The R&D system for industrial development in Taiwan

Tain-Sue JanT, Yijen Chen

National Chiao Tung University, Department of Management Science, 1001 Ta Hsueh Road, Hsinchu 30050, Taiwan Received 4 July 2004; received in revised form 20 December 2004; accepted 26 January 2005

Abstract

The research and development (R&D) system for industrial development in Taiwan is made up of three parts: industrial firms, government-supported institutes (GSIs), and academic institutes and universities. The Taiwanese experience showed that the effective interaction of the GSIs and the industrial firms has successfully supported the development of its industry. The Industrial Technology Research Institute (ITRI) played the key role in industrial development during recent decades. This study provides a comprehensive analysis of ITRI and the way in which it fulfills its role through an examination of its major tasks. The implications for developing countries are also discussed.

D 2005 Elsevier Inc. All rights reserved.

Keywords: R&D; Industrial development; ITRI; Task analysis

1. Introduction

The research and development (R&D) systems both of developed and developing countries are generally made up of three parts, namely industry, government, and academia [1,2]. In Taiwan, this system is composed of industrial firms, government-supported institutes (GSIs), and academic institutes and universities[3,4]. Most industrial firms in Taiwan are small and medium-sized enterprises1(SMEs). In 2002 SMEs represented 97.72% of the total number of firms[5]. Since most SMEs lack their own

0040-1625/$ - see front matterD 2005 Elsevier Inc. All rights reserved. doi:10.1016/j.techfore.2005.01.005

TCorresponding author.

E-mail addresses: jts@mail.nctu.edu.tw (T.-S. Jan), yjchen@itri.org.tw (Y. Chen). 1

According to the May 2000 definition of SMEs in Taiwan, in the case of the manufacturing, construction and mining and quarrying sectors, SMEs are defined as those enterprises with paid-in capital of less than NT$80 million or regular employees not exceeding 200 persons[5].

R&D resources, industrial development requires support from government and related R&D agencies. In addition, large enterprises tend to rely on their foreign partners for supporting technology acquisition and thus spend little on independent R&D activities [6]. Therefore, the government partially or wholly supports R&D agencies for purposes of technological development either through in-house development or by introducing technologies from developed countries[7]. The technologies are then transferred to the industrial firms so that the firms can conduct and improve their product development with low R&D risk.

Taiwan has two major institutes for industrial development: one is the Chung-Shan Institute of Science and Technology (CSIST) and the other is the Industrial Technology Research Institute (ITRI). The former is devoted to developing technologies for military sectors, and the latter is for civilian ones. CSIST was set up in 1969 under the direction of the Ministry of Defense. The special task of CSIST is the development of critical weapon systems such as missiles and the IDF fighter [8]. Unlike the development of military technologies in developed countries, most of the key technologies of these weapon systems were developed by CSIST itself and manufactured by military sectors. CSIST has been so dedicated to weapons systems technology development that it has contributed little to civilian industrial development during the last few decades.

Established in 1973, ITRI is a government funded R&D agency. In contrast to CSIST, ITRI is dedicated to technological development for civilian industries. ITRI is the largest non-profit research institute in Taiwan, and it fulfills a crucial role in R&D system development for Taiwanese industry. As an R&D agency, ITRI conducts R&D projects to develop technologies. Then ITRI transfers the technologies to the industrial firms for direct commercialization or for the development of commercial products. ITRI has successfully created the semiconductor industry and assisted the development of the information, optoelectronics, automotive, and machine tool industries[9–12]. Currently, some of these industries have significant positions in the international market. For example, two of the leading semiconductor foundry companies, Taiwan Semiconductor Manufacturing Company (TSMC) and United Microelectronics Company (UMC), are ITRI spin-off firms.

Before 1980, Taiwanese government policy did not encourage universities to engage in joint research ventures with industry[13]. Government R&D agencies such as the Academia Sinica, the most famous academic institute in Taiwan, play a central role as a conductor of basic research. The interactions between academic institutes and industrial firms have been so limited that the academic institutes have made less of a contribution to industrial development in Taiwan.

In summary, although the R&D system for industrial development in Taiwan consists of three parts— industrial firms, GSIs, and academic institutes—the effective interaction of the GSIs and the industrial firms is the most important factor in industrial development, a factor in which ITRI has played a critical role during the recent decades. In this paper, we will describe the background of ITRI, and then we will use the Mintzberg’s method of role and task analysis to explore the actual activities of ITRI. Finally, we will also apply this role analysis in order to compare the R&D systems for industrial development in the Newly Industrializing Countries (NICs).

2. Background of ITRI

ITRI is a nonprofit government-sponsored institute with two critical missions for industrial development. One is to upgrade existing industries through technology infusion and the other is to

implement government industrial policies by spearheading new high-tech industries[9,14–16]. In order to strengthen traditional industries, ITRI sets up laboratories or research centers to develop relevant technologies through short and medium-term R&D projects. These laboratories contract with industrial firms for the improvement in both quality and manufacturing processes of existing products. The main laboratories or centers of ITRI are summarized inTable 1. Later, the main laboratories or centers were extended to become the major subsidiaries of ITRI. ITRI also provides resources such as technical assistance, open laboratories, human capital, and technological information to industrial firms. Moreover, ITRI has set up testing centers for automobiles, electronics products, medical devices, and other products. In Taiwan, since industrial firms lack the R&D capacity to develop new industries, ITRI has become the key player in creating selected strategic industries. In such cases, ITRI has set up laboratories to conduct pre-competitive R&D projects sponsored by the Ministry of Economic Affairs (MOEA). Once projects are completed, technology is diffused through spin-offs, technology transfers, seminars, workshops, and industrial services. Forming a spin-off company based on a product developed in the laboratory is an effective method of technology diffusion[16]. ITRI moves a product from the laboratory to pilot production. Pilot production allows for the transfer of operating capabilities to a spin-off company. The government gets dividends after the companies begin to generate adequate revenues[17].

Table 1 ITRI chronology

Major subsidiaries of ITRI Related industries

Union Industrial Research Laboratories was founded in 1954 and evolved into the Union Chemical Laboratories (UCL) in 1983.

Chemical industry

Metal Industries Research Center was founded in 1969 and developed to become the Mechanical Industry Research Laboratories (MIRL) in 1982.

Machine tool, precision machinery, and automobile industries

The Electronics Industrial Research center was founded in 1974 and evolved into the Electronics Research and Service Organization (ERSO) in 1979.

ERSO focused on the Electronics, semiconductor, optoelectronics, computer, and communication industries Having restructured, ERSO adjusted to a new focus on the electronics, semiconductor, and flat panel display industries Materials Research Laboratories (MRL) was established in

1982.

Material industry Center for Measurement Standards (CMS) was founded in

1985.

Measurement instrument industry Electro-Optics and Peripherals Development Center was

spun off from ERSO in 1987, and then evolved into the Opto-Electronics and System Laboratories (OES) in 1990.

Optoelectronics industry

ITRI forced ERSO to restructure, which led to the subsequent separate establishment of the Computer and Communications Research Laboratories (CCL) in 1990.

Computer and communication industries

The fact that ITRI provides emerging technologies for businesses forced UCL and CMS to separate relative functions and establish the Biomedical Engineering Center (BMEC) in 1999.

Pharmaceutical, biomedical, and medical instrument industries

SoC Technology Center (STC) was founded to capture the emerging technology and to integrate multiple disciplinary competence between ERSO, OES, and CCL in 2003.

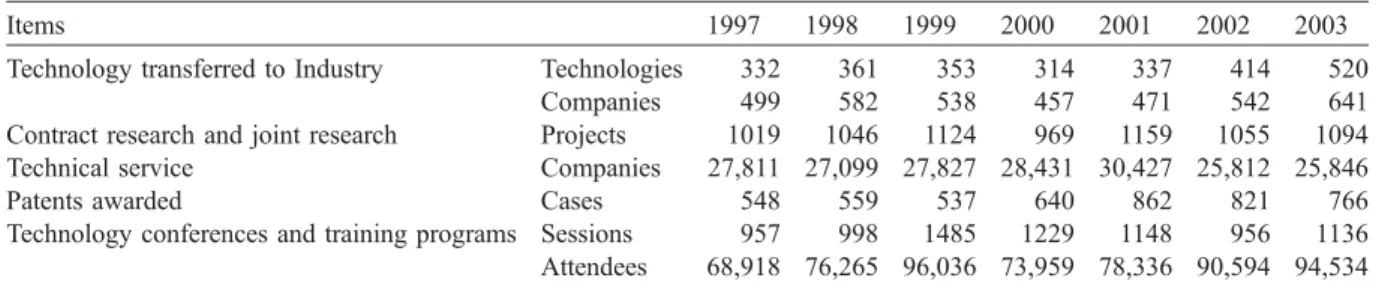

At present, ITRI has seven laboratories and five centers in which their R&D activities are undertaken. ITRI has been involved in a wide range of research fields, such as chemicals, computers, communications, electronics, optoelectronics, mechanics, materials, biotechnology, nanotechnology, energy, environmental protection, and industrial safety and health. The outputs of ITRI are summarized

inTable 2. Currently, ITRI’s budget is about US$500 million annually, as shown inFig. 1. ITRI obtained

about 54% of its funding from government-supported technology development programs, and the other 46% of its budget comes from industrial firms for contract research, joint research, and technical services. This means that ITRI gets about $230 million per year from the industrial sector for research services and technical assistance. ITRI provides services to assist private companies in generating internal revenues for additional research projects. ITRI has more than six thousand young and energetic researchers, and nearly 60% of its researchers hold advanced degrees. The diffusion of the human resources of ITRI into the industrial sector has been a great benefit to the country’s industrial

0 1000 2000 3000 4000 5000 6000 7000 '73 '74 '75 '76 '77 '78 '79 '80 '81 '82 '83 '84 '85 '86 '87 '88 '89 '90 '91 '92 '93 '94 '95 '96 '97 '98 '99 '00 '01 '02 '03 fiscal year number of employees 0 100 200 300 400 500 600 700 800 900

number of new patents awarded;

bud

g

et(US$M)

number of employees number of new patents awarded budget(US$M)

Fig. 1. ITRI operation and patents awarded. Table 2

Outputs of ITRI

Items 1997 1998 1999 2000 2001 2002 2003

Technology transferred to Industry Technologies 332 361 353 314 337 414 520

Companies 499 582 538 457 471 542 641

Contract research and joint research Projects 1019 1046 1124 969 1159 1055 1094 Technical service Companies 27,811 27,099 27,827 28,431 30,427 25,812 25,846

Patents awarded Cases 548 559 537 640 862 821 766

Technology conferences and training programs Sessions 957 998 1485 1229 1148 956 1136 Attendees 68,918 76,265 96,036 73,959 78,336 90,594 94,534 Source: The Annual Report of ITRI, 1997–2004.

development. In the past, more than 16,526 experienced engineers have left ITRI, about 81% of whom were transferred to private firms [14]. Today, many top managers of Taiwanese high-tech companies formerly worked for ITRI.

The development of ITRI is an evolving process. The establishment of each laboratory or research center is responsive to the R&D requirements of the industrial firms or the government’s need to develop new strategic industries. That is, these laboratories and centers have been set up to respond the requirements of the industrial environment. Although each laboratory or center conducts various R&D tasks, it seems that there are some R&D tasks that are common across the laboratories and centers. This paper utilizes the method of Mintzberg, who analyzed managerial activities by examining managers’ roles and tasks [18,19], to explore the common tasks of ITRI.

3. Roles and tasks analysis

In order to conduct a comprehensive analysis of the ways in which ITRI helps the industrial system in its development, this study uses the method of Mintzberg in his observations on the actual activities of managers by focusing on an analysis of their roles and tasks. Through a role analysis, we can see that ITRI has been vested with three major roles in industrial development: in a strategic capacity, as a facilitator, and by providing technical support.

Strategic role: the implementation of industrial policies as a government R&D agency and an initiator of new industrial firms. When the government plans to develop strategic industries that did not previously exist in the national industrial system, ITRI plays this role by through initiating, developing, and supporting activities.

Facilitating role: the facilitating of R&D capacities and various resources of the government and the industrial firms by creating an environment for increasing the efficiency of innovation, sharing costs, and reducing risks. This role can be further divided into two roles of ITRI as coordinator and incubator. The former involves coordinating industrial firms and research institutes by forming R&D alliances; the latter entails incubating high-technological firms.

Technical support role: the direct provision of technical assistance in order to meet the requirements of the industrial firms. This role can also be further divided into two roles of ITRI as technical partner and R&D agent. The former involves providing technical services and transferring technologies to industrial firms, and the latter entails acting as an R&D agent for domestic firms by contracting R&D projects.

Through task analysis, we find that ITRI has focused its energies on six tasks: spin-offs, R&D alliances, technology incubation, technology transfer, contract services, and technical services. The roles and tasks of ITRI are shown inTable 3.

3.1. Strategic role

When the government plans to develop strategic industries that did not previously exist in the national industrial system, ITRI plays a vital role by creating strategic industries through a well-planned strategy of assimilating foreign technology or generating new technology and transferring it to local firms through spin-offs. The success of this strategy depends on the vision of the leader, elaborate long-term planning, the commitment of resources, and the execution team. In order to play this strategic role, ITRI has focused on spin-offs to develop these strategic industries.

3.1.1. Spin-offs

Spin-offs are flagship companies and are intended as models of entrepreneurship to inspire new development in the industry. ITRI provides technologies, equipment, and human resources, and then combines these with industrial system capital to establish new spin-off companies. The creation of such spin-offs effectively stimulates technological investment and economic development. As of 2003, ITRI Table 3

The roles and tasks of ITRI

Roles Tasks Interactions Major outcomes

Strategic roles Spin-offs (Initiator) Spin-offs are flagships and are intended to be models for entrepreneurship, to initiate new development of the industry; New companies established by ITRI; New companies involving ITRI-developed intellectual property, ITRI’s staff, and/or pilot plant

ITRI spun off at least 12 new companies, including semiconductor manufacturing, automation, and optoelectronics firms; ITRI initiated Taiwan’s integrated circuit and industrial automation industries

Facilitating roles R&D alliances (Coordinator)

ITRI is an important player in integrating local firms and research institutes into R&D alliances; Through tightly knitted interaction, providing an opportunity for speeding up the efficiency of innovation and reducing risks.

Laptop PCs, Ethernet data switches, electric scooters, four-cylinder automotive engines, etc.

Technology incubation (Incubator)

Assisting new entrepreneurs with the incubator program, ITRI provides an environment for research communities, reduces the cost and risks for the industries, and initiates investment

ITRI successfully incubated over a hundred new companies with a total capitalization of approximately US$1 billion

Technical support roles Technology transfer (Technical partner)

Licensing of key components or technologies developed by ITRI to local firms; Licensing and sale of intellectual property rights to local firms

Helped industry break the established players’ monopoly; CD-ROM and DVD player total solutions (pick-up head, controller, spindle motor), carbon fiber bike frame, derailleur, etc.

Contract services (R&D agent)

Conducting new product

development, process improvement, and technology consulting under commercial contract to existing local companies; ITRI is as a local industry’s R&D partner

Upgrading traditional industries such as machine tool, motorcycle, textile, chemical, etc.

Technical services (Technical partner)

ITRI offers various services to local firms. These include testing, certification, instrument calibration, professional training, technical information, parts machining, and IPR infringement appraisal

Every year around 25 thousand firms needed ITRI for technical services in various technological fields; Every year ITRI holds about 900 sessions, activities attended by 60 thousand individuals

has successfully established 12 spin-offs, including semiconductor manufacturing, automation, optoelectronics, and biochip firms [14].

ITRI has fostered the rises of UMC, TSMC, TMC (Taiwan Mask), and VIS (Vanguard International Semiconductor), all international semiconductor companies that have attracted huge investment from overseas, and comprise the foundation of the semiconductor industry in Taiwan. The Taiwanese semiconductor industry began in the mid-1960s, when foreign enterprises used the low labor costs of Taiwan to establish their encapsulation plants. Crucial to the true development of the Taiwanese semiconductor industry was the intervention of the government in 1974 in establishing ERSO (Electronics Research and Service Organization) within ITRI, a government-supported R&D institute responsible for supervising the development of the semiconductor industry, and for providing relevant key technologies and human resources. ERSO was crucial in establishing the Taiwanese electronics industry through technology R&D, technology transfers and spin-offs. In 1976, ERSO introduced the 7 Am CMOS (Complementary Metal Oxide on Silicon) IC (integrated circuit) design and production process technology from RCA of the United States. Then in 1977, ERSO established the first IC pilot plant in Taiwan. Through absorption, utilization, and self-development, ERSO converted IC production process technology into merchandise and conducted a pilot run program. To avoid emphasizing production capacity at the expense of R&D at ITRI, ITRI considered transferring the merchandising to the private sector. At this stage Taiwan had no semiconductor industry, and the private sector lacked the confidence to establish IC firms. Therefore, ERSO decided to transfer technology and human resources to ITRI-derived companies. In 1979, UMC, the first IC company in Taiwan was born.

In 1982, ITRI initiated research on and development of Very Large Scale Integrated (VLSI) semiconductor production processes, and upgraded the 7 Am process to 2 Am technology. In 1987, R&D by ITRI resulted in the spinning off of Taiwan’s first 6-in. wafer fabrication foundry, TSMC, which was also the first pure semiconductor foundry in the world. ITRI transferred some 100 of the engineers it had trained to this spin-off and used its pilot plant as the manufacturing site for the fledgling TSMC. TSMC ran successfully right from the earliest stages of its development. This smooth running can be attributed to the transfer of personnel and equipment. In mid-1988, the production technology of TSMC was just nine months behind that of TI and Intel. The advanced semiconductor production process technology and the operating model of the semiconductor foundry led to the establishment of the semiconductor encapsulation, testing, and design industries as well as the consolidation of the Taiwanese semiconductor manufacturing industry. Taiwan did not have a complete system for the vertical division of the semiconductor industry by 1988, although one was gradually appearing[20]. To establish a complete supply chain for the semiconductor industry and to prevent brain drain, beginning in 1989 ITRI organized the transfer of people, technologies and equipment to the first photomask company in Taiwan, TMC. Since then Taiwan has had a complete semiconductor industrial system, including sub-industries in IC design, photomask manufacture, wafer fabrication, IC packaging and testing, with each sub-industry specializing in its own area of expertise[20]. In 1991, ITRI continued to conduct R&D on sub-micron production technology, and it developed the 0.7 Am and 0.5 Am production process technology in 1993. Additionally, ITRI invested NT$5.77 billion (approximately US$192 million) in technologies in order to spin off the first 8-in. wafer fabrication manufacturer in Taiwan, VIS. ITRI not only transferred semiconductor technologies but also provided VIS with the most advanced facility and equipment. This spin-off stimulated Taiwan’s DRAM (Dynamic Random Access Memory) manufacturing industry.

To summarize, ITRI has contributed greatly to the development of the Taiwanese semiconductor industry. ITRI established the ERSO, used government projects funds earmarked for semiconductor

technological capability, and introduced technologies from advanced nations. ITRI established UMC, TSMC, TMC, and VIS through technology absorption, utilization, and self-development. The Taiwanese semiconductor industry was thus established from the ground up.

3.2. Facilitating role

ITRI plays a facilitating role by orchestrating R&D capacities and various resources from government agencies and the industrial system. ITRI creates a constructive environment for speeding up research commercialization, sharing costs, and reducing risks to local companies. ITRI has focused its energies on the two tasks of creating an R&D alliance and the incubation of technology, which contribute to its facilitating role. These tasks have greatly contributed to the strengthening of interactions among government-supported research institutes, universities, and the industrial sector. Thereby the industrial system can better utilize R&D capabilities and bring research commercialization into being.

3.2.1. R&D alliances

R&D alliances are defined as including various cooperative researches and development mechanisms between industry, academia, and research institutes. Forming R&D alliances is a strategy by which corporations can speed up technology creation, acquisition, accumulation, and utilization. Since ITRI is a non-profit organization which has no commercial interests, it has also been successfully involved in R&D alliances with various firms for joint R&D, and with industry associations. R&D alliances have involved participating firms much more directly in co-developing core technologies or new technological standards which can be incorporated by the companies, through adoption and adaptation, into their own products[12]. Firms participating in the industry system trust ITRI to play a neutral role in institutionalizing specifications and maintaining market order, and they are ready to cooperate with ITRI in forming R&D alliances with manufacturers in order to share R&D costs, reduce risks, rapidly develop technologies, and so achieve time-to-market advantages. Over the last 15 years, at least 60 such R&D alliances have been established by ITRI in various industrial sectors. Such technological cooperation contributes to the industrial learning process, from imitation to innovation, and has created various new industries in Taiwan [12].

The development of the Laptop or Notebook PC (Personal Computer) industry provides a typical example of the above process. Desktop PC products matured during the 1980s. ITRI realized that a vacuum existed in the laptop PC market as well as in previous PC R&D efforts, which had provided hardware, operating system, and microcomputer system technological capabilities. However, in the Taiwanese Desktop PC industry, only a handful of industry leaders (most notably Acer) had caught the marketing trend. The remaining firms in the industry did not understand the technologies and the market. Moreover, it was still difficult to acquire certain key components and to establish uniformity in product specifications. Based on past technological successes, the Computer and Communications Research Laboratories (CCL) of ITRI proposed the ideas of bcommon machine architectureQ and bkey component standardizationQ to reduce investment risks and other barriers to firms’ self-development. CCL announced the new project and that they hoped to use bcommon machine architectureQ and bkey component standardizationQ strategies to develop a series of standardized components produced by Taiwanese manufacturers through mass production. Consequently, a division of labor was established in the industry, increasing the rate of domestic production and product competitiveness.

CCL/ITRI actively negotiated with the Taiwan Electrical Appliance Manufacturers’ Association (TEAMA)2, and announced this structure to local companies to attract their interest. In July 1990, 46 firms jointly established the Taiwan Laptop PC Consortium (TLPC) with TEAMA and CCL, using capital of US$2 million contributed by member firms. As agreed, members jointly conducted the development of new products and the institutionalization of certain standards and specifications. TLPC quickly completed a prototype and displayed it at the Comdex Fall computer show in 1990. This prototype demonstrated Taiwan’s technological capabilities for producing Laptop PCs, and laid a foundation for developing Laptop PCs in Taiwan. ITRI has created an R&D alliance to raise product standards, establish a division of labor among industries in order to reduce firm R&D costs, upgrade the technological level of the Taiwanese Laptop PC industry, and attract over 100 firms to participate in manufacturing. These measures have made Taiwan into a major global supplier of Laptop PCs.

3.2.2. Technology incubation

A technology incubator is an innovative system designed to assist entrepreneurs in the development of new technology-based firms, both startups and fledgling companies [21]. For ITRI, technology incubation activities help strengthen interactions between research institutes and industry, promote research commercialization, create opportunities for researchers to better utilize their capabilities. These activities effectively link technology, capital, and know-how to nurture entrepreneurs in order to accelerate the development of new companies and speed the commercialization of technology.

ITRI Incubator was established in 1996. ITRI Incubator was the first incubator in Taiwan and has undergone rapid growth over the years since its inception[22]. ITRI Incubator creates an environment that encourages Taiwanese industry to access the R&D resources of ITRI. ITRI Incubator targets entrepreneurs for the startup of new businesses. It assists new entrepreneurs, provides an environment for research communities, reduces the cost and risks for the industries, and initiates investment and personnel training. By June 2002, ITRI Incubator has successfully incubated over a hundred new companies with a total capitalization of approximately US$1 billion [14]. The areas that these new companies cover include telecommunication, precision machinery, biomedical, IC design, optoelec-tronics, and materials.

3.3. Technical support role

ITRI will offer technical assistance when industrial firms need it. To play its role of providing technical support role, ITRI has focused on technology transfer, contract services, and technical services in order to support industrial development.

3.3.1. Technology transfer

Technology transfer is the practical application of know-how, technical knowledge, or technology. The technology transfer process usually involves moving a technological innovation from an R&D organization to a receptor organization such as a private company[23].

2

The TEAMA now is known as the Taiwan Electrical and Electronic Manufacturers’ Association, TEEMA. The TEAMA is an industrial association that includes newly emerging industries like IC, PC, as well as traditional industries such as consumer electronic products and equipment.

The Taiwanese industrial system has developed numerous OEM-oriented (Original Equipment Manufacturer-oriented) firms that are highly proficient in manufacturing. However, these firms generally lack key technologies and thus pursue their own R&D capacities to develop technologies in order to ensure their long-term competitiveness. In these cases, the role of ITRI is to perform high-quality R&D and create the necessary key technologies, and then to transfer the resulting technologies to industry for commercialization via patent licensing, technology licensing, and personnel dissemination. By fulfilling these functions, ITRI has helped in achieving the prosperous development of related industries, and even changing the structure of the industry. Using key technologies it developed, ITRI assisted the industry in the areas of CD-ROM (Compact Disk Read-Only Memory)/DVD (Digital Versatile Disk) total solutions, carbon fiber bike frames, derailleurs, special chemicals, synthetic fibers, and more.

The case of optical disk drives (ODD) is an example in which ITRI played a crucial role in developing and diffusing local technological capabilities, in this case for CD-ROMs [24]. Taiwanese CD-ROM manufacturers were basically system integration producers. During the early stages of development, Taiwan possessed no autonomous technologies for key parts or components. Firms thus had to purchase pickup heads, spindle motors, and chipsets from major firms like Philips, OAK, Sony, Sanyo, Matsushita, and Toshiba. Taiwanese firms then combined these purchased parts and components with self-manufactured PCB, firmware, and mecha-loaders to produce finished products. In 1987, ITRI established the Opto-Electronics and System Laboratories (OES) and began work on optical disks; OES completed a prototype of a 5.25W writeable CD-ROM drive in 1991. In 1992, funded by the government, OES/ITRI actively carried out programs for CD-ROM development and the development of key parts and components. Subsequently, in 1994, CD-ROM began to become the standard storage device used in personal computers. As a result, numerous domestic firms invested in the development and production of CD-ROM. Because of the shortage of human resources with the necessary technological skills, these Taiwanese CD-ROM manufacturers poached OES personnel to work in industry. Consequently, human resources drained from OES to the industrial sector. OES transferred optoelectronics technology to over 20 local firms and provided over 40 optoelectronics technology engineers to the CD-ROM industry of Taiwan, representing a major injection of resources into the industry.

Having accumulated sufficient technology and production facilities, Taiwanese CD-ROM manufacturers led the CD-ROM industry along a path of rapid development. Specifically, these manufacturers achieved rapid improvements in product speed, as well as price competition resulting from rapid expansion of production capacity. Under keen price competition, Japanese manufacturers were compelled to pull out of the CD-ROM market because of their relatively high production costs. South Korean and Taiwanese firms stepped in to fulfill orders released by Japanese firms. In 1999, the volume of Taiwanese CD-ROM production overtook that of Japan for the first time, and Taiwan became the leading global CD-ROM manufacturer. However, foreign manufacturers monopolized the supply of costly key components, such as pickup heads, spindle motors, and controllers. Consequently, Taiwan was constrained by high production costs, seriously threatening the development of Taiwanese firms.

As such, ITRI proactively focused on the development of key components for CD-ROM. In 1997 and 1998, ITRI developed six types of pickup head modules and transferred these technologies to three manufacturers. ITRI assisted Acute Applied Technologies Inc. in establishing mass production technology, which enabled the company to begin mass production in 2000. By May 2002, the company could produce up to 700,000 units of product per month. In the spindle motor area, Sunonwealth Electric

Machine Industry cooperated with ITRI in 1996 to develop High-Speed CD-ROM drive spindle motor products. ITRI then transferred the DVD drive spindle motor technology, and established the Sunon Motor in 1999 especially for the purpose of manufacturing different types of drive spindle motors for local CD-ROM/DVD firms.

To further this development, ALi and ITRI engaged in a joint venture in 1997 for developing DVD-ROM (Digital Versatile Disk Read-Only Memory) Controller Channel Chipset. Owing to sluggish market growth, ALi and ITRI launched DVD player chipsets instead of DVD-ROM controllers. In 2001, average production volume per month exceeded 1 million units. ALi and MediaTek gained over 80% of the DVD controller market share in China. This enabled ALi and MediaTek to force Toshiba and Sony out of the mainland Chinese market. Due to ongoing R&D, in a continuing effort to improve production quality in Taiwan and thus break the Japanese monopoly, Taiwanese companies have developed total solutions for DVD players and DVD ROM.

In sum, the transfer of technologies and human resources from ITRI, the development of industrial R&D capacity, and the support for R&D have all contributed to the successful development of the ODD industry in Taiwan.

3.3.2. Contract services

ITRI has also played the role of a long-term R&D partner to traditional industries. The machine tool industry provides a good example. The Mechanical Industry Research Laboratories (MIRL) of ITRI has acted as a long-term R&D partner to the machine tool industry. This industry is associated extensively with other industries, and is fundamental to the structure of Taiwanese industry. Therefore, the machine tools industry is essential to the survival of the entire machinery industry, and many countries have located this industry as a strategic one. In 1969, total machine tool production in Taiwan was just US$9 million[11]. In contrast, by 2002 Taiwan was the sixth-largest producer of machine tools in the world, with total machine tool production of US$1.7 billion. This industry is primarily comprised of SMEs. Most of these firms are export-oriented, and exports have comprised over 75% of production during the last five years. These machine tool producers are concentrated geographically, with approximately 75% of them located in and around Taichung (a city in central Taiwan). To effectively support the development of the industry, MIRL/ITRI established the Taichung Technology Service Department in 1987 to provide technical and design support. In 1995, this department was expanded into a R&D center, which conducted R&D and technology service work on advanced machinery for tools, controllers, key parts and components. The Taichung branch of MIRL/ITRI interacted closely with the industry, in turn contributing to rapid technology innovation and diffusion [11]. MIRL/ITRI provides technical design and support to various machine tool producers. The top 20 firms in the industry (most notably Taichung Machinery Works and Fair Friend Group) have close relationships with MIRL/ITRI, and regularly assign MIRL/ITRI to develop new machine tool models (CNC lathe and machining centers, for example) or key components (CNC controllers and high speed spindles, for example). Consequently, the R&D center of MIRL/ITRI also is a major R&D partner for the machine tool industry.

3.3.3. Technical services

The government has consistently provided long-term research funds to sustain ITRI in developing industrial practices for the establishment of unique research facilities and the training of specialists, which could in turn support Taiwanese enterprises by providing technical assistance for product

development. Because of this, enterprises can maintain the quality of products that are marketed locally, regionally, and internationally. ITRI utilizes assorted technical services to play its role of technical support for industry development. ITRI provides various technical services to companies and individuals in the industrial system by request. These services include products testing, products certification, calibration of measuring equipment, parts machining, technology assessment, professional training, technical information, Intellectual Property Rights infringement appraisal, etc.

ITRI offers assistance to industry in performance products testing, assessment and certification so as to maintain acceptable standards for products that are marketed domestically and globally. Starting in 1995, roughly 25 thousand firms a year required ITRI to provide technical services in various fields, including chemical engineering, mechanics, communications, materials, and biotechnology. Taking DVD as an example, ITRI has been a member of the Steering Committee of the DVD Forum since 1998, and has participated actively in the discussion about new HD-DVD specifications [14]. OES/ITRI has established the most complete Class-A DVD verification lab in the world, and has provided verification services for the domestic ODD and DVD optical disks industry. Moreover, OES/ ITRI has helped six Taiwanese companies establish their own Class-B DVD verification labs. To take another example, MIRL/ITRI, which is fully accredited by the Environmental Protection Administration and Energy Commission of Taiwan, has established testing technologies and facilities for gasoline vehicle emissions/fuel economy and motorcycle/vehicle mileage accumulation.

In order to disseminate research results and technical information in a timely fashion, ITRI sponsors training courses, conferences, workshops, seminars, demonstrations and special events, and publishes technical reports and informational materials. Over the past five years, ITRI has developed and conducted many different interactive activities in the various technological fields; every year it holds about 900 sessions, attended by about 60 thousand individuals[14].

4. Discussion

4.1. Roles and tasks adjustment in ITRI

Once the firms in a well-developed industry have established their own R&D capabilities, ITRI turns its R&D projects over to new industries. For example, ERSO/ITRI successfully established Taiwan’s semiconductor industry through spin-offs. In order to respond to market competition, the spin-off companies, like TSMC and UMC, began establishing their own R&D centers in the 1990s to develop their own technological capacities. As a result, ERSO stopped conducting R&D projects on semiconductor process technology and diverted its resources into new research areas such as flat panel display technology, microsystems technology, and nanotechnology.

In fact, during recent years ITRI has been playing the new roles of information provider and educator in order to meet the new requirements of the government. As the industrial development environment becomes more complicated and dynamic, the government needs more technological information to help it make industrial policies. To meet this need, ITRI has established the Industrial Economics and Knowledge Center (IEK) to conduct R&D projects for evaluating the existing industry system and suggesting proposals about opportunities for developing new industries in the future. Therefore, ITRI has participated in the process of industrial policy making. In addition, ITRI, fulfilling its role as an educator, of providing high-quality training programs, founded ITRI College in

2003 to meet the new requirements of the industrial firms. Unlike a university, ITRI offers professional training courses taught by ITRI’s experienced researchers, who have themselves conducted R&D projects for industrial development. ITRI College trains and cultivates R&D professionals to supplement the scarcity of R&D human resources available from the higher education system.

In the long run, academic institutes and universities can eventually play a more vital role in industrial development. Most senior R&D researchers in Taiwan work in academia. In 2002, the number of doctoral degree researchers was 21,004, of whom 68.9% were at universities. Meanwhile, just 20.8% of the doctoral degree researchers were working in research institutes, while only 10.3% were working in the industry [25]. In the past, the academic researchers have made less of a contribution to industrial development because they were not encouraged to conduct R&D projects for industrial firms, and few firms could attract such researchers. Therefore, ITRI should play the role of coordinator in order to promote cooperation in R&D between universities and industrial firms. ITRI may foster such cooperation by launching large research programs that will facilitate the interactions between the academic R&D researchers and the industrial firms.

4.2. Further analysis of the success of ITRI

ITRI has played a critical and successful role as R&D agency for industrial development in Taiwan during recent decades. ITRI has played appropriate roles and conducted the tasks necessary to meet the government’s industrial policies and missions. However, other factors have also contributed to the successful development of industry in Taiwan. First, Taiwan has accumulated a pool of R&D human resources to conduct R&D activities. Taiwanese culture shows a preference for science and engineering over other disciplines, and society encourages students to go abroad to pursue advanced degrees. Taiwan ranked highest in the number of international students enrolled in the United States from 1983 to 1987

[26]. As a result, Taiwan has accumulated a great deal of R&D human resources from abroad. These R&D professionals have gone into the academic institutes and universities, GSIs, and industrial firms. With this large pool of R&D professionals as a resource, ITRI can act as an initiator by creating new strategic industries through spin-offs.

Secondly, the structure of the industrial firms called for the government and the GSIs to conduct R&D activities for them in the early stages of their development. Most industrial firms in Taiwan are SMEs, and large enterprises of the conventional industries spent little on independent R&D activities. Therefore, they needed the government and the GSIs to act as their R&D agency to provide their technologies for them. Among the GSIs, ITRI is the most successful R&D agency for the industrial firms.

Thirdly, Most Taiwanese industrial firms are manufacturing-oriented enterprises, not R&D-intensive ones. They concentrate their attention on cost-down activities to produce lower value-added products. Therefore, the R&D requirements of the firms are very limited. This may be a deeper reason why the interaction between academia and the industrial firms is limited. This also explains why ITRI plays such an important role in the industrial development of Taiwan. It is expected that academic researchers will increase their involvement in R&D projects for industrial firms when the firms gradually move to higher value-added products.

In summary, ITRI has played the appropriate roles and conducted the necessary tasks for assisting industrial firms. The success of the ITRI model depends on the particular cultural and economic situation

of Taiwan. The sources of R&D professionals, the structure of the industrial firms, and the policies of the government all contribute to the R&D system of industrial development GSIs in developing countries. 4.3. Role analysis to NICs

As typical newly industrializing economies, Taiwan, South Korea and Singapore are characteristic of export-oriented economies. Through role analysis, we see that GSIs play the role of an R&D agency for the government and the industrial firms in Taiwan, and the government plays the role of financial supporter to the GSIs. In contrast with Taiwan, Korean and Singaporean industrial firms conduct R&D projects by themselves, while their governments play the role of facilitator to help them develop their technology and industry.

Industrial firms in South Korea are composed of several chaebols (large firms) and some SMEs. The chaebols, such as SAMSUNG and LG, have their own R&D institutes that develop their technology. Most of the SMEs lack the resources for R&D and called on the GSIs to act as R&D agencies to meet their technology requirements. Since most of the competent researchers for industrial development are attracted by the chaebols, GSIs in Korea encounter difficulty in retaining competent researchers[27]. As a result, the Korean GSIs have R&D capacities insufficient to satisfy the requirements of the SMEs, and so the industrial development of South Korean relies on the chaebols, which set up their own R&D institutes for technology development. The Korean government acts as a facilitator, helping the chaebols obtain sufficient funds from the banking system.

Unlike Korea, Singapore is a city-state, with a small population economy. Industrial firms in Singapore are mainly composed of MNCs, and most R&D activities are conducted by these international companies. The development policy of Singapore is one of attracting the foreign direct investment (FDI) of MNCs for the country’s industrial and economic development. The Singaporean government successfully acts as a facilitator, providing superior infrastructure, efficient administration, and tax incentives for the MNCs. It seems that technological development is not the key factor in Singapore’s industrial and economic development.

5. Conclusion

The R&D system for industrial development in Taiwan is made up of three parts: industrial firms, government-supported institutes (GSIs), and academic institutes and universities. The effective interaction of the GSIs and the industrial firms has successfully supported the development of Taiwan’s industry. Among the GSIs, ITRI is the most successful R&D agency for the industrial firms. ITRI has played appropriate roles and focused on the tasks necessary to meet the technological and industrial development requirements of both the industrial firms and the government in Taiwan during recent decades.

Different NICs have their own developmental models. Through role analysis, we see that for Korea and Singapore, industrial technologies have been developed by the R&D institutes of chaebols and MNCs, respectively. In Taiwan, the industrial firms and the government call on the GSIs as their R&D agency. The ITRI experience is a valuable example to the developing countries whose industrial firms and government need their own GSIs to act as their R&D agency. In this case, factors such as the source of R&D professionals, the policies of the government, and the identification of the roles and tasks of GSIs will all contribute to the use of the ITRI model.

Acknowledgment

The authors would like to thank the anonymous reviewers for their helpful comments.

References

[1] R. Nelson, N. Rosenberg, Technical innovation and national systems, in: R. Nelson (Ed.), National Innovation Systems: A Comparative Analysis, Oxford University Press, Oxford, 1993.

[2] F. Betz, Management Technological Innovation: Competitive Advantage from Change, John Wiley & Sons, 1998, p. 74. [3] National Science Council, ROC, White paper on science and technology (2003~2006), National Science Council, Taipei,

2003, p. 11 (in Chinese).

[4] C. Hou, S. Gee, National systems supporting technical advance in industry: the case of Taiwan, in: R. Nelson (Ed.), National Innovation Systems: A Comparative Analysis, Oxford University Press, Oxford, 1993.

[5] L. Hsueh, A. Lim, G. Okrasa, White Paper on Small and Medium Enterprises in Taiwan, 2003. Small and Medium Enterprise Administration, Ministry of Economic Affairs, Taipei, 2003, p. 324.

[6] T. Jan, C. Hsiao, A four-role model of the automotive industry development in developing countries: a case in Taiwan, Journal of the Operational Research Society 55 (2004) 1145 – 1155.

[7] P. Chang, C. Hsu, The development strategies for Taiwan’s semiconductor industry, IEEE Trans. Eng. Manage. 45 (4) (1998) 349 – 356.

[8] T.-S. Jan, C.-G. Jan, Development of weapon systems in developing countries: a case study of long range strategies in Taiwan, J. Oper. Res. Soc. 51 (2000) 1041 – 1050.

[9] J. Mathews, D. Cho, Tiger Technology: The Creation of a Semiconductor Industry in East Asia, Cambridge University Press, Cambridge, 2000.

[10] F. Veloso, J. Soto, Incentives, infrastructure and institutions: perspectives on industrialization and technical change in late-developing nations, Technol. Forecast. Soc. Change 66 (2001) 87 – 109.

[11] R. Liu, J. Brookfield, Stars, rings and tiers: organisational networks and their dynamics in Taiwan’s machine tool industry, Long Range Planning 33 (2000) 322 – 348.

[12] J. Mathews, The origins and dynamics of Taiwan’s R&D consortia, Research Policy 31 (2002) 633 – 651.

[13] F. Wu, Opportunities and Challenges for the Cooperation Between Industry and University Innovation, Proceedings of the 7th Symposium in Industrial Management, Taipei, 1998, pp. 215 – 299 (in Chinese).

[14] Industrial Technology Research Institute, The Annual Report of ITRI. Hsinchu, Taiwan (various years 1991–2004). [15] O. Lin, Development and transfer of technology in Taiwan, ROC, in: O. Lin, C. Shih, J. Yang (Eds.), Development and

Transfer of Industrial Technology, Elsevier, Amsterdam, 1994.

[16] C. Hsu, H. Chiang, The government strategy for the upgrading of industrial technology in Taiwan, Technovation 21 (2001) 123 – 132.

[17] W. Boulton (Ed.), Electronics Manufacturing in the Pacific Rim. NTIS Report # PB97-167076, Loyola College in Maryland, Baltimore, 1997.

[18] H. Mintzberg, Managerial work: analysis from observation, Management Science 18 (2) (1971) 97 – 110. [19] H. Mintzberg, The manager’s job: folklore and fact, Harvard Business Review (1975 July-August) 49 – 61.

[20] P. Chang, C. Tsai, Evolution of technology development strategies for Taiwan’s semiconductor industry: formation of research consortia, Ind. Innov. 7 (2) (2000) 185 – 197.

[21] M. Yunos, Building an innovation-based economy: the Malaysian technology business incubator experience, J. Chang. Manag. 3 (2) (2002) 177 – 188.

[22] P. Hsu, J. Shyu, H. Yu, C. You, T. Lo, Exploring the interaction between incubators and industrial clusters: the case of the ITRI incubator in Taiwan, R&D Management 33 (1) (2003) 79 – 90.

[23] E. Rogers, S. Takegami, J. Yin, Lessons learned about technology transfer, Technovation 21 (2001) 253 – 261. [24] G. Noble, Conspicuous failures and hidden strengths of the ITRI model: Taiwan’s technology policy toward hard disk

drives and CD-ROMs. The Information Storage Industry Center, Graduate School of International Relations and Pacific Studies, Report 2000-02, University of California, San Diego, 2000, Also available at http://isic.ucsd.edu/papers/ Noble.shtml.

[25] Indicators of science and technology, National Science Council, ROC, 2003, p. 34, Tapei (in Chinese).

[26] Bureau of International Culture and Educational Relations, Education statistical information, Ministry of Education, Taipei, 2002 (in Chinese).

[27] L. Kim, Imitation to Innovation: The Dynamics of Korea’s Technological Learning, Harvard Business School Press, Boston, 1997, pp. 200 – 204.

Tain-Sue Jan (1952) is an associate professor of the Department of Management Science at National Chiao Tung University (NCTU) in Taiwan. In 1988, he received his PhD in management science from NCTU. His current research interests include systems approach to technology management and information management.

Yijen Chen (1955) is a special assistant to the general director of the Mechanical Industry Research Laboratories in Industrial Technology Research Institute (ITRI) in Taiwan. He is also a PhD candidate in the Department of Management Science at National Chiao Tung University in Taiwan.