國 立 交 通 大 學

管理學院碩士在職專班管理科學組

碩士論文

影響 LED 元件採購決定的因素

Influential Factors of LED Component

Purchasing Decision

研究生: 廖美蘭

指導教授: 張力元教授

Influential Factors of LED Component Purchasing Decision

Student: Monisha Liao Advisor: Dr. Charles V. Trappey

Department of Management Science

National Chiao Tung University

Abstract

The usage of LED is becoming wide spread with more creative applications. This survey explores which factors underlie the LED component purchasing decision. These insights provide LED manufacturers a means to improve services to better meet customer needs. The research also explores the relationship between LED package types and LED applications, the result provides a better understanding for LED users to select components for industrial and commercial applications.

Key word: Influential factor, LED quality, LED component, LED package type, LED application.

影響 LED 元件採購決定的因素 研究生: 廖美蘭 教授: 張力元教授 國立交通大學 管理學院碩士在職專班管理科學組

中文摘要

LED 的使用變得越來越廣泛, 而且有更多具創造力的應用。 這份論文意欲探討 是那些因素影響 LED 元件的採購決定, 這些觀察可提供 LED 工廠作為改善服務 的一個手段,以達到更符合客戶的需要的目的。這份研究同時也探討 LED 元件類 型與 LED 應用的關係, 這些結果使使用者更了解 LED, 進而有較佳的元件選擇 作為工業及商業的應用。關鍵詞:影響因素,LED 品質,LED 元件,LED 封裝類型,LED 應用。

Acknowledgement

There are many people I would like to express “thank you” to them, first of all, I want to thank you my ex-colleagues, my business associates, who helped me to do the questionnaires; secondly I want to thank you the company EOI, Formolight, EMC, who allowed me to do the questionnaires on their staffs; and finally, I want to thank you my advisor ---- Dr. Charles V. Trappey, who supervised and gave me suggestions on the writing of thesis.

Monisha Liao

National Chiao Tung University Hsin-Chu, Taiwan, R.O.C. April 2010

Table of Content

Abstract………..……….…..ii

Acknowledgement ……….. ………iv

Table of Content ………... ………...v

List of Tables .………...vii

List of Figures ………...ix

Chapter 1 Introduction ………..………..…...1

1.1 Motivation and Goal ………..….….1

1.2 Research Concept and The Research Technique ……….…….…2

Chapter 2 LED Industry ……….………..…………..4

2.1 Definition of LED ……….…...4

2.2 History of LED ……….………4

2.3 Current Stage of LED Technology Development and Application ………..…5

2.4 The LED Industries in Target Markets …... …….……...…6

2.4.1 LED Industry in Taiwan ….………. ……..………6

2.4.2 LED Industry in Europe ……….….…8

Chapter 3 Literature Review ………...11

3.1 Industrial Purchasing ………....11

3.2 Quality of LED Component ………..…….………..12

3.3 Buying Center ……….…..…………13

3.4 Re-buy ……….………..14

3.5 LED Applications ………..………...15

Chapter 4 Survey Objectives and Hypothesis ……….…….17

4.1 General Influential Factors of LED Component Purchasing ..…18

4.2 Quality Requirement of LED Component ………..……….…..19

4.3 First Time LED buyer versus Experienced LED Buyer…..…..20

4.4 R&D Personnel versus Purchasing Personnel …….………...20

4.5 Distributor versus Direct Customer ………20

4.6 Application versus LED Package Type ………...21

4.7 Outdoor versus Indoor Application ……….…………22

Chapter 5 Methodology and Research Result ……….25

5.1 Methodology ………25

5.1.1 Questionnaire Design and Pre-test ………..……....25

5.1.2 Sampling Design and Dispatch………..………..26

5.1.3 Data Collection and analysis………....26

5.1.4 Questionnaire Return Rate …….……… .26

5.1.5 Sample Distribution …………..……….…...27

5.2 Research Result ……….…. 28

5.2.1 Questionnaire Result Analysis …….……….………28

5.2.2 Hypothesis Test Result ……….…………43

Chapter Conclusion and Suggestion ………..………...46

6.1 Conclusion ………...46

6.2 Suggestion ………....47

References ……….48

Appendix A. Term Definition ………..……...53

Appendix B. Questionnaire (English)………..56

List of Tables

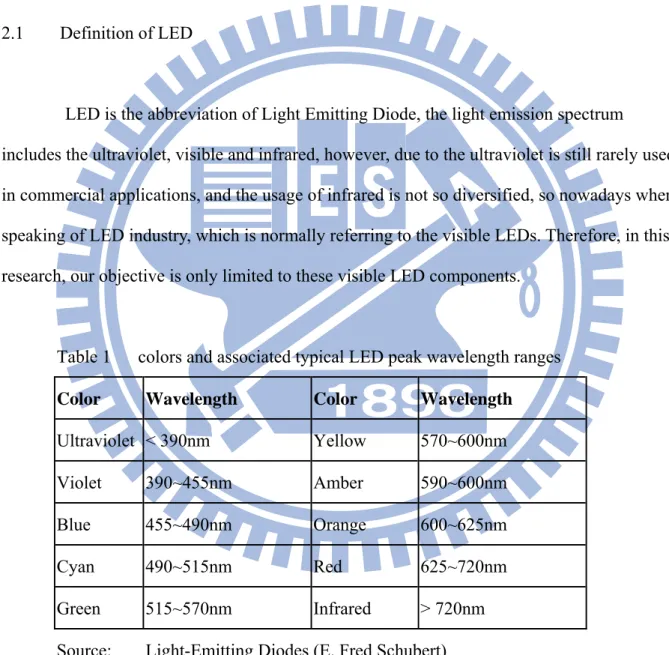

Table 1 Colors and Associated Typical LED Peak Wavelength Ranges …………..4

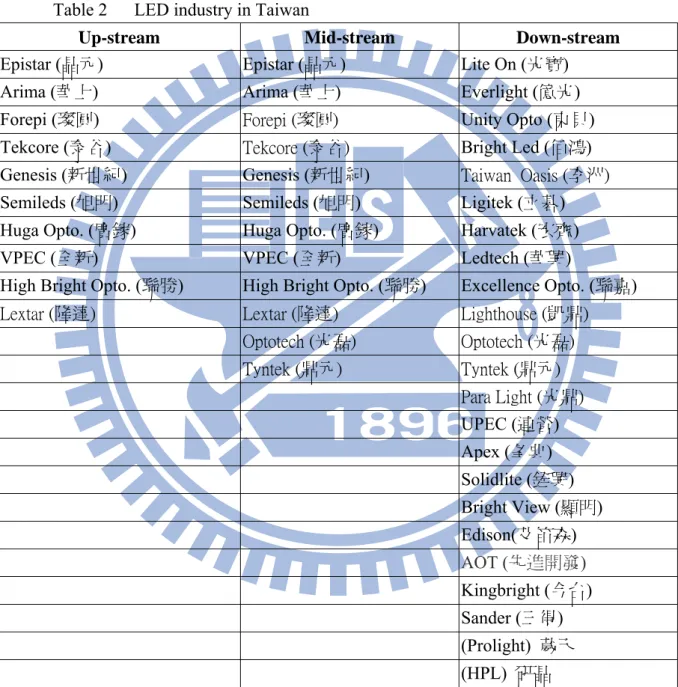

Table 2 LED Industry in Taiwan ………..8

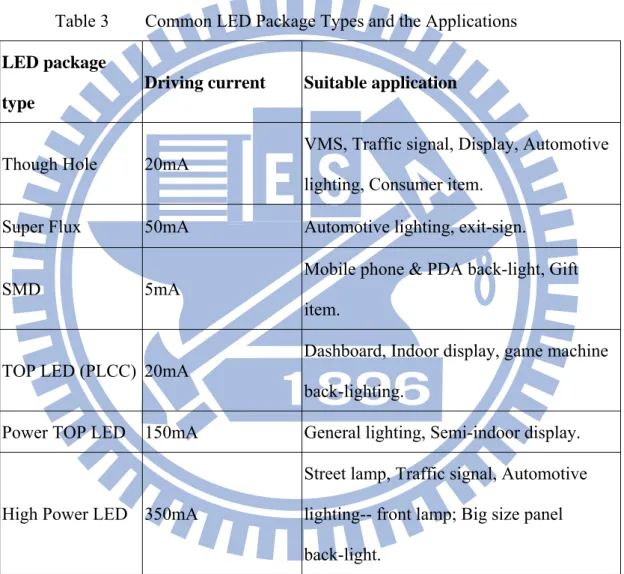

Table 3 Common LED Package Types and the Applications ……….…….16

Table 4 Category versus Hypothesis ………23

Table 5 Questionnaire Return Rate ………..27

Table 6 Sample Distribution in Categories ………..28

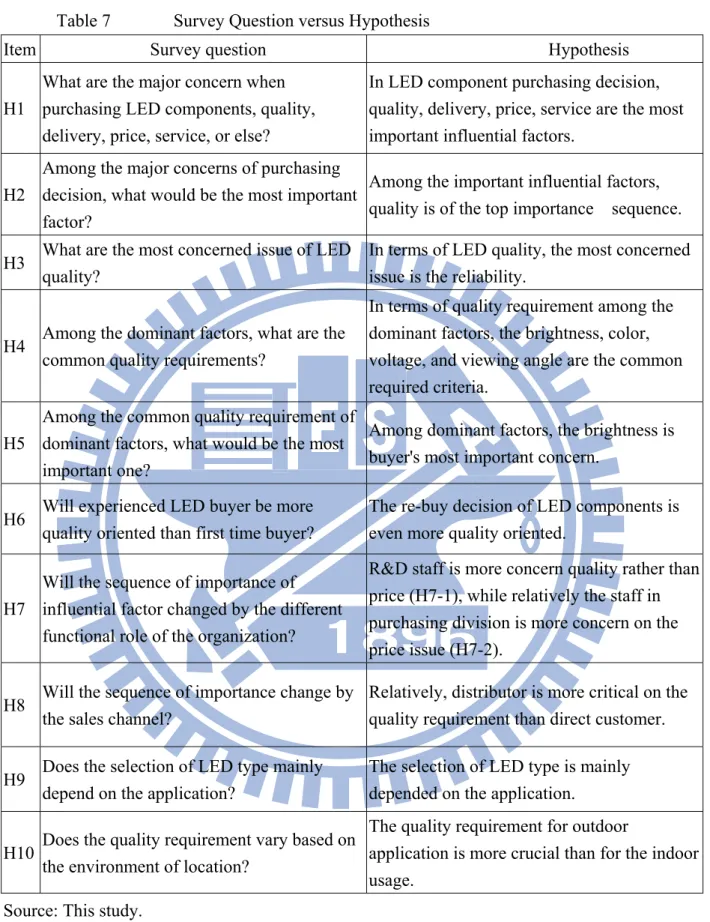

Table 7 Survey Question versus Hypothesis ………..…….29

Table 8 Mean and Standard Deviation of H1 ………..31

Table 9 T-test result of H1 ………31

Table 10 Quality versus Price ………..…32

Table 11 Quality versus Delivery ………..…..32

Table 12 Quality versus Service ………..…………32

Table 13 Quality versus Others ………33

Table 14 Binomial Test of Reliability (Recessive Factors) ………...34

Table 15 Mean and Standard Deviation of H4 ……….…35

Table 16 T-test result of H4 ……….……….36

Table 17 Brightness versus Wavelength ………..……….36

Table 18 Brightness versus Voltage ………..………37

Table 19 Brightness versus Viewing Angle ………..37

Table 20 Brightness versus Beam Pattern ………37

Table 21 ANOVA Test Result of H6 ………...38

Table 23 Paired T-test Result of R&D group ……….…39

Table 24 Sequence of Importance of Purchaser Group ……….….40

Table 25 Paired T-test Result of Purchaser Group ………..40

Table 26 ANOVA Test Result of H8 ………...41

Table 27 Binomial Test Result of H9 ………..42

Table 28 Binomial Test Result of H10 ………43

List of Figures

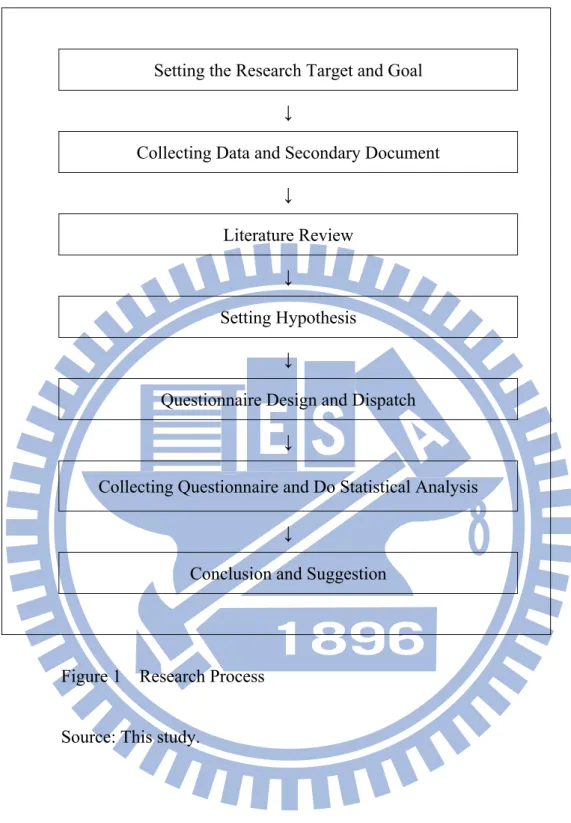

Figure 1 Research Process .. ……….3

Figure 2 Research Structure ………24

Figure 3 Influential Factors of LED Component Purchasing …..………30

Figure 4 Pro-Recessive Factors ………33

Figure 5 Recessive Factors of LED Quality ……….34

Figure 6 Dominant Factors of LED Quality ……….35

Figure 7 Purchasing Frequency of Respondents ………...38

Figure 8 First-time versus Re-buy ……….………38

Figure 9 Direct Customer versus Distributor ……….41

Figure 10 Frequency Distribution of H9 ………..…..42

Chapter 1 Introduction

In this chapter, first of all, author would like to express the motivation and goal of doing this survey; and secondly to explain the research concept and research technique.

1.1 Motivation and Goal

Because of the global climate is warming up, how to protect our planet and reduce the emission of carbon dioxide is becoming a big issue, green and energy saving industries have been put under spot light as a favorable solution.

LED (Light Emitting Diode) business has been developed in Taiwan for more than 30 years, the applications primarily had been focused on the binary LED for the low brightness application, such as: power-up indicator for equipments, numerical watches, calculators, however, this situation has been changed in the recent years. Nowadays, along with the technical development of LED, more and more applications are using LED, especially the high brightness LEDs, as their light source. Meanwhile, due to the LED characteristic of long-life, compact, energy-saving, anti-UV, is very environment friendly, it is regarded as the perfect substitution of fluorescent lamp and the next generation of lighting source.

For these reasons, many governments has put LED industry as one of their major national industries, and putting efforts to support the enterprises on the technical

improvement as well as creating business opportunities. Taking Taiwan and China for

example, governments have planned to launch many public infrastructure projects nationwide in favor of LED industry, such as: new installation or replacement of conventional traffic

signal and street lamp by using LED counterparts.

However, the purchasing of right LED for industrial application is not so easy if only judge it by the external (dominant) factors, in light of many new users of industrial

application which never apply LED components in their previous production line, the goal of this research intend to figure out the influential factors, try to determine the definition of LED quality requirement while purchasing LED components for different purpose. And believe in this way, we will be helpful to the LED industrial users to make right choice of material procurement for their products, and the LED component suppliers are able to provide the goods based on customer’s need and requirement.

1.2 Research Concept and The Research Technique

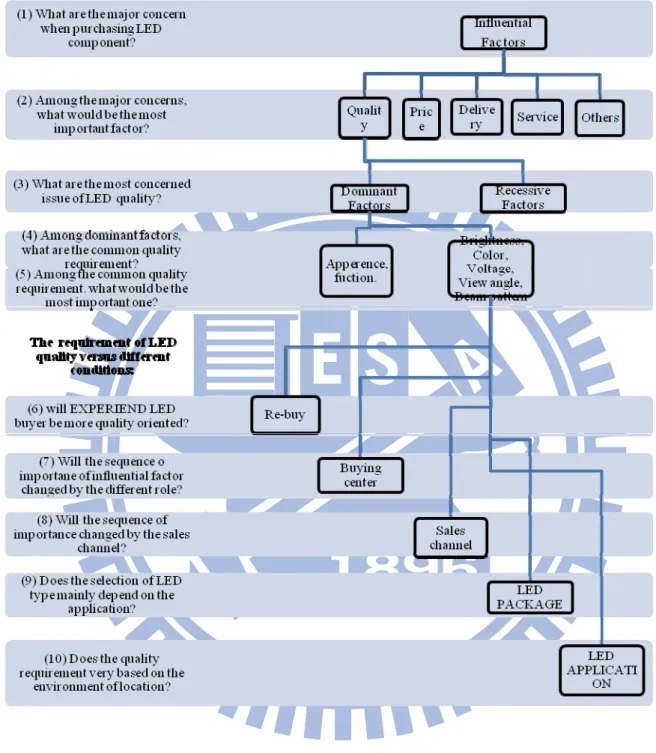

The concept of this survey is of 3 layers, the first step is to check out the influential factors of the LED component purchasing decision, and the next step is to find out what would be the most important factor among them, then, the final step is to find out if the important influential factors will be changed by different condition, or the requirement will be changed by different LED package type or LED application.

The methodology of this research is to collect data and perception from author’s years industrial practice, and review related academic literatures to set up the hypothesis, and then verify these hypothesis by means of questionnaire and statistical analysis by SPSS.

Setting the Research Target and Goal ↓

Collecting Data and Secondary Document ↓

Literature Review

↓

Setting Hypothesis

↓

Questionnaire Design and Dispatch ↓

Collecting Questionnaire and Do Statistical Analysis

↓

Conclusion and Suggestion

Figure 1 Research Process

Chapter 2 LED Industry

The content of this chapter is to descript the definition of LED, history of LED, and then the current stage of LED technology development and applications, as well as the status of LED industries in the target markets.

2.1 Definition of LED

LED is the abbreviation of Light Emitting Diode, the light emission spectrum

includes the ultraviolet, visible and infrared, however, due to the ultraviolet is still rarely used in commercial applications, and the usage of infrared is not so diversified, so nowadays when speaking of LED industry, which is normally referring to the visible LEDs. Therefore, in this research, our objective is only limited to these visible LED components.

Table 1 colors and associated typical LED peak wavelength ranges

Color Wavelength Color Wavelength

Ultraviolet < 390nm Yellow 570~600nm

Violet 390~455nm Amber 590~600nm

Blue 455~490nm Orange 600~625nm

Cyan 490~515nm Red 625~720nm

Green 515~570nm Infrared > 720nm

Source: Light-Emitting Diodes (E. Fred Schubert)

In year 1907, Mr. H.J. Round reported a light emission, yet it was invisible by human eyes, was caused by an electrical power source, , later on there were some related technical reports issued by Oleg Lossev, Rubin Braunstein, Bob Biard and Gary Pittman, and then in 1962, Nick Holonyak Jr. of General Electric developed the first visible LED (red). However, at this early stage, this new invention was not widely used due to the price was too high, only till 1968, Monsanto produced the GaAsP and supplied to Hewlett Packard for mass-producing the LEDs, mainly for the application of numeric LED displays, such as: calculators, wristwatches. (E. Fred Schubert, Light-emitting diodes, 2006.)

2.3 Current Stage of LED Technology Development and Application

LED industry is a compound technology of Semiconductor and material science, the mainstream technical development has been switched from the II-VI to III-V alloys due to the higher efficiency of light output, as the performance of III-V alloys LEDs has been improved dramatically in the past decades since 1962 the first visible LEDs were developed by Nick Holonyak Jr. of G.E . And nowadays, light emitting diode’s luminous efficacy exceeds 150 lm (lumen) per Watt. (Rssell D. Dupuis & Michael R. Krames, 2008). Moreover, the effect of multi-LED color blending provide the similar illuminated situation to halogens and

fluorescent light sources (Boissard & Fontoynont, 2009).

Under such circumstance, LED become an applicable component in many products, the applications are including street light, traffic signals, display, back-lighting of big panel, automotive lighting, architecture lighting, general lighting, agriculture lighting (for growing flower), and cover the fields of living (building), mobility, clothing, entertainment and advertising.

2.4 The LED Industries in Target Markets

General speaking, the LED industry is including the Up-stream (wafer), Mid-stream (die), and Down-stream (packaging), but in reality, it should include also the application, as no matter it is used for back-lighting, traffic sign, display or lighting, due to the characteristic of LED is so different from those applications in the conventional version, the users need to have knowledge of LED or need many engineering supports in terms of optical, mechanical, electronic and thermal design from their LED suppliers, as a result, almost all the

down-stream LED package manufactures are also engaged in the applications or offering LED modules, original equipment manufacturing (OEM), original design manufacturing (ODM ) or designing services for their clients. However, due to it would be too many to name the suppliers if we list all of them including the LED application providers and related

material suppliers, we therefore only reference the manufactures who engaged in LED wafer, chip and package as the LED industry.

LED industry in each country is various, however, Taiwanese LED supplies in principle are more focus on Chinese, Taiwanese, American, and European markets; As

Chinese and American markets are normally in charge by their branch offices or agencies, we therefore only target the Taiwanese and European market in this research.

2.4.1 LED Industry in Taiwan

In 1975, Taiwanese first LED manufacturer was set up, which acquired the equipment from Texas Instruments (TI), and manufactured the conventional LED for the applications such as, indicator of alarm, clock, later on the applications covered the

back-light of small size panel, mobile phone, PDA; as for the up-stream and mid-stream aspect, the first AlInGaP factory called United Epitaxy Company which was set up in 1993, the factory was merged by Epistar Corporation in 2005, and nowadays, there are over 10 major market players already.

Regarding the technology and usage, due to the dramatic technical improvement on the LED light output efficiency as well as on White LED, the applications were even widen to be used on many outdoor display, traffic sign, automotive lighting and general lighting, architecture lighting; and likewise, along with the technical development, the LED industry in Taiwan was transformed from the traditional to hi-tech oriented.

For example, the first field test and demonstration of LED traffic signal was installed in the Hsin-Chu Science Park in 1996, and then in year 2000 Taipei was the first city to use this new innovation, later in year 2003, one after another, Kee-Lung, Hsin-Chu, Tai-Chung, Chia-Yi, Tainan, and Kao-Hsiung also started to install LED traffic signal. By now, most of the cities and counties are already replaced the conventional traffic signal with LED’s, and in Year 2007, Taiwanese government launched a new project to replace all the remaining traditional traffic signals with LED’s within 3 years.

Besides this, the main applications of High Bright LED are including Display, Variable Message Sign (VMS), automotive lighting, landscape decorated lighting, commercial lighting, and now, the most trendy and highlighted application is LED street lamps and general lighting, as well as the back-lighting for big size TV panel.

developed for over 30 years with quite good technology recognition; and the Up-stream and Mid-stream industries were also well established since 1993; so, the overall Taiwanese LED industry structure is very well organized and completed, and play an important role in the global market.

Table 2 LED industry in Taiwan

Up-stream Mid-stream Down-stream

Epistar (晶元) Epistar (晶元) Lite On (光寶)

Arima (華上) Arima (華上) Everlight (億光)

Forepi (璨圓) Forepi (璨圓) Unity Opto (東貝)

Tekcore (泰谷) Tekcore (泰谷) Bright Led (佰鴻)

Genesis (新世紀) Genesis (新世紀) Taiwan Oasis (李洲)

Semileds (旭明) Semileds (旭明) Ligitek (立碁)

Huga Opto. (廣鎵) Huga Opto. (廣鎵) Harvatek (宏齊)

VPEC (全新) VPEC (全新) Ledtech (華興)

High Bright Opto. (聯勝) High Bright Opto. (聯勝) Excellence Opto. (聯嘉)

Lextar (隆達) Lextar (隆達) Lighthouse (凱鼎)

Optotech (光磊) Optotech (光磊) Tyntek (鼎元) Tyntek (鼎元) Para Light (光鼎) UPEC (連營) Apex (夆典) Solidlite (銓興) Bright View (顯明) Edison(艾笛森) AOT (先進開發) Kingbright (今台) Sander (三得) (Prolight) 葳天 (HPL) 研晶

Source: This study.

LED industry in Europe was various in each countries, generally speaking, it was mainly started from the Western Europe like in Germany, U.K., The Netherlands, and then gradually to other area and Eastern European countries, and like their American

counterparties, the major European LED manufacturers also move their factories or use the subcontractors in other countries, first tier companies like Philips Lumileds and Osram had their factories and sales channel all over the world, and using their patent advantage and technology development capability to keep their leading position in the market. Another similarity between European and United State LED industries is there are only few LED package manufacturers, the industry is more strong and focus on offering design service and technological integration for the LED application.

As for application, there are mainly for industrial usages, and rare for the consumer products; the most applied usages are the outdoor Display, score board, VMS in high way and at airport, train station, bus station, as for traffic signal application, the first action taken in Germany was by Siemens to cooperated with Aixtron AG and the City of Aachen, and installed the LED traffic signals in Aachen in year 1998, and after a test period with

successful result, Siemens was rewarded by the city of Aachen to retrofit about 111 junctions with LED traffic signals.

There was also experimental installation of LED traffic signal in London and Bristol in 1998, this new innovation had been adapted since, yet with slow movement, and this year (2009) London mayor Boris Johnson has announced to spend 2.4 million (pound) to replace 3,500 conventional traffic lights at around 300 junctions with LED signals.

nations, however, till now the biggest action was made in Spain, as in year 2008 Spanish government launched the biggest LED traffic signal tender of around 460,000 traffic signal heads, including 12”, 8”, 4” vehicle signals and pedestrian lights, both in 220V and 42V, to replace the traditional traffic signals with LED’s nationwide.

However, according to the regulation of European Union, the conventional light bulbs (fluorescent, halogen) will not be allowed in the market from September 2012, under the circumstance, the most trendy applications, besides the above mentioned industrial

Chapter 3 Literature Review

Chapter 3 is all about the academic literature reviews which related to this research, it includes the industrial purchasing, quality of LED component, buying center, re-buy, LED application and package, and all of these are the elements this survey would like to explore.

3.1 Industrial Purchasing

Procurement is very important and will influence the overall organizational success (Ellram, Zsidisin, Siferd & Stanley, 2002; N. Bharadwaj, 2003), and industrial purchasing are always based on the criteria and procurement definition of right time, right material, right quantity, right source and right price (Baily and Farmer, 1985; Paul Steele & Brain Court, 1996), while in terms of supplier’s point of view in industrial practice, it is said quality, price, lead time (delivery) and service determine the success of business. These are the two sides of one coin, as fulfill the former 3 elements of price (right price), quality (right material), lead time (right time), and provide good service to customer, the company would be of great chance to become the selected supplier ( the right source), to deliver the right quantity which buyer decided by either their purchasing strategy or demand. And it is found there were many academic studies also expressing such contention (Dempsey, 1978; Evans, 1981; Matthyssens & Faes, 1985; Wilson, 1994). As for the importance sequence of these elements would be very different depends on product categories or purchasing strategies, or other concerns (Bennion & Redmond, 1994; Bharadwaj, 2003; Jackson, 1985; Oliver, 1997; Sharma & Achabal, 1982), and might be changed over time (Wilson, 1994) or along with the new technologies or technical development (Cannon and Perrault, 1999).

previous studies were more focus on “ to evaluate suppliers differs by product category”, rather than to look into the “ key buying criteria” across the products and service. In his study he use the four groups: product quality, delivery fulfillment, price, post-sales service, to investigate the decision criteria which used in electronic components purchasing, and the result shown the most important criteria was the product quality.

In this research, the goal is to investigate if the major buying criteria are also among these 4 elements: quality, delivery, price, service; and to find out the importance sequence of these factors which influence customer’s decision when purchasing LED component for their application.

3.2 Quality of LED Component

Regarding the Quality, Price, Delivery, Service issues, in the LED industry, the Quality issue need to be highlighted, as the quality determine the price and also the lead time very much, if the yield rate is low to in compliance with customer’s requirement, then the cost will be high, and very likely need to produce another lot in order to get enough quantity to fulfill the order, yet in this way, the lead time will be prolonged.

Due to the quality issue is critical for LED, many studies have been focus on quality improvement, from chip material to process, to LED packaging; from upstream to

downstream, and to application. Such as: Improving the quality of injection molding during the LED Packaging process, to increase the percentage of qualification product (HE, LI & QI, 2007); With proper micro structure to reduce the residual stress in the LED chip, in order to improve the light extraction efficiency (Liuxi Tan, Jia Li, et al., 2008); the suggestion to use Multi Layer Ceramic-Metal Package (MLCMP) for high power LED to have better thermal

resistance (J. K. Park, H.D. Shin, et al., 2006); some studies tried to analyze the factors affecting color distribution of white LED ( Liu, S. Liu, Wang & Luo, 2008) or the LED-based lighting blending ( Boissard & Fontoynont, 2008), et al.. However, there were little survey worked on finding out the quality criteria of LED component.

As a matter of fact, the Quality of LED can not be measured only by “Dominant Factors”, like appearance, color, brightness, forward voltage or functional checking, but also the “Recessive Factors”, like reliability concern (life time expectation, light decay, heat dissipation, thermal shock resistance), not to mention the different color will also alter the importance of quality criteria. Under the circumstance, it is more difficult to be defined. At the side of manufacturer, the common testing is including the photometric, colorimetric, electrical parameters, such as: Luminous Intensity, Total Luminous Flux, chromaticity coordinates, peak wavelength, dominant wavelength, forward voltage, and reverse current (Zhou & Liu, 2009); yet when LED purchaser start to look for the LED components for their product, it is very important that they need to know what kind of LED is good for their usage, and which kind of quality criteria they need to set for the procurement process, and as far as our knowledge, there are not much of the studies from buyer or user’s prospect to determine the quality requirement which might be optimized to their application.

3.3 Buying Center

Most of industrial procurement decision are made by a group of people called

“ buying center” which might consists members from different divisions and with different of functional propose (Bunn, 1993). Some studies had been trying to verify the concept of the buying center, or the relative influential power in the purchasing activities. (Jackson, Keith & Burdick, 1984), and the researchers were including : Duncan 1965, Meier 1972, Wind 1978,

and Bellizzi 1981, however, the influence are vary due to the buying center structure and purchasing situation are different based on buy class, product type and type of decision (Jackson, Keith & Burdick, 1984).

In this research, the propose is to follow these academic studies, to have an empirical survey to find out if the quality requirement is vary by the different role of organization, in the LED industry. And besides the large-scaled organizational purchasing, there are also small company owners who are in the domain of company’s procurement decision (Ellegaard, 2009); and also distributors and agents, whose expectation of benefits from the relationship with suppliers might not be fulfilled (Ghosh, Joseph, Gardner and Thach, 2004), and their interests might conflict with suppliers’, so in this survey, we would try to also determine if their concern or requirement is different.

3.4 Re-buy

Buy classes were classified as three types: new buy, modified re-buy, and straight re-buy, by Robinson, Farris, and Wind (1967) in the attempt to verify some of the variations in the purchasing process (Jackson, Keith & Burdick, 1984); while, Lucero (2008) evaluated the key problems of industrial firms’ international purchasing and its post-purchase behavior, it was defined as: (1) the repeat order without modification: buyer will place order with the same product with same criteria. (2) Repeat purchase with modification: which is refer to changing supplier or criteria. (3) no re-buy.

No matter it is new buy or post-purchase, little information could be found regarding the issue of re-buy behavior in LED industry. Nevertheless, according to author’s experience in selling LED components and modules in the past 6 years, there are many of “ modified

re-buy “ behavior in terms of quality requirement, the reason might be due to there are too many new applications start to use LED as their light sources, and also many new users and buyers who never use or purchase LED components before, and are not familiar with either the LED characteristic nor the technical terms, and these new users might made some mistake or got wrong impression of LED characteristic on their first purchasing. In light of above reasons, this research intend to verify the requirement of different usage, and try to find out if there is a pattern could be followed by new and experienced LED users and buyers.

3.5 LED Applications

The applications of LED have been developing along with the technology

improvement, in the early state, LED is only good for exit-signs, back-lit and element-lit signs (graphic elements), and with great potential for traffic signs, airport runway markers, decorative purposes, spotlighting (Peralta & Ruda, 1998); up-to-date these applications are already the major popularities, moreover, there are also for the general illumination (home and office lighting, street lamps.) and for large-area flat-panel liquid-crystal displays (Russell, et al., 2008), as well as the special usages for medical applications (Zhang, et al., 2009; Aslan & Geddes, 2009). Overall, the LED applications are covering almost every kind of usage, from indicator, back- lighting, display, to general lighting, and from indoor to outdoor.

3.6 LED Packages

The package of LED is to bond the chip with PCB and envelop the chip with epoxy compound, there are many types of LED packaging with different manufacturing processes, but in general, the processes including the mounting, wire bonding, cutting, testing and packing (He, Li, and Qi, 2007) .

The common LED package types are including Through hole, Super Flux,

surface-mount device (SMD), plastic leadless chip carrier (PLCC ), and high-power LED, and each type is of its advantage and characteristic, users normally choice the suitable type to design their product, based on the optimized combination of size, illumination, voltage, viewing angle, thermal resistance, and heat dissipation.

Table 3 Common LED Package Types and the Applications LED package

type

Driving current Suitable application

Though Hole 20mA VMS, Traffic signal, Display, Automotive

lighting, Consumer item.

Super Flux 50mA Automotive lighting, exit-sign.

SMD 5mA Mobile phone & PDA back-light, Gift

item.

TOP LED (PLCC) 20mA Dashboard, Indoor display, game machine

back-lighting.

Power TOP LED 150mA General lighting, Semi-indoor display.

High Power LED 350mA

Street lamp, Traffic signal, Automotive lighting-- front lamp; Big size panel back-light.

Chapter 4 Survey Objectives and Hypothesis

Although LED is trendy and been used in many kind of application, its characteristic is very different from the previous light sources of halogen and fluorescent, only the term of “ quality “ which is referring to different criteria, and these criteria might vary depending on different application, different LED package type, and also different color. According to author’s experience in the industry practice, in general, the requirement including at least: brightness ( Luminous Intensity, Total Luminous Flux), color (chromaticity coordinates, peak wavelength, dominant wavelength), forward voltage and viewing angle. More over, there are also beam pattern and reliability issues which related to light decay, life time expectation, Electrostatic Discharge (ESD) protection, thermal resistance, heat dissipation. And the importance of these criteria is vary based on the application and also the LED package type used, and sometimes is just subjected to the buyer or user’s experience of the previous LED usage.

This research aims to find out the important factors which influence the purchasing of LED component, and the quality requirement of the LED, also the relationship between the LED type and LED application. The criteria mentioned in above paragraph are presumed the most important influential factors, in terms of quality requirement; and in industrial practice, there are also some suggestion regarding LED type used in related to the LED application (Table 3 Common LED package types and applications); based on these information and also the academic studies reviewed in the chapter 3, we therefore would like to proceed a survey and try to find out if these assumptions would be confirmed, and if there are different requirement among the various purchasing roles and the LED applications. The following research questions are derived from the literature review:

(1) What are the major concern when purchasing LED components, quality, delivery, price, service, or else?

(2) Among the major concerns of purchasing decision, what would be the most important factor?

(3) What are the most concerned issue of LED quality?

(4) Among the dominant factors, what are the common quality requirements?

(5) Among the common quality requirement of dominant factors, what would be the most important one?

(6) Will experienced LED buyer be more quality oriented than first time buyer?

(7) Will the sequence of importance of influential factor changed by the different functional role of the organization?

(8) Will the sequence of importance change by the sales channel? (9) Does the selection of LED type mainly depend on the application?

(10) Does the quality requirement vary based on the environment of location?

4.1 General Influential Factors of LED Component Purchasing

As mentioned in Chapter 3, Bhardwaj (2003) pointed out, in related to industrial purchasing, quality, delivery, price and service were the four key attributes to evaluate supplier’s performance, and among them, the quality issue was ranked as the most important element in the electronic components procurement, therefore, we set the hypothesis 1 and 2 as follows to be verified if it is also confirmed in the LED components purchasing:

H1: In LED component purchasing decision, quality, delivery, price, service are the most important influential factors.

H2: Among the important influential factors, quality is of the top importance sequence.

4.2 Quality Requirement of LED Component

As mentioned in chapter 3, the LED quality is related to “dominant factors” (appearance, color, brightness, forward voltage, function) and the “Recessive Factors” : reliability (life time expectation, light decay, heat dissipation, thermal shock resistance, ESD protection); believe the reliability is the most concern of all LED component user, however these “ Recessive Factors” could not be verified in a short time, what user could got from manufacturer is only the reliability testing data of factory’s previous production or chip as reference and assurance.

H3: In terms of LED quality, the most concerned issue is the reliability.

Regarding the “ Dominant Factors”, the common on-site testing during the LED production line is including the Luminous Intensity, Total Luminous Flux, chromaticity coordinates, peak wavelength, dominant wavelength, forward voltage, and reverse current (Zhou & Liu, 2009); which reflect the general requirement of photometric, colorimetric, electrical parameters of LED component; and due to LED’s light output is directional, on the condition of the same total luminous flux, the bigger the viewing angle, the less the dominant intensity. And according to author’s experience in LED industry, customers care the most is about the brightness. So, the hypothesis 3 and 4 are set as follows:

H4: In terms of quality requirement among the dominant factors, the brightness, color, voltage, and viewing angle are the common required criteria.

H5: Among the dominant factors, the brightness is buyer’s most important concern.

4.3 First Time LED Buyer versus Experienced LED Buyer

The buy classes were classified as: New buy, straight re-buy, and modified re-buy (Robinson, et al. 1967), and according to author’s experience working in LED industrial, there were many of modified re-buy behavior in LED component purchasing, therefore, the hypothesis set to be verified is:

H6: The re-buy decision of LED components is even more quality oriented.

4.4 R&D Personnel versus Purchasing Personnel

The purchasing decision were likely also influenced by the buy center structure and its members (Bunn, 1993), the research presumed the R&D staff is more focus on the product quality, while purchasing personnel’s work is more on the mission of cost-down.

H7: R&D staff is more concern quality rather than price (H7-1), while relatively the staff in purchasing division is more concern on the price issue (H7-2).

Ghosh, et al. (2004) investigated to understand distributor’s expected benefits from supplier, and among the indicated 7 items, “ improve overall quality” was of the great importance. Which is make sense, as selling good quality or big brand products would make easy access to their customers, and reduce their expenses of dealing with claim or defective product return, as for price, they could simply make up certain margin at the landing cost of any product distributed. However, when industrial LED user purchasing the component from LED package manufacturer, besides quality, very likely his major concern is price, because he want to cost down to keep their products to be competitive in the market, and they are capable to modify or re-layout their products based on the characteristic of the purchased LED.

H8: Relatively, distributor is more critical on the quality requirement than direct customer.

4.6 Application versus LED Package Type

Kauffman (1994) studied the influences on industrial buyers’ choice of products, and found product application and type were mattered. Although Kauffman’s study classified the product type as “ commodity “ and “ differentiated “, and the product application of

“ administrative “, “ capital “, and “ Production process “ for all product categories, in this survey, author devote in LED industry, use the product type of different LED packages and the LED applications, the propose is trying to verify the relationship between product type (LED package type) and LED application which been general used in industrial practice. For example, conventional SMD type is perfect for the mobile phone back-light device, due to its compact size and low voltage drive character; while High-Power LED is more suitable for

big TV panel back-lighting, or the street lamps, therefore, the hypothesis set as follows:

H9: The selection of LED type is mainly depended on the application.

4.7 Outdoor versus Indoor Application

According to author’s knowledge and experience, due to the outdoor environment is more crucial than indoor’s, so, even the same LED package is used, the quality requirement for outdoor and indoor application is not the same.

H10: The quality requirement of LED for outdoor application is more crucial than for the indoor usage.

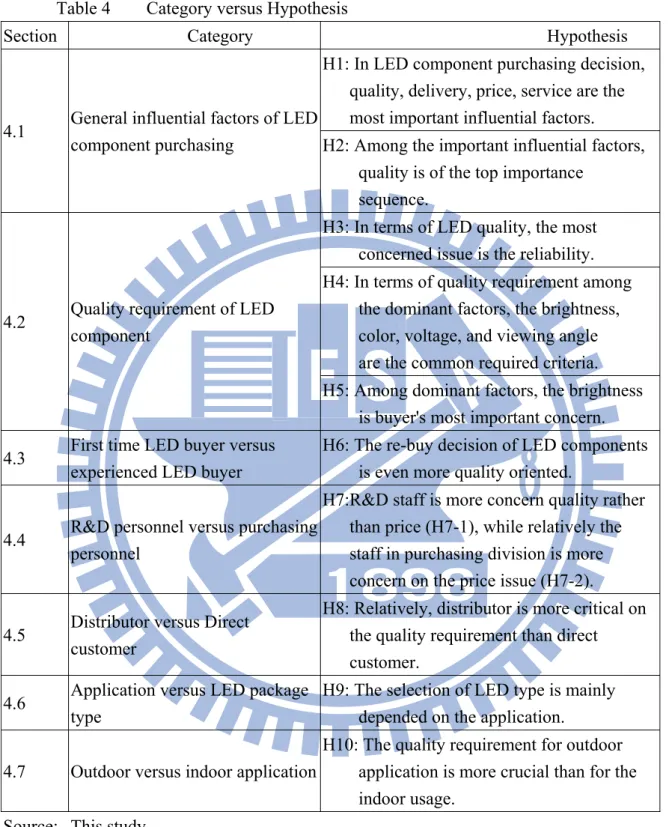

Table 4 Category versus Hypothesis

Section Category Hypothesis

4.1 General influential factors of LED

component purchasing

H1: In LED component purchasing decision, quality, delivery, price, service are the most important influential factors. H2: Among the important influential factors,

quality is of the top importance sequence.

4.2 Quality requirement of LED

component

H3: In terms of LED quality, the most concerned issue is the reliability. H4: In terms of quality requirement among

the dominant factors, the brightness, color, voltage, and viewing angle are the common required criteria.

H5: Among dominant factors, the brightness is buyer's most important concern.

4.3 First time LED buyer versus

experienced LED buyer

H6: The re-buy decision of LED components is even more quality oriented.

4.4 R&D personnel versus purchasing

personnel

H7:R&D staff is more concern quality rather than price (H7-1), while relatively the staff in purchasing division is more concern on the price issue (H7-2).

4.5 Distributor versus Direct

customer

H8: Relatively, distributor is more critical on the quality requirement than direct customer.

4.6 Application versus LED package

type

H9: The selection of LED type is mainly depended on the application.

4.7 Outdoor versus indoor application

H10: The quality requirement for outdoor application is more crucial than for the indoor usage.

Figure 2 Research Structure Source: This study

Chapter 5 Methodology and Research Result

As mentioned in the chapter 1, the methodology of this survey is proceeded by using questionnaire send to LED sellers, buyers and users, then using SPSS to do the result analysis by several statistical methods, to verify the hypothesis expressed in chapter 4.

5.1 Methodology

5.1.1 Questionnaire Design and Pre-test

Based on the hypothesis, author made survey on the targeted objects, which was described in the next section of Sampling Design, and design the questionnaire to verify the hypothesis. Firstly, author did the pre-test on 10 ex-colleagues, who working in LED industry, to see if they understand the questions, and then based on their commend and the response of the pre-test, author corrected some typing mistakes and modified the questionnaire by adding questions to ask respondents to make the influential factors in the sequence of importance.

Regarding the questionnaire design, in order to verify the quality requirement of LED components, author defined the LED quality into two sections: Dominant Factors and Recessive Factors (Reliability issue) , as the Dominant Factors are the normal on-site

inspection, while recessive factors are the long term testing of reliability, which only could be approved after a long period of time. And the questionnaire was mainly divided into five parts: the first part is regarding respondents’ profession category & company business type; the second part is related to the influential factors of LED component purchasing decision; third part is for find out the quality requirement of LED components; fourth part is in regard to the choice of LED package type and LED application; and the final part (fifth part) is the basic

personal information of respondents. As for the importance score, the Likert (5-scale) is applied, meanwhile, when respondent make the sequence of importance by A, B,C,D,E: A was converted to 5 points, B means 4 points C means 3, D presents 2, and E equals to 1 point.

5.1.2 Sampling Design and Dispatch

It is aimed to do the survey on people who work in related to LED industry, the target respondents are the LED components sellers, buyers, and users. The targeted survey market is Taiwan and Europe, and the sampling size is around 115 persons (62 copies to Taiwanese customers, mainly to 3 companies: EOI, Formolight, and EMC; and another 53 copies to European customers), which were sent to European customer by E-mail for efficiency and time saving, as for Taiwanese customers, it were either sent by E-mail or handed over the hard copies.

5.1.3 Data collectionand Analysis

The collection of the questionnaire was also by either E-mail or handed over the hard copies in person, each of the questionnaires sent back by E-mail, the correspondence was recorded and kept; and all of the data of these questionnaires were filed and kept in confidentiality for this survey only. The result analysis was proceeded by the descriptive statistic (sample distribution, frequency distribution, mean) and also the inductive statistic (Binomial, ANOVA, T-test evaluation) by SPSS.

The total sent-out questionnaires were 115, and returned copies were 81, the return rate was 70%, among them 1 copy was invalid and another 14 copies were not met the criteria (as some people with multiple job functions at work; or the business type of some companies is also of multiple function acted as manufacturer and distributor, or trading company.) , so the total analyzed questionnaires were 66 copies, which make the utility rate at 57% (66 out of 115 copies), see Table 5.

Table 5 Questionnaire Return Rate

Area sent-out sent-back Return rate Invalid not meet criteria Valid Utility rate

Europe 53 23 0.43% 1 7 15 0.28%

Taiwan 62 58 0.94% 0 7 51 0.82%

Total 115 81 0.70% 1 14 66 0.57%

Source: This study.

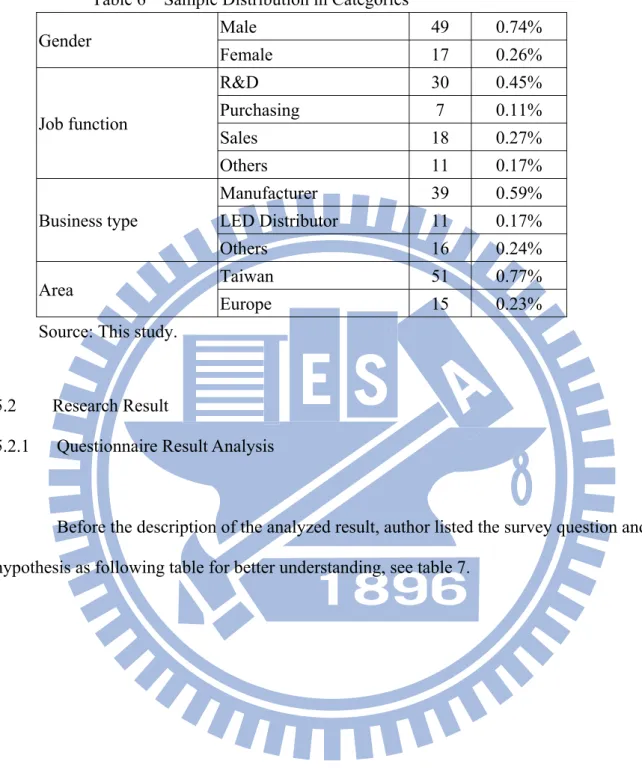

5.1.5 Sample Distribution

The total analyzed questionnaires were 66 copies(See Table 5), the sample

distribution was shown in the different categories: Gender, Job function, business type and area, in the Table 6 as reference. With some of these categories, this survey proceeded statistical analysis to verify several hypothesis in the following sections.

Table 6 Sample Distribution in Categories Gender Male 49 0.74% Female 17 0.26% Job function R&D 30 0.45% Purchasing 7 0.11% Sales 18 0.27% Others 11 0.17% Business type Manufacturer 39 0.59% LED Distributor 11 0.17% Others 16 0.24% Area Taiwan 51 0.77% Europe 15 0.23%

Source: This study.

5.2 Research Result

5.2.1 Questionnaire Result Analysis

Before the description of the analyzed result, author listed the survey question and hypothesis as following table for better understanding, see table 7.

Table 7 Survey Question versus Hypothesis

Item Survey question Hypothesis

H1

What are the major concern when purchasing LED components, quality, delivery, price, service, or else?

In LED component purchasing decision, quality, delivery, price, service are the most important influential factors.

H2

Among the major concerns of purchasing decision, what would be the most important factor?

Among the important influential factors, quality is of the top importance sequence.

H3 What are the most concerned issue of LED

quality?

In terms of LED quality, the most concerned issue is the reliability.

H4 Among the dominant factors, what are the

common quality requirements?

In terms of quality requirement among the dominant factors, the brightness, color, voltage, and viewing angle are the common required criteria.

H5

Among the common quality requirement of dominant factors, what would be the most important one?

Among dominant factors, the brightness is buyer's most important concern.

H6 Will experienced LED buyer be more

quality oriented than first time buyer?

The re-buy decision of LED components is even more quality oriented.

H7

Will the sequence of importance of influential factor changed by the different functional role of the organization?

R&D staff is more concern quality rather than price (H7-1), while relatively the staff in purchasing division is more concern on the price issue (H7-2).

H8 Will the sequence of importance change by

the sales channel?

Relatively, distributor is more critical on the quality requirement than direct customer.

H9 Does the selection of LED type mainly

depend on the application?

The selection of LED type is mainly depended on the application.

H10 Does the quality requirement vary based on

the environment of location?

The quality requirement for outdoor

application is more crucial than for the indoor usage.

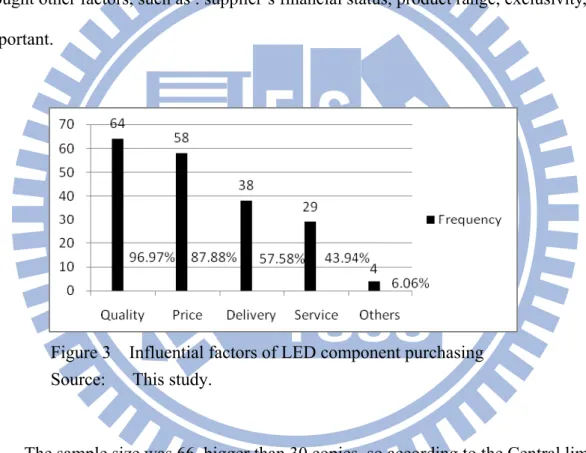

H1: In LED component purchasing decision, quality, delivery, price, service are the most important influential factors.

Result: According to the result of questionnaires, the frequency distribution (Figure 3) shown most of the people agreed the Quality (96.97%), Price (87.88%), Delivery

(57.58%) and Service (43.94%) were the important influential factors when they made decision of LED component purchasing, while only 4 out of 66 people (about 6.06%) thought other factors, such as : supplier’s financial status, product range, exclusivity, also important.

Figure 3 Influential factors of LED component purchasing Source: This study.

The sample size was 66, bigger than 30 copies, so according to the Central limit theorem, it was assumed normal distribution. This survey was using Likert 5-scale, so the value > 3 would be accepted. The Mean of Quality was 4.8485, Price was 4.6061,

Delivery was 3.8030, and Service was 3.6563, all of them shown of importance. Author used the one sample T-test to verify based on the 95% confidence interval, P < 0.05. And

the result shown Quality, Price, Delivery, Service of great significant, the P value was 0 for all of 4 items, see Table 9, so the hypothesis H1 was accepted.

Table 8 Mean and Standard Deviation of H1

N Mean

Std.

Deviation Std. Error Mean

Quality 66 4.8485 0.43826 0.05395

Price 66 4.6061 0.55133 0.06786

Delivery 66 3.803 0.78876 0.09709

Service 64 3.6563 0.96311 0.12039

Others 15 3.6 1.54919 0.4

Source: This study.

Table 9 T-Test result of H1

Test Value = 3 T value Degree of Freedom P value Mean Difference Quality 34.265 65 0 1.84848 Price 23.666 65 0 1.60606 Delivery 8.271 65 0 0.80303 Service 5.451 63 0 0.65625 Others 1.5 14 0.156 0.6

Source: This study.

H2: Among the important influential factors, quality is of the top importance sequence.

Result: Based on the above Frequency distribution of H1 (Figure 3), it shown the quality issue is the most important influential factor (96.97% ) of the LED component

purchasing decision. Author also do the T-test result based on the 95% confidence interval, P < 0.05, to compare Quality factor to Price, Delivery, Service and Others individually by the value of Mean, and all the results shown the significance (P value =0), see Table 10, 11, 12 and 13, so the hypothesis H2 was accepted.

Table10 Quality versus Price

Test Value = 4.6041 T value Degree of Freedom P value Mean Difference Quality 4.53 65 0 0.24438

Source: This study.

Table 11 Quality versus Delivery

Test Value = 3.8030 T value Degee of Freedom P value Mean Difference Quality 19.38 65 0 1.04548

Source: This study.

Table 12 Quality versus Service

Test Value = 3.6563 T value Degree of Freedom P value Mean Difference Quality 22.099 65 0 1.19218

Table 13 Quality versus Others Test Value = 3.6 T Value Degee of Freedom P value Mean Difference Quality 23.143 65 0 1.24848

Source: This study.

H3: In terms of LED quality, the most concerned issue is the reliability.

Result: In terms of LED quality, from the frequency distribution shown 58 out of 66 persons (around 88%), see Figure 4, agreed the reliability issue (Recessive factors) was the most important concern, while only about 12% of people think otherwise. And the recessive factors of LED quality was shown as follows for LED user’s reference.

Figure 4 Pro-Recessive factors Source: This study.

Figure 5 Recessive factors of LED quality Source: This study.

Author used binomial test (based on sign-test of non-population) to verify, if the value >0.5 then it would be accepted. The actual vale was 0.88, the test result was approved of great significance (see Table 14, P value =0), so the H3 is accepted.

Table 14 Binomial Test for Reliability (Recessive Factors)

N

Observed

value Test value P value

relability (Recessive Factors) Group 1 (Pro) 58 0.88 0.5 .000(a) Group 2 (Con) 8 0.12 Total 66 1

(a) ---- Based on Z Approximation. Source: This study.

H4: In terms of quality requirement, (among the dominant factors) the brightness, color, voltage, and viewing angle are the common required criteria, for all LED package types.

Result: The method is the same as the H1, from the Frequency distribution (Figure 6), we could tell the Brightness (63/66), Wavelength (51/66), Voltage(28/66), Viewing Angle(40/66), Beam Pattern (29/66) were very important criteria; this study also did the verification by one sample T-test (see Table 15 and Table 16), the result shown the P value were =0, Brightness, Wavelength, Voltage, Viewing Angle were of significance (Table 16), so the H4 was accepted.

Figure 6 Dominant factors of LED quality Source: This study.

Table15 Mean and Standard Deviation of H4

N Mean Std. Deviation Std. Error Mean

Brightness 66 4.8333 0.45007 0.0554

Wavelength 66 4.2121 0.96898 0.11927

Voltage 64 3.7031 0.92031 0.11504

View Angle 65 4.0615 0.8638 0.10714

Table 16 T-test result of H4

Test Value = 3

T value

Degree of

Freedom P value Mean Difference

Brightness 33.093 65 0 1.83333

Wavelength 10.163 65 0 1.21212

Voltage 6.112 63 0 0.70313

View Angle 9.908 64 0 1.06154

source: This study.

H5: Among the dominant factors, the brightness is buyer’s most important concern.

Result: From the above Frequency distribution of H4 (Figure 6), the Brightness factor is 95.45% which presents the most importance, and this survey used T-test to do the verification, comparing the Mean of Brightness to Wavelength’s, Voltage’s, Viewing Angle’s, and Beam Pattern’s, to see if the Brightness factor with significance. And the result shown all of the P value is 0, see Table 17, 18, 19 and 20.), so H5 was accepted.

Table 17 Brightness versus Wavelength

Test Value = 4.2121

T value

Degree of

Freedom P value Mean Difference

Brightness 11.214 65 0 0.62123

Table 18 Brightness versus Voltage

Test Value = 3.7031

T value

Degree of

Freedom P value Mean Difference

Brightness 20.401 65 0 1.13023

Source: This study.

Table 19 Brightness versus Viewing Angle

Test Value = 4.0615

T value

Degree of

Freedom P value Mean Difference

Brightness 13.932 65 0 0.77183

Source: This study.

Table 20 Brightness versus Beam Pattern

Test Value = 3.7031

T value

Degree of

Freedom P value Mean Difference

Brightness 20.401 65 0 1.13023

Source: This study.

H6: The re-buy decision of LED Components is even more quality oriented.

Result: Among the 66 samples, 63 persons had experience with LED components, 3 persons never used LEDs (see Figure 7); for verify this hypothesis, author classified these 63 respondents into two groups, purchased LED “ Once” as the first –time user, and the others as the “re-buy” purchaser (see Figure 8), then using the SPSS software by the method of

ANOVA to analyze if the Quality factor present significant difference between these two groups, the F value is 0.065, and the result ( P value is 0.799 which is more than 0.05) shown there was no significance (see Table 21), so the H6 was rejected.

Figure 7 Purchasing frequency of Respondents Source: This study.

Figure 8 First-time versus Re-buy Source: This study.

Table 21 ANOVA result of H6 (Quality --- First buy versus Rebuy)

Sum of Squares Degree of Freedom Mean

Square F value P value

Between Groups 0.013 1 0.013 0.065 0.799 Within Groups 12.472 64 0.195 Total 12.485 65

H7: R&D staff is more concern quality rather than price (H7-1), while relatively the staff in purchasing division is more concern on the price issue (H7-2).

Result: From the job junction break-down, in the sample distribution Table 6, shown there were R&D 30 persons, while purchaser was 7 persons. This hypothesis was evaluated in 2 parts: H7-1 for the R&D group, and H7-2 for the purchasing personnel. (1) H7-1: Author picked out the R&D group’s selection of Quality factor to compare with Price factor, using the paired T-test to verify, although from the ranking shown Quality was greater than Price (Table 22), we found from the result of paired T-test in Table 23, the value was not of statistic significance, therefore, the H7-1 was rejected;

Table 22 Sequence of Importance

R&D group Quality Price Delivery Service

Mean 4.8667 4.6000 4.0000 3.3667

Ranking 1 2 3 4

Source: This study.

Table 23 Paired T-test of R&D group (Quality versus Price)

Mean Std. Deviation T value

Degree of

Freedom P value

Quality -

Price 0.26667 0.73968 1.975 29 0.058

Source: This study.

sequence was quality first, second was price, and delivery and service were both in the third place. This survey was used also the paired T-test to compare the Price factor to Quality, Delivery and Service, to see if there was of great difference. And the result (Table 25) shown, although Quality was more important, Quality compared with Price was not of statistical significance, while Price compared with Delivery and Service were of significance. It meant purchasing staffs regarded the Price factor was more important than the Delivery and Service factor, but the Quality and Price factor were both very important, so H7-2 was rejected.

Table 24 Sequence of Importance

Purchasing group Quality Price Delivery Service

Mean 5.0000 4.5714 3.7143 3.7143

Ranking 1 2 3 3

Source: This study.

Table 25 Paired T-test result of Purchaser group (Purchasing --- Price versus Quality, Delivery, Service)

Mean Std. Deviation T value Degree of Freedom P value Quality-Price 0.42857 0.53452 2.121 6 0.078 Price-Delivery 0.85714 0.69007 3.286 6 0.017 Price-Service 0.85714 0.69007 3.286 6 0.017

Source: This study.

H8: Relatively, distributor is more critical on the quality requirement than direct customer.

Result: From the respondents’ company business type break-down (Table 6 sample distribution), it shown there were 39 manufacturers (59.09%), 16 ( 24.24%) of others (IC design company), and 11 (17%) were distributors; these companies were classified into two

groups: Direct customer (Manufacturer and Others), and Distributor, see Figure 9, and then using ANOVA to verify if the Quality factor was more important to Distributors than to the

direct customers. And the result (Table 26) shown of no significance, so the H8 was rejected.

Figure 9 Direct customer versus Distributor Source: This study.

Table 26 ANOVA test result of H8 (Quality --- Distributor versus Direct)

Sum of Squares

Degree of

Freedom Mean Square F value P value

Between

Groups 0.303 1 0.303

1.592 0.212

Within Groups 12.182 64 0.19

Total 12.485 65

Source: This study.

Result: There were 63 out of 66 persons (95.45%) agreed the selection of LED type should be depended on the application (Figure 10), author used the binomial test (sign-test of non population) to verify, as the observed value 0.95 was bigger than the set criteria of 0.5, the result (see Table 27) shown of great significance (P value=0), so the H9 was accepted.

Figure 10 Frequency distribution of H9 Source: This study.

Table 27 Binomial test result of H9

N

Observed

value Test value P value

YES_item21 Group 1 63 0.95

0.5 .000(a)

Group 2 3 0.05

Total 66 1

(a) --- Based on Z Approximation. Source: This study.

H10: The quality requirement of LED for outdoor application is more crucial than for the indoor usage.

Result: The same as H9, also 95.45% of respondents (63/66) agreed the quality requirement of LED for outdoor application was more crucial than for the indoor usage (please refer to Figure 11); author also applied the binomial test (sign-test of non-population) on this hypothesis, and the result (Table 28) approved it was of significance. So, H10 was accepted.

Figure 11 Frequency distribution of H10 Source: This study.

Table 28 Binomial Test result of H10

N

Observed

value Test value P value

YES_item22 Group 1 63 0.95

0.5 .000(a)

Group 2 3 0.05

Total 66 1

(a) --- Based on Z Approximation. Source: This study.

From the hypothesis test result ( Table 29), it is obviously shown the most important influential factors of LED components purchasing are the Quality, Price, Delivery, and Service, just like most of the industries. And, the Quality issue is no doubt the most

outstanding and of the top importance to all the people who make the purchasing decision, in spite of different functional role in the organization ( no matter it is to R&D or to Purchasing staff), in spite of how many times they used or purchased LED (first time or re-buy), and in spite of they are direct or indirect user (manufacturer or distributor).

However, due to the special characteristic of LED, the quality of LED need to be highlighted and treat with care, this survey classified the quality of LED into Dominant Factors and Recessive Factors , as former could be checked out instantly, and are the normal requirements of on-site inspection during the production; the latter is regarded to the LED reliability, most of the factors could be only tested and approved along with time, and 87.88% (58/66) of respondents thought the reliability (Recessive Factors) would be their most

concern. As for the Dominant Factors, it shown Brightness, Wavelength, Voltage, Viewing Angle are the normal required criteria, and among them the Brightness is the most important factor.

In regard to the relationship between LED package type and LED application, in this survey also shown 95.45% (63/66) of the respondents agreed the selection of LED package type was mainly depended on the LED application, and the requirement of LED quality for outdoor usage would be more crucial than for the indoor’s.

Table 29 Hypothesis Test Result

Item Hypothesis Test result

H1 In LED component purchasing decision, quality, delivery, price,

service are the most important influential factors. Accepted

H2 Among the important influential factors, quality is of the top

importance sequence. Accepted

H3 In terms of LED quality, the most concerned issue is the reliability. Accepted

H4

In terms of quality requirement among the dominant factors, the brightness, color, voltage, and viewing angle are the common required criteria.

Accepted

H5 Among dominant factors, the brightness is buyer's most important

concern. Accepted

H6 The re-buy decision of LED components is even more quality oriented. Rejected

H7

R&D staff is more concern quality rather than price (H7-1), while relatively the staff in purchasing division is more concern on the price issue (H7-2).

H7-1: Rejected H7-2: Rejected

H8 Relatively, distributor is more critical on the quality requirement than

direct customer. Rejected

H9 The selection of LED type is mainly depended on the application. Accepted

H10 The quality requirement for outdoor application is more crucial than for

the indoor usage. Accepted

Chapter 6 Conclusion and Suggestion

It is good to see more and more people use the environment friendly LED to make industrial and commercial products, in order to help users understand more of the

characteristic and how to make the better use of the LED, this survey had intended to find out the important influential factors of LED purchasing decision, as well as the relationship between LED package type and LED application, based on the result of this study, the conclusion was made in this chapter, and also the suggestion for future study.

6.1 Conclusion

Quality, Price, Delivery, Service indeed are indeed the most influential factors of LED components purchasing decision, however, in LED industry the Quality would be the key concern among all of these factors, especially the reliability issue of LED quality. Although the recessive factors which related to reliability issue could not be checked out instantly, LED manufacturers (including wafer, die, package and application) should be aware of this demand and, besides the dominant factors , put more efforts on improving the quality of recessive factors: Life time, light decay, thermal shock resistance, heat dissipation, to ensure the reliability of LED.

Meanwhile, as most of the respondents agreed, the selection of LED package type is mainly depend on the LED application and quality requirement for outdoor application is crucial than the indoor usage, in order to make the best of LED for the functional and cost efficiency , the required criteria of LED and the selection of LED package type should be matched to the application, for example, if the application is the emergency lighting

(back-light for EXIT sign), then the manufacturing user might choose the wide viewing angle LED but not necessary with the brightest luminosity; when the application is the VMS on the highway, then it might select the LED with wide viewing angle and with high brightness LED, and then based on these criteria to select suitable LED package type for use.

And in the managerial meaning, this survey helps LED manufacturers to understand better customer need, with which they might be able to set up a sales strategy accordingly, and improving the competitiveness on these key factors. However, this research is focusing on the influential factors of LED component purchasing only, and due to the sampling size and category are limited to mainly within Taiwan and Europe, it might not correctly present the actual situation in the worldwide market.

6.2 Suggestion

In this survey, it is shown most of the users agreed the selection of LED package type depended on the application, but this is just a rough indication. For future study, it is suggested to do more survey on the relationship between the LED package type and LED application, to find out if certain package type is more suitable for certain application, and to find out the right match and draw the relationship diagraph, in order to give better guideline for LED users.

References

1. Akanegawa, M.; Tanaka, Y.; Nakagawa, M.; Basic study on traffic information system using LED traffic lights, Intelligent Transportation Systems, IEEE Transactions on Page(s):197 – 203, Volume 2, Issue 4, Dec. 2001.

2. Baily, P. and Farmer, D. Purchasing principles and Management, 5th ed., Pitman, London., 1985.

3. Bharadwaj N., Investigating the Decision Criteria used in Electronic Components Procurement, Industrial Marketing Management, Page(s): 317-323, vol. 33, 2004. 4. Boissard, S.; Fontoynont, M.; Optimization of LED-based Light Blending for Object

Presentation, Color Research and Application, Page(s): 310-320,vol. 34, no. 4, August 2009.

5. Cannon J.P., Perreault W.D., Buyer-seller relationship in business markets, Journal of Marketing Research, Page(s): 439-460, 36/4, 1999.

6. Dhafr N., Ahmad M., Burgess B. and Canagassababady S., Improvement of quality performance in manufacturing organizations by minimization of production defects, Robotics and Computer-Integrated Manufacturing, Page(s): 536-542, vol. 22, 2006. 7. Ellegaard C., The purchasing orientation of small company owners, Journal of Business

& Industrial Marketing, Page(s): 291-300, 24/3/4 , (2009).

8. Ghosh A.K., Joseph W.B., Gardner J. T. and Thach S. V., Understanding industrial distributors’ expectations of benefits from relationships with suppliers, Journal of Business & Industrial Marketing, Page(s): 433-443, vol. 19, no. 7, 2004.

9. He S.G., Li L., Qi E.S., Study on the Quality Improvement of Injection Molding in LED Packaging Processes based on DOE and Data Mining, IEEE 2007.