1098 IEEE ELECTRON DEVICE LETTERS, VOL. 32, NO. 8, AUGUST 2011

Efficiency and Droop Improvement in GaN-Based

High-Voltage Light-Emitting Diodes

C. H. Wang, D. W. Lin, C. Y. Lee, M. A. Tsai, G. L. Chen, H. T. Kuo, W. H. Hsu, H. C. Kuo, Senior Member, IEEE,

T. C. Lu, Member, IEEE, S. C. Wang, Life Member, IEEE, and G. C. Chi

Abstract—The efficiency and electrical characteristics of GaN-based high-voltage light-emitting diodes (HV-LEDs) are in-vestigated in detail. The spatial distribution of light output and simulation results showed that 100-V HV-LED with smaller mi-crochips had superior current spreading. As a result, under 1-W operation, the luminous efficiency of 100-V HV-LED with smaller microchips was enhanced by 7.8% compared to that of 50-V HV-LED, while the efficiency droop behaviors were reduced from 28% in 50-V HV-LED to 25.8% in 100-V HV-LED. Moreover, smaller microchips exhibited lower series resistance and forward voltage, leading to higher wall-plug efficiency.

Index Terms—Current spreading, efficiency droop, high volt-age, light-emitting diodes.

I. INTRODUCTION

L

IGHT-EMITTING diodes (LEDs) based on GaN have been believed to be the next-generation environment lighting sources, particularly for solid-state lighting [1]. As an energy-saving lighting source, the quantum efficiency or the lumen efficiency of LEDs should be further improved. In order to obtain considerable light output power in only one unit, large LED chip size and high operation power are commonly adopted. However, current crowding effect and ef-ficiency droop would be introduced [2], [3], which significantly degrade the performances of LEDs. Current crowding issue in GaN-based LEDs is basically due to the unequal carrier mobility between holes and electrons in GaN-based materials, particularly for horizontal-type chip structure, which results in carriers crowding near the electrode. This phenomenon leads to higher operation voltage, larger series resistance (Rs), andlocally high current density and heat [4]. In addition, efficiency droop was pointed out to be associated with carrier overflow as well as overheating of the LED chip at high current

den-Manuscript received April 5, 2011; revised April 30, 2011; accepted April 30, 2011. Date of publication June 9, 2011; date of current version July 27, 2011. This work was supported in part by the National Science Council in Taiwan under Grant NSC100-3113-E-009-001-CC2.

C. H. Wang, D. W. Lin, C. Y. Lee, G. L. Chen, H. T. Kuo, W. H. Hsu, H. C. Kuo, T. C. Lu, S. C. Wang, and G. C. Chi are with the Department of Photonics and Institute of Electro-Optical Engineering, National Chiao Tung University, Hsinchu 30010, Taiwan (e-mail: josephwang.eo97g@nctu.edu.tw; davidlin1006@hotmail.com; goddess@ms4. url.com.tw; zorro0201@yahoo.com.tw; jicket00@hotmail.com; hckuo@ faculty.nctu.edu.tw; josephwang.eo97g@nctu.edu.tw; hsuantting.eo96@g2. nctu.edu.tw; timtclu@mail.nctu.edu.tw; josephwang.eo97g@nctu.edu.tw; gcchi@mail.nctu.edu.tw).

M. A. Tsai is with the Department of Electrophysics, National Chiao Tung University, Hsinchu 30010, Taiwan (e-mail: zorro0201@yahoo.com.tw).

Color versions of one or more of the figures in this letter are available online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/LED.2011.2153176

sity [5]. Consequently, current crowding effect would further accelerate droop behavior, which has been recently reported by Malyutenko et al. [6]. To minimize the droop behavior induced by current crowding, employing smaller die area would be helpful [7]. Former research on alternating-current LEDs (AC-LEDs) employed multiple-microchip design to realize self-rectifier in LED [8]. However, the reliability issues of AC-LED make it hard to be commercialized. The concept of microchips employed in direct-current LEDs (DC-LEDs) is still promising. These series-connected microchips in one large chip would obtain very high forward voltage under dc operation, but correspondingly, they have relatively low driving current, as compared to conventional large-chip DC-LEDs under the same power. This high-voltage and low-current operation is safer and more efficient for indoor power transformers. In this letter, characteristics of high-voltage LEDs (HV-LEDs) are investigated both experimentally and numerically. Current spreading and efficiency behavior in HV-LEDs with driving voltage at 50 and 100 V are also presented.

II. DEVICEFABRICATION

The LEDs were grown on a c-plane sapphire substrate by a metal-organic chemical vapor deposition system. The structure consisted of a Si-doped n-GaN layer, InxGa1−xN/GaN multiple

quantum wells, a Mg-doped p-AlGaN electron blocking layer, and a Mg-doped p-GaN layer. A similar chip process could be referred to [8]. The 10-μm-wide isolation trenches between microchips were etched down to the sapphire surface by in-ductively coupled plasma etcher method. Then, a 500-nm-thick passivation SiO2 layer was deposited by a plasma-enhanced chemical vapor deposition system to prevent short circuits between each microchip. After the transparent conducting layer was deposited, the Cr/Au connecting bridges and contact metal were simultaneously evaporated by an e-beam evaporator, so each microchip has independent n-pad and p-pad.

Unlike AC-LEDs, these microchips are all connected in series, so the operation voltage would be the sum of the total chips. For operation voltages at 50 and 100 V under 1-W injection, the total numbers of microchips are 16 and 30, respectively. For comparison, the total area of our LEDs was about 1.3 mm2. Despite the difference in operation voltage, the dimensions of a microchip in 50- and 100-V HV-LEDs were about 370 μm× 221 μm and 228 μm × 190 μm, respec-tively. The peak emission wavelength of our blue LEDs was 445 nm. The LEDs were mounted in Luxeon package for

WANG et al.: EFFICIENCY AND DROOP IMPROVEMENT IN GaN-BASED HIGH-VOLTAGE LIGHT-EMITTING DIODES 1099

Fig. 1. Measured (a) luminous efficiency versus current density and (b) forward voltage versus current density in single microchip of 50- and 100-V HV-LEDs. The dash lines represent the position of 1-W operation.

sufficient thermal dissipation and dispensed with YAG-432 phosphor.

III. RESULTS ANDDISCUSSION

It is worth noting that, under 1-W operation, the current densities of a single microchip in 50- and 100-V HV-LEDs were 24.51 and 26.13 A/cm2, respectively, as shown in Fig. 1. The luminous efficiencies under 1-W operation for 50- and 100-V HV-LEDs are 93.7 and 100.8 lm/W, respectively, and the correlated color temperature is around 6000 K. This result demonstrates that, by simply decreasing the microchip size from 370 μm× 221 μm to 228 μm × 190 μm, the luminous efficiency could be enhanced by 7.6%. Moreover, efficiency droop behavior, defined as (ηpeak− η1 W)/ηpeak, is slightly reduced from 28% in 50-V LED to 25.8% in 100-V HV-LED. Since the epitaxial structure and chip process were the same, these improvements in white LEDs are unusual and interesting.

The effective series resistance (Rs) of diodes can be defined

as Rs= ΔV /ΔJ , where ΔV is the difference in voltages

across the series resistance between the two operating points and ΔJ is the difference in current densities [9]. Since the area of each microchip in 50-V HV-LED is designed to be equal, so does the 100-V one, as shown in Fig. 2. Hence, the forward voltage should be uniformly distributed among these microchips. Despite the existence of connecting bridges, the calculated Rs’s of a single chip in 50- and 100-V HV-LEDs

are 0.0283 and 0.022 Ω· cm2, respectively, and the forward voltages are 3.29 and 3.17 V, respectively. These results show that 100-V HV-LED with more or smaller microchips exhibits better electrical characteristics than 50-V HV-LED.

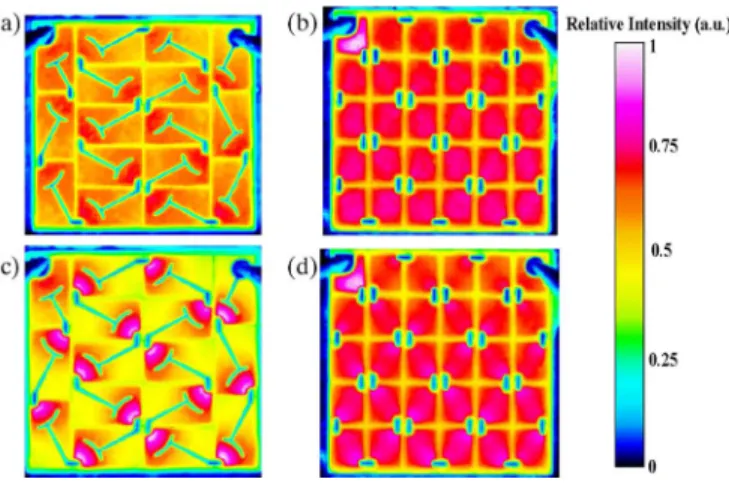

Fig. 2 shows the spatial distribution of light output with the same integration time of the image detector for 50- and 100-V HV-LEDs, respectively. Since the higher density of current has stronger light emission, the spatial distribution of light output can be related to the distribution of current density. Under 0.1-W operation, the current crowding effect in these two LEDs is not obvious, and the output power of 100-V HV-LED is slightly higher than that of the 50-V one. However, under 1-W operation, as shown in Fig. 2(c) and (d), noticeable light emission concentrated near the n-pad in every single microchip of 50-V HV-LED. This phenomenon is quite common in horizontal-type GaN-based LEDs, and mostly, using fingerlike contacts alleviate this effect [10]. While the dimension of microchips is down to 228 μm× 190 μm in 100-V HV-LED,

Fig. 2. Measured spatial distribution of light output under 0.1-W operation for (a) 50- and (b) 100-V HV-LEDs and under 1-W operation for (c) 50- and (d) 100-V HV-LEDs.

the current crowding effect is almost negligible under 1-W operation. This result indicates that, even without fingerlike contacts, the current crowding can be simply alleviated by narrowing down the dimension of microchips.

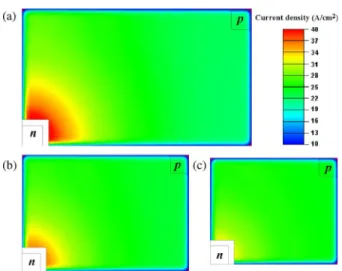

To further investigate how the dimension of microchips affects current crowding effect, the current density distribution and I–V curve with various sizes of mesa were simulated by SpeCLED software which is developed by STR [11]. The modeling structures of epitaxy and chip were referred to our experiment. Since the commercial LEDs have some concerns about sufficient current spreading, the fingerlike contacts are necessary. The simulation results only discuss about the current spreading versus area of the microchip, proposing a systematic comparison. Fig. 3(a)–(c) shows the distribution of current density with microchip sizes of 370 μm× 221 μm, 300 μm × 210 μm, and 228 μm× 190 μm, respectively. The largest and smallest microchips are referred to 50- and 100 V HV-LEDs, respectively. The total current densities of these microchips are about 25 A/cm2. Even though the average current densities are the same, the current distribution in the 370 μm× 221 μm mi-crochip shows more serious crowding near the n-pad than that in the smaller one. The peak current density in the 370 μm× 221 μm microchip is about 40 A/cm2, which is much higher than 32 A/cm2of the 228 μm× 190 μm one.

Fig. 4 shows the simulated characteristics of voltage versus current density of these three microchips. The series resistance in the 370 μm× 221 μm microchip is about 1.3 times of that in the 228 μm× 190 μm microchip, which is quite similar to our experiments. In addition, smaller chip area has relative smaller forward voltage at 25 A/cm2. The simulated wall-plug efficiency (WPE) of the 228 μm× 190 μm microchip is enhanced by 5% compared to that of the 370 μm× 221 μm one, which indicates that superior current spreading can effectively enhance the quantum efficiency of LEDs.

Also, we examined the light extraction efficiency (LEE) of 50- and 100-V HV-LEDs by Monte Carlo ray tracing method. The results showed that the LEE of 30 microchips is about 1% slightly less than that of 16 microchips, indicating that lateral extraction of microchips is not responsible for the enhancement of luminous efficiency. Therefore, the enhancement in luminous efficiency and droop behavior in 100-V HV-LED is mainly due

1100 IEEE ELECTRON DEVICE LETTERS, VOL. 32, NO. 8, AUGUST 2011

Fig. 3. Simulated distribution of current density under 25-A/cm2operation

for (a) 370 μm× 221 μm, (b) 300 μm × 210 μm, and (c) 228 μm × 190 μm microchips.

Fig. 4. Simulated forward voltage versus current density in microchips of 370 μm× 221 μm, 300 μm × 210 μm, and 228 μm × 190 μm.

to employing the microchip design, which leads to superior current spreading and higher WPE.

IV. CONCLUSION

In summary, the characteristics of GaN-based HV-LED with different sizes of microchips have been investigated both ex-perimentally and numerically. Experiment results showed that 100-V HV-LED with 228 μm× 190 μm microchips has higher luminous efficiency, better droop behavior, and lower series resistance under 1-W operation, as compared to 50-V HV-LED with 370 μm× 221 μm microchips. The luminous efficiency of 100-V HV-LED was 100.8 lm/W, which was 7.8% higher

than that of 50-V HV-LED. In addition, the droop behavior was reduced from 28% in 50-V HV-LED to 25.8% in 100-V HV-LED. The spatial distributions of light output confirmed that smaller microchips exhibit more uniform current distribu-tion, which would be the major reason for the improvements. Furthermore, simulation results confirmed that better current spreading and higher WPE of smaller microchips lead to su-perior performances of LEDs. These works show that HV-LED is very promising as an alternative solid-state lighting source.

ACKNOWLEDGMENT

The authors would like to thank Dr. C. J. Pan of Helio Opto-electronics Corporation and Dr. Y. L. Li of Genesis Photonics Incorporation for their technical support and Dr. J. C. Li of Xiamen University for her kindly suggestions.

REFERENCES

[1] S. Pimputkar, J. S. Speck, S. P. DenBaars, and S. Nakamura, “Prospects for LED lighting,” Nat. Photon., vol. 3, no. 4, pp. 180–182, Apr. 2009. [2] X. Guo and E. F. Schubert, “Current crowding in GaN/InGaN light

emitting diodes on insulating substrates,” J. Appl. Phys., vol. 90, no. 8, pp. 4191–4195, Oct. 2001.

[3] M. H. Kim, M. F. Schubert, Q. Dai, J. K. Kim, E. F. Schubert, J. Piprek, and Y. Park, “Origin of efficiency droop in GaN-based light-emitting diodes,” Appl. Phys. Lett., vol. 91, no. 18, p. 183 507, Oct. 2007. [4] H. Kim, J. M. Lee, C. Huh, S. W. Kim, D. J. Kim, S. J. Park, and

H. Hwang, “Modeling of a GaN-based light-emitting diode for uniform current spreading,” Appl. Phys. Lett., vol. 77, no. 12, pp. 1903–1904, Sep. 2000.

[5] C. H. Wang, J. R. Chen, C. H. Chiu, H. C. Kuo, Y. L. Li, T. C. Lu, and S. C. Wang, “Temperature-dependent electroluminescence efficiency in blue InGaN/GaN light-emitting diodes with different well widths,” IEEE

Photon. Technol. Lett., vol. 22, no. 4, pp. 236–238, Feb. 2010.

[6] V. K. Malyutenko, S. S. Bolgov, and A. D. Podoltsev, “Current crowd-ing effect on the ideality factor and efficiency droop in blue lateral InGaN/GaN light emitting diodes,” Appl. Phys. Lett., vol. 97, no. 25, p. 251 110, Dec. 2010.

[7] V. Adivarahan, S. Wu, W. H. Sun, V. Mandavilli, M. S. Shatalov, G. Simin, J. W. Yang, H. P. Maruska, and M. Asif Khan, “High-power deep ultraviolet light-emitting diodes based on a micro-pixel design,”

Appl. Phys. Lett., vol. 85, no. 10, pp. 1838–1840, Sep. 2004.

[8] H. H. Yen, H. C. Kuo, and W. Y. Yeh, “Characteristics of single-chip GaN-based alternating current light-emitting diode,” Jpn. J. Appl. Phys., vol. 47, no. 12, pp. 8808–8810, Dec. 2008.

[9] H. Kampwerth, T. Trupke, J. W. Weber, and Y. Augarten, “Advanced luminescence based effective series resistance imaging of silicon solar cells,” Appl. Phys. Lett., vol. 93, no. 20, p. 202 102, Nov. 2008. [10] H. Rodriguez, N. Lobo, S. Einfeldt, A. Knauer, M. Weyers, and

M. Kneissl, “GaN-based ultraviolet light-emitting diodes with multifinger contacts,” Phys. Stat. Sol. (A), vol. 207, no. 11, pp. 2585–2588, Nov. 2010. [11] STR group. [Online]. Available: http://www.semitech.us/products/