Developing a Reference Framework for Measuring the Supply Chain

Capability

Hsin-Lu Chang1 Department of MIS, National Chengchi University, Taiwan

hchang@mis.nccu.edu.tw

Chia-ying Hsuan2 Department of MIS, National Chengchi University, Taiwan

Huai-Chia Weng3 Department of MIS, National Chengchi University, Taiwan

Abstract

This research aims to develop a framework for measuring the supply chain capability. The literature review and company interviews allow us to propose four capabilities and relative measurements. A field survey is then conducted in the Taiwan PC industry to assess the measurements. To ensure the measurements are valid, we apply two-step measurement assessments: the factor analysis and initial reliability are first conducted and then followed by item-total correlation, optimal reliability coefficients, convergent validity, and discriminant validity. The resulting model is an 18-item and three-dimension construct. The three dimensions are: (1) reducing transaction related risk, (2) promoting good relationship, and (3) managing environment change. The confirmatory factor analysis then suggests us to arrange the three dimensions in two groups. The first group includes the first dimension, indicating the firm capability, and the second group includes the other two, expressing the inter-firm capability. The contribution is multi-folded. Validated supply chain capability measures can help managers better gauge the characteristics of the collaborations. IT researchers can build upon the model developed in this study through further examination of the factors that are discovered.

Keyword: Supply chain capability, Inter-organizational systems, Information technology, Supply chain management

1. Introduction

Supplier-customer relationships have undergone radical changes in recent years because the business environment has changed (e.g., volatility in demand, curtailment of product life cycle, changing of information technology, and so forth). Facing this situation, new organizational forms such as the extended or agile enterprise emerge to allow for a tighter link among strategic partners - customers, suppliers, or other third party service providers - that decide to dovetail their capabilities to provide a seamless and electronically enabled closed loop of unimpeded business processes. Corporate supply chains become more network-connected and involve more business partners. Since this kind of supply chain collaboration involves more business partners than traditional inter-firm coordination, the issue such as how to develop good supply chain capabilities to handle the increasing complexity and dynamism is becoming more important than ever.

According to resource-based theory, firm resources and capabilities are the source of sustained competitive advantage [3, 12]. Thus, to make the supply chain collaboration successful, it is important to offer an integrated view of what capabilities a supply chain should obtain in terms of transaction handling capabilities, relationship capabilities, IT capabilities, and so on.Those capabilities may cause the firms to gain more competitive advantages and benefits. We believe that a systematic investigation of these influences could offer significant insights for firms to manage their supply chain network. Thus, this paper seeks to contribute to the literature on supply chain studies through (1) the development and formalization of a framework of supply chain capabilities within the supply chain network; and (2) the operationalization and test of the framework through primary field data obtained in industrial supply

chains.

2. Literature Review

Some researchers have recognized the significance of supply chain capabilities. Riggins and Mukhopadhyay (1994) assert that companies with good supply chain capabilities can increase the interdependent benefits [21]. Dyer and Singh (1998) emphasize the impact of relational rents on inter-firm collaboration, the benefits that cannot be generated by either firm in isolation and can only be created through the joint idiosyncratic contributions of the specific alliance [11]. Angeles and Nath (2000) find that focal firms prefer to partner with suppliers that have good capabilities to handle supply chain problems including channel inventory management, manufacturing planning and scheduling, demand forecasting, and distribution and transportation planning [1]. Further, Craighead and Shaw in 2003 argue that supply chain performance is dependent on multiple capabilities: supply chain partners capabilities, manufacturing firm capabilities, information technology capabilities, and operational capabilities [9]. These capabilities, along with final customer’s desire, create and accumulate the value of the supply chain.

Although researchers use different concepts and theories to investigate supply chain capabilities, we derive four levels of supply chain capability according to the resource-based view: technology level, transaction level, relationship level, and environment level. We discuss each accordingly.

Technology Level. The basic resource-based theory examines the link between a firm's internal characteristics and performance. It suggests that firm’s IT resources such as IT investment and IT staffs enable a firm to implement successful IT strategies. Some scholars also recognize that firm’s IT capability not only affect firm’s internal performance but also the performance of supply chain. Bensaou and Venkatraman (1995) propose that the greater the multiplicity of channels and the frequency of information exchanges, the greater the information processing capabilities of the dyad [5]. They assert the information processing capabilities of a relationship will increase with greater intensity and scope of the use of the technology between the two firms. In similarly, Riggins and Mukhopadhyay (1994) suggest that the great volume of business communications for which the firm uses EDI and the high degree to which the firm becomes immersed in EDI of doing business as the efficient ways to maintain partner relationship [21]. Transaction Level. Clemons and Row (1992) propose three major sources of transaction risk: transaction-specific capital, asymmetries in information, and loss of resources control, and suggest create firm’s capability that better control these resources can resolve these transaction risks [7]. For the transaction-specific capital, Clemons and Row (1992) suggest that the characteristics of software used, such as reusability, modularity, replicability of know-how, coupled with open standards, IT support for conversion and transaction, and intuitive interfaces that reduce the costs of training or re-training can reduce this risk substantially [7]. On the other hand, information asymmetries, the second source of transaction risk, mostly possibly occur in cases of performance measure ambiguity. Kumar and van Dissel (1996) refer that the performance measure ambiguity may be reduced by using information technology to generate and collect monitoring information that would otherwise be too expensive to collect manually [17]. The third transaction risk, loss of resource control, occurs when resources are transferred as part of the relationship and these resources cannot be returned or controlled in the event of the termination of the relationship [7]. Information know-how is the most possible resource that may be lost of control, since firms are very difficult to control the access and subsequent utilization of such resources. Previous literature also shows that such resource contention and conflict can be much reduced while conducting pre-established concurrency control and security mechanisms beforehand. Besides, the control of such resource is better placed in the hands of a neutral third party such as a trade association, exchange, government agency, or a joint venture company [17].

the successful market players have the capability of timely responsiveness and rapid and flexible product innovation, coupled with the management capability to effectively coordinate and redeploy internal and external competences [26]. They define the ability to achieve new forms of competitive advantage as “dynamic capabilities”. The focal point is to hold the timing and then to adapt, integrate, and reconfigure internal and external resource to response the rapid technological change and changing business environment. Such capabilities can be mainly divided into two groups based on their focused problems. One is to handle information uncertainties and the other is to task uncertainties. In order to handle information uncertainty, Clemons and Row (1993) suggest related technologies and systems to gather information surrounding dynamic supply chain environment, for example, a system to help firms gather dynamic information to forecast the customers’ needs [8]. Besides, open and frequent communications between firms and firms’ partners is also a way to handle the information uncertainty risk [1]. Task uncertainty arises due to the specific set of tasks carried out by the organizational agent responsible for the interorganizational relationship. In this work, the task uncertainty refers to the uncertainty of selling/buying activities because our research focuses on selling and buying activities of the supply chain. Bensaou and Venkatraman (1995) suggest that setting up the clearly known way, established practices and procedures employees follow, as well as detail and clear job descriptions are the ways and means to handle the uncertainty of selling/buying activities [5].

Relationship Level. Besides the dynamic view, some scholars extend the RBV to relational view while arguing that a firm’s critical resources may extend beyond firm boundaries, and the benefits often linked to the relational network that the firm is embedded [15]. Applying the relational view to the supply chain context, firms that have capabilities to maintain good relationships with trading partners can reduce transaction costs, negotiation costs, and uncertainty about the opportunistic behavior, thereby having a positive effect on performance. These capabilities include long-term relationship, reputation, investment both sides, complementarity of technology, business practice, goal, and culture, as well as regulations to handle the management dependency [10, 11, 13, 17]. We summarize them into three categories: trust, complementarity, and management dependency and describe them in the following paragraphs respectively.

Based on Dwyer, Schurr, and Oh (1987), trust is defined as “the belief that a party’s word or promise is reliable and the party will fulfill his/her obligations in an exchange relationship” [10]. Lewis and Weigert (1985) recognize the significance of trust in uncertain/risky environment and refer that persons involved in a risky course of action can act competently and dutifully while they trust with each other [19]. Therefore, trust is an important concept in understanding expectations for cooperation and planning in a relational contract.

Dyer and Singh (1998) define complementary resource endowments as distinctive resource of alliance partners that collectively generate greater rents than the sum of those obtained from the individual endowments of each partner [11]. Similarly, Bensaou (1997) argue that compatibility in goals and technological capabilities reduce the uncertainty about the partner’s inclination and potential intentions for opportunistic behavior and therefore invite cooperation [4]. Further, cultural differences between two organizations are also likely to exacerbate the transaction risks by increasing the risk of different interpretations of the transaction contract [17].

Management dependency is another important factor to handle the fairness of supply chain relationship. According to Hart and Saunders (1998), relative dependence in a dyadic relationship between customer and supplier is a determinant of power [13]. Often the powerful partners provide software free of charge, long term incentive, risk sharing, education seminar, and cost subsidy to less power company who otherwise may not be able to justify the investment [21, 27].

resources and shared by relational network partners. These resources and capabilities may result in special competitive advantages or benefits in supply chain collaboration.

3. Research Framework

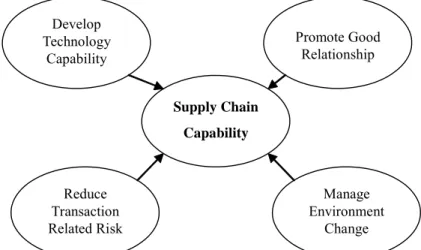

According to our previous discussion, we argue that an enterprise with good supply chain capability should be able to handle the supply chain collaboration more successfully. These views are synthesized into the following definition and are characterized by Figure 1:

Supply chain capability is a company-owned ability to well operate company’s supply chain networks, which can efficiently aid the companies to handle the collaborative activities with their trading partners. The scope of considering the supply chain capability is from the basic technology level to the environment level, which include how to improve the transaction efficiency, how to reduce the transaction risk, how to promote a good relationship, and how to resolve the uncertainty in the dynamic environment.

Supply Chain Capability Develop Technology Capability Reduce Transaction Related Risk Promote Good Relationship Manage Environment Change

Figure 1. Research Framework for the Development of Supply Chain Capability Construct 4. Research Methodology

The content analysis results in an initial pool of 26 items with at least 4 items in each dimension. Table 1 shows the measures for each dimension, operationalized using the items provided in the referenced studies. Each item is presented on a seven-point Likert scale.

In preparation for large-scale data collection, the resulting questionnaire was pilot-tested by six executives that are directly responsible of IOS collaborations during fall 2004. These six executives come from three different types of firms in Taiwan PC industry: the component supplier, the service provider, and the manufacturer. The findings of pilot-test are consistent with our model.

Table 1. Item Measures for Supply Chain Capability Construct Factors Items Measures of Develop Technology Capability (TC)

TC1 Percentages of transaction by IOS links [5, 22] TC2 Number of partners that are connected by IOS links [5] TC3 Degree of IOS integration with each process [5, 22] TC4

IOS usage and integration

TC5 Degree of IOS integration with current enterprise systems [5, 22] TC6 Degree of technology investment in IOS [22]

Information

infrastructure TC8 Establishment of applications to support tasks [5] Factors Items Measures of Reduce Transaction Related Risk (TR)

TR1 Successful implementation experience [7] TR2 Modularity and replicability of know-how [7] Reducing

transaction-specific

capital TR3 Following the industrial standard [7] Managing information

asymmetries Managing loss of resource control

TR4 Pre-established security mechanisms [17] Factors Items Measures of Promote Good Relationship (GR)

GR1 Existed undergoing supply chain collaboration projects [4] GR2 Establishment of clear norms for business behavior [4, 11] GR3 Sharing confidential or proprietary information [1, 11, 25] Trust

GR4 Open and frequent communications [1] GR5 Similar IT infrastructure [16, 17] GR6 Compatible company culture [11]

GR7 Similar decision processes to handle transactions [17] Complementarity

GR8 Providing similar support of cooperative firms by top management [1, 4] GR9 Technology support or cost premiums [22, 27]

Management

dependency GR10 Education seminars or system implementation expertise [21] Factors Items Measures of Manage Environment Change (EC)

EC1 Related technologies and systems to help gather information [8] EC2 Explicit regulations to measure trading performance [17] Manage information

uncertainty

EC3 Sending the timely, accurate, and complete information [1] Manage uncertainty of

selling/buying activities

EC4 Clearly known practices and procedures in doing inter-firm tasks [5]

After pilot test, we conduct a general survey in Taiwan PC industry to validate our proposed framework. Data were collected using a questionnaire instrument. We coordinated with six Taiwan PC firms, three of which have participated in our pilot-test. For each firm, a purchasing and/or engineering senior manager at the central division was first asked to select a set of suppliers under his or her responsibility. Then for each of the selected suppliers these senior managers helped identify the purchasing agent and/or engineer to whom we could send the questionnaire. The total data set constitutes a representative sample of n = 352. Among all returned questionnaires, 55 were found to be complete and usable; this represented a response rate of 15.625 percent.

5. Empirical Assessment of Construct Measurement

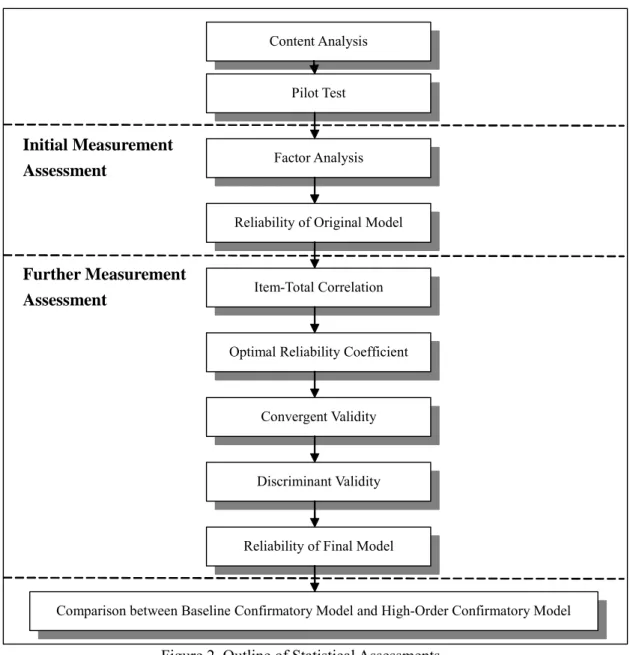

Once the data is collected, the verification of this model is conducted through a series of statistical techniques. From a theoretical standpoint, the measurement properties of a construct can be evaluated using a variety of techniques, including internal and external validity, theoretical meaningfulness, internal consistency of operationalization, convergent validity, discriminant validity, and nomological validity. From an operational standpoint, however, the following minimal subset is considered important: unidimensionality and convergent validity, reliability, and discriminant validity [6, 24]. The statistical assessments follow the outline given in Figure 2 and the rationale of this outline is described as follows.

Initial Measurement

Assessment Factor Analysis

Reliability of Original Model

Further Measurement Assessment

Content Analysis

Item-Total Correlation

Optimal Reliability Coefficient

Convergent Validity

Discriminant Validity

Reliability of Final Model

Comparison between Baseline Confirmatory Model and High-Order Confirmatory Model Pilot Test

Figure 2. Outline of Statistical Assessments 5.1 Initial Measurement Assessment

The completeness issue is first investigated. Items in this study were selected based on a broad review of literature which satisfies the content validity. The pilot test was done with six executives that are directly responsible of IOS collaborations. Such methodology assures that the model is complete. We then conduct the factor analysis to identify underlying constructs from a large number of interrelated variables. The result is a solution with four factors, each with eigenvalues greater than 1.0. Two items (TC3 and TC4) are excluded from the original model as their factor loadings are less than 0.4 (0.35 recommended by Churchill (1979)), and three items (TC6, TC7, and TC8) that measure the information technology infrastructure are removed to Factor2, resulting in a 24-item model. According to the results of the factor analysis, we point out that the Factor1 measures the technology capability which related the IOSs, the Factor2 presents the technological and managerial capabilities to reduce the transaction related risk, the Factors3 contributes the abilities to promote the good supply chain relationships, and the Factor4 expresses the capabilities to handle the uncertainties of the environment change. The initial reliability is assessed by Cronbach’s α coefficient for each of the dimensions determined from the factor analysis. The

alpha coefficient for each factor isabove 0.8 except TC (Table2), indicating an acceptable reliability [18]. Table 2. Measurement Properties of Proposed Model

Factors Measures of Model Fit

Independence Model X 2 (276) = 4.994 Overall Model Factor Reliability = 0.940 Independence Model X 2 (3) = 2.967 Technology Capability (TC) Factor Reliability = 0.473 Independence Model X 2 (21) = 15.260 Capability to Reduce

Transaction-Related Risk (TR) Factor Reliability = 0.818

Independence Model X 2 (45) = 10.036 Capability to Promote Good

Relationship (GR) Factor Reliability = 0.838

Independence Model X 2 (6) = 15.588 Capability to Manage Environment

Change (EC) Factor Reliability = 0.842 5.2 Further Measurement Assessment

To further improve reliability, item-total correlation and optimal reliability coefficients are suggested for use [20]. Under these two procedures, no items are dropped from the model, and therefore the model is still a 24-item model.

Then, the construct validity of each item is examined to ensure that the items included in the model measure the construct. To establish the construct validity of a measure, the literature suggests that the analysis must determine convergent validity and discriminant validity [13, 20]. A multi-trait/multi-method (MTMM) is used for convergent and discriminant validity of the model. The smallest within-dimension correlations for TC, TR, GR, and EC are 0.21, 0.38, 0.43, and 0.51. These correlations are significantly higher than zero and indicate convergent validity [20].

To establish discriminant validity, the relationship between measures from different dimensions should be very low. Using the MTMM approach, discriminant validity for each item is tested by counting the number of times each inter-correlation more highly with an item of a different variable than with items of its parent dimension [20]. It is notable that all items of TC are dropped, eliminating the dimension from the model, and one item (TR2) of transaction level and two items (GR4 and GR7) of relationship level are excluded from the model. After above procedures, six items are dropped from the 24-item model, making it an 18-item model.

After a series of measurement assessment, Table 3 shows the reliability coefficient values for the final model. The reliability of two factors, TR and GR, is increased and the factor, EC, without adjusted items is leveling off. All the items in the factor TC are dropped because they violate the discriminant validity. In summary, the adjusted model with an overall reliability of 0.943 represents good instrument validity. The summary of statistical assessment is shown in Figure 3.

Table 3. Measurement Properties of Final Model

Factors Measures of Model Fit

Independence Model X 2 (153) = 6.070 Overall Model

Factor Reliability =0.943

Independence Model X 2 (15) = 17.310 Capability to Reduce

Transaction-Related Risk (TR) Factor Reliability = 0.907

Independence Model X 2 (28) = 10.870 Capability to Promote Good

Relationship (GR) Factor Reliability = 0.920

Independence Model X 2 (6) = 15.588 Capability to Manage

Factor Analysis

Reliability of Original Model Content Analysis

Item-Total Correlation

Optimal Reliability Coefficients

Convergent Validity

Discriminant Validity

Reliability of Final Model Pilot Test Further Measurement Assessment 24-item model 1. Dropping TC3 and TC4 in technology level 2. Moving TC6, TC7, TC8

form technology level to transaction level 18-item model 1. Dropping TC1, TC2 and TC5 2. Dropping TR2 3. Dropping GR4 and GR7 26-item model 24-item model 24-item model 24-item model Initial Measurement Assessment

Figure 3. Summary of Statistical Assessments 5.3 Evaluating a Covariation Model of Supply Chain Capability

The further verification of this model is through the use of confirmatory factor analysis. According to Segars and Grover (1998) [23], the analytical framework of confirmatory factor analysis provides an appropriate means of assessing the efficacy of measurement among scale items and the consistency of a pre-specified structural equation model with its associated network of theoretical concepts. The EQS for Windows program (Version 6.0) is utilized as the analytical tool for estimating the measurement and structural equation models developed in this study.

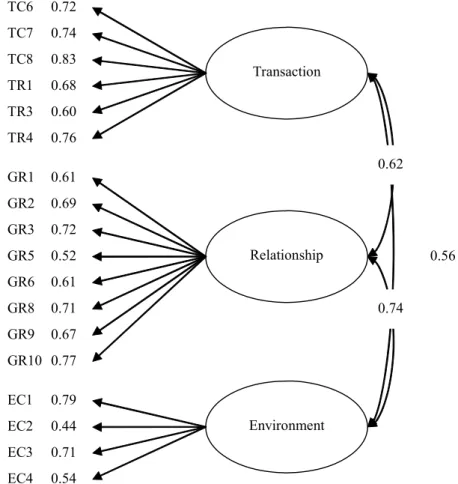

The 18-item model, derived from last section, forms the baseline confirmatory model for the supply chain capability construct. The baseline model suggests that transaction, relationship, as well as environment are independent in their prediction of supply chain capability (Figure 4). Table 4 reports the

goodness-of-fit summary for the baseline model. The X 2 divided by its degrees of freedom is 1.99, which is conforming to the recommended 2 [24]. The goodness-of-fit (GFI) for the baseline model is 0.834, which is below the recommended 0.9 [24]. However, it is not out of line with other exploratory studies developing measures for complex organizational phenomena. The root mean square residual (RMSR) is 0.089, which is below the recommended 0.1 [24], providing further evidence of a good fit for this model. The reliability is above the cutoff of 0.8 that is good for exploratory studies. Overall, the fit indicators seem to suggest that each criterion is capturing a significant amount of variation in the latent dimensions of the supply chain capability construct.

Transaction TR3 TR4 EC2 GR1 GR2 GR3 GR8 GR9 GR10 EC1 EC3 EC4 0.54 0.71 0.79 0.77 0.67 0.71 0.72 0.69 0.61 0.44 0.76 0.60 TC6 0.72 TC7 0.74 TC8 0.83 TR1 0.68 Relationship Environment 0.62 0.56 0.74 GR5 0.52 GR6 0.61

Figure 4. Baseline Confirmatory Model for Supply Chain Capability Construct Table 4. Model Fit Indices for Baseline Model

Number of Latent Variable 3

Total Number of Items 18

X 2/degrees of freedom 262.674/132=1.99

p-value 0.000001

Goodness of Fit 0.834

Root Mean Square Residual 0.089

Factor Reliability 0.943

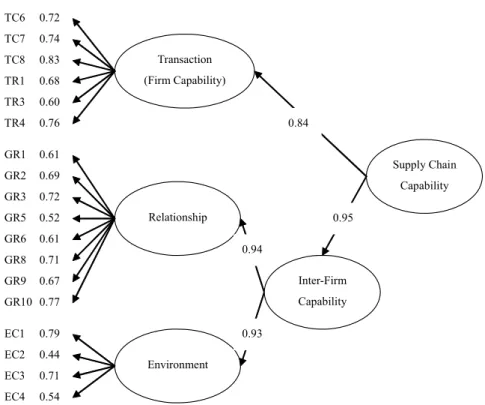

The second-order model was iteratively modified to improve its fitness. Table 5 shows the model fit indices for the alternative model and the structure is shown in Figure 5. Overall, the fit indices for the second-order model are satisfactory based on the criteria of X 2 / degrees of freedom (df), GFI, RMSR,

and reliability.

Table 5. Model Fit Indices for Second-Order Confirmatory Model

Number of Latent Variable 5

Total Number of Items 18

X 2/degrees of freedom 262.674/129=2.

04 p-value 0.000001

Goodness of Fit 0.834

Root Mean Square Residual 0.089

Factor Reliability 0.943 Transaction (Firm Capability) TR3 TR4 EC2 GR1 GR2 GR3 GR8 GR9 GR10 EC1 EC3 EC4 0.54 0.71 0.79 0.77 0.67 0.71 0.72 0.69 0.61 0.44 0.76 0.60 TC6 0.72 TC7 0.74 TC8 0.83 TR1 0.68 Relationship Environment GR5 0.52 GR6 0.61 Supply Chain Capability 0.93 0.94 0.84 Inter-Firm Capability 0.95

Figure 5. Second-Order Confirmatory Model for Supply Chain Capability Construct

It has been suggested that the efficacy of second-order model be assessed through examination of the target (T) coefficient (T = X 2 (baseline model)/ X 2 (alternative model)) (Segars and Grover 1998). The

coefficient has a lower bound of 1.0 if the higher-order model is sufficiently captures the factor in the model. As shown in Table 5, the coefficient between the baseline model and second-order model is 0.98. The value suggests that the addition of the second-order model does increase chi-square. Therefore, the second-order model is a truer representation of the model structure and that the second-order model can be accepted over the baseline model.

6. Discussion

It is notable that all items of TC were either dropped or moved, eliminating the dimension from the construct. The possible reason is that technology capability is not a performance differentiator for both suppliers and original equipment manufacturers (OEMs) in Taiwan PC industry. Most of the suppliers in Taiwan PC industry are small and medium-sized enterprises (SMEs); therefore the trading means of the interorganizational collaboration may greatly depend on the requests of their customers. The customers choose the suppliers with a long-term relationship so that the quality, cost, and the price of the offerings are trustworthy, rather than choose those simply having better technology abilities. Thus, from the SMEs’ perspective; suppliers do not consider the technology capability as a major ability for supply chain collaboration. On the other hand, from the perspective of OEMs, they are big and powerful in the Taiwan PC market. Due to the government support and similar customer pool, most of them have developed high but similar technology capability to conduct the inter-firm coordination. Technology capability can not generate competitive advantage for them.

The statistical analysis also suggests us to move the items that measure the IT investment to the transaction level, indicating that the investment of IT infrastructure is an important factor to reduce transaction related risks. This change represents that the firms’ IT infrastructure can not directly influence the supply chain capability by itself, but it indirectly affect by reducing the transaction risks. This finding is basically consistent with previous IT research [2, 7, 8, 17]. For example, Kumar and van Dissel (1996) propose a framework that considers the IT as a supporting role in reducing transaction costs and transaction risks. In order to reduce the transaction risks such as overgrazing of the common, fouling or contaminating, and poaching the commons, Kumar and van Dissel (1996) suggest that IT may be used effectively as the village constable to guard against these risks [17]. According to the results of Clemons and Row (1992), IT is both creating the opportunity for cooperation and providing the monitoring capability to reduce the transaction risk associated with cooperation [7]. Their research shows that the IT increases the amount or timeliness of information transferred across firm boundaries as well as reduces the information asymmetries which result in transaction risks. Therefore, instead of being treated as an independent supply chain capability, IT should be viewed as one of the transaction enablers.

In summary, our research points out the IT capability is not a significant supply chain capability for good supply chain collaboration. This result is contrast with most of past related studies as they treat technology as one of the important factor for inter-firm collaboration. Though this finding may need further justification in the future, it reflects the fact that more and more companies view IT as a foundation for inter-firm transaction, but not a weapon for creating competitive advantage. In our interview, most companies agree that technology is not a major concern while considering supply chain collaboration, other factors like trust or the power of partners play more important role.

6.2 Structure of the Construct

Another interesting aspect of this study is the discovery of a second-order confirmatory model. The three dimensions are modeled as baseline latent variables, determined by two second-order latent variables. The first label presents the firm capability which can effectively help company handle the transaction related risk with the technical and managerial abilities. The second label expresses the inter-firm capabilities that include the abilities to promote good supply chain relationship and capacity to handle the uncertainties in the dynamic environment. The dimensions of our final model are described as follows.

Firm capability: The dimension consists of a transaction level describing abilities of reducing transaction

risks: degree of technology investment in IOS (TC6), establishment of IT infrastructure (TC7), establishment of applications to support tasks (TC8), successful implementation experience (TR1), following the industrial standard (TR3), and pre-established security mechanisms (TR4). The first three items are from the technical perspective to reduce the transaction risks and the other three items are from the managerial perspective to prevent the transaction risks.

Inter-firm capability: the dimension includes two levels – (1) promote good relationships and (2) manage environment change. The relationship level measures how to well maintain the supply chain relationships

with trading partners, including the items of existed undergoing supply chain collaboration projects (GR1), establishment of clear norms for business behavior (GR2), sharing confidential or proprietary information (GR3), similar IT infrastructure (GR5), compatible company culture (GR6), providing similar support of cooperative firms by top management (GR8), technology support or cost premiums (GR9), and education seminars or system implementation expertise (GR10). The environment level comprises of the capabilities of handling the environment uncertainties: related technologies and systems to help gather information (EC1), explicit regulations to measure trading performance (EC2), sending the timely, accurate, and complete information (EC3), and clearly known practices and procedures in doing inter-firm tasks (EC4). Thus, to understand firms’ supply chain capability, this study suggests the companies have to consider two dimensions: firm capability and inter-firm capability. The firm capability presents the abilities to reduce the transaction related risks, and the inter-firm capability indicates the abilities to handle the relationships and environment issues. It is interesting to notice that past research seldom considers the ability to handle environment uncertainty as an important supply chain capability. However our study indicates that such capability becomes more and more important in the current e-business environment where customer requests frequently change, product obsoletes quickly, and customization becomes a norm

7. Conclusion

Many organizations are reengineering their business processes in order to take full advantage of supply chain collaboration. Our study seeks to uncover the key company-owning capability that can contribute to the supply chain collaboration. The proposed framework measures the supply chain capability in four levels: (1) the technology capability in terms of IOS usage and integration as well as information technology infrastructure, (2) the transaction risk resolution capability, (3) the capability to maintain good relationships, and (4) the capability to reduce uncertainties of external environment.

To pretest the applicability of this model, we conduct interviews with three companies in Taiwan PC industry. The findings are consistent with our model. To further test the model, we conduct a general survey with main Taiwanese PC firms during spring 2005. After a series of measurement assessment, the supply chain capability construct is adjusted as a second-order model. The model consists of two groups of items. The first group captures the firm capability for resolving the transaction risk. The other group presents the inter-firm capabilities for promoting good relationship and managing the environment uncertainties with trading partners.

As any empirical investigation, weaknesses in our methodology and data are present [18]. First, the number of observations upon which the analyses are performed is in the barely acceptable range. Although we have cited evidence that our sample size is minimally adequate, we recognize that other researchers might take exception to our small size. Second, the survey data utilized in this study are collected from firms in the Taiwan PC industry. Although the utilized sampling frame has been widely-used in similar studies and contains organizations which likely participate in the activity of interest, no claim of externally validity for this study’s findings can be made. Instead, these findings can only be generalized to the population of firms within the sampling frame.

However, at the very least, the components of supply chain capability and the measurement instrument developed in this study provide a good starting point for further investigations of the supply chain capability construct. Validated supply chain capability measures can help managers better gauge the characteristics of the collaborations. IT researchers can build upon the model developed in this study through further examination of the factors that are discovered. Further research can be conducted by the cross-industry or cross-country survey in the future to verify these results.

References

1. Angeles, R., and Nath, R., “An Empirical Study of EDI Trading Partner Selection Criteria in Customer-Supplier Relationships,” Information and Management (37:5), 2000, pp. 241-255.

2. Bakos, J. Y., “Information Links and Electronic Marketplaces,” Journal of Management Information Systems (8:2), 1991, pp. 31-52.

3. Barney, J. “Firm Resources and Sustained Competitive Advantage,” Journal of Management (17:1), 1991, pp. 99-120.

4. Bensaou, M., “Interorganizational Cooperation: The Role of Information Technology, An Empirical Comparison of U.S. and Japanese Supplier Relations,” Information Systems Research (8:2), 1997, pp. 107-123.

5. Bensaou, M., and Venkatraman, N., “Configurations of Interorganizational Relationship: A Comparison between U.S. and Japanese Automakers,” Management Science (41:9), 1995, pp. 1471-1492.

6. Byrd, T. A., and Turner, D. E., “Measuring the Flexibility of Information Technology Infrastructure: Exploratory Analysis of a Construct,” Journal of Management Information Systems (17:1), 2000, pp. 167-208.

7. Clemons, E., and Row, M., “Information Technology and Industrial Cooperation: The Changing Economics of Coordination and Ownership,” Journal of Management Information Systems (9:2), 1992, pp. 9-28.

8. Clemons, E., and Row, M., “Limits to Interfirm Coordination through Information Technology: Results of a Field Study in Consumer Packaged Good Distribution,” Journal of Management Information Systems (10:1), 1993, pp. 73-95.

9. Craighead, C. W., and Shaw, N. G., “E-Commerce Value Creation and Destruction: A Resource-Based, Supply Chain Perspective,” Database for Advances in Information Systems (34:2), 2003, pp. 39-49.

10. Dwyer, F. R., Scurr, P. H., and Oh, S., “Developing Buyer-Seller Relationships,” Journal of Marketing (51:2), 1987, pp. 11-27.

11. Dyer, J. H., and Singh, H., “The Relational View: Cooperative Strategy and Sources of Interorganizational Competitive Advantage,” Academy of Management Review (23:4), 1998, pp. 660-679.

12. Grant, R. M. “The Resource-Based Theory of Competitive Advantage: Implications for Strategic Formulation,”

California Management Review (33:3), 1991, pp. 114-135.

13. Hart, P. J., and Saunders, C. S., “Emerging Electronic Partnerships: Antecedents and Dimensions of EDI Use from the Supplier’s Perspective,” Journal of Management Information Systems (14:4), 1998, pp. 87-111. 14. Iskandar, B., Kurokawa, S., and Leblanc, L., “Adoption of Electronic Data Interchange: The Role of

Buyer-Supplier Relationships,” IEEE Transactions on Engineering Management (48:4), 2001, pp. 505-517. 15. Jeffrey H. Dyer and Harbir Singh, “The relational view: Cooperative strategy and sources of interorganizational

competitive advantages,” The Academy of Management Review (23:4), 1998, pg. 660-679.

16. Konsynski, B. R., and Mcfarlan, F. W., “Information Partnership – Shared Data, Shared Scale,” Harvard

Business Review (68:5), 1999, pp. 114-120.

17. Kumar, K., and van Dissel, H. G., “Sustainable Collaboration: Managing Conflict and Cooperation in Interorganizational Systems,” MIS Quarterly (20:3), 1996, pp. 279-300.

18. Lewis, B. R., and Byrd, T. A., “Development of a Measure for the Information Technology Infrastructure Construct,” European Journal of Information Systems (12:2), 2003, pp. 93-109.

19. Lewis, J. D., and Weigert, A., “Trust as a Social Reality,” Social Forces (63), 1985, pp. 967-985. 20. Mahmood, M. A., and Soon, S. K., “A Comprehensive Model for Measuring the Potential Impact of

Information Technology on Organizational Strategic Variables,” Decision Sciences (22:4), 1991, pp. 869-897. 21. Riggins, F. J., Kriebel, C. H., and Mukhopadhyah, T., “The Growth of Interorganizational Systems in the

Presence of Network Externalities,” Management Science (40:8), 1994, pp. 984-998.

22. Riggins, F. J., and Mukhopadhyay, T., “Interdependent Benefits from Interorganizational Systems:

Opportunities for Business Partner Reengineering,” Journal of Management Information Systems (11:2), 1994, pp. 37-57.

23. Segars, A. H., and Grover, V., “Strategic Information Systems Planning Success: An Investigation of the Construct and Its Measurement,” MIS Quarterly (22:2), 1998, pp. 139-163.

24. Sethi, V., and King, W. R., “Development of Measures to Assess the Extent to Which an Information Technology Application Providers Competitive Advantage,” Management Science (40:12), 1994, pp. 1601-1627.

25. Soliman, K. S., and Janz, B. D., “An Exploratory Study to Identify the Critical Factors Affecting the Decision to Establish Internet-based Interorganizational Information Systems,” Information and Management (41:6), 2004, pp. 697-706.

26. Teece, D. J., Pisano, G., and Shuen, A. “Dynamic capabilities and strategic management,” Strategic

Management Journal (18:7), 1997, pp. 509-533

27. Wang, E., and Seidmann, A., “Electronic Data Interchange: Competitive Externalities and Strategic Implementation Policies,” Management Science (41:3), 1995, pp. 401-418.