Case Studies on the Implementation of Knowledge

Management in the Distribution Industry: Worldpeace and

Alltek

Pei-Di Shen Ming Chuan University

Tsang-Hsiung Lee National Chengchi University

Chia-Wen Tsai Ming Chuan University

Yi-Fen Chen

Chung Yuan Christian University

Abstract

!A hot topic, knowledge management (KM) is enthusiastically discussed and implemented in high-tech and software industries, as it is the basis for competitive advantage. We have heretofore neglect whether KM is suitable for implementing in other industries. In this article, two cases from the distribution industry, Worldpeace and Alltek, were studied to illustrate how KM is implemented and increases the firms’ competitive advantage. We analyze the implementation of KM in terms of knowledge creation, storage/retrieval, transfer and application. As distributors, these firms have to learn and change faster than designers and manufacturers. The findings point out that not only the upstream and downstream firms in IC industry have to implement KM, but also the midstream firms could benefit, as they face the rapidly changing technologies of upstream firms and the different and changing requirements of downstream customers. Moreover, some insights from these case studies and the enabling roles of KM processes are presented in the discussion section of the paper.

Keywords: Knowledge Management, Distributors, Case Study

೯ၡౢޕᆅᔈҔϐঁਢࣴزɡШѳکӄࣽ!

؇ٵဓ

ܱ ࡹݯεᏢၗૻᆅس ጰৎЎ ሎεᏢറγғ ഋەි ύচεᏢ୯ሞຩܰᏢس

ᄔा

ޣᜋᆓ౩(knowledge management, KM)ӌཾᝯތᓺ༖ޟஅᙃȂӰ Ԫӵଽऋཾڷᡝཾϛೝኄݿиዥ੨Ӵଆ፣ȄณՄȂޣᜋᆓ౩ ࠓலೝ܇ΟζџоᎌҢܻڏтཾ࿋ϛȄҏंـٺҢڍএ IC ၯ ཾএਰɯWorldpeace ڷ AlltekȂپၛភޣᜋᆓ౩ޟஈПԒȂоቨ໌ ӌཾϞᝯތᓺ༖ȄҏंـၼҢޣᜋഺഅȃޣᜋᓽԆȃޣᜋಋᙽڷޣᜋ ᔖҢޟᢎᘈȂپϷݙޣᜋᆓ౩ޟஈႆแڷ؏Ȅҏंـี౪Ϛѫ IC ཾΰή෬ӌཾᔖᄂޣᜋᆓ౩Ȃѓࢂϛ෬ޟӌཾζџᄂޣᜋᆓ ౩ՄڧઉȂ੫տϛ෬ޟၯ୦७ᄇऋᡐ᎐פഀȃഺཱིแ࡙ଽޟΰ ෬ӌཾȂоЅሯؑϚӣȃࡊᇧϽแ࡙ଽޟή෬ࡊИȂӰԪ IC ཾϛ෬ ޟၯ୦҆ሯШΰ෬ޟ IC ೩ॎኅ୦ڷή෬ޟᇧഅ୦פഀӴᏰಬڷ ᔖᡐȂᄇޣᜋᆓ౩ζԤफ़ϸޟሯؑȄԪѴȂҏंـζШၶڍএএ ਰᄂޣᜋᆓ౩հݲΰޟӣȂٮ໌Ι؏ଆ፣ڏԙђᄂޣᜋᆓ౩ޟ নӰȄ ᜰᗤԅȈޣᜋᆓ౩ȂၯཾȂএਰंـIntroduction

Today a ‘Third Industrial Revolution’ is under way; knowledge will replace land and a firm’s physical or financial resources as the most important asset (Thurow, 1999). Even Drucker (1993) argues that in the new economy, knowledge is not just another resource alongside the traditional factors of production - labor, capital and land, but is the only meaningful resource today. Tangible assets will be decreased or consumed because of use, but intangible assets ņ knowledge, information and technology will grow through sharing and application. Knowledge is a limitless resource in the knowledge-based economy, organizations should learn, store, transfer and apply knowledge to add value or gain competitive advantage (Sveiby, 1997). Knowledge management refers to identifying and leveraging the collective knowledge within the organization to help in competing (von Krogh, 1998).

However, knowledge management is usually discussed and implemented in high-tech industries (e.g., TI, TSMC, and Winbond) and the software industry (e.g., Microsoft and Oracle), where it is the basis for competitive advantage. For example, Texas Instrument (TI) saved a surprising amount of money by transferring the best practice from 13 semiconductor fabrications to other applications. In Taiwan, many IC and computer-related businesses are well known because of the quality of their products and their speed to deliver goods. The upstream firms or suppliers in the electronic industry (e.g., Winbond, UMC, and Powerchip Semiconductor Corp.) implement knowledge management in their organizations. Similarly, the downstream firms or manufacturers (e.g. Quanta Computer Inc., ASUS Computer Inc., and Foxconn Electronics, Inc.) also put knowledge management into their practices. However, in the midstream firms or distributors, there are just a meager amount of firms that really implement KM in their companies. Therefore, we have neglected whether KM is still suitable for implementing in the distribution industry.

The IC distributors in Taiwan evolved from partnerships, starting enterprises within family, into the overall arrangement in Asia, with output value in 2004 beyond 38.7 billion USD. People outside the IC distribution industry may consider that distributors just transact the business, but they don’t have their own products, even though the scale of IC distributors has become greater. So an inaccurate notion existed that it wasn’t necessary to innovate or put knowledge management into practice in distribution industry. In fact, the IC distributors have to face not only the rapidly changing upstream firms, but also the different and changing requirements of downstream customers. Therefore, distributors have to change and learn faster even than their suppliers and customers to face the drastically changing and intensely competitive environment.

In this article, we studied two cases from the distribution industry to illustrate how KM was been implemented for strategic application and increased the firms’ competitive advantage. Moreover, we also hope this article could provide some insights for managers when they plan to put KM into practices in their distribution firms.

Literature Review

Knowledge management (KM) refers to identifying and leveraging the collective knowledge within the organization to help in competing (von Krogh, 1998). Knowledge management is concerned with systematic, effective management and utilization of an organization's knowledge resources (Demarest, 1997). It consists of the creation, storage, arrangement, retrieval and distribution of an organization's knowledge (Demarest, 1997; Saffady, 2000). Alavi & Leidner (2001) classified the processes of knowledge management into four steps: knowledge creation, knowledge storage/retrieval, knowledge transfer and knowledge application, representing a detailed process framework of organizational knowledge management with a focus on the role of Information Technology.

Knowledge Creation

Organizational knowledge creation involves developing new content or replacing existing content within the organization’s tacit and explicit knowledge (Pentland, 1995). In today’s rapidly changing environment, organizations have to focus on the creation of knowledge, instead of on quickly obsolescent existing knowledge. When organizations innovate, they do not simply process information from the outside in, but use information to solve existing problems and adapt to the dynamic environment. They actually create new knowledge and information from the inside out, in order to redefine both problems and solutions and, in the process, to re-create their environment (Nonaka & Takeuchi, 1995). New knowledge is a necessary raw material for innovation and the creation of knowledge; both are closely tied to new products and services (Hauschild, Licht & Stein, 2001). When a firm starts to develop new products or services, or when organizational knowledge is antiquated or insufficient, a firm should innovate and create new knowledge by means of organizational learning activities to face the challenges.

Knowledge Storage/Retrieval

While new knowledge is developed by individuals, organizations play a critical role in articulating and amplifying that knowledge (Nonaka, 1994). Actually, the storage, organization, and retrieval of organizational knowledge are referred to as organizational memory (Stein & Zwass, 1995; Malhotra, 2000). An organizational memory includes knowledge residing in various component forms, including structured information stored in electronic databases, written documentation, expert systems, documented

organizational procedures and processes and tacit knowledge acquired by individuals and networks of individuals (Tan, Teo, Tan, & Wei, 1998).

Since the organizational knowledge is at company-level, it should be identified or shared by the organization members and recorded in a knowledge system. Two strategies are being used for storing knowledge (Hansen, Nohria & Tierney, 1999):

(1) Codification: Provide high-quality, reliable, rapid information-systems implementation by reusing codified knowledge;

(2) Personalization: Provide creative, analytically rigorous advice on high-level strategic problems by channeling individual expertise.

Knowledge Transfer

The distribution and transfer of knowledge is an important process in knowledge management (Alavi & Leidner, 2001; Huber, 1991). Knowledge should be shared and generalized within the organization. Generalization occurs not only when single ideas are moved, but also when the entire process of moving ideas becomes institutionalized within an organization (Yeung, Ulrich, Nason, & von Glinow, 1999). The institutional process embedded in a firm and the capability of generalizing ideas consistently is important elements to meet the real goal of knowledge management.

For shared knowledge to be meaningfully used, the knowledge needs to be coupled with mechanisms for organization, retention, maintenance, search and retrieval of the information (Stein and Zwass, 1995). Such mechanisms are often computer-based, ranging from simple keyword organizing principles to complex intelligent agents and neural network that grow with the expansion of knowledge repositories (Ellis, Gibbs and Rein, 1991; Johansen, 1988; Maes, 1994). The use of collaborative technologies (CT) is fundamental to make virtual teams work. A collaborative technology also referred to as a virtual workplace, should be able to record, at a minimum, the process of the group, an agenda, libraries of solutions and practices, different forms of interaction, meta-information, and provide shared information storage, access and retrieval (Ellis et al., 1991; Ishii, Kobayashi and Arita, 1994; Kling, 1991; Nunamaker, Briggs and Mittleman, 1995; Romano, Nunamaker, Briggs and Vogel, 1998; Thornton and Lockhart, 1994). For optimum knowledge sharing and reuse, CTs include not only a mechanism for exchanging knowledge (such as E-mail), but a mechanism for creating a knowledge repository and a mechanism for accessing the knowledge repository (Majchrzak, Rice, King, Malhotra and

Ba, 1999).

Besides the technology-based channels, organizations should provide other mechanisms to transfer and distribute knowledge to ensure unrestricted collaboration. For example, knowledge that is more or less explicit can be embedded in procedures or represented in documents, databases, CTs, and then transferred accurately. But, transfer of tacit knowledge generally requires extensive personal contacts (Davenport & Prusak, 1998). Organization members tended to use face-to-face or phone for the more ambiguous tasks of managing external relationships and conflicts, brainstorming, and strategic direction-setting. Nonetheless, the members tend to use the synchronous CTs for the more routine tasks of analysis, and project statusing (Majchrzak et al., 1999). Webster and Trevino (1995) suggested that rational and social factors should be included in comprehensive models of media choice that address both traditional and new media. In conventional communications environments, individuals’ behavior choice was found to be largely underpinned by so-called rational determinants. Conventional media such as the telephone, facsimile, and printed documentation have been in use for extensive periods, during which views of what are effective, and then rational decisions of choice have grown over time and been validated by experience, and are implicitly shared by the user community (Breu, Ward and Murray, 2000). In newly implemented IT-enabled communications environments, individual media choice was found to be overwhelmingly informed by so-called socialcultural determinants of how these technologies might most adequately and effectively be used (Webster and Trevino, 1995; Fulk and Boyd, 1991).

Knowledge Application

Knowledge application means making knowledge more active and relevant for firms in creating value since organizational knowledge needs to be employed into a company’s products, processes and services (Bhatt, 2001; Demarest, 1997). Employees use all available resources, including the corporate knowledge base, to improve their chance of reaching the goals of the organization (Hauschild et al., 2001). The source of competitive advantage resides in the application of the knowledge rather than in the knowledge itself (Alavi & Leidner, 2001). As stated by Prokesch (1997), using knowledge more powerfully than your competitors is a key to battling it out in the global information era. Learning from the experience of others and reusing materials that have been effective

elsewhere improves the quality and speed of problem solving (Cross & Baird, 2000). Knowledge should really be used to create value for the company, and when it is applied, the company can judge the validity and suitability.

2.2 Distributors

A distribution system is a key external resource. Normally it takes years to build, and it isn’t easily changed. It ranks in importance with key internal resources such as manufacturing, research, engineering, and field sales personnel and facilities. It represents a significant corporate commitment to large numbers of independent companies whose business is distribution – and to the particular markets they serve. It represents, as well, a commitment to a set of policies and practices that constitute the basic fabric on which is woven an extensive set of long-term relationships (Corey, 1991). Intermediaries smooth the flow of goods and service. This procedure is necessary in order to bridge the discrepancy between the assortment of goods and services generated by the producer and the assortment demanded by the consumer. The discrepancy results from the fact that manufacturers typically produce a large quantity of a limited variety of goods, whereas consumers usually desire only a limited quantity of a wide variety of goods (Stern and El-Ansary, 1996).

The use of intermediaries largely boils down to their superior efficiency in making goods widely available and accessible to target markets. Through contacts, experience, specialization, and scale of operation, marketing intermediaries offer the firm more than it can usually achieve on its own. Members in the marketing channel participate in marketing flows and perform a number of key functions such as: (1) Information; (2) Promotion; (3) Negotiation; (4) Ordering; (5) Financing; (6) Risk taking; (7) Physical possession; (8) Payment; (9) Title (Kotler, Ang, Leong and Tan, 1999).

Research Method

3.1 Case Study Method and Case Selection

Case study is applied to illustrate how the distributors put knowledge management into practice, and how they pay different weight of attention

to the four processes of knowledge management. The use of case studies as a research tool, as exemplified by Yin (1994), should investigate a contemporary phenomenon within its real-life context when boundaries between phenomenon and context are not clearly evident and in which multiple sources of evidence are used. Case study method was chosen to explore and descript the implementation of knowledge management in distribution industry in Taiwan. We used case studies to illustrate how high-tech firms put knowledge management into practice.

The case selection is very important in any study. In Taiwan, many of the upstream firms (e.g., Winbond, UMC, and Powerchip Semiconductor Corp.) and downstream firms (e.g. Quanta Computer Inc., ASUS Computer Inc., and Foxconn Electronics, Inc.) of the electronics industry have been implementing knowledge management in their organizations. However, in the intermediaries or distributors, there are just a meager amount of firms that really implement KM in their companies. The cases in this study were selected from the distribution industry after a pilot study surveying the distributors to find those really implementing KM. Two cases, Worldpeace and Alltek, were selected from the semiconductor distribution industry. They are in a tiny minority among distributors in Taiwan that really implement KM and obtain advantage from the efficiency of implementation. The first case, WorldPeace, is the largest and leading electronic component distributor in the Asia Pacific region. The second case, Alltek, is a professional design house and distributor of communication technologies. It began trading on Taiwan's OTC (over-the-counter) market in 2003. It is the first distributor with the capability of researching and designing chips, modules, and systems.

3.2 Data Collection and Analysis Method

For case study method, sources of evidence could be documentation, archival records, interviews, direct observations, participant-observation, and physical artifacts. In this study, in-depth interviewing and evidentiary documents were used as primary and secondary sources of data collection from the cases, respectively. For example, we had four interviews with the Corporate Vice President, Associate Vice President of Corporate Marketing and Communication Office, and Assistant Manager of the Knowledge Management Department of Worldpeace, respectively. We also had three interviews with the spokesman, Vice President of Technology Department, and Assistant Manager of MIS Department of Alltek, respectively. We

cross-checked each of their statements with different managers in different interviews. The proposal of the implementation of knowledge management in Alltek was also provided by the spokesman of Alltek.

Case data was collected from multiple sources, including interviews, company profiles, journals, doctoral dissertations, documents from the firms, information on the website and knowledge portal, books published in Taiwan, and internal documents. The data collected from different sources were triangulated for their validity. Moreover, a chain of evidence was established by keeping track of the processes of implementing knowledge management in Worldpeace and Alltek, and to control the construct validity of the study. Data and content was collected and analyzed systematically. The case study proposal and database were applied in this study to control the reliability. It should be noted that the two cases are extremely different in scale, that is, Worldpeace is a large-scale enterprise while Alltek is a small-scale one in distribution industry. We selected these cases of different scales in order to increase the generalization of this study.

Two cases, Worldpeace and Alltek will be used to illustrate how distributors implement knowledge management and the enabling roles knowledge management plays in their implementations. We adopt the model modified from Alavi & Leidner (2001) to describe and analyze the implementations of KM in terms of knowledge creation, storage/retrieval, transfer and application.

Knowledge Management Practice: Case Studies

4.1 Worldpeace Knowledge Management Practice

Knowledge Creation

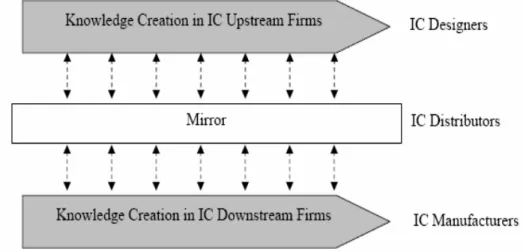

In the IC distribution industry, firms have to keep their knowledge consistent with their supply chain; that is, when their upstream firms or suppliers innovate or create new knowledge about IC products, the distributors must get that new knowledge instantly. However, many innovations occur and much new knowledge is created in the IC design industry, so, distributors have to work hard to keep up with their suppliers even though they seldom create knowledge by themselves. In order to provide the newest information and knowledge for customers, Worldpeace keeps knowledge consistent with suppliers by being a so-called “mirror” of

the knowledge creation of their suppliers. This means that the knowledge will be transferred the IC designer to the distributor as it was created or devised. The distributor acts the same as the designer in knowledge creation; therefore, this way of learning from suppliers is called “mirror”. On the other side, when new requirements from customers or information about market demand are generated, the distributor also has to acquire the knowledge. Besides acquiring the knowledge from suppliers and customers, Worldpeace plays an important role in transferring knowledge between upstream and downstream firms whenever knowledge is created (See Figure 1).

In addition to the technical knowledge from suppliers, Worldpeace also creates market intelligence from customers. Worldpeace regards customers’ suggestions and complaints as the material of knowledge creation. As a distributor, information regarding customers’ status and propositions is extremely valuable to Worldpeace. Therefore, both suppliers and customers are critical sources of knowledge to Worldpeace.

Figure 1 Knowledge Creation with Suppliers and Customers – “Mirror” Knowledge Storage/Retrieval

As distributors, they don’t produce, but transfer manufacturers’ products or services to customers, so they make profit by managing knowledge and information about products. In Worldpeace, knowledge and information are well stored in their database, and employees can get it via intranet. Worldpeace will become a distributor for B2B e-commerce based on the knowledge management platform of its self-developed information system that is named EIP (Enterprise Internal Portal). It established

E-service for Customer Relation Management (CRM) to greatly improve the transaction process. The information on status of order, accounts receivable, customers’ status is recorded in EIP.

A report must be completed when any project closes. The new knowledge, findings, specifics, and experiences in the case must be recorded. In particular, a “standard knowledge” mechanism is implemented before the knowledge or information is stored in EIP. For effective knowledge sharing and understanding, the knowledge in Worldpeace should be standardized. So, the engineers, salesmen and the employees of Worldpeace are educated to write a standard document when they store knowledge that they learned or discovered. The policy of “standardized knowledge” is critical when implementing knowledge management.In Worldpeace, knowledge and information are well stored in their database, and employees can get it via intranet. Worldpeace will become a distributor for B2B e-commerce based on the knowledge management platform of its self-developed information system that is named EIP (Enterprise Internal Portal). It established E-service for Customer Relation Management (CRM) to greatly improve the transaction process.

Knowledge Transfer

Two approaches were applied in Worldpeace to transfer knowledge. Explicit knowledge is stored in the EIP system in the standard format. Managers, engineers, salesmen, and employees could access the knowledge that they need according to their priority. Worldpeace, headquartered in Taipei, Taiwan, has a solid and complete Asia-Pacific service network. It has over 20 sales offices in Hong Kong, China, Singapore, Malaysia, Thailand, Philippines, Japan, and India etc. around the greater China and Asia Pacific region. Employees everywhere can access the EIP system via Internet. This EIP system is divided into four sections presented in four colors: blue, green, red, and orange. The colors represent the headquarters, branches in Taiwan, branches in China, and branches in ASEAN, respectively. Thus, employees can store and access the information and knowledge within the same color section.

The second approach is for tacit knowledge transfer. In the distribution industry, tacit knowledge could be the experience of sealing a business deal. The salesmen or managers, who are master in making deals or marketing, will be invited to give a lecture or speech for employees. Besides, some special or excellent cases will be studied to discover their characteristics, called “Worldpeace DNA”. Associate Vice President of

Corporate Marketing and Communication Office will study and decide which case is worth publicizing. The case study will proceed, and Assistant Manager of Knowledge Management will have interviews with the salesman or manager to complete this case study. After it is completed, it will be stored in the EIP system for Worldpeace employees’ reference. Knowledge Application

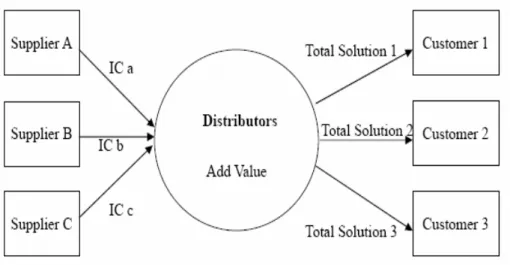

There are three kinds of domain knowledge in the distribution industry: first, knowledge about products, meaning the nature of IC chips; second, knowledge about application, meaning the purpose, function and application of the products; finally, knowledge about system integration, which means how to integrate IC chips in a module or system. Therefore, distributors build the knowledge base of products first, then understand how and where to apply them. Then, they try to discover how to integrate different IC chips in a module.

Being distributors, they don’t design IC, nor produce IC chips. They create value for customers by integrating chips from different suppliers in a module and providing total solutions add value for their customers (See Figure 2). Moreover, they emphasize the reuse and flow rate of knowledge. The margin cost will decrease progressively if they reuse their knowledge and intellectual property more frequently. Therefore, compared to other processes in knowledge management, knowledge application is more emphasized in distribution industry.

Figure 2 The Total Solutions Provided by Integrating Different IC Chips through Distributors

4.2 Alltek Knowledge Management Practice

Knowledge Creation

As a professional design house and distributor of communication technologies, Alltek always tries to create knowledge for new modules. For technical knowledge, Alltek not only provides consultations for customers, but also co-designs the customized modules with customers. The twenty-three Field Application Engineers (FAE) in Alltek provide support for customers to develop new products. They provide downstream firms the total solutions from the designing stage to the sample testing stage, and consultations on market trends. Alltek developed its own technical ability through project of planning and designing, and so translates into a value-adding distributor.

In addition, Alltek also creates knowledge about the market of communication technology. Two of their departments are connected with knowledge creation: Marketing and Products Promotion. They search for and collect the perspectives and viewpoints of market trend from their customers and suppliers. That is, as a distributor, they may seek the marketing information from upstream and downstream firms as they create knowledge. Then, they have internal meetings and communicate with the engineers in the Technology Department on a regular schedule to produce the products that match the customers’ requirements.

Therefore, Alltek creates technical knowledge with their suppliers and downstream firms, and collects the market information from their suppliers and downstream firms. This distributor seeks technical knowledge and marketing knowledge and from upstream and downstream firms as the first process of knowledge management.

Knowledge Storage/Retrieval

Alltek built a “knowledge-base” in which to store or record the knowledge when a project is completed. A team member records the experience in this project, including the responses and comments of customers and members in this project. This record of experience helps to build the next project, and complete it faster and more efficiently. For the knowledge from suppliers, such as technical documents, beta version information, and information on new products is stored in the database. Besides, they also collect the information about customers’ product development and store it in database. This information can be a valuable reference for marketing.

Furthermore, the information about order status and transactions is recorded in the ERP system, to deliver the components to downstream firms just in time and speedily. Through the information in this ERP system, Alltek could help their customers to plan for stock and decrease the risks of stock. Alltek records and monitors the required components in the designing stage in Alltek’s ERP system to help customers enter the market rapidly.

However, tacit knowledge isn’t so easy to store quickly. Even if it’s stored in the database, the user may not locate the knowledge he wants if he inputs the non-matching key words. However, because of being an IC distributor, most knowledge in this industry is of explicit nature, so, the knowledge-base and database still play important role for Alltek to store and record knowledge within their organization.

Knowledge Transfer

Field Application Engineers (FAE) in Alltek not only have to transfer the suppliers’ reference circuits and reference designs to downstream firms, but also have to hold technical conferences and presentations to transfer the knowledge to the members within the organization and to sales representatives and design engineers of downstream firms. Regarding Alltek’s own knowledge, its research results are transferred and diffused to downstream firms positively. For example, Alltek transferred the technology of “High Data Rate DSL (HDSL)” to U-KING Communications Corp., and earned a great fee for technology transformation and downstream firms’ long-term cooperation. Hence, the implementation of KM and sharing or transferring of knowledge is the approach to improve or sustain their relationship with customers.

In order to keep knowledge transferring within Alltek, they have formed several channels: a community of practice (for technical knowledge), institution of master and apprentice (for marketing and negotiating), the best practice for learning, IP map of experts, and interviews with experts. In addition, special training has been held to facilitate organizational knowledge transfer in Alltek.

Knowledge Application

Alltek applies the knowledge acquired from upstream and downstream firms and what they developed by themselves to produce samples for promotion. They also applied knowledge to produce semi-finished products for downstream firms to shorten the time to

certification. Alltek provides the reference circuits, reference designs from upstream firms, and the total solutions integrated by Alltek to assist customers in solving their designing and manufacturing problems. That is, Alltek applied knowledge in this supply chain to help the whole supply chain to be more frictionless and competitive, and increase Alltek’s profits and rewards.

Knowledge and information about customers and market conditions could also be applied to bring profitability. The newly hired salesmen could take over cases by applying the knowledge and information stored in the databases and ERP system; so, employees can be involved in the business situation very quickly. Also, Alltek designs modules and provides total solutions according to market trends and the market information acquired from the suppliers’ and customers’ viewpoints. Therefore, Alltek could supply components that customers needed to increase the profitability of new products.

Discussion and Insights

With stiff global competition, high-tech companies face the challenge of shorter product life cycle, the rapid depreciation of tangible assets and the transience of employees (especially for marketing employees and salesmen in the distribution industry). It is essential for distributors to put knowledge management into practice positively and actively. Most knowledge in the distribution industry is explicit; therefore, it’s more suitable and convenient to put knowledge management into practice. Although firms in IC distribution industry don’t design and produce IC chips or IC products, they still could implement KM to create value for their customers, increase profit and cut down cost by using and reusing knowledge.

Based on the literature and case studies of Worldpeace and Alltek, three insights are gleaned from in this study. Table 1 shows the comparison of the implementations of knowledge management in Worldpeace and Alltek.

Insight 1 KM Contributes to the Whole Supply Chain of the Electronics Industry

The upstream and downstream firms of the electronics industry are implementing knowledge management in their organizations for several years. However, there is still no research to discuss whether KM could be applied in the midstream firms. The cases in this study provide us the insight that KM can be implemented in the distribution industry to help firms to apply knowledge strategically and keep robust relationships with their suppliers and customers. One result of putting KM into practice is to accelerate the products’ time to market. Even more, distributors have more need to implement KM more urgently than designers and manufacturers because they need to face the rapidly changing technologies of upstream firms and the different, changing requirements from downstream customers. The efficiency of KM implementation contributes not only to the performance of IC designers and IC manufacturers, actually, it benefits to the whole supply chain of the electronics industry. A supply chain could profit and grow by implementing knowledge management and applying knowledge efficiently in every link of this supply chain.

Insight 2 The Effects of KM Comes from the Investment in IT

From the cases in this study, we found that the implementation of KM in Worldpeace is less hindered than in Alltek. One of the main reasons may be the investment in IT. The critical information technology in Worldpeace’s implementation of KM is a self-developed system named EIP (Enterprise Internal Portal). Worldpeace invested lots of money to develop this system to support daily work and the storage and transfer of knowledge. According to the Associate Vice President of Corporate Marketing and Communication Office of Worldpeace, they invest very generously in technologies that may be the basis of competition or contribute to their market edge. In proportion to Worldpeace’s investment in IT, Alltek seems to be more cautious. Therefore, we propose that more emphasis on investment in IT may result in more effective outcome from KM. That is, in order to have better KM performance, firms have to invest more in IT, although there is no guarantee the investment will automatically result in success consequentially.

Insight 3 Fully Supports and Clear Vision of Executives is Necessary to the Implementation of KM

In the interviews with the Associate Vice President of Corporate Marketing and Communication Office of Worldpeace, we found that the executives of Worldpeace fully supported the implementation of KM and the related activities in their organization. The president of Worldpeace attaches great importance to the new technologies that enable or help their operation. For example, they announced 2000 as the first year of the e-commerce era, and started their electronic customer service system. The next year, they also announced 2001 as the first year of e-Group. They developed their MIS in house, and imported a knowledge management system in 2002. The executives declare clearly what to do and profess their full support. However, the implementation of KM in Alltek is not as clear and definite as in Worldpeace. They don’t have the whole-hearted support from executives to put KM into practice, either. So, we claim that full support from executives may increase the efficiency of KM. That is to say, upper-level managers should show their support resolutely so that employees could execute KM more confidently and freely.

Knowledge management for firms should focus on the source of competitive advantage or ‘dynamic capabilities,’ emphasizing the dynamic character of the environment and capabilities of appropriately adapting, integrating and reconfiguring internal and external organizational skills, resources and competencies. This study suggests that the competitive advantage of distributors lies in their applying knowledge to help their suppliers and customers improve time-to-market. The application of knowledge and information plays an enabling role in the implementation of knowledge management in the distribution industry. As the cases show, through Worldpeace’s and Alltek’s timely response and co-innovation with suppliers and customers, there should be a mechanism or system to effectively create, store, transfer and apply the knowledge. The description of the implementations of KM in both Worldpeace and Alltek has demonstrated efficiency and achievement in these regards. Therefore, it is essential and positive for distributors to realize the necessity to put knowledge management into practice in order to gain or sustain competitive advantage in the knowledge-based economy.

Conclusion and Suggestions

creation, storage/retrieval, transfer and application when businesses implement knowledge management in the distribution industry. Two cases, Worldpeace and Alltek are studied to reveal the real practice of IC distributors implementing KM. From the description in the cases, we found that distributors have to implement KM more urgently than designers and manufacturers because they need to face the rapidly changing technologies of suppliers and the different, changing requirements from customers. Findings in this article indicate that IC distributors pay special attention to knowledge application in order to integrate various knowledge and chips from different suppliers into a module and provide total solutions that create value for their customers. Furthermore, findings in this study also reveal that emphases on investment in IT and support from executives have potential to improve the efficiency and the favorability in implementation of KM.

This study may have practical implications for the distribution industry, not just IC distributors. Distributors in other industries could refer to the implementation in Worldpeace, and avoid some imperfections that have occurred in Alltek. However, being distributors, they have to be well informed of the knowledge and information from suppliers, customers, competitors, and the market. So, they should focus on the use and reuse of the knowledge and information from the supply chain and market. To maximize the impact of knowledge management processes, the implementation of work-flow design and information systems should reflect an understanding of the vital role that knowledge plays in contributing to improving the firm’s performance and profitability and customers’ intentions.

However, overall applications from case studies are difficult to infer from a few cases and the generalization of the findings is limited to the contexts studied (Yin, 1994). Future research could adopt other cases in the distribution industry and apply quantitative methods to consider or calculate the weight of knowledge management processes in implementation of knowledge management. Besides, researchers could investigate the enabling roles of knowledge management in other industries, beyond the bounds of high-tech and related industries.

References

Alavi, M. & Leidner, D. E. 2001. Review: Knowledge Management and Knowledge Management Systems: Conceptual Foundations and

Research Issues. MIS Quarterly 25(1), pp.107-136.

Bhatt, G. D. 2001. Knowledge management in organizations: examining the interaction between technologies, techniques, and people. Journal of Knowledge Management 5(1), pp.68-75.

Breu, K., Ward, J. and Murray, P. 2000. Success Factors in Leveraging the Corporate Information and Knowledge Resource Through Internets. In Knowledge Management and Virtual Organizations, Malhotra, Y. (ed.); USA: Idea Group Publishing; pp.306-320.

Corey, E. R. 1991. Industrial Marketing: Cases and Concepts, Englewood Cliffs, NJ: Prentice Hall.

Cross, R. & Baird, L. 2000. Technology is not Enough: Improving Performance by Building Organizational Memory. Sloan Management Review 41(3), pp.69-78.

Davenport, T. H. & Prusak, L. 1998. Working Knowledge: How Organizations Manage What They Know, Boston: Harvard Business School Press.

Demarest, M. 1997. Understanding Knowledge Management. Long Range Planning, 30(3), pp.374-384.

Drucker, P. F. 1993. Post-Capitalist Society, Oxford: Butterworth Heinemann.

Ellis, C. A., Gibbs, S. J. and Rein, G. 1991. Groupware: Some Issues and Experiences. Communications of the ACM, 34(1), pp.39-58.

Fulk, J. and Boyd, B. 1991. Emerging Theories of Communication in Organizations, Journal of Management, 17(2), pp. 407-446.

Hansen, M. T., Nohria, N. & Tierney T. 1999. What’s Your Strategy for Managing Knowledge? Harvard Business Review, 77(2), pp.106-116. Hauschild, S., Licht, T. & Stein, W. 2001. Creating a Knowledge Culture.

The McKinsey Quarterly, (1), pp.74-81.

Huber, G. 1991. Organizational Learning: The Contributing Processes and the Literatures. Organization Science 2(1), pp.88-115.

Ishii, H., Kobayashi, M. and Arita, K. 1994. Iterative Design of Seamless Collaboration Media. Communications of the ACM, 37(8), pp.83-97. Johansen, R. 1988. Groupware: Computer Support for Business Teams,

New York: Free Press.

Kling, R. 1991. Cooperation, Coordination, and Control in Computer-Supported Work. Communications of the ACM, 34(12), pp. 83-88.

Kotler, P., Ang, S. H., Leong, S. M., and Tan, C. T. 1999. Marketing Management: An Asian Perspective, Singapore: Prentice-Hall.

Maes, P. 1994. Agents That Reduce Work and Information Overload. Communications of the ACM, 35(11), pp.30-40.

Majchrzak, A., Rice, R. E., King, N., Malhotra, A. and Ba, S. 1999. Computer-Mediated Inter-Organizational Knowledge-Sharing: Insights from a Virtual Team Innovating Using a Collaborative Tool. Information Resources Management Journal, 13(1), pp.44-53.

Malhotra, Y. 2000. Knowledge Management & New Organization Forms: A Framework for Business Model Innovation. Information Resources Management Journal, 13(1), pp.5-14.

Nonaka, I. 1994. A Dynamic Theory of Organizational Knowledge Creation. Organization Science 5(1), pp.14-37.

Nonaka, I. & Takeuchi, H. 1995. The Knowledge-Creating Company, New York: Oxford University Press.

Nunamaker, J., Briggs, R. and Mittleman, D. 1995. Electronic Meeting Systems: Ten Years of Lessons Learned. In Groupware: Technology and Applications, Coleman, D. and Khanna, R. (ed.); NJ: Prentice-Hall; pp.49-193.

Pentland, B. T. 1995. Information Systems and Organizational Learning: The Social Epistemology of Organizational Knowledge Systems. Account, Management and Information Technologies, 5(1), pp.1-21. Prokesch, S. E. 1997. Unleashing the Power of Learning: An Interview

with British Petroleum’s John Browne. Harvard Business Review 75(5), pp. 5-19.

Romano, N. Jr., Nunamaker, J., Briggs, R. and Vogel, D. 1998. Architecture, Design, and Development of An html/javascript Web-based Group Support System. Journal of the American Society for Information Science, 49(7), pp.649-667.

Saffady, W. 2000. Knowledge Management: An Overview, Information Management Journal, 34(3), pp.4-8.

Stein, E. W. & Zwass, V. 1995. Actualizing Organizational Memory with Information Systems. Information Systems Research, 6(2), pp.85-117. Stern, L. W. and El-Ansary A. I. 1996. Marketing Channels, 5th ed, Upper

Saddle River, NJ: Prentice Hall.

Sveiby, K. E. 1997. The New Organizational Wealth: Managing & Measuring Knowledge-Based Assets, Calif.: Berrett-Koehler Publishes.

Tan, S. S., Teo, H. H., Tan, B. C., and Wei, K. K. 1998. Developing a Preliminary Framework for Knowledge Management in Organizations. In Proceedings of the Fourth Americas Conference on Information

Systems, Hoadley, E. and Benbasat I. (ed.), Baltimore, MD; pp.629-631.

Thornton, C. and Lockhart, E. 1994. Groupware or Electronic Brainstorming. Journal of Systems Management, 45(10), pp.10-12. Thurow, L. C. 1999. Building Wealth: The New Rules for Individuals,

Companies, and Nation in a Knowledge-Based Economy, New York: Harper Collins.

von Krogh, G. 1998. Care in Knowledge Creation. California Management Review, 40(3), pp.133-153.

Webster, J. and Trevino, L. K. 1995. Rational and Social Theories as Complementary Explanations of Communication Media Choices: Two Policy-Capturing Studies. Academy of Management Journal 38(6), pp.1544-1572.

Yeung A. K., Ulrich D. O., Nason S. W., & von Ginow M. A. 1999. Organizational Learning Capability, New York: Oxford University Press.

Yin, R.K. 1994. Case Study Research Design and Methods, 2nd edn. Thousand Oaks, CA: Sage.

Thurow, L. C.: Building Wealth: The New Rules for Individuals, Companies, and Nation in a Knowledge-Based Economy. New York: Harper Collins (1999).

Appendix:

1. Overview of Worldpeace:

World Peace Group, established in Taipei, Taiwan in 1981, became an OTC listed-company in 1987 and a TSE-listed company in June 2000. Its capital is 0.97 billion USD in 2004, and its group sales in 2006 were 20 billion USD. with over 40% growth rate. It is the largest and leading electronic component distributor in the Asia Pacific region; moreover, it was ranked the sixth-largest among top global semiconductor distributors worldwide by EBN (a dedicated semiconductor website) in its yearly selections in 2003. With offices across the Asia Pacific region and 1700 employees (including more than one hundred engineers for technical support), it combines 60 product lines for a large economic scale. Worldpeace is building a solid distribution and service channel to grow with its customers. Its ultimate value resides in customers' satisfaction with its industry-leading services, such as technical support, logistic management and e-services.

Worldpeace was awarded NO. 11 of top 500 service industry companies by Taiwan Common Wealth Magazine and was NO. 1 of information, communication, and IC distribution industry in 2005. Worldpeace builds close relationships with their suppliers, to reliably provide customers’ IC components with high quality service at competitive prices. Their suppliers include 60 world-famous firms, like Intel, TI, Philips, Hynix, and Vishay etc. They integrate the components of computer, communication, and consumer electronics to provide more competitive combination of products, and provide customers the convenience of one-stop-service. Worldpeace’s primary products are ASSP, Central Processing Unit (CPU) /Micro Processing Unit (MPU), Memories, Logic Components, Linear Components, and Discrete Components.

In, Worldpeace, the Department of Knowledge Management was founded to facilitate the implementation of KM. Worldpeace invested positively in the information technologies or systems that help them to gain competitive advantage and contribute to potential profit. They stored and transferred their knowledge, information, order status, and market conditions in their self-developed information system that is named EIP (Enterprise Internal Portal)

2. Overview of Alltek:

Alltek Technology Corporation is a professional distributor of communication technologies, founded in Taipei in 1991. It is a new IPO firm, and a professional design house and distributor of communication technologies. It is the first distributor that has the capability of researching and designing chips, modules, and systems. Alltek was awarded NO. 235 of top 500 service industry companies by Taiwan Common Wealth Magazine in 2005. Alltek incorporates technical and marketing experts from top international companies so as to differentiate themselves from general distributors. They not only provide their customers with competitive product price and in-time delivery, but they also integrate all communication ICs and solutions for customers. Their operating income was 55.17 billion USD with 200 employees in 2006. Relative to Worldpeace, Alltek is much smaller in scale and business volume.

Alltek has kept good relationship with their suppliers for several years; they even co-design components with their suppliers. The suppliers of Alltek are Accelwork, Atmel, AudioCodes, Broadcom, Bourns, CML, Hitachi AIC, IDT, Infineon, Mindspeed, MMC, ON Semiconductor, Supertex, Trumpion, and Widcomm. The primary products in Alltek are

Wireless Communication Components, Broadband Access Devices, Optical Devices, Voice Processing Devices, Protection Devices, and Power Management Devices.