Proceedings of the 2002 IEEE International Conference on Robotics 8 Automation

Washington, DC May 2002

Modeling, Scheduling, and Prediction

for Wafer Fabrication:

Queueing Colored Petri-Net and GA Based Approach

An-Chih Huang, Li-Chen Fu, Ming-Hung Lin, and Shun-Yu Lin

Department of Computer Science and Information Engineering National Taiwan University, Taipei, Taiwan, R.O.C.

Abstract-In this paper, we propose a modeling tool named QCPN (Queueing Colored Petri Net). The main idea of this tool is to combine the original CTPN (Colored Timed Petri Net) with the queueing systems. With QCPN model, we can predict the delivery date of

any specific product under some scheduling policies eflcientfy and rather precisely. In the scheduling phase. we use the GA based approach to search,for the optimal combination of a number of heuristic rules. This QCPN based GA scheduler can greatfy reduce the computation time so as to meet the need f o r a rapidly changing environment.

1.

Introduction

In recent years, semiconductor manufacturing n- dustry grows rapidity and it has become one of the most competitive fields. Due to equipmnt uncertainty, prod- uct diversity, process intricacy, and ever improving technologies, the semiconductor manufacturing is per- haps the most complicated manufacturing process found today.

This paper addresses the problem of prediction and scheduling. If we want to meet requirements of custom ers, we have to precisely estimate the cycle time of all orders as well as other performance measures (work in process, machine utilization) first Based on these measures, the manager or fab engineers can control the operation and the manufacturing times easily, and the customers can know the date of lot delivery beforehand. Thus, prediction becomes an extremely important and challenging task. There are many papers [1][2] which proposed to model manufacturing facilities to predict product cycle time. Among them, the mathematical model based on Queueing Theory is the most commonly used one, which is also adopted in this paper. In order to accomplish the taslc of prediction, a wafer fab model based on QCPN (Queueing Colored Rtri Net)[lO] is proposed in this paper. This model not only helps us to evaluate these Performance measures, but also helps us to develop and evaluate our scheduler easily. Petri Net has played an important role in modeling field. It has been developed into a powerful tool for discrete event systems; particularly in manufacturing systems. Many extensions of Petri net were introduced, such as colored Petri net [3], and timed Petri net which were widely used in manufacturing systems. The colored timed Petri net (CTPN) is used to model the furnace in the IC wafer fabrication [3] and in the whole wafer fabrication manufacturing system [4][1 I]. Jeng et al. [5] reported a project of applying Petri net methodologies to detailed

modeling, qualitative analysis, and performance evalua- tion of the etching area in an IC wafer fabrication system located in the Science Based Industrial Park in Hsin Chu, Taiwan.

There are many papers on planning and scheduling. Wein [6] has investigated the effect on both input E-

lease policies and dispatching policies, though via a detailed simulation study. Most conventional heuristic procedures use a priority rule. Traditional dispatching methods like FIFO, critical ratio, least slack time and least queue time have been proposed [7J In recent years, an interest in using probabilistic search methods to solve job shop problem has been growing rapidly. Lee et al. [ 8 ] combined the machine learning and genetic algorithm in the job shop scheduling.

The organization of this paper is described

as

fol- lows. In Section 2, the definitions of the proposed Queueing colored Petri net (QCPN) are revealed here, and the detailed systematic method of QCPN model is discussed in Section 3. In Section 4, we first describe the problem of prediction. Then, we describe the way of delivery prediction when some priority-based dispatch- ing rules are adopted. Some popular scheduling prob- lems and lot released control policies used in wafer fab- rication are discussed first in Section 5. Then, a GA embedded search method over the QCF” model is e m ployed. In Section 6, we briefly describe the implemen- tation of the simulation tool. In addition, we demon- strate the examples of using the proposed mechanism and analyze the performance. Finally, conclusions and future research are provided in Section 7 and 8.2.

Queueing Colored Petri-net

In our method of combining Petri Net and Queueing network, we introduced a special kind of tran- sition, namely, “queueing transition” into the original Colored Timed Petri Net to represent the role of queue- ing system. The following is the definition of QCPN.

2.1 Definition

of Queueing Colored Petri-net

A Queueing Colored Petri Net (QTPN) is a bipar-tite graph, defined by a 12-tuple, CTPN=

(Pi,

P,,4,

T,,T,,

Tr,

T,,,

4,

C, 1,0,

M), whereP, set of immediate places;

P,

set of communication places;T, set of immediate transitions:

q,

set of mapping transitions;T, set of timed transitions;

T,,,

set of macro transitions;Tq set of queueing transitions;

C

color set of transition andplace;I input functions;

0 output ,functions; M the marking.

An elaboration of these elements is the same as the ordinary CTPN[3][6]. The icon definition of CTPN is illustrated in Fig. 1 ImmPriiatr Stnrhaatir Pl;irr

0

tmiixitini;0

ImmcrliiitP-

t u n a i t i n n M d D D h l ! twiwitinn=

TimPd-

OueueiiirrrinYitinn t i’ii IIY i ti n n

Figure 1 Icon definition of CTPN

A s mentioned, we introduced six kinds of transi- tions and two kinds of places into our model. The brief description of these transitions and places are given as follows.

Immediate places: Immediate places are the same as the ordinary places but without the time attribute. Communication places: The interconnection k- tween different modules is achieved by the commu- nication place [3].

Macro transitions: Each macro transition contains a module of the model, and this module combines arcs, places and transitions [3].

Immediate transitions: Immediate transitions are the same as the ordinary transitions in CPN (Col- ored Petri-net).

Mapping transitions: After firing the mapping transitions, the token corresponding to a certain color that enables this type of transition is trans- ferred to another place with the predefined color. Timed transitions: Timed transitions describe the time properties of resources or time delay. Stochastic transitions: The transition times may belong to one of several distributions in stochastic transitions.

Queueing transitions: A token that enables the queueing transition q with respect to the color qc will be assigned a queueing time (waiting time). Each queueing transition can be embedded with a priority queueing model. The waiting time for the queueing transition can be calculated by the queue- ing model. After the queueing time delay, this transition can be fired.

In Figure 2(a), the original service queue is illus- trated b y C T P N . With our proposed QCPN, this E-

source contention subset can be illustrated in Figure 2(b). In this figure, original place resource in Figure 2(a) is removed. It is replaced by a queueing transition enter.

The queueing transitions are embedded with the priority queueing model. Thus, this queueing model o n calcu- late the delay (waiting) time of the queueing transition.

-U-

illrf,-r rnir-r w r v i m rcvicc t D U ~ D U ~

Figure 2 (a) Original resource contention (b) QCPN resource contention

2.2 Waiting Time of Queueing Transition

The tool group in a semiconductor foundry is a typical priority queue. Because of operation reasons, lots are classified into several priority classes. The ur- gent lots are given the highest priority for operation. We can use G/G/l/Priority queueing system to calculate waiting time. The mean waiting time is approximated by incorporating an adjustment factor j into M/G/l/priority model [ 11. Denote

W,,

as waiting time of token of (pri- ority) class p,4

as arrival rate of token of class p, x: as 2’ld-order moment of wafer processing time of token of class p. Then,-

-

f:

1i’”;’jiwhere j i

=

‘ 5 . k -k ‘:.A ,~f,.

and c , , ~ are the squares of variation. coefficients of the inter arrivals and processing times of the lots with priority p . The parameterc:,~

and C,f,, can b eob-

tained from the historical running data of the wafer fab.

w,=

j = ‘(1

-

0”-

CT y + ,1

CS2k 4-’

2

3.

Wafer Processing Model

W e use h e proposed QCPN to model the whole wafer manufacturing system.

Figure 3 Conceptual architecture of the wafer fab model

The details

of

the model including Capability Routing Module, Machine Group Module and Equip- ment Module are described in the following sections. Figure 3 illustrates the conceptual architecture of the proposed model.Capability Routing Module

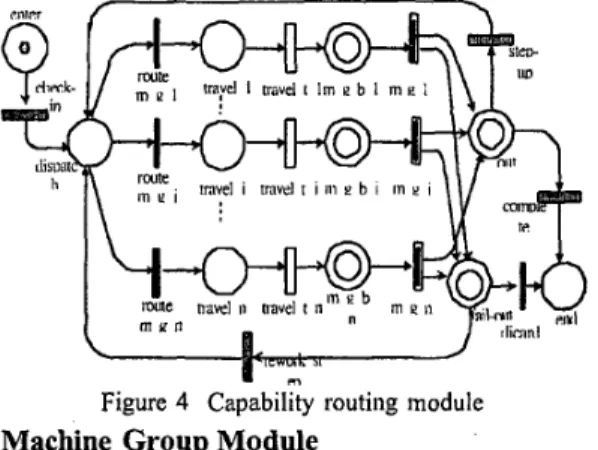

The main purpose of Capability Routing Module is to model the logical process flow of the semiconductor manufacturing systems.

Figure

4

Capability routing moduleMachine Group Module

The machine group module contains one or more identical machines (or processing units). This module is responsible for dispatching the lot to an appropriate equipment module.

-5

w t c E i 1 cntcr c I I cauin i IFigure 5 Machine

group

moduleEquipment module

The QCPN equipment model is illustrated in Fig- ure 6. The waiting time of the tokens (lots) is calculated using the priority queueing model of the queueing tran- sition.

Figure 6 QCPN based equipment module The machine failure mechanism and periodical maintenance subnet is not modeled in Petri-net in Figure

6 .

Such occasional events can be modeled as the lotsthat directly arrive at the highest priority queue [ I ] in priority queueing model mentioned above. -

4.

Delivery Prediction

In order to provide more information to the cus- tomer, and to help them to make ordering decisions, we need to estimate some performance measures precisely and efficiently. In this section, we use the wafer proc- essing model described in Section 3 to predict the deliv- ery date of the order.

4.1 Necessary Input Parameters

Since QCPN is a semi-simulation tool, we can con- struct our system model and simulate it. Thus, some input parameters are needed to simulate the system. We describe these parameters in the fo llowiiig items. 0 Current system state: This information includes

the current status of the lots and the machines. U Future Demands: These are the potential orders,

which will be released in the future.

0

Current rules: These are scheduling rules that will be adopted in the future.0 Other parameters: These parameters include the probability of machine failure, rework probability of lot, and some other minor parameters that will affect the precision.

The predictor can also answer some what-if ques- tions by simulating result.

4.2

Priority Assigning Method for General

Priority-Based Rules

As mentioned, we use the priority queueing model as a part of our modeling tool. When various scheduling rules are used, we have to decide which priority class the lot should be assigned to.

After the highest and lowest value of the lots in fab are found, we can assign the lot to different priority class according to the following equation.

c

=

1

P

-

v m l nx

( v m o x>p>

~ v n ~VI,,

-Y,m

c

= p (P'vm0.JC = I @<VnrmJ

where

P

is the number of priority classes, V,,,,, is the highest priority value among lots, V,,, is the lowest pri- ority value among lots, p is the priority value of the tar- get lot, and C is the priority class that this lot should be assigned to. Note that the value of V,,,,and

Knj,r

need to be updated periodically.The proposed QCPN model based predictor which can predict some performance measures such as lot due date over the corresponding QCPN model. Since the prediction must be performed under some kind of scheduling rules, the priority assigning method proposed here can combine the scheduling rules with the predic- tion.

5. Wafer Fab Scheduler

Most semiconductor manufacturing companies suf- fer from high WIP level and long cycle times. Hence, it is important to develop a production scheduling system that can help minimize cycle time and WIP as well as to meet the due date constraints.

5.1 Genetic Algorithm

There are two sub-problems in the scheduling problem. First, what searching method do we apply to optimize the scheduling results? Next, how do we evaluate the performance of each scheduling policy? For the first sub-problem, we apply a Genetic Algorithm. On the other hand, for the second sub-problem, we use mathematical analysis based on our QCPN model to address the performance evaluation. In other words, we evaluate the objective measures of our fitness function through the analyzing procedure of the proposed QCPN model. The general structure of a genetic algorithm is given in L. M. Wein [9].

5.2 Mixed Dispatch Rule

The main idea of this scheduler in this paper is to use a GA algorithm to find the appropriate lot release rule, machine selecting rule and dispatching rule. In addition, we try to mix som: dispatching rules together and use GA search to find the appropriate mixed mode of each machine. This method, first normalize theivalue of priority-base dispatching rules used in our method into the same range. Then, it uses different combinations of these rules to generate different execution sequence of lots on each machine.

Different priority-based rules may have different ranges of values. The main goal of this transformation (or normalization) is to transform these priority values into the same range. Note that

in

some rules the smaller priority value represents the higher priority of a lot, so we need to make the value negative. The transformation equation will bec

= P-

V“v,

-

VI,,,.where

V,,,,,

(Vmin) is the highest (lowest) priority value among lots, C is the transformed value, and p is the tar- get lot priority (the value to be transformed). Then, the priority value of different rule can be transformed into values between 0-1. Note that each priority-based dis- patching rule has its ownV , , ,

and V,,,i,,,so

that wecan

track the range of values of each rule.

We use EDD, CR, SRPT, LS, and Penalty rules in this paper, and each rule has a discrete parameter range, say, from 0 to 3. We multiply this parameter with the transformed priority value of each rule, and then add these values up. The summation is divided by the sum of the parameters, and then the priority of the mixed rule is obtained. Whether some comb inations of these rules may be useful or not, the GA search algorithm will eliminate those “bad” combinations, and reserve only good combinations of chromosomes after generations.

5.3.

Chromosome Representation

There are three types of genes in our chromosome:

g ,

,g,,

, andg,,

which denotes lot release policy, machine selection rule, and dispatch rule respectively,g,

= ( a , b , c , d , e )

is a five-tuple where 0 a: selected parameter for SRPT17

b: selected parameter forEDD

0 c: selected parameter for CR 0 d: selected parameter for SLACK 0 e: selected parameter for Penalty

For each rule in

g,

andg,,,

, it is described sim- ply as follows:UNIF: Uniform Distribution CONWIP: Constant WIP W R Workload Regulating UTIL-L: Lowest Utilization

SQL: Shortest Queue Length

SEPT: Shortest expected processing time

The rules we selected for gene codes are listed in Table 1.

Table I Gene codes

Lot Release Pol i- Machine Selecting Dispatch

cies Rule Rules

I

These gene codes are directly related to our QCPN model. Thedispatch rule is related to QCPN model by selecting an appropriate priority queue for each

lot.

Since the transformed priority value is between 0 and 1, we can calculate the appropriate priority queue by

C =

[U,

x P 1 ,

wherep, is the transformed priority value of the lot, and C is the priority class (queue) this lot should be assigned to. The waiting time can be calcu- lated by M/G/ Upriority queueing model described in Section 2.The chromosomes can be created after the genes are defined. The main goal of the GA search algorithm is to find a good chromosome that can satisfy the prede- fined requirements such

as

shorter cycle time and higher meet-due-date rate.5.4. Fitness Function

In common situations, we have multiple objective measures. How to integrate these functions becomes an important issue. One of the methods is to combine them into a scalar fitness solution by weighted-sum approach: Here, we explain the function definition as follows: (c is a chromosome (i.e., solution))

f ( c )

= w,.fi (4

+wz.

f,

(4

+ w3.h(c)

4

is the score for throughput rate,J is the score for the loss due to the number of or- ders which failed to meet due date.

The value

of

these scores is obtained from the QCPN wafer fab model. We code any possible schedule solutions into the chromosomes. The scheduler simu- lates the quality of the individual chroniosome in detail through the PN platform to guide the proper genetic evolution to produce a good enough schedule.6 . Experiment

To verify the effectiveness of the proposed work, we build a virtual fab model based on the data from a semiconductor fab in Hsinchu, Taiwan. However, for business protection, all the data are scrambled, but the scale is approximately kept. In this model, there are to- tally 477 machines in 43 machine groups. The machines in each machine group may range from 3 to 45. There are two production lines in this model. The first produc- tion line is a reentrant line comprising 416 operations, and the second production line comprising 322 opera- tions. Since the nurnber of machines in the fab and that of operations in the production line are large, the com- plexity in simulation, prediction and scheduling is enormously increased.

Some machine groups in this model contain batch-processing machines. The parameters such as MTTF (Mean Time to Failure), MTTR (Mean Time to Repair) and scheduled maintenance are also included in

this model. Finally, scheduled maintenance means that the machine will be maintained after n times of opem- tions.

6.1 Experiment Results

In this section, we design some experiments to evaluate the performance of our predictor and scheduler. In these experiments, work in process of the fab is not empty in the beginning of evaluation. We generate the information of these lots by taking a snapshot of the simulation model already in steady state. The period of evaluation is 3000 hours (about 4 5 months) if we did not mention. Similarly, the average rate of lot release is 6.4 lots per day. Our experiments are perfomied on the mixed production line, and the proportion of two types oflotsis 1:l.

The Precision of The Predictor

In

this experiment, we arbitrarily choose three or- ders and compare their delivery prediction values with simulation ones. Each order containes two lots with dif- ferent type (flow), and the interval of order release is 8 hours. In order to verify the performance of the predic- tor on different dispatching lules, the four rules SRPT, EDD, CR and LS are chosen for comparison. Table 2shows the configuration of these three orders.

OrderP42

I

328I

1148.71 1308.71 OrderP62I

488Figure 7 illustrates the results of this experiment. The accuracy of prediction ranges from 90% to 98%, depending on the rule used.

I

Pa4

X X "

U 0

1

"-

C A "-*

rrs1

I^^-

---

-

Figure 7 Complete time comparison

The Performance

of

The GA Scheduler

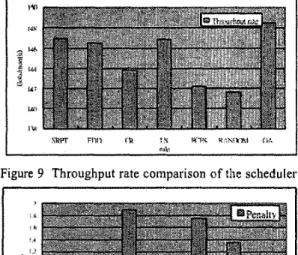

Here, we compare the performance measures of our scheduler with other priority-based heuristig rules first. The period of evaluation is 3000 hours, and the interval of order release is 7.5 hours. The due date of the orders is the order release time plus 640 hours, and the penalty is randomly generated values ranges from 0 to 10. The GA parameters we use to search for a better chrom- some are listed as follows:

0

Population size: 100

Generation size:IO

0

Crossover rate: 0.70

Mutation probability: 10 %0

Cutoff utilization level: 50%0

Fitness function proportion0 Cycle time: 3

0 Throughput rate: 1

0 Penalty: 3

The scheduler is based on the QCPN model to evaluate the performance measures. The computation time of GA scheduler is about 2-3 minutes.

Form Figure 7, we found that the proposed QCPN based predictor have high precision when different pri- ority based rules are used. For the predictor, it can also achieve some requirements such as performing quick-responding prediction whereas maintaining good preciseness

I

w r i I r m m t ~-FI I?A\IYE\! t i \

r is.

Figure

9

Throughput rate comparison of the schedulerFigure 10 Penalty comparison of the scheduler From Figure 8 t o 10, we found that the proposed GA scheduler perforins much better than other- priority based rule. It has a lower mean cycle time for lots spent in the fab, a higher throughput rate for a fab, and a lower value of penalty. As a result, the proposed CA scheduler has a significant impact on wafer fab scheduling by pro- viding obvious performance improvements even though the fab has a mixed production.

7.

Conclusion

In this paper, we proposed one novel modeling tool, named, QCPN (Queueing Colored Petri Net). The main idea of this tool is to combine the original CTPN with the queueing systems. With QCPN model, we can PE- dict the product delivery date precisely and efficiently under some scheduling policies. We achieve this goal by periodically changing the priority of each lot. Since most

of

the scheduling tules (dispatching rules) are pri- ority basedones,

changing the priority of each lot can reflect the behavior of these rules. In the scheduling phase, we use the CA based approach to search for the optimalcombination of a number of heuristic rules. This approach can reduce the solution space to find the good solution more quicldy. So this GA scheduler can serve the rapidly changing environment well.8. Discussion and Future Research

Applying QCPN as the underlying model in our simulator saves much computation time. For GA, which needs many runs of siinulation to obtain its solution, this advantage is much more valuable. There will be some loss of the accuracy of the simulation froin using thequeueing transition, however, we can reduce its impact by some mechanism slch as updating the arrival rate periodically. Since there is no single rule which always performs very well, the use of mixed rule shows its merit. In the future research, we will keep

on

the topic of the mechanisms making the arrival rate more accurate and better methods tomix

the rules.Reference

D.

P. Connors, G. E. Feigin, andD.

D. Yao, “ A Queue- ing Network Model for Semiconductor Manufacturing,” IEEE Transactions on Semiconductor Manufacturing, vol. 9, no. 3, pp. 412-427, 1996.P. Buchholz, “A New Approach Combining Sirmilation and Randomization for the Analysis of Large Continu- ous Time Markov Chains.”, ACM Transactions on Modeling and Computer Simulation, Vol. 8, No. 2, April

M. H. Lin and L. C. Fu, “Modeling, Analysis, Simula- tion, and Control of Semiconductor Manufacturing Sy s- tems: A Generalized Stochastic Colored-Timed Petri-Net Approach,” IEEE Intemational Conference on Systems Man, and Cybernetics, 1999.

M. C. Zhou and M.

D.

Jeng, “Modeling, Analysis, Simulation, Scheduling and Control of Semiconductor Manufacturing Systems: A Petri Net Approach,” IEEE Transactions on Semiconductor Manufacturing, vol. 1 1, no. 3, pp. 333-357, 1998.M. D. Jeng, X. Xie, and S. W. Chou, “Modeling, Quali- tative Analysis, and Performance Evaluation of the Etching Area in an IC Wafer Fabrication System Using Petri Nets,” IEEE Transactions on Semiconductor Manufacturing, vol. 1 I , no. 3, pp. 358-373, 1998.

L.

M.

Wein, “Scheduling Semiconductor Wafer Fabrica- tion,’’ IEEE Transactions on Semiconductor Manufac- turing, vol. 1, no. 3, pp. 11 5-130, 1988.K. R. Baker, “Sequencing Rules and Due-Date Assign- ments in Job Shop.’’ Management Science, Vol. 30, No. 9, pp.1093-1104, Sep. 1984

C. Y. Lee, S. Piramuthu, and Y. K. Tsai, “Job Shop Scheduling with a genetic algorithm and machine leam- ing”, Intemational Journal of Production Research, vol. 35,no.4,pp. 1171-1191, 1997.

S. M. Sait and H. Youssef, VLSI Physical Design Auto- mation: Theory and Pratice, McGraw-Hill, New York,

1995.

1998, pp. 194-222.

[lo] M. H. Lin, “Modeling, Analysis, Prediction and Sched- uling for Virtual Wafer Fabs”, Ph.D. Thesis, Department of Computer Science & Information Engineering,

NI-

tional Taiwan University, 200 1.

[