A Framework of Generating Collaborative and Dynamic New Product Development Process

Hsien-Jung Wu, Member, IEEE and Hung-Wen Hsu

Abstract-Since the changing business environment due to globalization, conventional process of new product development (NPD) is no more sufficient for an enterprise to ensure its original market competitiveness. Traditional strategy of NPD, which largely depends on inventory levels and market analysis, may results in ignoring factors in a supply chain. In particular, members of the business alliance require more flexible product development strategy to operate in coordination with each other.

It is then necessary for an enterprise to reengineer its NPD process to meet requirements from different viewpoints. A framework of generating dynamic NPD process under the environment of collaborative commerce is proposed in this paper.

A hand tool company located in central Taiwan is used as a case study for the above purpose. Business models adopted in this company have intensive relationships with the NPD strategy and processes. The proposed framework reengineers the R&D process using systematic analysis tool widely applied in BPR projects.

Based on the simulation, collaborative and dynamic NPD process can be reached using the proposed framework.

Index Terms-Business process reengineering (BPR), collaborative commerce, new product development (NPD).

I. INTRODUCTION

A

framework of collaboratively and dynamically generating new product development (NPD) process is proposed in this paper. Traditional new product development, which largely depends on inventory levels and market analysis, may results in ignoring issues needed to be address in a supply chain. Therefore, the process of NPD is not solely executed in the R&D section. It is then necessary for an enterprise to reengineer its NPD process to meet requirements from different perspectives. To reengineer the NPD process, several issues can be considered such as business process reengineering, business alliance, supply chain management and collaborative commerce. In stead of focusing software system development, this paper discusses flexible NPD process in terms of business process reengineering. The role of NPD process in a business alliance as well as a supply chain is then analyzed to identify opportunity of NPD. Finally, a framework of generating dynamic NPD process under the environment of collaborativeManuscript received April 16, 2007. This work was supported in part by the National Science Council of Taiwan under Grant NSC-95-2221-E-468-001.

H.J. Wu is with the Department of Information Science and Applications, Asia University, Taichung 413, Taiwan. (e-mail: psuhjw@asia.edu.tw).

H. W. Hsu, is with the Department of Information and Design, Asia University, Taichung 413, Taiwan.

commerce is proposed in this paper. A hand tool company located in central Taiwan is used as a case study to simulate the generation of flexible NPD process. Currently, series of high quality hand tools products emphasized on human factor concern are under development in this company through cooperation provided by members of the business alliance. In this case study, a business alliance is formed through acquisition and partnership shared in a supply chain. For the case company, its current strategy ofNPD is largely influenced by the inventory levels and market analysis gathered from members in this alliance. Since most of its products are exported to Northern American and European markets with different brands (OEM, ODM and OBM), process ofNPD for this company is therefore in a changing nature. Business models adopted in this company then have intense relationships with the NPD processes. Several NPD processes are generated by simulating various requirements issued from members of the alliance. Based on the simulation, collaborative and dynamic NPD process can be reached using the proposed framework. It also provides a structure of implementing collaborative commerce for future software system development. This paper is organized as follows. In Section 2, related works ofNPD are briefly discussed. Section 3 describes the framework of generating dynamic NPD process. Section 4 summarizes the results of simulation implemented in this case study. Finally, Section 5 provides our concluding comments.

II. LITERATURE REVIEW OF NPD

NPD is normally a long process with various activities involving strategy development, product planning, concept generation and screening, market analysis, manufacturing development and others [3]. Major research areas of NPD is analyzed in [7] including NPD processes, NPD success measures, project leadership, customer involvement, accelerated product development, teamwork management, and so forth. In an age of change, NPD is increasing in importance to a firm. During the NPD process, external and internal communication in NPD teams is one of the critical success factors. Measurement of product development success and failure is discussed in [4] [10]. In addition to efforts from R&D section, inter-firm collaboration ofNPD can be used to reduce internal investment and gain access to resources in the partner firms [12]. Partners from a business alliance can share marketing information to improve NPD efficiency.

Cross-functional teams in product development are

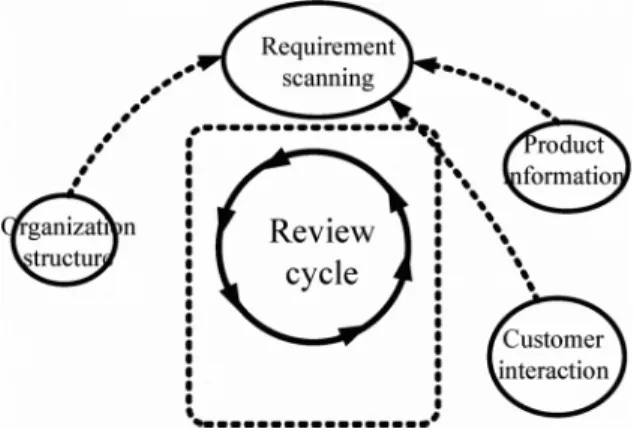

Fig. I. The framework of generating NPD process

--- --- .. ....

# • • • • • • • • • • • • • • •~.

\

..........

........ ..

.. ..

...

Fig. 2. The framework of generating NPD process

A. Requirement Scanning Module

In the new product requirement scanning module shown in Fig. 2, a review cycle is regularly performed at the center R&D section. Initiatory product concepts collected from different functional units and partners that trigger potential NPD projects are examined in a routine and timely manner. Three dimensions are used as inputs to this review cycle. The first dimension is the organization structure which shows the level and responsibility of R&D branches located at subsidiary companies and partners in the business alliance. In some cases, the business alliance is formed through acquisitions that make NPD processes even more complicated. The second dimension is product information related to target new product. It is essential for generating further effective NPD process based on newly and relevant product information. Various product information examples used for this purpose are listed as follows:

• Product specification

• Product lines

• Product family structure

• Inventory level at subsidiary companies and partners

• Component and product distribution in the supply chain generating dynamic NPD process is described in detail as follows.

increasingly constructed to allow an organization to create a team-oriented culture [2]. Due to the globalization, this kind of NPD team formation has the advantage of integrating different product requirements. Cross-domain knowledge sharing such as software development also helps NPD to improve product development process [7].

Process ofNPD is an important factor that influences stages of product development [1] [6]. The lack of process discipline becomes a critical obstacle to successful NPD [11]. A composite model of concurrent product development consists of three constructs: early simultaneous influence, in-process design controls and computer information technology; is applied to service sectors to manage NPD innovation [5].

Issues of early cross-functional involved in NPD process is discussed in [8] [13]. For computer information technology, it also plays an essential role in the NPD process. An investigation of the Internet's role in NPD activities is analyzed in [9]. To meet different product requirements, process ofNPD should be regularly reviewed since the issues of continuous quality improvement and product elimination are important elements in the NPD process [14]. In response to routine review ofNPD process , tools of business process reengineering can be used to assist in examine the NPD 's contribution to an enterprise. Based on the above literature review, this paper focuses on the discussion of NPD process under the environment of collaborative product development.

Ill. FRAMEWORK OF GENERA TING NPD PROCESS To clearly define the concept of a new product is a critical step in the NPD process. Normally a new product has several dimensions of concept since the versatile motivation perceived by stakeholders such as customers , suppliers , distributors and R&D engineers. It will waste time to gain an acceptable new product definition if no consensus reached among all stakeholders. It is then helpful to maintain new product requirement discussion between partners regularly. Conflicts are inevitable during the discussion between different functional units. Historical product information related to NPD should also be collected during NPD stages. A platform of internal and external communication is required throughout the NPD process. Computer information technology plays an important role of constructing this platform.

As mentioned in previous sections, NPD process for an enterprise cooperating with other partners in a business alliance or supply chain should be in a flexible and collaborative manner. In this case, the process ofNPD is not solely executed in the R&D section but required to integrate various product requirements from related partners. In the beginning of the NPD project , requirements collected from different business units and partners are scanned and analyzed . A framework of collaboratively and dynamically generating NPD process for an enterprise which owns branches and business alliance is proposed in this paper. This framework consists of four modules: requirement scanning module, feedback module , process reengineering module and NPD module . Fig. I shows the structure of this framework and the mechanism of

The final dimension in the requirement scanning module is customer interaction. Through close interaction with customers, specific and unique new product requirements can be identified during this stage. In particular, customers located all over the world due to global business environment show versatile NPD opportunities for an enterprise.

B. Feedback Module

NPD process is complicated in nature and closely connected with stakeholders. Internal and external communication is essential factor for making necessary modification during the NPD stages. Feedbacks such as product concept screening, production capacity, resource allocation, NPD project priority, current market status, and product segmentation are adequately communicated in this module. The strategy of product development restricted by business goal also should be considered as an important feedback from the upper management level.

c.

Process Reengineering ModuleSince many collaborative activities are performed during NPD stages, previous and original NPD processes adopted in different subsidiary companies and partners may cause conflicts and result in NPD failure. For each R&D division located in different companies, NPD process should be flexible to come to a compromise for reaching satisfactory NPD efficiency. Several tools widely applied in business process reengineering (BPR) can be used to review the appropriateness ofNPD workflow. Examples of such tools are: cause and effect analysis, function analysis system technique, value analysis/value engineering, Petri nets, and other performance measures used in quality assurance area. Several software tools also provide useful NPD process reengineering analysis: IDEF andARIS.

D. NPD Module

The final module in the proposed framework is actual output of NPD process. It includes similar steps described in several literatures [7] [9]: new product definition, strategy development, team building, concept generation and screening, market analysis, testing, production line development, and final commercialization. Since the review cycle embedded in the requirement scanning module is regularly performed and integrated with dimensions of organization structure, product information and customer interaction; the eventual result of NPD process generated in this stage has the collaborative and dynamic feature. The performance of NPD process can be evaluated through the connection with feedback module and process reengineering module. Based on the scale of NPD adopted in this stage, R&D units involved in NPD are also selected.

IV. CASE STUDY

The case study company presented in this paper, anonymously indicated by "K Group", was founded in 1984 originally as "K Company". It produces professional tools and

D.I.Y. tools with its well-known brand name throughout the tool industry. In 1998, K Company received the Certificate of ISO 9002 followed by an effort of receiving the Certificate of ISO 9001(2000) in 2004. To offer better service and understand the international customer's needs, this company operates its branch offices in France, Germany, Mexico and China. In recent years, K Company continuously reengineers its business processes through business alliance and series of acquisition to form the "K Group" for expanding its market shares. Currently, the K Group has four subsidiary companies and joins a business alliance through investment in relevant business.

Currently, its product lines include hand and pneumatic tools. Various product series had been manufactured and sold in many countries. Products such as socket, ratchet, wrench set, screwdriver, pliers, hammers and other accessory are selected and assembled as a tool set to meet different customer requirements. Since individual tool is designed and manufactured by subsidiary companies and partners in the business alliance, the management of NPD project is complicated. The most bothersome problem is confusion of NPD team's responsibility.

As the enterprise rapidly grows, problems of product development occur simultaneously. Since each subsidiary company has its own R&D division, integration of product development process is required. In addition to product specification and market analysis, inventory level of subsidiary companies and partners in business alliance should be also considered during the NPD process. To solve the NPD problems, starting from 2006, the K Group initiates a plan of integrating NPD throughout the enterprise for its human factor hand tools series. An integrated enterprise information system is the ultimate goal of this plan. However, in stead of focusing software system development, this paper discusses flexible NPD process in terms of business process reengineering.

Current development processes are examined to eliminate the redundancy. In particular, collaborative design during NPD process is the major concern and several scenarios of product development are used as examples to simulate and illustrate the generation of dynamic NPD process through the proposed framework. Scenarios of NPD situation are discussed with the center R&D section which directly reports to headquarter of the K Group.

Scenario 1:

• Product: human factor series- tool display with tools

• Type: stand, cabinet, board, shelf, hook

• Tool: socket, ratchet, wrench set, screwdriver, pliers, hammers

• Design: new display with inventory tools

• Brand name: different

• Involvement: center R&D section, subsidiary company, supplier

Scenario 2:

• Product: human factor series- tool display without tools

• Type: stand, cabinet, board, shelf

The ultimate goal of the K Group's plan is to develop an integrated enterprise information system. Currently , in terms of SDLC of an information system development, the ongoing development is toward its system analysis stage. Based on experiments of the above scenarios , several problems are identified as follows:

Scenario 3:

• Product: human factor series-impact socket set

• Type: series with different sizes

• Design: new case and new socket

• Brand name: different

• Involvement: center R&D section , subsidiary company

• The review cycle embedded in the requirement scanning module provides timely examination of new product concept screening.

• Process reengineering module has function of reducing redundant activity of product development.

• Feedback module is essential to encourage early involvement.

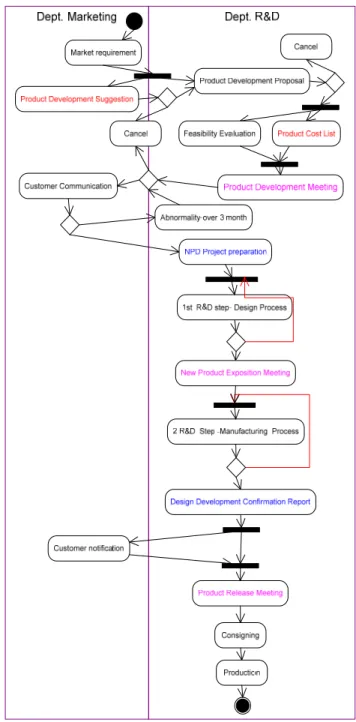

Fig. 3. The activit y diagram of proposed NPD process

Description of new product requirement for different NPD projects is inconsistent.

Product family structure is not obvious due to complicated tools features and product classification.

The launcher of a NPD concept influences the subsequent NPD process.

Product elimination and quality improvement are not viewed as an alternative ofNPD strategy.

Computer information system used in different branches and subsidiary companied are incompatible.

•

•

•

•

•

Design: new tool display Brand name: different

Involvement: center R&D section, subsidiary company , supplier

This study first uses focus group approach to discuss and collect historical data. Problems of workflow conflict are identified by Petri nets. The purpose of applying Petri nets is to examine the collaboration required during original NPD process. Currently, a systematic view ofNPD system is created by use of Unified Modeling Language (UML) use case diagram. Actors in this diagram show complicated connection between employees from different organizations. Time compression, instead of cost reduction , is used as a measure to eliminate unnecessary links due to the time-to-market pressure.

After several iterations of tuning current process, the review cycle of identify feasible new product concept can be regularly executed at center R&D section. Dimensions of organization structure and product information are checked during requirement scanning stage. However, customer interaction is not performed at this time. Feedback of internal and external communication is done by NPD project meeting.

An activity diagram of UML shown in Fig. 3 is applied to describe a NPD process for the case study. The bottleneck of current NPD project shows several targets of improvement.

Activity of "product development suggestion" is first added into process executed by Marketing Department. Three meetings respectively aimed at product development, new product exposition, and product releases are scheduled to arouse commitment ofNPD team members.

The implementation of the proposed framework in the case study is still an ongoing effort. Our research team keeps discussing with designated R&D team and analyzing the generation process for further modification. The advantages of using the proposed framework to generate NPD process are listed as follows:

• •

•

v.

CONCLUSIONIt is necessary for an enterprise with branches and subsidiary companies to reengineer its NPD process to meet requirements from different perspectives. To reengineer the NPD process, several issues can be considered such as business process reengineering, business alliance, supply chain management and collaborative commerce. This paper discusses flexible NPD process in terms of new product development process reengineering. The role ofNPD process in a business alliance is analyzed to identify opportunity of NPD. A proposed NPD process is generated to improve product development in the case study. Difference between current and proposed NPD process is compared. Finally, a framework of generating dynamic NPD process under the environment of collaborative commerce is proposed in this paper. Future study of this research will focus on information system development and product information identification for NPD proj ect.

REFERENCES

[1] R.G. Cooper and E.J. Kleinschmidt, "Determinants of timeliness on product development",Journal ofProduct Innovation management, Vol.

11, pp. 381-396,1994.

[2] A. Donnellon, "Cross-functional teams in product development:

accommodating the structure to the process", Journal of Product Innovation management, Vol. 10, pp. 377-392,1993.

[3] A. Griffin, "PDMA research on new product development practices:

updating trends and benchmarking best practices",Journal of Product Innovation management, Vol. 14, pp. 429-458,1997.

[4] A. Griffin and A.L. Page, "An interim report on measuring product development success and failure", Journal of Product Innovation management, Vol. 10, pp. 291-308,1993.

[5] F.M. Hull "A composite model of product development effectiveness:

application to services", IEEE Transactions on Engineering Management, Vol. 51(2), pp. 162-172,2004.

[6] W. Montoya and R. Calantone, "Determinants of new product performance: a review and meta-analysis",Journal ofProduct Innovation management, Vol. 11, pp. 397-417,1994.

[7] S. Nambisan and D. Wilemon, "Software development and new product development: potentials for cross-domain knowledge sharing", IEEE Transactions on Engineering Management, Vol. 47(2), pp. 211-220, 2000.

[8] E.M. Olson, O.C. Walker, and R.W. Ruekert, "Organizing for effective new product development: the moderating role of product innovativeness",Journal ofMarketing, Vol. 59, pp. 48-62, 1995.

[9] M. Ozer, "Process implications of the use of the Internet in new product development: a conceptual analysis",Industrial marketing Management, Vol. 32, pp. 517-530,2003.

[10] M. Ozer, "A survey of new product evaluation models", Journal of Product Innovation management, Vol. 16, pp. 77-94, 1999.

[11] A.L. Page, "Assessing NPD practices and performance: Establishing crucial norms",Journal ofProduct Innovation management, Vol. 10, pp.

273-290, 1993.

[12] H. Perks, "marketing information exchange mechanisms in collaborative new product development",Industrial marketing Management, Vol. 29, pp.179-189,2000.

[13] X.M. Song, R.J. Thieme, andJ.Xie, "The impact of cross-functional joint involvement across product development stage: an exploratory study", Journal ofProduct Innovation management, Vol. 15, pp. 289-303,1999.

[14] C. Tomkovick and C. Miller "Perspective - riding the wind: managing new product development in an age of change", Journal of Product Innovation management, Vol. 17, pp. 413-423, 2000.