http://cer.sagepub.com

Concurrent Engineering

DOI: 10.1177/1063293X0000800106

2000; 8; 50

Concurrent Engineering

Shen-Chou Yeh and Chun-Fong You

Implementation of STEP-Based Product Data Exchange and Sharing

http://cer.sagepub.com/cgi/content/abstract/8/1/50

The online version of this article can be found at:

Published by:

http://www.sagepublications.com

can be found at: Concurrent Engineering

Additional services and information for

http://cer.sagepub.com/cgi/alerts Email Alerts: http://cer.sagepub.com/subscriptions Subscriptions: http://www.sagepub.com/journalsReprints.nav Reprints: http://www.sagepub.com/journalsPermissions.nav Permissions:

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

50

CONCURRENT ENGINEERING: Research and

Applications

Implementation

of

STEP-Based Product Data

Exchange

and

Sharing

Shen-Chou Yeh and

Chun-Fong

You

1

Department

of MechanicalEngineering,

National TaiwanUniversity, Taipei,

Taiwan,

ROC Received 13September

1999;accepted

in revised form 14 November 1999Abstract: Product data exchange and sharing is an important issue for miscellaneous information systems. STEP-based product data exchange and sharing provides a useful mechanism for implementing concurrent engineering and promoting the realization of CALS’ en-vironment. This paper implements a pilot system for STEP-based PDE (Product Data Exchange) system based on the requirement of

product data exchange between and within enterprises. The system incorporates engineering information in the design and

manufactur-ing stages and guarantees the consistency of the product data exchange and sharing. Complete development processes of systems, in-cluding AAM (Application Activity Model), ARM (Application Reference Model), and AIM (Application Interpretation Model), are illustrated

herein. AAM utilizing BPR (Business Process Reengineering) approach is employed to develop ARM, which is then mapped to AIM mod-els from part 41, part 42, part 44, AP 203, AP 214 in STEP The system’s database is based on the integrated AIM models in STEP to as-sure the capability for product data exchange and sharing. The kernel data structure is a combination of engineering information and product-oriented definitions. The data from miscellaneous information systems, such as CAD/CAM, MRP/MRPII, ERP, and PDM, in the

de-sign and manufacturing phase of a product’s life cycle can be exchanged using this system. This paper also employs STEP to present an integrated product-oriented data structure to manage engineering information from different information systems.

Key Words: product data exchange, product data sharing, product data management, concurrent engineering, STEP

1. Introduction

Product data

exchange

andsharing

must assure theinteroperation

ofproduct

data from miscellaneous informa-tion systemsby

eitherdefining

standardized data models forrepresenting

product

datall-4

orimplementing

systemar-chitecture for

reducing

the barrier ofproduct

dataexchange

andsharing

[5-8].

STEP standardprovides

a robust datastructure for the

exchange

ofproduct

data models[9,1 OJ.

However,

no informationsystem

currently

has thecapability

to

flexihly

manage STEP-basedproduct

data frommiscella-neous information systems. The data sources of different

product

information within STEP-basedproduct

data mod-els are defined tointegrate

the information.This

project

aims to define theproject

data modelsusing

EXPRESSlanguage

and setup the STEP-basedproduct

datarepository

forproduct

data management andexchange

for automobilemanufacturing

industries and their first-tieredsuppliers.

The STEP-basedproduct

datarepresentation

asil-lustrated in

Figure

may

come from miscellaneous ilfolma-tion systems, such asCAD/CAM,

MRP/MRPII, ERP, andPDM.

Although

additional information from one system canbe attached and

implemented,

STEP cannotincorporate

pieces

of information from miscellaneous systems. There-pository accomplished

in this paper canalllalgalllate

the databased on STEP and a real STEP-based data

repository

toachieve

product

dataintegration.

Distinctmethodologies

forproduct

dataexchange

andsharing, including

part 21,

SDAI,

COM, and

CORBA,

are discussed in the next section.1.1 Review of the

Implementing

Conceptual

Layer

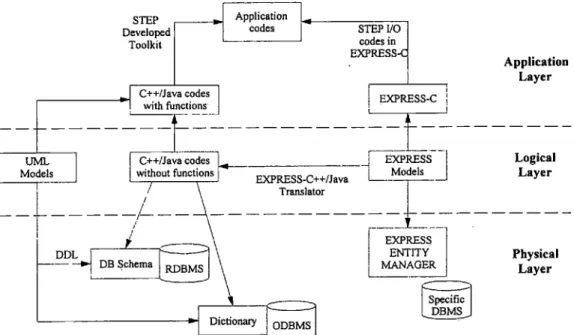

Object-oriented language

with UML(Unified

Modeling

Language)

modeling methodology

isproposed

toequip

the STEP-basedrepository

system

with EXPRESS datamodels,

since EXPRESSlanguage

lacks the I/Ocapability

forpro-gramming j

1 I J.

Object-oriented modeling language

also has the benefit ofbeing

robust,flexible, extensible, direct,

and reusable. The conventional means ofestablishing

aSTEP-based system is to use EXPRESS

language

to model thecon-ceptual

models, and then construct theapplication

layer by

object-oriented

and EXPRESS-Clanguages

asdepicted

inFigure

2. Theconceptual

data models are translated into anRDBMS (Relational DataBase

Management

System),

merged

into an ODBMS(Object-oriented

DataBaseMan-agement

System),

ormanaged by

an EXPRESS modelman-agement

system, to construct thephysical layer

of thesys-tem.

1.2 The

Physical

Layer

The

physical

layer

inFigure 2

contains the kernel database and network communication media structure. The ODBMS1

Author to whom correspondence should be addressed.

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

Figure 1. STEP-based product data representation.

provides

better storage of information within the STEP-based system than theobject-oriented conceptual

data mod-els because the latter affects the construction of the database schema. Best results can be obtainedby

emptoying

theRDBMS after

object-oriented modeling

because it iscom-patible

with relational databases and it willguarantee

the ef-fectiveness of thelegacy

systems data retrieval. Thecom-plexity

of the information to be stored iskey

tochoosing

between the ODBMS or the RDBMS as the former is suitable

four

complexly

related data, such as the PDM and CAD/CAMsystem, while the latter is suitable for

large quantities

of data.The main concern that must be addressed when

adopting

RDBMS as the kernel of STEP-based system is theintegra-tion

of legacy

data. It is best achievedby

ODBC(Open

Data-BaseConnectivity)

because it canincorporate legacy

databy

merging

the schemaof legacy

data into the STEP-basedsys-tem

[ 12 J.

On the otherhand,

if the ODBC driver of anODBMS is used. the data

residing

on ODBMS can also beshared

by

the RDBMS.The

physical layer

of the STEP-based PDMS should beequipped

with a dataexchange,

an external shareddatabase,

or a distributed database method to secureproduct

dataexchange

andsharing.

The dataexchange

method enablesproduct

data within a PDMS to beexchanged

asphysical

files

expressed

in aplain

text[ 13].

This methodeasily

fa-cilitatessetting specifications, conducting

tests and diversesystem

applications.

Theexternally

shared database methodaccesses a common database between

companies

on acontract basis. Data are

copied

from the PDMS of thecompa-nies into the common database. The distributed data-base method distributes the

product

data among the PDMS ofcompanies

that canconcurrently

share access[

1-~-16].

Thevirtually

shared database method may be theulti-mate in

product

datasharing

intended to create a concurrentworking

environment becausealthough

the data arephysi-cally

shared on internet network, the database functions as asingle

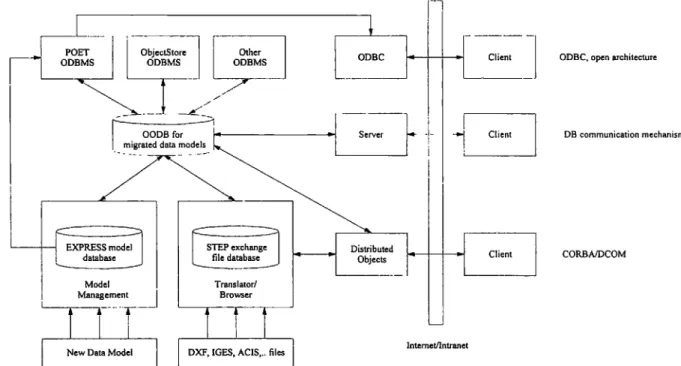

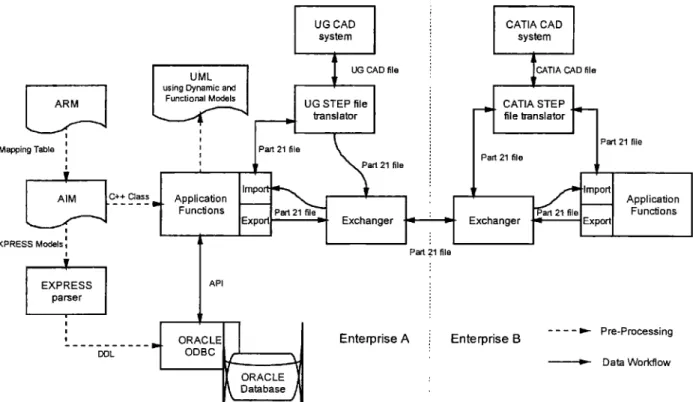

unit.The construction of a STEP-based distributed database

management system is illustrated in

Figure

3. The left side indicates thegeneration

of the internalrepresentation

of EX-PRESS codes, such as themigrated

data models in Section 2.This can be used to construct the

database, generate

parser codes, andimplement

C++ codes. The C++ codes arecom-piled

by

an ODBMS to add the management functions intooriginal

C++ codes. At the same time, a schemadictionary

Figure 2. Approach for establishing a STEP-based system.

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

52

Figure 3. Approach for constructing STEP-based distributed management system.

and its related codes are

generated

andmanaged by

theODBMS. The shared database environment is achieved with the ODBC driver

provided

by

ODBMS[ 17,18].

Figure

4presents

three mechanisms of network communi-cation,including

an ODBC mechanism, a databasecommu-nication mechanism, and a CORBA/COM mechanism, with

their

operation

methods, that can all work within aSTEP-based PDMS. The ODBC mechanism comhines all informa-tion from the different systems into the unified data schema. Database communication relies on the ODBMS, while the

most

popular approach

is the use o1- TCP/IPprotocol

to ad-dress the PDMS server side. The CORBA/COM mechanismallows the distributed

objects

to communicate with each dis-tribute the information of PDMS.1.3 Review of

Implementation

ofApplication Layer

The

application

layer

must connect theoperations

of thephysiral layer

to theconceptual layer.

The effectiveness of data management andcompatibility

with STEP arealways

opposite,

because theimplementation

of STEP-basedsys-tem

using

ARM or AIM indicates two differentapproaches

119].

Popular

database preprocessor toolsgradually

solveFigure 4. Three mechanisms of network communication.

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

this

phenomenon,

so thatprototyping applications

can ber-~rpidly

developed

andeasily

connected to the target data-base. Theapplication

orpresentation layer

is formedby

ref-erencing

models in theconceptual layer

to meet diversere-quirements.

A flexiblemodeling

and better communication interface are themajor

issues for a STEP-based PDMS.They

should be considered to

adopt

differentrequirements

from distinct ventures. Itemphasizes

how toflexibly synchronize

the

conceptual

models and the data structure and how toes-tahlish a network communication interface. Communication

interfacing

isimportant

for a distributed PDMS to meet the need ofmanaging

andsharing

information. Since the STEP-based system is anobject-oriented

system, most communica-tion interface relies on Java,CORBA,

or DCOM to achieve the distributed environment.STEP utilizes SDAI to

integrate

the systemby sharing

the AIMproduct

data of information systems such as CADsys-tem, PDMS, etc.

~?0,? 1 ~.

The SDAI can beregarded

as anAPI

(Application Programming

Interface) to store and share theproduct

dataindependent

of thesystem’s physical layer.

The SDAI should not be usedduring

thepractical

utilization stage since it ismerely

an interface tooperate

the database of EXPRESSlanguage.

The STEP-based data based on theap-plication

object

level ismanaged

by

using

HLDAI(High

Level Data Access Interface) that is auser-friendly

interfacewith an

application

view. A STEPengineer

can access the STEP database without an SDAI or AIMby

using

theHLDAI

(High

Level Data AccessInterface).

A STEPengi-neer shall construct the STEP data

exchange

systemaccord-ing

to its kernel data schema that is a data structure definition of informationsystems.

2.

System

ArchitectureThe bolder lines in

Figure 2

indicate themethodology

ap-plied

todevelop

the STEP-basedrepository

system in this paper. Theintegrated product

data models in STEP arecre-ated

by

a UMLmodeling

tool that generatesprogrammable

C++ codes and is translated into an

object-oriented

database,POET. The

generated

C++ codes are used todevelop

theap-plications

in thepresentation

layer,

while theobject-oriented

database isready

forstoring

the instances of the data models.Any

change

in theconceptual

models willimmediately

after the data models in thephysical

layer.

An 00 management mechanism, such as an OODBMS or serializationmecha-nism of

object-oriented

language,

is used todevelop

STEP-based PDMS toaccomplish

the management of STEP-basedinformation,

rather thanusing

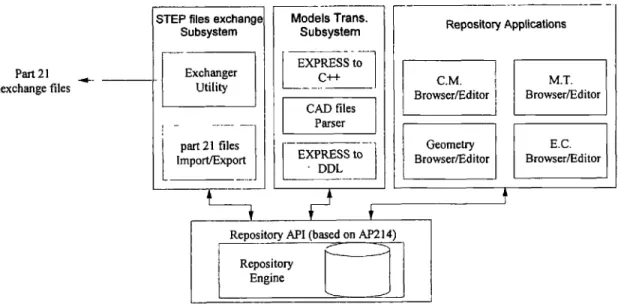

SDAI or HLDAI.A STEP-based

product

datarepository

isdeveloped

to ful-fill therequirements

ofproduct

datamanagement,

exchange,.

andsharing.

Theproduct

information models followISO-10303,

STEP standard, while dataexchange, sharing,

and managementmethodology

follow themethodologies

de-fined in STEP. Therepository

canexchange

product

data and manage the CAD models and technical information asil-lustrated

inFigure

5. The functional components include anInternet-based

exchange

subsystem,

applications,

utilities, and arepository

database with an accessapparatus.

Defining

theproduct

data modelsusing

STEP standard-izcs the informationrepresentation

to assure theimplemen-tation of information

sharing.

The STEP filesexport/import

functions in thesystem

can be used togenerate

theexchange

files. Theaccompanying

utilities andapplications

can beused to demonstrate the

integration

andmanagement

capa-bility

of STEP-basedrepository.

The hest

possible

model of the STEPsystem

must becre-ated herein since the

quality

of the models affects theimple-mentation of the

system.

A subset data models based onAP2 14 is used as the kernel information models of the

infor-mation within the

development

andmanufacturing

stages

in thetarget

industry

[22],

This section describes thedevelop-ment of each task,

including modeling

the information mold-els,developing

kernel database,developing

theapplications,

anddeveloping

the utilities. Thefunctionality

andimple-mentation

methodologies

used in thepilot

system aredis-cussed in detail.

2.1 Overall

System

ArchitectureThe

repository

system should have thefollowing

compo-nents to manage

product

informationeffectively,

database management system with database interface,repository

sys-tem with access interface, utilities, and

applications,

asillus-trated in

Figure

6.The database interface

provides

theregistration

function, themanipulating

functions ofapplication

interfaces and meta-data, and themanaging

functions of user informationand database

engine.

Therepository

interfaceprovides

thevaulting, formatting,

andbrowsing

functions of allexecuting

threads. The utilities,including

system

administration and functions management,provide

and maintain information infrastructure andoperations.

The userregistration,

manage-ment, and verification are alsusupported

by

the utilities. Theapplications

provide

the end-user with aworking

interface tofulfill their

requirements.

Theimported

andexported

infor-mation follows the subset data models of AP214 in STEP1231.

The information i*eti-leB-zil andexchange

of theapplica-tions in the system,

including product

information and CAD models, follows ISO-10303 Part 20 serials like Parts 2 and 22.2.2

Modeling

the Information ModelsThe

conceptual

data models of therepository

system mustbe modeled to define the data schema. The models include AAM, ARM, AIM, and other models with

specific

program-ming language.

AAM is used to model theactivity

models withindesign

andmanufacturing

stages

while the dataman-aged

within theactivity

is modeled in ARM. ARM is thenmapped

onto the standardized data models in STEP. AIM is then translated into the models in C++ forimplementation

by

the

object-oriented language.

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

54

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

2.2.1

MODELING

CONCEPTUAL DATAMODELS

The

conceptual

data models of therepository

system in-ctude AAM, ARM, and AIM. Allconceptual

data Illodelv of the tablcs and CAD models in thcpilot

system arerepre-sented

using

EXPRESSlanguage

and illustratedby

EX-PRESS-G.

Thcaphlicatiun objects

of CAD models and theten sets ot~ technical information,

including engineering

re-)ated documents, material,

specification. expressed

with EX-PRESS models are defined andrepresented by

EXPRESS-G notation. The context of theconceptual

data models can be classified as the information models of CAD models and technical documents. The data models of CAD models in AIM follow AP?()3 in STEP, white the ones in the technical documents follow AP?()3, ? 1-t. and Part -t() serials parts. The AAMcaptures

the process information models in thedesign

andmanufacturing

stages. AAM utiliies IDEFOmodeling

nWhuUolo~~y.

The ARMemploys

thc’ data modes in the ven-turc. and EXPRESSlanguage

to model the information. The AIM. clcrivedhv mapping

ARM with STEP standard,reprc-,ent; STEP-based standardised

industry

data models in this paper.2.2.2 MIGRATE DATA MODELS FOR TECHNICAL INFORMATION AND CAD MODELS

Thc CAD geometry information mode) represents the

product-oriented

data structure wpresented

inFigure

I . The technical information, orproduct-oriented

data structure, isrepresented by

miscellaneous industrial table sheets. An item view is used to combine the technical information w ith the CAD models so one can track the informationthrough

the entireentity.

With this mechanism, we can reduce dataex-change, reformatting,

data management,design history,

doc-ument barriers

I ~41

whileimplementing

concurrentengi-ncerin~~.

2.2.3 IMPLEMENTATION MODELS

All

implementation

models used to define the data models of therepository

and theapplications

follows UML forOOA and OOD of theapplications.

The Data Mudels (I.E. Static Modets) andSequence

Muclels ( I.E.Dynamic

Modeb) of thcapplications

are used to manage the data structure andoper-ating

procedures.

Since theconceptual

data modelsof

prod-uct information are

specified

by

EXPRESSlanguage

and EXPRESS-Ggraphical

notation, the EXPRESSlanguage

is translated into C++ format tor use as thc reference models for the data schema of therepository

system.2.3

Developing

DatabaseThe database interface of the

repository

system manages thc databaseaccording

toconceptual

models. The informa-tiontechnology

will not be restrictedby specified

methods since theapplications

arc notdirectly

connected to a database Illanagementsystem.

Thcrelationship

of allobjects

with alist of functions and attributes of classes can be obtained

us-ing

UMLmodeling language

tospecify

the API. The API oCthe

repository

comes from the database API. which isspeci-t’icd

by

UML. EXPRESS-C models andIDL (Interface

Defi-nitionLanguage)

can also be used to handleobjects

within the CORBA architecture. Theapplications

of therepository

system useconceptual

models to access the information stored in the databasethrough

a set of interfaces. Theappli-cation interfaces can he from the lowest level API, which is the kernel

application

interface, to thehighest

levelAPI,

which is theapplication-oriented

API. Theapplication-ori-ented API can use the information models to map the

corre-sponding

instance to findthe necessary

information. The API can he classified into four kinds of API: Kernel AP1.Dictionary

API, Classification API. andObject

API. The relational database management system is usedby

therepository

system as the kernel database. A DDL(Data

De-scription Language)

isgenerated

and used to setup the table schema and data schema of the RDBMS. Theapplications

can access information of the tablc; or CAD models

through

the RDBMS. With the EXPRESS-tl)-DDL translator. the EXPRESSlanguage

can be translatcd into thecorresponding

DDL. The definition andrelationship

betweenobjects

can bemapped

into thecorresponding

data schema. Therefore, thegenerated

DDL can be used to get the definition andrelation-ship

of theobject-oriented

models in the RDBMS.The database access

operations

of theapplications

use theODBC

Bridge

of the RDBMS to communicate with the data-base. These accessoperations

encapsulWe corresponding

SQL

statements. Forexample,

the &dquo;Add New&dquo;operation

will Iencapsulate

thc INSERT statementof SQL.

while the &dquo;Edit&dquo;operations

willencapsulate

the UPDATE statementof SQL.

All of these

operations

will bepackaged

as a set of API. ODBC is used as the standard access interface of databaseto

amalgamate

with other RDBMS. Theapplications

Litilize the ODBCBridge

of the RDBMS to sendSQL

statement toeasily

access theobject

information of the databasethrough

ODBC interface. Theapplications

can use the same API toaccess data from distinct database to

amalgamate

different RDBMS. even ODBMS with an ODBCbridge.

2.4

Developing Applications

The

configuration

management,engineering

dataman-agement. geometry, and

ordering applications

are alldevel-oped according

to the AAM models advanced herein. Theconfiguration

managementapplication

can be used toman-age the

product configuration

data of therepository.

Thecontent of the

con figuration

data consists of theproduct

defi-nition as Wc’ll Wengineering change

request,suggestion,

andengineering change

issue. Theengineering

dataapplications

can be used to manage the

repository’s engineering

data, such as material management and testreport.

Thegeometry

application

is used todisplay

and render the 3D CAD model of theproduct,

while theordering application

can he used tomanage the data from the

purchase

department.

The

upplications

use kernel APIencapsulating

theSQL

of the database to access the kernel database. The API ot’there-© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

56

Figure 7. Functionality of the repository system.

pository

accesses the kernel database because the API ispackaged

as the API of therepository.

Theexport/import

subsystem

translates information from/to therepository

witha STEP-based

approach.

Thesubsystem

can be a stand-aloneapplication

or a module of anapplication.

It can be classifiedas an

export/import subsystem

or a CAD roodelexport/im-port

subsystem dcpending

on its function. Themajor

func-tionality

of thesubsystem

istranslating

the information of the tables or CAD models to and frompart 21

formats.The browser and editor are the fundamental

function-alities for each

application

of therepository

system, aa illus-trated inFigure

7. Theapplication

instances of thephysical

objects

and therelationship

between theseobjects

aredis-played

with different views. The structural browser andedi-tor divide the

graphical

user interface into twopartitions:

arapid display

of the information items on the left, and the content of the item selected on theright.

Different form views with proper controls should be used todisplay

its in-formation for distinctapplications

of the tables. A browser for CAD models is also animportant

issue forapplication.

A browser for AP203 CC6 isdeveloped

to solve the inconsis-tency for STEP 1 iles of distinct CAD systems. Anintegrating

system is alsodeveloped

to move the information from theCAD

systems

and therepository

system. 2.5 UtilitiesThe system

administration,

application

management, andauxiliary

tool utilities can be used tohelp develop

and main-tain all information in therepository

system.

Themajor

func-tions include:1. To

generate

and manage theproduct

data models of therepository

system2. To generate and manage the data schema in the

repository

system3. To record the user’s information for

managing

the user’sprivilege

4. To translate information from and to proper format, such

as EXPRESS to C++ codes, and translation between CAD systems

The

exchange

utility

isdeveloped

in Java to secure usage across distinctplatforms

between industries to transferpart

2 1-iles. Theexchanger

can monitor the progress of files andexamine the

completeness

of theexchange

files. It can beused in either server or client modes for

switching

the roles forapplication requirement.

The transaction information could also be saved to trace the user’slogin.

The translators used in thispaper adopt

one of the UG and CATIAsystems

toavoid the information loss.

3.

Implementation

The

repository

system

is tested in twomanufacturing

in-dustries.industry

A andindustry

B, toverify

thesystem

ar-chitecture.

Industry

A has the entirerepository

system, whileindustry

B, the first-tieredsupplier

ofindustry

A,

has just

theapplications

andexchanger.

Theprocedures

are discussedseparately

because theprocessing

of tables and CAD modelsare not the same.

’rhe CAD translators used for the test are UG and CATIA

translators, which are the

major

CAD systems used in the twoindustries. The

operating

system used forthe UG translator is Microsoft NT 4.0, while the one used for the CATIAtransla-tor is the IBM RS6000 UNIX. Both of these CAD translators

can translate the native CAD models into standard formats

based on AP203 and AP214. The translators for AP203 and IGES 5.3 of the two CAD systems are used to translate solid and surface CAD models to

verify

the CAD models transla-tionby

STEP and IGES. Theexchanger

utility

runs on both© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

PC Windows NT 4.0 and IBM RS6000 UNIX environments because of the

system

environments of the industries. Theapplication

scenario is theco-design

situation between thesetwo

industries.

Industry

Aemploys

aconceptual design

orengineering

change

case, and then transfer relatedinfoma-tion.

including

CAD models and related technical informa-tion. toindustry

B.Industry

B evaluates theconceptual

de-sign

orengineering change

and then transfers theirdesigns

orsuggestions

for that case. The same process isrepeated

as thefinal

design

isapproved

and themanufacturing

andordering

information is readied forproduction.

The screendumps

forthe

developed repository

systems

andexchanger

areillus-trated in

Figure

8. 3.1 Scenario 1Industry

A translates theengineering

data and CAD mod-els of aproduct

and then sends them toindustry

B.Applica-tion A includes

configuration

management,

engineering

data,

geometry,

andordering applications

as illustrated inFigure

9. Eachapplication

has itscorresponding conceptual

data modelsusing

EXPRESS,

formedby

a serial of processfrom AAM to

implementable

models in Section 2.2. The fi-nal models are translated and built into the Oracle databasesof the

repository

system.

The databases utilize the datastruc-ture, schema, and definition of the

migrated

data models toassure data

consistency.

Theapplications

of therepository

can then be

developed

based on these databases.Geometry

information is included in theproduct

informa-tion, since theproduct

information is linked andmanaged by

PDMS. Thepart 21

files of the CAD models aregenerated

from the translator of UG and CATIA. The

part

21 files inin-dustry

A aregenerated by

the translator of the UGSystem.

A STEP CAD model viewer for AP203 isdeveloped

to render the 3D models to browse the CAD models in part 21 formats. Thepart

21 files areparsed

and stored in thecorresponding

tables of the databases in

repository

to store thegeometry

in-formation inpart

21 tiles. Both of theseoperations

aresup-Figure 8. Screen dumps for the developed repository system.

© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

58

Figure 9. Working process of the applications of the repository system.

ported

inapplication

A since the source of thegeometry

in-formation can be

part ?

1 files in thedirectory

of the disk ordatabases in the

repository.

3.2 Scenario 2Industry

B receives theengineering

data and CAD models of aproduct,

and then sends back thedesign

informationaf-ter

design

orredesign. Application

B consists of theconfigu-ration management,

engineering

data, geometry, andorder-ing applications

ofindustry

B, as illustrated inFigure

9.Although

industry

B has no datarepository,

the informationexchange

andmanagement

can also beaccomplished by

us-ing

part 21exchange

files.Application

Bimports

andex-ports the

part 21

files of theengineering

data and CAD mod-els fromindustry

A. Since theconceptual

data models of each table arepre-knmvn

to these ten sets ofapplications,

thedata from

application

A can be received andinterpreted by

application

Bdirectly by mapping

the samemigrated

mod-els. Thisprocedure

is alsoapplied

to the dataexchange

of CAD models fromapplication

A.New

part ?

1 files of the CAD models from the CATIAsys-tem are

generated

and thenpassed

toindustry

Athrough

theexchanger

after theredesign

orengineering change

of the CAD files. The STEP viewer is used to browse thepart 21

I files of the CAD models inapplication

A as in scenario l. Thepart ?

1 files of the CAD models aregenerated by

the translator of CATIAsystem.

4. Conclusion

Product data

exchange

andsharing

mechanism can beac-complished

based on therepository

system.Figure

10illus-Figure

10. Product data exchange and sharing mechanisms for STEP-based repositorysystem. © 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

trates the summary

of applicable methodology

of the STEP-basedrepository

system. R 1 and R2 are the full set of there-pository

system,

while A I and A2 represent theapplication

of therepository

system without arepository

database. The dataexchange

andsharing

scenarios can be R-R,R-A,

orA-A. The data

exchange

andsharing

mechanism are listed inFigure

I ():part 2).

SDAI withaccessing

databasefunctional-ity,

ODBC,accessing

API of DBMS, COM or CORBA. Themechanism

using

part

21 relies on thequality

andflexibility

ofimport/export

functional module to assure thequality

ofthe data

exchange

andsharing.

The mechanismusing

SDAI relies on theflexibility

of information modelsmanagement

and translation to assure the

quality

of the dataexchange

andsharing.

The mechanism thatemploys

ODBC relies on the translation andconsistency

of information models from theobject-oriented

data structure and relational data structure toassure the

quality

of the dataexchange

andsharing.

Themechanism that

manipulates

the API of DBMS relies on theflexibility

of information models management and transla-tion. The mechanismusing

COM or CORBA relies on thedevelopment

of services on distributed environment to as-sure thequality

of the dataexchange

andsharing.

Thesemechanisms co-exist to

accomplish

the dataexchange

andsharing

between and within industries.The data

repository

developed

herein is used to setup the management system for technical document and CAD mod-els. The informationexchange

andsharing

is easy to processbecause the information

representation

and management is based on standardizedproduct

data models. The interna-tional standard, STEP, secures theimplementation

andex-tensibility

of therepository

system. The systemintegration

of miscellaneous systems, such as MRP, MRPII, PDMS, ERP, can be ensured with the standardized data models. The sameapplication

will be extended to other areas of themanu-facturing

industries toorganize

their virtualenterprise

envi-ronment and promote their

productivity.

References1. K. Hodota, "Product and information

life-cycle

withproduct

configuration

database system on Internet," in 21stCentury

Commerce & CALS EXPO International

Conference

’97, 1997.2. A.

McKay,

F. Erens, and M. S. Bloor,"Relating product

defi-nition andproduct

variety,"

Research inEngineering Design,

vol. 2, pp. 63-80, 1996.

3. O. A. Suarez, J. L. A. Foronda, and F. M. Abreu, "Standard based framework for the

development

ofmanufacturing

con-trol

system,"

International Journalof Computer Integrated

Manufacturing

System,

vol.11,

pp.401-415,

1998.4. J. K. Wu, T. H. Liu, and G. W. Fischer, "An

integrated

PDES/STEP based information model for CAE and CAMap-plications,"

in The Second InternationalConference

onAuto-mation

Technology,

1992, pp. 179-187.5. Y. M. Chen and Y. T. Hsiao, "A collaborative data

manage-ment framework for concurrent

product

and processdevelop-ment," International Journal

of Computer

Integrated

Manu-facturing System,

vol. 10, pp.446-469, 1997.

6. R. Jordim-Goncalves et al.,

"Implementation

of computerinte-grated

manufacturing

systemsusing

SIP: CIM case studiesus-ing

a STEPapproach,"

International Journalof Computer

In-tegrated Manufacturing System,

vol. 10, pp.172-180,

1997. 7. Y. V. R.Reddy

et al.,"Computer

support for concurrentengi-neering," Computer,

vol. 26, pp.12-16,

1993.8. G. L. Smith and J. C.

Muller, "PreAmp—a pre-competitive

project

inintelligent manufacturing technology:

anarchitec-ture to demonstrate concurrent

engineering

and informationsharing,"

ConcurrentEngineering :

Research andApplica-tions, vol. 2, pp. 107-115, 1994.

9. F. Chaxel, E.

Bajic

and J. Richard, "Mobile databases nodes formanufacturing

information management: a STEP basedap-proach,"

The International Journalof

AdvancedManufac-turing Technology,

pp. 125-133, 1997.10. I.

Bailey,

P.Spiby,

and J.Vuoskoski,

"Pilotimplementation

of processplant lifecycle

functional dataexchange conforming

toSTEP AP-221, Part 2:

Logical

&physical

data models," ES-PRIT-IV,PIPPIN,

1997.11. P.

Spiby

and D. Sanderson, "Introduction to EXPRESS 2," ISO SC4/WG10 Document N58, June 1998.12. L.

Bernosky, "Turning legacy

data intoenterprise

informa-tion," in 21stCentury

Commerce & CALSEXPO InternationalConference

’97, 1997.13. D. An et al., "A

product

dataexchange integrated

structureus-ing

PDES/STEP for automatedmanufacturing application,"

Computers

Industry Engineering,

vol. 29, pp.711-715, 1995.

14. Y. Tanaka et al., "Product data

sharing

among distributed het-erogeneous PDMs," in CALS EXPO ’97 International, 1997. 15. S. D. Urban et al., "Aheterogeneous,

active databasearchitec-ture for

engineering

datamanagement,"

International Journalof Computer

Integrated

Manufacturing System,

vol. 7, pp. 276-293, 1994.16. S. D. Urban, J. J. Shan, and M. T.

Rogers,

"Engineering

datamanagement

archieving

integration through

databasetechnol-ogy," Computing

& ControlEngineering

Journal, pp.119-126, 1993.

17. D. L.

Spooner,

"Anobject-oriented

product

databaseusing

ROSE,"

Journalof

Intelligent

Manufacturing,

vol. 5, pp. 13-21,1994.18. S. K. Ke and S. C. Yeh, "The

pilot

system for STEP-basedproduct

dataexchange,"

in CALS/EC EXPO ’98Japan,

pp. 197-206, 1998.19. S. Rahimifard and S. T. Newman, "A

methodology

todevelop

EXPRESS data models," International Journal

of Computer

Integrated

Manufacturing System,

vol. 9, pp. 61-72, 1996. 20. R. N.Botting

and A. N. Godwin,"Analysis

of the STEPstan-dard data access interface

using

formal methods,"Computer

Standards &

Interfaces,

vol. 17, pp. 437-455, 1995.21. A. Goh et al, "A

study

of SDAIimplementation

onobject-ori-ented databases,"

Computer

Standards &Interfaces,

vol. 16,pp. 33-43, 1994.

22. H. Scheder,

"Requirements

of car manufacturers forproduct

data management in an extended

enterprise,"

STEP-Forum97,

1997.

23. ISO, 1997, ISO 10303-214 CDII—Core Data for Automotive Mechanical

Design

Processes, 1997.24. B.

Prasad,

Concurrentengineering

fundamentals, Vol. 2,Inte-grated product

development, Upper

SaddleRiver,

N.J., Prentice Hall PTR,1996-1997,

pp. 367-375.© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com

60

Chun-Fong

YouChun-Fong

You,

Associate Pro-fessor in theDepartment

of Me-chanicalEngineering,

NTU, got his Master’s and Ph.Ddegrees

from Cranfield Institute ofTechnology,

UK. Hisprofessional specialties

in-clude Solid ModelSystems,

Com-putatioilal

Geometry

and theInte-gration

of CAD/CAM.Shen-Chou Yeh

Shen-Chou Yeh received his Master’s

degree

in MechanicalEn-gineering

from NSYSU. He iscur-rently

a Ph.D student at the NTUworking

in the area ofproduct

dataexchange,

sharing,

andmanage-ment

using

STEP. His researchin-terest is in the

enabling

technologies

for STEP-based informationsystem

anddeveloping

andimplementing

STEP-basedmanufacturing

indus-try standard in Taiwan.© 2000 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

at NATIONAL TAIWAN UNIV LIB on August 25, 2008

http://cer.sagepub.com