T. and Kao, C.-Y., Journal of Biomedical Materials Research, 42, 134-147 (1998).

27. Idage, S. B.; Badrinarayanan, S. Langmuir, 14, 2780 (1998).

28. Isnard, N., Fodil, I., Robert, L. and Renard, G., Experimental Gerontology (2002).

29. Jokinen, J., Dadu, E., Nykvist, P., Kapyla, J., White, D.J., Ivaska, J., Vehvilaninen, P., Reunanen, H., Larjava, H., Hakkinen, L. and Heino, J., Journal of Biological Chemistry, 279, 31956-31963 (2004).

30. Juliano, D.J., Saavedan, S.S. and Truskev, G.A., Journal of Biomedical Materials Research, 27, 1103-1113 (1993).

31. Klee, D., Ademovic, Z., Bosserhoff, A., Hoecker, H., Maziolis, G. and Erli, H.-J., Biomaterials (2003).

32. Kumar, S.; Baldwin, M. J.; Fewell, M. P.;

Haydon, S. C.; Short, K. T.; Colins, G. A.;

Tendys, J. Surf. Coat. Technol., 123, 29 (2000).

33. Lam, K., Zhang, L., Yamada, K.M. and Lafrenie, R.M., Journal of Cellular Physiology, 189, 79-90 (2001).

34. Lange, R., Luthen, F., Beck, U., Rychly, J., Baumann, A. and Nebe, B., Biomolecular Engineering, 19, 255-261 (2002).

35. Lazos, D., Franzka, S. and Ulbricht, M., Langmuir, 21, 8774-8784 (2005).

36. Legeay, G.; Brosse, J. C.; Epaillard, F. Double Liaison-Chim. Peint., 111/35, 367-368 (1986).

37. McCurdy, P. R.; Butoi, C. I.; Williams, K. L.;

Fisher, E. R. Phys. Chem., 103, 6919 (1999).

38. Miyamoto, S., Katz, B.-Z., Lafrenie, R.M. and Yamada, K.M., Fibronectin and Integrins in Cell Adhesion, Signalling, and Morphogenesis. In:

K.M. Yamada (ed.), Fibronectin and Integrins, pp. 119-129, Annals New York Academy of Sciences, New York (1999).

39. Mosher, D.F., Fibronectin. Progress in

Hemostatis and Thrombosis, 5, 111-51 (1980).

40. Nakayama, Y.; Takahagi, T.; Soeda, F. J. Polym.

Sci., Polym. Chem., 26, 559 (1988).

41. Plemmons, D. H.; Parigger, C.; Lewis, J.;

Homkohl, J. Opt. Soc. Am., 2493 (1998).

42. Raynter, R. W. Surf. Interface Anal., 26, 674 (1998).

43. Renevier, N.; Czerwiec, T.; Collignon, P.;

Michel, H. Surf. Coat. Technol., 98, 1400 (1998).

44. Ricard, A. Le Vide, 275, 1 (1995).

45. Ricci, J.L., Alexander, H. and Howard, C., Materials Research Society Symposium Proceedings, 252, 221-227 (1992).

46. Richardson, R.L., Campion, D.R. and Hausman, G.J., Cell and Tissue Research, 251, 123-128 (1988).

47. Sapehia, R. Biomater., Artif. Cells, Immobilization Biotechnol., 21 (5), 647 (1993).

48. Sethuraman, A., Han, M., Kane, R.S. and Belfort, G., Langmuir, 20, 7779-7788 (2004).

49. Shahidzadeh, N.; Arefi-Khonsari, F.; Chehimi, M.

M.; Amouroux, J. J. Surf. Sci., 352, 888 (1996).

50. Sherratt, M., Bax, D., Chaudhry, S.S., Hodson, N., Lu, J.R., Saravanapavan, P. and Kielty, C.M., Biomaterials, 26, 7192-7206 (2005).

51. Steele, J.G., Johnson, G., Griesser, H.J. and Underwood, P.A., Biomaterials, 18, 1541-1551 (1997).

52. Supiot, Ph.; Callebert, F.; Dessaux, O.;

Goudmand, P. Plasma Chem. Plasma Process., 13, 539 (1993).

53. Thomas, K.A. and Cook, S.D., Journal of Biomedical Materials Research, 19, 875-979 (1985).

54. Timmermans, E. A. H.; Jonkers, J. I. A. J.;

Thomas, I. A. J.; Rodero, A.; Quintero, M. C.;

Sola, A.; Gamero, A.; van den Mullen, J. A. M.

Spectrochim. Acta B, 1553 (1998).

55. Underwood, P.A., Whitelock, J.M., Bean, P.A.

and Steele, J.G., Journal of Biomaterials Science, Polymer Edition, 13, 845-862 (2002).

56. van Oss, C. J.; Good, R. J. J. Macromol. Sci.

Chem., 26 (8), 1183 (1989).

57. Wang, M. J.; Chang, You-Im; and Poncin-Epaillard, Fabienne; Surface and Interface Analysis, 37, 325-331 (2005).

58. Wild, S.; Kesmodel, L. L. J. Vac. Sci. Technol., A, 19 (3), 856 (2001).

59. Poncin-Epaillard, F.; Chevet, B.; Brosse, J. C. J.

Adhesion Sci. Technol., 8 (4), 455 (1994).

60. Wilson, C.J., Clegg, R.E., Leavesley, D.I. and Pearcy, M.J., Tissue Engineering, 11, 1-18 (2005).

61. Woodcock, S.E., Johnson, W.C. and Chen, Z., Journal of Colloid and Interface Science (2005)

六、計畫成果自評:

本研究內容依據行政院國科會所核准 之專題研究計畫進行,執行內容符合原計

畫之進度,結合即時與物理化學分析方法 研究電漿聚合薄膜並探討其於生物材料領 域之應用。計畫的執行,首先完成電漿聚 合不同單體以製備薄膜之參數研究,在物 理化學分析方面,利用石英震盪微量天平 (quartz crystal microbalance)和 profilmeter 測量薄膜之重量以及厚度,量化的薄膜沉 積速率;並且利用多種物理化學方法,定 性測量薄膜之性質。其中包括利用由 X-ray Photoelectron spectroscopy 以 及 Fourier Transform Infrared 分析各類薄膜的化學鍵 結。在即時分析方面,利用此光學散射光 譜分析電漿聚合反映時,腔體中的反應物 質之演化,能夠與物化分析的結果相互映 證,推導聚合時的化學反應機制。

為探討電漿聚合薄膜於生物材料之應 用,利用培養不同的細胞 (Chinese Hamster Oval cells and fibroblasts)於電漿聚合薄膜 之上,進行研究。研究結果發現,電漿聚 合因能有效引入含胺基的官能基,因此除 了能夠有效幫助細胞附著,也能提高細胞 在薄膜上之活性。此項分析為利用 SEM 以 及 MTT 試驗獲得之結果。此項結果意義相 當重大,因為我們證實了利用電漿聚合的 薄膜,能夠經由調控電漿聚合之參數而控 制其厚度以及性質,同時能夠與細胞有正 向的交互作用,因此研究成果將可應用於 生物材料。

本研究利用界面科學、物理化學、材 料科學以及生物醫學等技術與知識,整合 電漿技術與生物材料領域,除了具有學術 研究價值之外,同時具有可能貢獻於材料 科學、化學工程、組織工程學,改善生物 材料以增進人類醫學進步之潛能。參與本 研究之研究助理已經於 97 年 7 月順利完成 碩士學位,研究成果已參加 2008 年 6 月於 重慶所舉辦 之 Material Research Society Meeting (MRS 2008),口頭發表研究成果。

與與會學者交流,因此本研究除了適合發 表於學術期刊,更有繼續進行深入研究,

應用於生物材料發展之價值。

8

行政院國家科學委員會補助專題研究計畫成果報告

※※※※※※※※※※※※※※※※※※※※※※※※※※

※ ※

※

結合即時與物理化學分析方法研究電漿聚合薄膜※

※ ※

※

並探討其於生物材料領域之應用用※

※ ※

※※※※※※※※※※※※※※※※※※※※※※※※※※

計畫類別:個別型計畫 □整合型計畫 計畫編號:NSC96-2221-E-011-080

執行期間:2007 年 08 月 01 日至 2008 年 07 月 31 日

計畫主持人:王孟菊

計畫參與人員:張慶全(研究助理)、王淑玲(研究助理) 、 劉建宏(研究助理)

本成果報告包括以下應繳交之附件:

□赴國外出差或研習心得報告一份

□赴大陸地區出差或研習心得報告一份

出席國際學術會議心得報告及發表之論文各一份

□國際合作研究計畫國外研究報告書一份

執行單位:國立台灣科技大學化學工程系

中 華 民 國 97 年 10 月 10 日

出席國際學術會議心得報告

計畫編號 96-2221-E-011-080

計畫名稱 結合即時與物理化學分析方法研究電漿聚合薄膜並探討其於生物材料領域

之應用 出國人員姓名

服務機關及職稱

王孟菊

國立台灣科技大學化學工程系 助理教授 會議時間地點 2008 年 6 月 08-12 日,重慶

會議名稱 2008 International Materials Research Society Conference

發表論文題目

Preparations of Amine-containing Thin Films by Plasma Polymerizations for application in Biosensors.

Meng-Jiy Wang, Ching-Chuan Chang and Shu-Ling Wang;

Department of Chemical Engineering, NTUST, Taipei, Taiwan.

一、參加會議經過

Material Research Society is a society based in the United States and the society has enjoyed long history with reputation of rapidly exchanging pioneer research among scientists in all fields associated to material science. The author has been participating and presenting papers in previous MRS conferences in the United States. Therefore with this great opportunity that MRS held the very first international MRS conference in Asia, the author has sent a paper to the MRS society and the paper has bee selected as an oral presentation for the conference.

The registration of conference started at the evening of the 08

th

June, 2008. Most of the attendees arrived in Chongquin for registration. Officially the MRS conference started at 08:00 am at the 09th

June morning, the meeting started with an important keynote speech from Nobel Laurent of Chemistry (2000): .Alan J. Heeger from UC Santa Barbara. He is well known for his pioneering research in the co-founding of the field of semiconductor and metallic polymers. Professor Heeger talked about applying his pioneer works on inventing the hybrid inorganic-organic material for solar cells related researches. The research was so successful that not only many prizes including the Nobel prize, but also there are companies to adapt their research works into real products to generate solar energy effectively.After the keynote speech, 9 different sessions, including energy and environmental materials, electronic and ceramic materials, magnesium and biomedical materials, started at 10:30am. During the whole conference, mostly I joined the photovoltaic and biomedical materials sessions because my research groups focused on preparing novel materials, including integrate organic and inorganic materials, study the interactions between biomolecules and materials, and apply thin film development techniques.

For the eco and environmental sessions, most of the talks focused on the developments and modification of existed materials into ecomaterials. The strategy includes develop new materials such as nano materials or hybrid of various materials. The strategies include using multi-walled carbon nanotubes, nanoribbons, or using adhesion molecules for waste removal by vanadium (iv) benzenedicarboxylate, formaldehyde-free adhesives, copper implanted austenitic, enzyme biofuel, dendrimers, reinforced composites, or polymer composites. Some novel catalysts are proposed, some computational study methods are also suggested to combining with material research works.

The Photovoltaics sessions are probably the most populated sessions that many people are very interested in providing various novel energy generation methods are discussed. For example, different methods are discussed to develop photovoltaics by direct write methods, by PECVD, or by heterojunction structure in terms of materials managements and costing down.

In the fields of solar cells, dye-sensitized solar cells and quantum dot solar cell are heavily discussed. These include the discussions on the thin films developments for the energy generation cells: by using quasi-solid polymer electrolytes, diamond-like carbon and iii nitride thin-films or highly crystalline low band-gap indolocarbazole /benzothiadiazole copolymers.

Novel catalysts or nanomaterials in the energy generation methods are also discussed by using electrocatalysts, nanoporous metals. Platinum/carbon anodic catalyst or modificative chitosan and carbon nanotubes supported palladium-based catalysts.

My research works actually associated with both material and biomedical sciences. Therefore, during thisconference,Iam particularly interested in thesessionsof“BiomaterialsforMedical Applications”. The subjects presented in this meeting are not only trying to solve the current problems but also to propose novel methods and materials. For example, due to the highly-demanded applications in the fields of Drug Delivery and Tissue Engineering, there are extensive discussions on the synthesis and modification of Nanobiomaterials.

The most important consideration while designing a biomaterials is the biocompatibility of the materials, the subjects focused on Cell-biomaterials Interactions and Biomaterials-Surface Modification have drawn tremendous attention in this meeting. Novel materials have been proposed to either integrate conventional metal, ceramic and composite into biometal, bioceramics and multi-components composites, the newly designed materials with nano-structures with good compatibility have also been investigated.

My paper was presented on the afternoon of the 11

th

of June. This is my first conference since I returned to Taiwan and to give presentation international-wise. I am very pleased with the results of presentation. First of all, I have got few good questions from audiences. One question as asked from Professor Yu, from Missouri University, he has been conducting similar research topics as I did and he is particularly interested in the plasma polymerization techniques in my lab. The secondquestions came from Professor Li from National Singapore University. Professor Li has paid particular attention on the thin film characterization methods and I have replied him about the techniques that we have conducted. Due to the time limit, the last question was proposed by Professor Yan from Hong Kong Polytechnic University, as a chemist, Professor Yan tried to understand the complicated plasma system and the interactions between the reactive species with the biomaterials. It was a good experience that I could gain some discussions and ideas by exchanging ideas. The more important outcome I found for my presentation is that there are few PhD came to ask me questions and expressed strong desire for their future research. I think my talk has inspired young scientists and it’s particularly important in my opinion.

Overall, this is a fruitful meeting where I have met researchers from every corners of the world and have exchanged novel ideas and discussions. I will continue to participate Materials Research Society (MRS) meeting for its features of high quality and well organizations.