國立台灣大學工學院土木工程學系 碩士論文

Department of Civil Engineering College of Engineering National Taiwan University

Master Thesis

木塑材料在太平洋東亞地區之應用潛能調查

An investigation of the pervasive potential of wood-plastic composite (WPC) in the East Asia & Pacific (EAP) region

池尻謙太 Kenta Ikejiri

指導教授: 詹瀅潔 博士 Advisor: Ying-Chieh Chan, Ph.D.

中華民國 109 年 7 月 July 2020

Acknowledgement

Foremost, I would like to thank my supervisor Ying-Chieh Chan for her guidance throughout this study. My sincere thanks also go to Research Assistant Mei-chin Chen, since this study would not have been possible without her dedicated support.

Finally, we would like to express our profound gratitude to all those who participated in the questionnaires and interviews for this research.

Abstract

This study investigates the pervasive potential of wood-plastic composite (WPC) in the East Asia & Pacific (EAP) region. First, the characteristics of WPC, including

environmental compatibility, life cycle cost, material strength, and material properties, were reviewed, and the issues related to WPC marketing in the EAP region, were investigated.

A questionnaire survey was conducted to examine WPC’s subjective attitudes and impressions from the perspective of WPC users, including architects and landscape designers. As case studies, three regions (Japan, Taiwan, Vietnam) were selected based on income level, and a total of 53 responses were obtained. An interview was then conducted with one interviewee from each of the three regions to obtain the survey results’ objective validity. Some differences, such as public awareness, general

impressions, and severe challenges of WPC in each region, were gained. Based on the above attitude survey, the following four improvements relevant to WPC were

proposed: better texture, better environmental friendliness, better marketing, and design flexibility. Then objective evaluations of each improvement were obtained through a second questionnaire survey, and finally, interviews were conducted with WPC manufacturers to ask about the feasibility of the improvements.

This study revealed that WPC is infrequently used or intentionally avoided in all the three target regions, and the future spread of WPC will be expected in Taiwan and Vietnam, where WPC has recently introduced, rather than Japan, where the WPC industry has already matured. For its widespread use, it will be necessary to establish a new distribution system that takes into account the repeated recycling of WPC products

with government intervention, and architectural education on the proper use of WPC together with traditional building materials.

Keywords: wood-plastic composite (WPC), East Asia & Pacific (EAP), environmental friendliness, recyclability, marketing, cost-effectiveness

Table of Contents

1.1 Background and Problems ... 1

1.2 Aim and Objectives ... 8

1.3 Methods ... 8

2.1 Introduction to WPC ... 10

2.2 Life Cycle Assessment (LCA) of WPC ... 16

2.3 Life Cycle Cost (LCC) of WPC ... 20

2.4 Market Research of WPC ... 22

2.5 Public Perception of WPC ... 25

3.1 Introduction to the Attitude Survey ... 27

3.2 Questionnaire ... 28

3.2.1 Hypotheses... 28

3.2.2 Respondents’ Attributes ... 28

3.2.3 Results and Interpretations ... 30

3.3 Interview... 36

3.3.1 General Information ... 36

3.3.2 Results and Discussions... 37

4.1 Introduction to the Improvements ... 41

4.2 Proposals ... 41

4.2.1 Better Texture ... 41

4.2.2 Better Environmental Friendliness ... 42

4.2.3 Better Marketing ... 44

4.2.4 Design Flexibility ... 45

5.1 Introduction to the Feasibility Survey ... 46

5.2 Questionnaire ... 46

5.2.1 Respondents’ Attributes ... 46

5.2.2 Results and Interpretations ... 47

5.3 Interview... 50

5.3.1 General Information ... 50

5.3.2 Results and Discussions... 50

6.1 Conclusions ... 55

6.2 Future Work ... 56

List of Figures

Figure 1. 1 Global map with each country shaded according to the estimated mass of

mismanaged plastic waste in 2010 (Source: Jambeck et al. 2015) ... 1

Figure 1. 2 Estimated consumption of plastic by end-used sector (Source: Geyer et al, 2017) 3 Figure 1. 3 Annual primary plastic waste generation by sector (Source: Vezér and Morrow 2018) ... 4

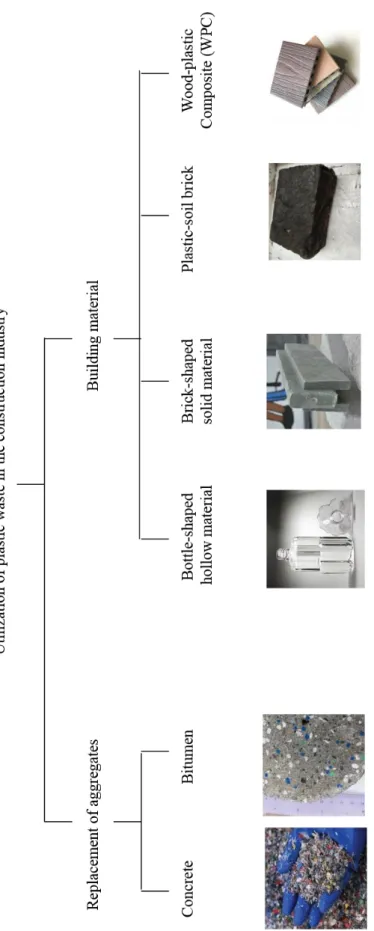

Figure 1. 4 Classification of the utilization of plastic waste in the construction industry ... 5

Figure 1. 5 EcoARK in Taipei as an example of building made from plastic bottles (Source: Inhabitat®) ... 6

Figure 1. 6 BRICKARP in Colombia as an example of building made from plastic bricks (Source: TRT World) ... 7

Figure 1. 7 Research flow ... 9

Figure 2. 1 Close view of WPC (Source: Changxing hanming technology Co.,LTD)... 10

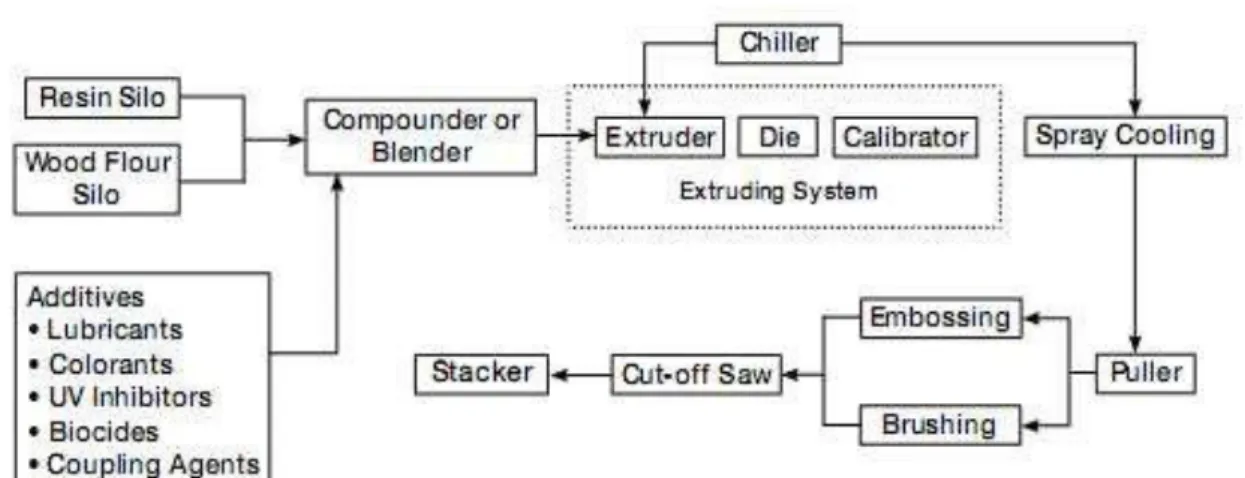

Figure 2. 2 The WPC manufacturing process with extrusion forming (Source: Ghasem 2013) ... 11

Figure 2. 3 Global WPC market share in 2019 (Source: Grand View Research) ... 12

Figure 2. 4 Example of some applications of WPC (Source: HaunSu Tech Corporation) ... 13

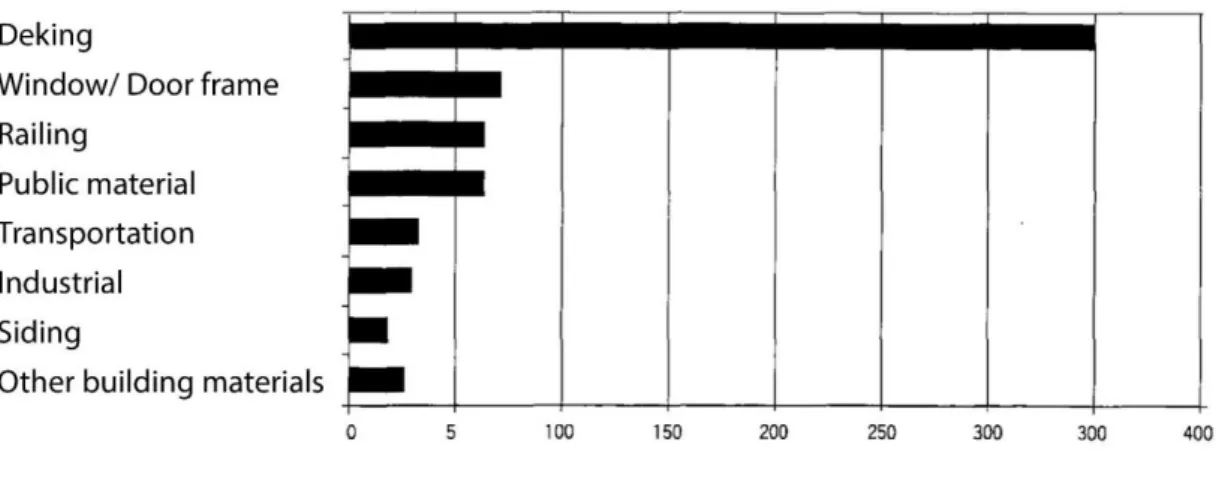

Figure 2. 5 Main applications of WPC in the U.S and EU (Source: Kiguchi 2005) ... 14

Figure 2. 6 Life cycle impact assessment for the four decking products per 100 ft2 (Source: Bergman et al. 2014) ... 17

Figure 2. 7 LCCO2 value of WPC and woods by processes (Source: Hidari et al. 2006) ... 19

Figure 2. 8 Costs of each deck over time (Source: GreenScape 2006) ... 20

Figure 2. 9 Average annual costs of each deck over their lifespan (Source: GreenScape 2006)

... 21

Figure 2. 10 Development scale of WPC in China from 2009 to the first half of 2016 (Source: China Industrial Information Network) ... 22

Figure 2. 11 Global production of WPC in 2010 and 2012, and forecast for 2015 (Source: Carus et al. 2014) ... 23

Figure 2. 12 Changes in production volume of WPRC in Japan (Source: Association for Popularization of WPRC) ... 24

Figure 2. 13 Embossing machine of WPC (Source: Qingdao Hegu Wood-Plastic Machinery Co.,Ltd.) ... 26

Figure 3. 1 Gender of the respondents from the three regions ... 29

Figure 3. 2 Ages of the respondents from the three regions ... 29

Figure 3. 3 Respondent’s awareness of WPC ... 30

Figure 3. 4 Use experience of WPC of the respondents from the three regions ... 31

Figure 3. 5 Use frequency of WPC ... 32

Figure 3. 6 Overall evaluation of WPC ... 33

Figure 3. 7 Intentional avoidance of use of WPC ... 33

Figure 3. 8 Reasons of negative evaluations ... 34

Figure 3. 9 Reasons of positive evaluations... 34

Figure 3. 10 The climate comparison between Taipei and Tokyo (Source: ZenTech) ... 38

Figure 4. 1 Improvement of the texture of WPC (Left: before, Right: after) ... 42

Figure 4. 2 The conventional one-way distribution system of WPC ... 43

Figure 4. 3 The new circular distribution system of WPC ... 43

Figure 4. 4 The cost simulation of WPC decking over its lifespan ... 44

Figure 4. 5 The cost simulation of wood decking over its lifespan ... 44

Figure 4. 6 The example of color variation of WPC products (Source: The Good Guys) ... 45

Figure 4. 7 Design change of WPC in a short span ... 45

Figure 5. 1 Ages of the respondents from the three regions ... 46

Figure 5. 2 Gender of the respondents from the three regions ... 47

Figure 5. 3 Important aspects of WPC ... 48

Figure 5. 4 Future use of WPC ... 48

Figure 5. 5 Correlation between awareness and future use of WPC ... 49

Figure 5. 6 Example of wood shavings (Source: WORLD EXPORT COMPANY LIMITED) ... 51

List of Tables

Table 1. 1 Waste estimates for 2010 for the top 20 countries ranked by mass of mismanaged plastic waste (Source: Jambeck et al. 2015) ... 2

Table 2. 1 Physical and mechanical properties and costs for WPC, wood and plastic (Source:

HuanSu, Dias and Alvarez 2017, Arnandha et al. 2017) ... 15

Table 3. 1 Assumptions for the sample size ... 27 Table 3. 2 Summary of hypotheses and results... 35

Table 5. 1 List of common sources for the plastic and wood fiber used in some WPC products in U.S. (Source: Winandy et al. 2004) ... 52 Table 5. 2 List of some WPC products in U.S. (Source: Winandy et al. 2004) ... 53

Introduction

1.1 Background and Problems

Our planet is drowning in plastic pollution. As of 2015, approximately 6300 metric tons (Mt) of plastic waste had ever been produced in the world, of which about 9% had been recycled, 12% was incinerated, and 79% was either

landfilled or discharged to the natural environment (Geyer et al. 2017). In 2010 alone, more than 270 Mt of plastic waste was generated in 192 coastal countries, with approximately 5 to 13 Mt of it leaking into the ocean (Jambeck et al. 2015).

Moreover, a minimum of more than 5 trillion plastic particles weighing over 260,000 tons afloat at sea was estimated in 2014 (Eriksen et al. 2014).

Now, plastic pollution is a globally recognized and non-negligible problem as it has been recognized as a “serious issue of global concern” by The United Nations Environment Assembly (UNEA 2016). However, it must be noted that Asian countries, especially East Asia & Pacific (EAP) region contributes to it

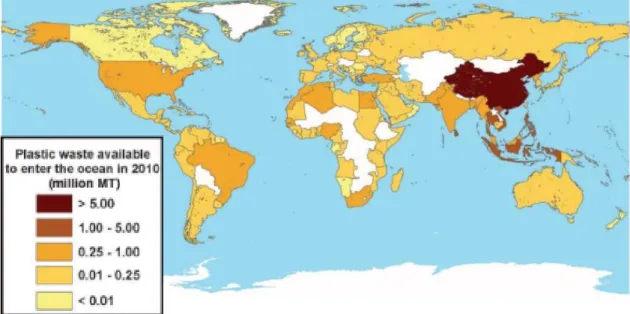

Figure 1. 1 Global map with each country shaded according to the estimated mass of mismanaged plastic waste in 2010 (Source: Jambeck et al. 2015)

most. As shown in Figure 1.1, the countries generated mismanaged plastic waste in 2010 are heavily biased toward EAP region. Table 1.1 shows that 13 of the top 20 countries which generated mismanaged plastic waste in 2010 were Asian countries (Jambeck et al. 2015). Moreover, it can be seen from the table that the top five polluters had caused more than half of global marine plastic pollution:

China, Indonesia, Philippines, Vietnam, and Sri Lanka, and all of them are Asian countries. By doing a simple calculation, more than 2.5 trillion plastic particles weighing over 130,000 tons can potentially afloat at Asian seas.

Plastic waste entering the oceans adversely affect marine life and indirectly threaten human life. Although the research on health hazard caused by the marine plastic pollution is still underdeveloped (Law and Thompson 2014), it has been evidenced that plastic waste and micro-plastic ingested by marine life can enter the human food chain; thus human health could be threatened (Gallo et al. 2018). Therefore, massive removal of plastic waste that can leak into the sea must be dealt with immediately.

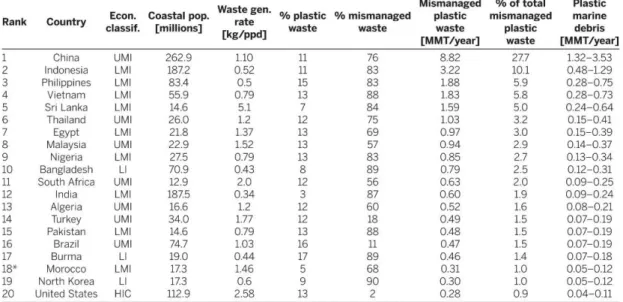

Table 1. 1 Waste estimates for 2010 for the top 20 countries ranked by mass of mismanaged plastic waste (Source: Jambeck et al. 2015)

The reduction of plastic waste can be classified into four ways: landfilling, incineration, recycling, and reusing (Hidayat et al. 2019). The effective

treatment method has been discussed for decades, and the pros and cons of each method have ever been reported from various aspects such as energy, cost, or pollution by each process (Bernado et al. 2016). Although the superiority of landfilling and incineration for specific products such as newspaper has been reported (Finnveden et al. 2000), many researchers still support recycling

(Denison 1996, Eriksson et al. 2005). Therefore, continuous recycling promotion in various industries is essential.

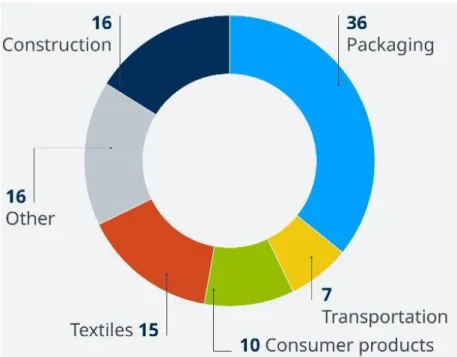

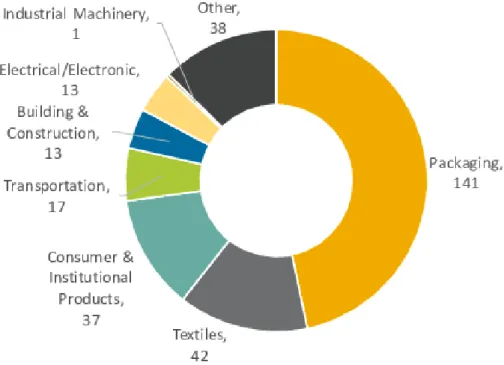

The construction industry is known as the second-largest consumer of plastic (Figure 1.2), but it is also one of the significant seven sectors contributing to plastic waste generation (Figure 1.3). However, the use of plastic waste in the construction industry has recently started to get attention. Although there are

Figure 1. 2 Estimated consumption of plastic by end-used sector (Source: Geyer et al, 2017)

various applications of plastic waste utilization in the construction industry, they are not originally designed for intending the “massive recycling” of plastic waste.

As shown in Figure 1.4, the applications can mainly be classified into six. The first application might appear as a replacement of aggregates used for creating concrete or bitumen. Grounded plastic waste can be added to them at a certain percentage before they are formed. Apart from such auxiliary use, plastic waste can also be a major building material. The first attempt of plastic bottles house in Africa was in the village of Yelwa in Nigeria. Plastic bottles have been used instead of bricks, bounding the bottles together with string, and at the end applied the plaster. The application as bottle-shaped hollow material can also be seen in Asia, as represented by EcoARK in Taipei, Taiwan (Figure 1.5).

Figure 1. 3 Annual primary plastic waste generation by sector (Source: Vezér and Morrow 2018)

Figure 1. 4 Classification of the utilization of plastic waste in the construction industry

However, massive consumption of plastic waste by these applications could hardly be realized. Brick-shaped solid materials have been developed mainly in South Africa against the backdrop of low-income housings. Since it can use 100% of discarded plastic waste (plastic bags, milk bottles, etc.) as a raw

material, it is regarded as a “green” material. Similarly, bricks impregnated with plastic waste has recently been developed and researched, but only a few studies could be found. The last application, wood-plastic composite (WPC), can also use recycled plastic as a raw material. WPC, especially those containing

recycled materials, are called as wood-plastic recycles composite (WPRC). For its creation, generally particles made of plastic waste and wood waste (sawdust, planer shavings, chips, etc.) are mixed and melted together, then molded and injected in any shapes.

For the massive recycling of plastic waste, the application as replacement of aggregates can first be excluded from the options because the used amount of plastic waste seems relatively small. The replacement is generally up to around

Figure 1. 5 EcoARK in Taipei as an example of building made from plastic bottles (Source: Inhabitat®)

25% (Khajuria and Sharma 2019), and it has also been reported that the material strength decreases in proportion to the volume ratio of plastic content (Siddique 2008). The bottle-shaped hollow material should also be excluded because of the same reason, due to its hollow shape. On the contrary, brick-shaped solid

materials (Figure 1.6) seems promising, but the material has just recently been introduced in South America, so it does not seem applicable in EAP region. On the other hand, WPC can be mixed up to around 60% of plastic waste, and is widely manufactured and distributed in the region. However, there are no studies that have evaluated WPC’s potential from the perspective of the massive

recycling of plastic waste, although the material seems to have high potential.

As a new destination for large amounts of abandoned plastic waste, seeking WPC’s potential is crucial now.

Figure 1. 6 BRICKARP in Colombia as an example of building made from plastic bricks (Source: TRT World)

1.2 Aim and Objectives

This study’s general objective could be to evaluate the pervasive potential of WPC as a building material for the massive recycling of plastic waste. This can be divided into the following three specific objectives.

- To reveal the current problems of WPC in the EAP region

- To propose some improvements to solve the problems of WPC in the EAP region

- To evaluate the proposed improvements of WPC

1.3 Methods

First, literatures regarding life cycle assessment (LCA) and life cycle cost (LCC) of WPC have been reviewed to summarize the fundamental information and confirm the advantages and disadvantages of the material, which form the basis of the investigation of the potential of WPC. Afterward, a brief market research has been conducted to grasp the actual market conditions of WPC in the EAP region.

Though there are myriad studies on LCA and LCC of WPC, no literatures regarding users’ attitudes toward the material could be found; therefore, it was necessary to conduct an attitude survey to comprehend the actual attitude of them. In addition to questionnaires, several interviews were implemented.

Three regions are selected as case studies, Taiwan, Japan, and Vietnam because all of these regions were adjacent to the ocean, which implies they can potentially contribute to the plastic pollution. Additionally, the income-level of these three regions varies (Fantom and Serajuddin 2016), so comparative analysis between them can be performed, and promising measures for each of

the regions can be designed individually. This study can hopefully be applied to any other EAP regions.

Based on the problems obtained by the literature review and attitude survey, some improvements of WPC have been proposed. Subsequently, the second questionnaires to evaluate the proposed improvements has been conducted accordingly. Ultimately the second interviews for WPC manufacturers have been implemented to assess the feasibility of the improvements.

Figure 1. 7 Research flow

Literature Review

2.1 Introduction to WPC

Wood-plastic composite (WPC) is defined as a composite material containing wood (in various forms such as fiber or flour) and thermoplastic materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or

polystyrene (PS). The concept is straightforward: to combine the best

characteristics of both wood and plastic (Liukko et al. 2007), for example, high water resistance, high corrosion resistance and low drying shrinkage of plastic, and natural texture of wood (Figure 2.1). In other words, WPC can compensate for the drawbacks of both materials such as high water absorption, low flexural strength, relatively short service life, low fire resistance, and unevenness of wood (HuanSu), and low elastic modulus of plastic (Imaizumi 1965).

Figure 2. 1 Close view of WPC (Source: Changxing hanming technology Co.,LTD)

As raw materials of WPC, usually by-products of the mechanical wood processing industry (e.g., sawdust) and recycled plastics are used (Liukko et al.

2007), although virgin materials can also be used. After the wooden filler is blended with polymer matrix, the material can be pelletized within an extruder, then melted and formed into the final shape by injection molding, extrusion or compression molding (Tabarsa et al. 2011). The extrusion forming is shown in Figure 2.2 as one of the WPC manufacturing processes.

The moldability, which was a long-cherished dream for wood industry is one of the unique characteristics of WPC, but the most distinctive feature is said to be the environmental friendliness, thanks to its high recyclability. Virtually abandoned or recycled material can be used as all the raw materials except for additives for producing WPC, and even the used WPC products can potentially be recycled multiple times.

Figure 2. 2 The WPC manufacturing process with extrusion forming (Source: Ghasem 2013)

WPC can be widely used in various applications, but the largest user is the building and construction sector (Figure 2.3). Over the last few decades, WPC has rapidly increased its market share as a building material (Carus and Gahle 2008), and the decking market is the biggest contributor to the growth, while other products such as siding, railing, and furniture also exist to a smaller extent (Figure 2.4). As shown in Figure 2.5, the lion’s share of WPC goes for decking.

Therefore, from the time WPC was introduced to the present day, decking has always been its main application.

Table 2.1 shows a comparison of physical and mechanical properties for WPC, wood, and plastic. As mentioned in the first half of this section, WPC is a

material that has the advantages of both wood and plastic, so the material property of WPC is generally equal to or superior to those of wood and plastic.

Concerning the physical properties, it can be seen that extremely low water

Figure 2. 3 Global WPC market share in 2019 (Source: Grand View Research)

absorption of WPC is achieved thanks to the plastic material as a raw material, and this characteristic significantly contributes to its excellent corrosion

resistance. It can also be observed that the density of WPC is relatively stable, as opposed to the varied density of wood and plastic depending on their species or types. On the other hand, the mechanical properties of WPC hinge on wooden raw materials. The loss of grain stabilizes the variation in strength due to the difference in the fiber direction of the wood. As a result, WPC’s relatively higher and more stable strength than wood and plastic could be realized. It is worth noting that WPC’s tensile strength is much lower than that of wood (parallel to grain), but this is not a significant problem considering that WPC is not generally used as structural members. Rather, bending and shear strength become objects of concern for WPC when it is generally used as a deck material, and WPC surpasses plastic more than twice at those values.

Figure 2. 4 Example of some applications of WPC (Source: HaunSu Tech Corporation)

Overall, WPC seems to be an excellent building material with equivalent or better material performance than wood.

Figure 2. 5 Main applications of WPC in the U.S and EU (Source: Kiguchi 2005)

Table 2. 1 Physical and mechanical properties for WPC, wood and plastic (Source: HuanSu, Dias and Alvarez 2017, Arnandha et al. 2017)

2.2 Life Cycle Assessment (LCA) of WPC

Life Cycle Assessment (LCA) is a modeling tool to assess environmental impacts related to products over their entire lifespans: from raw material extraction, manufacturing, distribution, use, and disposal or recycling (Curran 2014). The environmental impacts obtained by LCA analysis make it possible to quantitatively compare two or more materials, and select the one that has the lowest environmental impacts. However, LCA also has limitations that lead to doubts about its results. LCA studies depend on their different assumptions and scenarios, as LCA evaluates the real world in a simplified model. Studies can also have different scopes, so these unique conditions can vary from one study to the others, leading to different LCA results. Data are often obtained from the local databases, government, or specific firms or organizations, so the assumed locations and material availability can profoundly affect the results. Therefore, it should be borne in mind that the LCA analyzes presented here were performed under different conditions.

While WPC’s environmental friendliness is still subject to a controversial debate, it seems to be a common ground that WPC is inferior to solid wood concerning environmental impacts, whereas WPC can be an eco-friendly alternative to virgin plastic (Teuber et al. 2016). Bolin and Smith have

conducted an LCA analysis to measure and compare the environmental impacts of decking made of WPC, and from alkaline copper quaternary (ACQ) treated timber (Bolin and Smith 2011). The result showed that the use of WPC offers higher environmental impacts, such as approximately 14 times more fossil fuel use and 8.5 times higher total energy use.

However, it has been evidenced that WPC made from virgin materials has a greater environmental impacts than plastic. In 2013, an LCA analysis of redwood decking in the U.S. has compared to three other materials: polyvinyl chloride (PVC), WPC with virgin materials, and WPC with recycled materials (Bergman et al. 2014). The result indicated that WPC, especially the one using virgin materials exhibited substantially higher environmental impacts in terms of not only its total energy, but also all six key impact categories they quantified:

global warming potential, acidification potential, respiratory effects,

eutrophication potential, ozone depletion, and smog potential (Figure 2.6). For example, WPC’s total energy with virgin materials was roughly 33 times larger

Figure 2. 6 Life cycle impact assessment for the four decking products per 100 ft2 (Source: Bergman et al. 2014)

than that of redwood, and 2.2 times greater than that of WPC with recycled materials, whereas it was 1.4 times lower than that of PVC. According to their interpretation, producing WPC with recycled materials has significant

environmental advantages over producing WPC with virgin materials. This suggestion implies WPC is an application that assumes the use of recycled materials, in the first place.

In contrast to a number of studies on LCA of WPC in the U.S. and Europe, only a few studies are available in Asia. Fuchigami et al. have quantified life cycle CO2 (LCCO2) of WPC with recycled plastic, which is called “WPRC” to verify and compare the effect of CO2 emission reduction against two

alternatives: WPC with virgin plastic and aluminum (Fuchigami et al. 2011).

Similar to the result of the study conducted by Bergman et al., LCCO2 of WPRC was almost 1.7 times lower than WPC with virgin plastic.

However, these conclusions appear to be based only on the assumption that all raw materials are locally available. Tsai has carried out an LCA study in Taiwan and concluded that WPC’s energy consumption was 2.5 times lower than that of wood (Tsai 2011). The author has not clearly mentioned the interpretation against the result, but it can be inferred that the result is because the study assumed all the wood products are imported from foreign countries, hence excessive energy for transportation might arise.

Some studies regarding LCA of WPC in comparison with other products are reviewed so far, but it must be considered that WPC can potentially be recycled itself after its lifespan if a precise LCA analysis over its entire lifespan will be performed. However, the recyclability of WPC has been inadequately researched yet (Teuber et al. 2016), so only a few papers are available. Various constraints,

including the degradation of wood component on repeated processing at a temperature around 220 °C (Shahi et al. 2012), or the thermal and oxidative degradation of polymer (Beg and Pickering 2008) have been reported. A research conducted by Hidari et al. is one of the few available publications on LCA of WPC considering its recyclability (Hidari et al. 2006). They have compared and evaluated the environmental burden (LCCO2) in a series of processes (from production to recycling or disposal) of WPC and two types of natural wood (macaranduba and red cedar). The result showed that WPC has the lowest LCCO2 value when considering WPC’s carbon fixation (Figure 2.7).

From the above, it can be said that the use of WPC containing much of recycled materials should be encouraged, since it is eco-friendlier than at least virgin plastic, and its environmental friendliness is comparable to that of wood if carbon fixation is considered.

Figure 2. 7 LCCO value of WPC and woods by processes (Source: Hidari et al. 2006)

2.3 Life Cycle Cost (LCC) of WPC

WPC’s material cost is generally higher than competing solid wood; however, when maintenance and life cycle costs over decades are considered, WPC should be less expensive (Calkins 2009). According to an examination by the author, maintenance costs for an 800 square foot deck found that a cedar deck would cost $2,000 more than a WPC decking after five years of installation. In order to verify the assumption, life cycle cost analysis should be the best method, but to the best of our knowledge, there are only a few studies on how the use of WPC is cost-effective in the long-term view over other alternatives such as solid wood, tile or aluminum.

Ghasem has implemented an economic model assessment of WPC production from agricultural waste, then economic investment and required infrastructure facilities have been estimated (Ghasem 2013). A case study of the economic plan of WPC with 5,000 tons per year was assumed, and the total investment of 68,100 million rials with a rate of return of 46.35% was calculated, suggesting that WPC manufacturing is economically feasible and worth investing in Iran.

Figure 2. 8 Costs of each deck over time (Source: GreenScape 2006)

Tsai has also carried out an LCC analysis of WPC compared with PVC and wood, and the result indicated that the life cycle cost was highest for WPC products, while wood products had the lowest cost (Tsai 2011). Although the result is contrary to the above, as is the case in LCA, it can be inferred that this is because timber is imported from overseas, resulting in the higher transport costs.

GreenScape has provided a decking cost calculator that compares the costs of building a new deck with WPC, plastic, and wood over their lifespans

(GreenScape 2006). The service lives of 25 to 50 years for WPC and 10 to 20 years for woods are assumed based on low and high cost estimates. Figure 2.8 shows the cost comparison between four decking materials: recycled HDPE, WPC, cedar/ redwood, and southern yellow pine. It illustrates that the life cycle costs of recycled HDPE and WPC are much lower than that of other woods, even though the initial costs of the former two materials are almost the same or slightly higher than that of the last two materials. The difference in cost is more significant in the comparison of average annual costs (Figure 2.9). According to their calculation, the average annual cost of WPC is one fourth as much as that

Figure 2. 9 Average annual costs of each deck over their lifespan (Source: GreenScape 2006)

of woods, and this is because WPC was assumed to be free of maintenance costs.

From the above, it can be said that the life cycle cost of WPC is comparable or less expensive than that of wood in a comprehensible view; thus, this idea should be correctly recognized.

2.4 Market Research of WPC

Since WPC has been found to be an alternative material to wood in the 1980s, the market size has increased up to $4.06 billion in 2015 (GrandViewResearch), and the growth is prospected to continue at a sustained growth rate. According to a market report, the global WPC market was projected to reach $5.84 billion by 2021, at a CAGR of 12.4% from 2016 to 2021 (MarketsandMarkets). Most notably, the market in Asia-Pacific was forecasted to grow at the highest CAGR in this period. The most significant contributor is the world’s leading producing

Figure 2. 10 Development scale of WPC in China from 2009 to the first half of 2016 (Source: China Industrial Information Network)

country of WPC, China, which has overtaken North America in 2015 with a production of 1.8 million tons of WPC (Figure 2.10).

The second-largest producer of WPC in Asia is Japan, followed by Southeast Asian countries and India (Figure 2.11). However, the production of WPC in Japan was merely one-sixteenth of China’s, which implies that there is an overwhelming difference in WPC’s manufacturing price and competitiveness.

Figure 2.12 represents the transition in WPRC (WPC with recycled materials) production in Japan from 2010 to 2018, and it has decreased after peaking in 2013, indicating that the production is stagnant.

As well as Japan, the market of WPC in Taiwan seems to be tough. Wu has summarized the global WPC industry’s situation and suggested the bottlenecks

Figure 2. 11 Global production of WPC in 2010 and 2012, and forecast for 2015 (Source: Carus et al. 2014)

of the development of the WPC industry in Taiwan (Wu 2008). Firstly, the barrier to entry into the WPC industry is high since the production technology of WPC is easily accessible for new entrants, and the equipment can also be easily purchased. In addition to this general issue, the author has listed some serious problems specific to Taiwanese WPC industry, which had been obtained during an interview with the relevant industry players. The following is a partial excerpt.

- The Taiwanese WPC market is too small, and competition is fierce.

- There is no universal standard specification for producing WPC, and too many molds are needed for the production.

- The Taiwanese WPC market must directly face the rampant overseas competition and low-cost products in Southeast Asia.

- The quality of the recycled materials used as raw materials for producing WPC is not uninformed, resulting in unstable processes and low-quality of the products. s

Figure 2. 12 Changes in production volume of WPRC in Japan (Source: Association for Popularization of WPRC)

From the above, it can be concluded that the WPC market in EAP region except China seem to be in a tough situation, so a new and promising marketing strategy is needed to develop it further.

2.5 Public Perception of WPC

WPC has not seemed to sufficiently attract interest of potential customers due to its appearance and relatively high costs. It has been revealed that the following five categories were most preferred among 19 core categories of solid wood, wood-based panels and WPC: naturalness, wood-likeness, smoothness, living impression, and value (Jonsson et al. 2008). From this results, it can be read that the general public still prefer the natural texture of wood even for WPC and other synthetic materials.

As WPC is a relatively new invention, the public view of WPC is difficult to evaluate (Klyosov 2007). Some might have never heard of WPC or still prefer real wood. Although many customers have accepted the appearance of WPC, some are still dismissive as it is even referred to as “fake wood” or “the material wanting to look like wood” (Coste 2015).

Regionally, it was said that Asians give the appearance importance rather than the durability of WPC, regardless of how much polymers are contained in the material (Gardner et al. 2008). Japanese and Korean WPC manufacturers’

endeavors to produce a realistic wood appearance by the surface treatment, including embossing (Figure 2.13) and mechanical processing, are due to this Asian specific preference.

While WPC’s higher durability than wood seems certainly attractive for the public, it does require larger upfront costs, instead (Klyosov 2007). There is not

much comparison of average initial cost for building WPC and wooden decking, but according to the assumption provided by Trex, WPC’s initial costs including material cost and installation cost can nearly be double that of wood.

From the above, it can be seen that WPC has not always been well received.

Considering that it is a relatively new material, it may be difficult for the older generation who are familiar with traditional materials such as traditional wood to suddenly accept the use of WPC.

Figure 2. 13 Embossing machine of WPC (Source: Qingdao Hegu Wood-Plastic Machinery Co.,Ltd.)

A Survey of Users’ Attitude toward WPC

3.1 Introduction to the Attitude Survey

Though the WPC’s objective characteristics were clarified in the previous chapter, there has never been a study on subjective evaluation of WPC from the users’ point of view. This chapter presents their subjective attitudes and

impressions against WPC based on the results of questionnaires and interviews conducted with WPC users (mainly architects and landscape designers). As stated in section 1.3, respondents were limited to people from the three regions, Taiwan, Japan, and Vietnam. All the questionnaires were created using Google Form and distributed via social media and email. Firstly, the original

questionnaire was created in English (see Appendix 1) and translated into three languages. The distribution took place in early March 2020, and the collection took about a month. Chi-Square tests was used to examine the significance of the differences in answers between the three regions. Chi-Square p-value (from now on referred to as “p-value") p < 0.05 was set as a level of significance. The ideal sample size and some variables used for its calculation are shown in Table 3.1. Since the actual sample size is 53, which is small compared to the ideal value (approximately 64), this questionnaire is only for obtaining a general idea of users’ perception.

Table 3. 1 Assumptions for the sample size

3.2 Questionnaire 3.2.1 Hypotheses

The following six hypotheses were given based on the information obtained in the previous chapter.

H1. The users’ awareness of WPC is low (less than half)

H2. WPC is infrequently used (more than half of users sometimes/ seldom use it)

H3. The use of WPC has been intentionally avoided by its users (more than half of its users have ever intentionally avoided using it before)

H4. The users’ overall evaluation of WPC is bad (more than half of users have bad impression towards WPC)

H5. “Environmental friendliness” is the key factor for users’ positive evaluations (majority of the users value it most)

H6. “Not good texture” and “high cost” are the main factors for users’

negative evaluations (majority of the users recognize them as the main drawbacks of WPC)

3.2.2 Respondents’ Attributes

A total of 53 people (Japan: 16, Taiwan: 17, Vietnam: 20) from various industries participated in the questionnaire. Their ages differed greatly among the three regions; Japanese respondents were the oldest, with 60% of people over the age of 46, while all the Vietnamese respondents were lower than 45 years old (Figure 3.1). The gender ratio was also very different; most of the respondents were male in Japan and Vietnam, whereas women accounted for the majority in Taiwan (Figure 3.2). While over 70% were from the architectural

field in Japan and Vietnam, landscape designers occupied the majority in Taiwan.

Figure 3. 1 Ages of the respondents from the three regions

Figure 3. 2 Gender of the respondents from the three regions

3.2.3 Results and Interpretations

Contrary to the hypothesis: H1, WPC was quite well-known among the respondents from all the regions (Figure 3.3). In detail, over 90% of the Japanese and Vietnamese respondents have already known it, while its

awareness for Taiwanese was slightly low: approximately 80%. As the p-value was around 0.53 which was greater than 0.05, there seems no significant

differences in the answers between the three regions. This result could be due to Taiwanese respondents’ field of business, which was biased towards landscape designers. Regarding the usage experience of WPC, Figure 3.4 shows that Japanese respondents have ever used it most, while it has been occasionally used for Vietnamese. Specifically, more than 80% of Japanese respondents have ever used WPC for their projects, whereas only half of Vietnamese respondents have ever used it before. Statistical significance of the differences was also confirmed since the p-value was approximately 9.43E-03 which was far lesser than the threshold. As stated in section 3.2, this is presumably because the WPC industry

Figure 3. 1 Respondent’s awareness of WPC

is at the maturity stage in Japan, although it is still growing in the other two regions.

As shown in Figure 3.5, WPC is infrequently used in all the three regions, proving that the hypothesis: H2 seems valid. The answers form the three regions significantly differed since the p-value was about 6.36E-04. It should be noted that almost half of Japanese respondents answered “seldom,” and only

“sometimes” was chosen by Vietnamese, while Taiwanese answers were evenly distributed. This result could also be caused by the field of business, which implies that WPC is more frequently used in the landscape design field. Not surprisingly, majority of the respondents have intentionally avoided using WPC (Figure 3.6); thus, the hypothesis: H3 seems valid. The diverse distribution of the answers among the three regions was also confirmed as the p-value was approximately 9.85E-05. Notably, those who conceded the experience were by far the most Japanese with the reason of “not good texture” and “high cost,

Figure 3. 2 Use experience of WPC of the respondents from the three regions

“ representing that Japanese respondents are sensitive to aesthetics of WPC most. In contrast, approximately two-thirds of Taiwanese respondents who admitted intentional non-use claimed mismatches for their project. So it could be inferred that the concepts of the projects and clients’ intention are highly

respected when considering using WPC. At the end of the questionnaire, an overall evaluation of WPC was asked. As demonstrated by Figure 3.7, the majority of respondents answered “good” or “very good,” resulting in the invalidity of the hypothesis: H4. The proportion of those who had a bad impression increased in the order of Vietnam, Taiwan, and Japan. Besides, the answer “very bad” only appears in the Japanese answers and it ccould be inferred; this is because WPC’s shortcomings have been highlighted in Japan, where the industry is already matured. The respondents in each region had a similar diverse distribution by the reasons for the positive evaluation (Figure 3.9), although the p-value was about 6.28E-15 which is extremely lesser than

Figure 3. 3 Use frequency of WPC

0.05. Overall, it was highly regarded for WPC’s durability and maintainability rather than its eco-friendliness, against the hypothesis: H5. This tendency is particularly noticeable in Taiwanese answers, where the answer “environmental friendliness” accounts for only 10%. Figure 3.10 shows the reasons for their negative impressions against WPC. As hypothesized in H6, “not good texture”

Figure 3. 6 Intentional avoidance of use of WPC

Figure 3. 7 Overall evaluation of WPC

was certainly a key factor for the negative evaluations. However, “high cost”

was not really considered as one of the severe drawbacks of WPC, while

“mismatch with my projects” was the second most important factor. Assuming that most of the mismatches are also due to the texture or appearance of WPC, the negative impression of WPC seems mostly because of aesthetic reasons.

Figure 3. 8 Reasons of positive evaluations

Figure 3. 9 Reasons of negative evaluations

In summary, it was proved that the two out of six hypotheses (H2 and H3) could be supported (Table 3.2). Despite the high awareness of WPC, it has become clear that its use is rarely considered in practice. On the other hand, the users’ impressions on WPC does not seem to be so bad as shown in the previous chapter. Contrary to the hypothesis, “environmental friendliness” and “high cost” were not seriously considered as the pros and cons of WPC, and it seemed that “high durability” and “texture” were important for its users when it comes to the consideration of building materials.

Table 3. 2 Summary of hypotheses and results

3.3 Interview

3.3.1 General Information

A total of three interviewees were selected from each of the three regions.

Japanese and Vietnamese interviewees were architects, while the Taiwanese one was from the consulting engineering field. As the Japanese interviewee had a working experience in Vietnam, some differences in the way of thinking about building materials, including WPC between Japan and Vietnam, were obtained.

Since the Taiwanese interviewee had some Japanese customers he has known for a long time, some differences in attitudes towards building materials could also be obtained.

While interviews with Japanese and Vietnamese were conducted via video calls, the one with Taiwanese was face to face. The interviews were held to ask the validity of our interpretation against the results of the first questionnaire, and to obtain their opinions and suggestions on the improvements of WPC from the user’s point of view. Before the following questions, the overview of this research was briefly introduced, and some information about the questionnaire, including the respondents’ attributes, hypotheses, results, and interpretations, were explained.

- How about the awareness or popularity of WPC around their fields or regions?

- How do they think about the product life cycle of WPC in their regions?

- What do they think is the cause of the answer “mismatch with my projects”

in their fields or regions?

- What kind of causes for intentional avoidance of using WPC in their fields or regions?

- How are the pros and cons of WPC recognized in their fields or regions?

- How are their perceptions of the environmental friendliness of WPC?

- How are their impressions against the cost of WPC in their regions?

3.3.2 Results and Discussions

In this subsection, the results and interpretation obtained from the interviews in each region will be presented separately.

a. Japan

Generally, WPC seemed well-known in Japan, as the interviewee has stated.

Given the difference in climates, what is required in Vietnam is the robust structure of buildings rather than the texture of the interior or exterior building materials, while it is often prioritized in Japan. Hence, finishing building materials are less likely to be the main topic in Vietnam; instead, the spatial relationship through materials are more focused.

Since using WPC in the construction industry is overwhelmingly new compared to the long history of using wood as a building material in Japan, it seems too early to judge the use frequency of WPC even if the industry is said to be already matured, as he argued. It should also be noted that the

“green” building boom of recent years has only begun only two decades ago.

However, as he also argued, Japan has a rich heritage of wood use and the sturdy wood market, which can potentially weaken the competitiveness of WPC in Japan.

According to him, WPC is generally recognized as a recyclable “green”

material in Japan, and suppliers’ promotion might greatly influences this public perception. As almost 30% of the Japanese respondents have known WPC via catalog or newspaper in the questionnaire, these information

sources can inevitably form the perception. Regarding the negative impression of WPC, he has agreed with our interpretation that WPC is shunned by its users before the consideration of costs, due to its not good texture. WPC seems not readily accepted by Japanese as long as they value the profound feeling of textures, as he felt WPC looks “lighter and cheaper”

material, comparing with wood.

b. Taiwan

WPC is also quite popular in the landscape industry for uses such as street furniture or pedestrian deck in Taiwan, as the interviewee has said. For Taiwanese customers or investors, service life and maintainability were apparently of paramount importance due to the warm and humid climate in Taiwan (Figure 3.10). Because of this issue, Taiwanese WPC users tend to prefer WPC with a large portion of plastic. The materials made only of

Figure 3. 4 The climate comparison between Taipei and Tokyo (Source: ZenTech)

plastic can even often chosen by the users. As seen above, WPC is mainly recognized as a “long-lasting” and “easily maintainable” material in Taiwan.

As well as Japanese, the way Taiwanese WPC users understand WPC’s strengths and weaknesses might be heavily affected by suppliers. However, it seems that WPC’s environmental friendliness seemed still skeptical in Taiwan, although suppliers should also promote it. As the interviewee stated, natural wood is also regarded as an eco-friendly material when carbon fixation is considered. Regarding the negative impression against WPC, only Taiwanese answers contained “high cost” among the answers from the three regions in the questionnaire. As he argued, this could be because WPC is often a compromising alternative of natural wood and is inevitably used even if users would like to use wood instead because of the harsh weather in Taiwan. Therefore, they might suddenly realize that the initial cost of WPC is higher than that of natural wood, and this experience has formed the recognition.

c. Vietnam

Although WPC seemed well-known also among Vietnamese architects, they have only a little experience in using WPC in their projects, so it seemed rare for them to consider using it as the first option from a wide variety of

alternative building materials, as the interviewee stated. WPC is mainly used for public buildings when the maintainability is taken into account, while the use of WPC can seldom be seen in private projects such as resort hotels where aesthetics is highly regarded.

According to the interviewee, architects’ consideration and decision to build materials could be greatly influenced by their backgrounds. Though the

use of appropriate building materials according to project types is one of the fundamental knowledge in architectural education, the proper use of WPC has seldom been taught anywhere yet. As the interviewee insisted, this might be a primary cause why WPC has often been a “second option” in Vietnam.

Against the expectation, WPC’s product price is generally lower than natural wood in Vietnam, as he said. However, wooden building materials are infrequently used because of the harsh climate in Vietnam and its relatively poor installability. As he puts, the installation of wooden components normally takes at least a few months for building a standard deck, whereas WPC requires only a few weeks at the longest. Another problem of wood is that only skilled labor can properly install the wooden components, while WPC is relatively easier to install thanks to its

homogeneity of the material; hence even unskilled workers can install it without any difficulties. No comparison of installation speeds between WPC and wood decks was found, but good installation speeds of WPC due to its unique properties such as lack of splinters, easiness to cut, saw, nail, and screw have been reported (Klyosov 2007).

Proposal for Improvements of WPC

4.1 Introduction to the Improvements

In this chapter, four improvements of WPC designed based on the problems obtained in the previous chapter will be presented. The problems can be summarized as below.

- WPC seems to be infrequently used or even intentionally avoided by its users, mainly due to the aesthetic reasons

- The distinctive and unique feature of WPC, environmental friendliness has not been highly regarded and duly evaluated

- Initial cost of installing WPC is generally higher than that of wood - WPC is considered as a “cheap-looking” and “monotonous” building

material

The improvements to be introduced will address the above four issues in order.

4.2 Proposals

4.2.1 Better Texture

The texture of WPC is generally homogeneous and does not have the unevenness of natural wood, and this is one of the causes that can make WPC look unnatural. The traditional uniform texture will be as close as natural wood by increasing unevenness (Figure 4.1).

4.2.2 Better Environmental Friendliness

In order to maximize the environmental friendliness of WPC, the

conventional one-way distribution system needs to be reconsidered, where recyclability is not considered and encouraged (Figure 4.2). A circular distribution system based around shoppers will promote the recycling of WPC products that have reached the end of their service life (Figure 4.3).

This system seems significantly eco-friendlier than the conventional ones, as the products can be endlessly be recycled as long as the quality is

guaranteed.

Figure 4. 1 Improvement of the texture of WPC (Left: before, Right: after)

Figure 4. 2 The conventional one-way distribution system of WPC

Figure 4. 3 The new circular distribution system of WPC

4.2.3 Better Marketing

Simple cost simulations of WPC and solid wood as deck materials over their lifespans are provided. The decking area of approximately 30 square meters (320 square feet) and the longest lifespan of 30 years of WPC (twice as much as wood’s) were assumed to be functional units. The installation cost and maintenance (replacement) costs per every five years are set to the values shown in the figures. Based on the assumptions, the initial cost of installing WPC is about 1.7 times higher than that of wood, but WPC’s life cycle cost over 30 years is about half of wood’s. Therefore, using WPC seems far more cost effective.

Figure 4. 5 The cost simulation of wood decking over its lifespan

Figure 4. 4 The cost simulation of WPC decking over its lifespan

4.2.4 Design Flexibility

The new distribution system will allow customers to change WPC products in a short span of five to ten years regularly (Figure 4.6). Since the system can flexibly incorporate the latest design trends or processing technologies of WPC, customers will be able to choose their favorite design from many variations according to their tastes; thus, WPC will no longer be monotonous (Figure 4.7).

Figure 4. 7 Design change of WPC in a short span

Figure 4. 6 The example of color variation of WPC products (Source: The Good Guys)

Feasibility Survey of the Improvements of WPC

5.1 Introduction to the Feasibility Survey

In this chapter, an evaluation survey of the proposed improvements is presented.

In order to objectively assess the adequacy of the improvements, questionnaires targeting people in all fields, including potential customers of WPC, has been conducted. The distribution was carried out in late April, and the collection took almost three weeks. As well as the previous one, the questionnaire was created using Google Form, and distributed through social media and email. The four improvements were introduced before some questions were asked (see Appendix 2).

5.2 Questionnaire

5.2.1 Respondents’ Attributes

A total of 50 people from various fields took part in the questionnaires.

Figure 5. 1 Ages of the respondents from the three regions

Looking at their ages, it can be seen that the majority are younger people aged 26 to 35, and the number of participants gradually decreases as the age increases (Figure 5.1).

In terms of gender, male participants account for about three-quarters of the total, so the results of this questionnaire can be said to reflect the views of young men in particular (Figure 5.2).

5.2.2 Results and Interpretations

Regarding the future use of WPC, almost 90% of the respondents answered

“yes” or “maybe” (Figure 5.3). It is worth noting that the percentage of answers

“maybe” exceeded “yes", indicating that majority of the respondents are still hesitant to use WPC in the future, even with the proposed improvements.

Generally, the four aspects: texture, environmental friendliness, cost, and design flexibility, seemed equally important to all the respondents (Figure 5.4).

Figure 5. 2 Gender of the respondents from the three regions

Specifically, the majority valued “texture,” while “environmental friendliness”

seemed less important for considering building materials.

Figure 5.5 shows the correlation between awareness and future use of WPC.

The result indicates that those who knew of the existence of WPC want to use it

Figure 5. 3 Future use of WPC

Figure 5. 4 Important aspects of WPC

in the future more, although the p-value was 0.35 which implies there is no significance between different answers.

From the above, it can be said that the four improvement points are equally promising, and it is essential to improve the texture. However, the skeptical attitude toward the improvement of environmental friendliness by the new distribution system could be read, so careful discussion shoud be necessary before the consideration of its implementation.

Figure 5. 3 Correlation between awareness and future use of WPC

5.3 Interview

5.3.1 General Information

In this chapter, a survey conducted to objectively explore the feasibility of the proposed improvements will be presented. Two interviews for WPC

manufacturers were implemented, in face to face and through a video call.

Taiwanese manufactures were chosen as samples for both interviews, because the results obtained from this survey would be applicable to the other two regions, since the Taiwanese data were mostly between the ones from the other two regions in the two questionnaire surveys. The first manufacture (from now on referred to as “FM") is one of the leading WPC manufacturers who has invented the idea of high-performance wood-alternative. The second

manufacturer (from now on referred to as “SM") is the only manufacturer in Taiwan that recycle their products, as described below. They are also known for having global partners in the EAP region.

5.3.2 Results and Discussions

As a raw material, PE, PP, and PVC were commonly used, while PS was rarely used by both two manufacturers. FM mainly used recycled PP and PE, whereas SM used virgin PVC. Instead of using virgin material for manufacturing WPC, SM often recycle their own products after their service life. In the recycling process, the abandoned products are collected and crushed into small pieces, and then the final products are shaped without any additives or chemicals.

However, regardless of the types, plastic materials seem locally unavailable since China restricted exports of recycled plastics due to pollution problems. So it is common for Taiwanese WPC manufacturers to import plastic materials from technologically advanced countries such as Japan, South Korea, or China.

For instance, FM usually lies in a stock of compressed recycled plastic bricks from Japan because it is hard for them to procure them locally or from China, since there are no regulations to deal with pollution issues in Taiwan. For the above reason, there are almost no local suppliers of recycled plastic bricks or particles there. Another issue they claimed is that the government does not seem to have any regulations to guarantee the quality of recycled plastic materials.

On the other hand, wood materials seemed to be readily available for the WPC producers in Taiwan, as both two manufacturers said they usually obtain it locally. For example, FM’s primary source of wooden materials are local furniture factories that provide furniture waste such as wood shavings obtained during the manufacturing process of furniture (Figure 5.6). Not surprisingly, the wooden materials are almost free if an annual contract is in place. However, in return, the materials have to be picked up even if the WPC producer does not need them anymore.

Figure 5. 4 Example of wood shavings (Source: WORLD EXPORT COMPANY LIMITED)

Table 5.1 shows the list of the common sources for the plastic and wood fiber used in some WPC products in the U.S. Although the use of recycled plastic looks dominant, it was clarified that this is only possible in technologically advanced regions, as SM stated. Under such circumstances, the question of whether it is still economical to continue importing plastic materials for technological developing regions such as Taiwan and Vietnam still remains.

The wood:plastic ratio that the two manufacturers adopt slightly differ; FM adopts 40:60 whereas SM mixed 30% to 40% of wood content. As shown in table 5.2, the ratio is generally around 50:50 in the U.S., and it is technically possible to blend the lower proportion of plastic content than that of wood.

Moreover, since the ratio of 70:30 was suggested as an optimal wood:plastic ratio on the properties of WPC (Chen et al. 2005), it could be said that the two Taiwan’s WPC manufacturers adopt a relatively large portion of plastic content.

However, the author also stated that plastic content contributed to decrease moisture content, water absorption and thickness swelling of WPC products, increasing its density and blending strength. The increase of dimensional stability was also confirmed when the plastic content ratio increased. Since the

Table 5. 1 List of common sources for the plastic and wood fiber used in some WPC products in U.S. (Source: Winandy et al. 2004)

above positive effects are advantageous for the humid climate in Taiwan, it is no wonder that the two WPC manufacturers use a large portion of plastic to

produce their products.

Nevertheless, increasing plastic content ratio can mean increasing the costs of the WPC products. As FM confessed, the price of plastic materials is roughly ten times higher than that of wood materials; thus, the material costs highly depend on the price of plastic materials. For the above reason, many WPC producers have been attempting to reduce the proportion of plastic content, and the latest cutting-edge technologies will potentially make it possible to reduce it up to around 20%, as FM prospected. The idea of reducing the plastic content ratio goes against our intention, but it does lead to lower costs of final products.

Therefore, the continuous pursuit of searching for the most optimal wood:plastic ratio from the perspective of not only costs but also environmental friendliness or material property incorporating the latest technologies is crucial.

Regarding improving the texture of WPC, FM provided a valuable insight that it seems nonsense to regard WPC as “a material wanting to be wood” because they are fundamentally different materials with their own features. Hence, the

Table 5. 2 List of some WPC products in U.S. (Source: Winandy et al. 2004)

manufacturer disagreed with our first proposal to make the texture of WPC as close as possible to natural wood, arguing that it is essential to emphasize WPC’s unique characteristics without comparing it with wood. However, it is inevitable for WPC manufactures to make their products look like wood since not a few customers still prefer the wood-like texture, although there are various types of WPC products, including the one with anti-bacterial coating or rubber, all of which imitates wood.

In contrast to the texture, WPC’s environmental friendliness does not seem to attract the attention of customers, since it is skeptical even for the manufacturers.

SM has argued that most WPC products seems not as durable as advertised because PE or PP are commonly used for their production to reduce material costs. WPC is generally said to have a useful life of up to 30 years (Renshaw 2014), but the actual service life of distributed products is considerably short (3 to 5 years), and there are even products that are inferior in both price and quality to natural wood. It might still be eco-friendly considering its recyclability, but the recycling of used WPC products is not encouraged since the recycling technology of processing WPC is not mature enough in Taiwan at the present stage, and the quality of recycled WPC products cannot be guaranteed under the current market system.

In order to improve theses situations and make people aware of the environmental friendliness and the low life cycle cost of WPC, our second proposal: new distribution system seemed reasonable from the eyes of SM. As they suggested, the whole system should be driven, supported, or monitored by the local government, but at the present stage, WPC is not included in waste recycling system at least in Taiwan. So SM operates their recycling system all

by themselves; thus outsourcing is necessary, and it is not easy to centralize it.

However, as they expected, it is still possible to propose the government to adopt some regulations to make WPC producers bear the responsibilities for recycling the used products that have reached their service life.

Conclusions and Future Work

6.1 Conclusions

This research aimed to evaluate the pervasive potential of wood-plastic composite (WPC) as a building material for the massive recycling of plastic waste in the East Asia & Pacific (EAP) region. After reviewing WPC’s objective characteristics and the current situation of the WPC industry in the region, a total of two questionnaires and two interviews were conducted to explore the evaluation of WPC from the users’ perspective.

Since WPC’s excellent environmental friendliness and cost-effectiveness still does not seem to be well known, it can be said that WPC is likely to be prevailed in the future by dint of these distinctive features. Specifically, first of all, the proper use of WPC according to the project types should be taught in

architecture education, and the supplier themselves should also provide appropriate recognition to its users.

However, there are still some fundamental issues such as WPC’s costs and material properties that we might not be able to improve. Also, even if more WPC is manufactured and a large amount of plastic waste is recycled, the attempt WPC manufacturers have been trying to reduce the proportion of plastic in order to reduce costs is against the intention.

Another significant challenge is the need to improve recycling technologies for used WPC products. At least in Taiwan, due to the lack of such technologies, a number of used products are disposed of without ever being recycled.

Furthermore, the difficulty of manufacturing plastic raw materials due to the technical or ethical point of view of contaminated water treatment, and the high cost of importing it have become clear.

From the above, it cannot be asserted that WPC is the best material from the viewpoint of massive recycling of plastic waste. While continuing to focus on WPC, potentials for other materials will need to be explored as well.

6.2 Future Work

This study limited the samples to only three regions: Taiwan, Japan, and Vietnam, and the potential survey was conducted with only two manufacturers in Taiwan. It should also be noted that the subjects in the evaluation survey differed from those in the attitude survey. Furthermore, the cost simulations referred or performed in this paper are based on figures in literatures, and did not take into account real cost information including freight costs, average price of products, labor costs for installation, replacement, and dismantling of WPC in the sample areas. Therefore, further research is needed on detailed cost

simulations and marketing strategies in EAP region, then hopefully the potential of massive recycling of plastic waste will rigidly be evaluated.

References

Arnandha, Y. Satyarno, I. Awaludin, A. Irawati, I. S. Prasetya, Y. Prayitno, D. A.

Winata, D. C. Satrio, M. H. Amalia, A. (2017). Physical and mechanical properties of WPC board from sengon sawdust and recycled HDPE plastic.

Procedia Eng., 695-704.

Association for Popularization of WPRC. (n.d.). Wood-Plastic Recycled Composite.

Retrieved from Market size of WPRC: https://wprc.info/data/market.html

Beg, M. D., & Pickering, K. L. (2008). Reprocessing of wood fibre reinforced

polypropylene composites. Part I: Effects on physical and mechanical properties.

Composites, 1091–1100.

Bergman, R., Sup-Han, H., Oneil, E., & Eastin, I. (2013). Life-Cycle Assessment of Redwood Decking in the United States with a Comparison to Three Other Decking Materials Final Report. Seattle: CORRIM.ORG.

Bernardo, C. A., Simoes, C. L., & Pinto, L. M. (2015). Environmental and Economic Life Cycle Analysis of Plastic Waste Management Options. A Review. PPS, 1- 4.

Bolin, C. A., & Smith, S. (2010). Life cycle assessment of ACQ-treated lumber with comparison to wood plastic composite decking. J. Clean. Prod., 620-629.

Calkins, M. (2009). Materials for Sustainable Sites. New Jersey: Wiley & Sons.

Carus, M., & Gahle, C. (2008). Injection moulding with natural fibres. Reinforced plastics, 18-25.