Proceedings of the 2009 13th International Conference on Computer Supported Cooperative Work in Design

The Analysis and Development of Taiwan's Industrial Logistics Hubs

Charles

v.

Trappeyl, Amy J.C. Trappey2, Gilbert YP. Lin2, C.S. Liu

3and W.T. Lee

31

Dept. ofManagement Science, National Chiao Tung University, Taiwan

trappey@faculty.nctu.edu.tw

2

Dept. ofIndustrial Engineering and Engineering Management, National Tsing Hua University,

Taiwan

trappey@ie.nthu.edu.tw

3

Identification and Security Technology Center, Industrial Technology Research Institute, Taiwan

WT_Lee@itri.org.tw

Abstract

With the trend of globalization, enterprises require to extend their logistics scope from domestic to international, integrate logistics networks, and improve the agility and efficiency of global operations. This paper reviews the design and implementation of the industrial logistics hubs which belong to six manufacturing sectors in Taiwan over the past five years. Different industries have their own industry character, business strategy, and logistics models. Therefore, this paper organizes the executive problems and their corresponding solutions during project execution phases. Finally, this paper depicts the companies' executive experience and presents the future outlook for other companies and industry sectors' reference.

Keywords: Logistics Hub, Supply Chain, Outlook.

1. Introduction

Taiwan's industrial sectors are playing an important role in the global supply chain. According to the Ministry of Economic Affairs' report, the percentage of manufacturing orders placed in Taiwan and produced overseas exceeded 47% in October 2007. Compared with two years ago (38%), the percentage has increased 9% within two years. The overseas manufacture of information and communication products has exceeded 70% and the products made by the traditional manufacturing industry (e.g., mechanical, electrical products, household appliances, transportation vehicle, toy, and sports goods) has reached 40% [I]. Thus, Taiwan industries are transferring orders abroad at a fast rate requiring new global configurations in the supply chain. The means by which industries strengthen and enhance supply chain efficiency and decrease logistics management cost have become a critical factor for Taiwan economic development.

In order to respond to the demands for new logistics hub across industry sectors, the Department of Commerce of the Ministry of Economic Affairs commissioned the 978-1-4244-3535-7/09/$25.00 ©2009 IEEE

Identification and Security Technology Center of Industrial Technology Research Institute (ITRI) to execute an integrated logistics and business hub development project from 2004 to 2008. The main purpose of this project is to assist industry to integrate information flows (via the business hub) and material flows (via the logistics hub) to facilitate global supply chain linkage. The business hub offers the information sharing and management functions for raw material and component procurement, inventory control, transportation tracking, customs clearance services, customer order processing, and other activities at the request of the supply chain participants. The logistics hub is a physical facility which is operated by the Logistics Service Providers (LSPs) and focuses on management of physical logistics operations including shipment consolidation, warehousing, transportation, packing, collaborative replenishment, and tax-bonded warehousing. The operation model of the integrated industrial logistics hub is shown in Figure I. Shipping InSlnlCtions Goods Receiving Goods Tracking Order Tracking InvclIloryQucry

Figure1.The integrated business and logistics hub The development project positions the manufacturers as the leader to form the strategic alliances with trading partners (e.g., suppliers, customers, carriers, forwarders, truckers, and brokers) and the primary financier of the integrated hub. The functional goal of the hub is to integrate

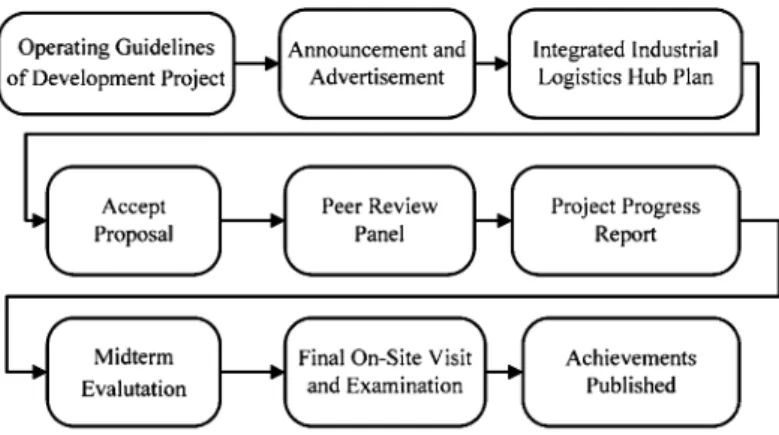

supply chain resources, provide real-time material supply, ensure information transparency, improve logistics efficiency, and increase customer service quality. Another goal of the project is to push the aligned partners to outsource tasks to domestic LSPs. Thus, the LSPs receive detailed requirements from the industry sectors and receive financial inception to develop professional and globally oriented services. The execution steps for the development project are shown in Figure 2. The manufacturer provides the content and detailed planning for the hub. With the goal of hub integration as a prerequisite, the manufacturer derives the hub specifications according to the scope of the project:

• Provide an integrated plan for the material and component supply-chain and product global demand-chain operations.

• Develop an inbound shipping system for the material and component joint-purchasing and outbound shipping system for product joint-ordering.

• Provide an order tracking and query system for the material and component supply-chain that satisfies product global demand.

• Develop an inventory and safety stock management system for products, materials, and components. • Develop a goods tracking and query system for

products, materials, and components.

• Develop a collaborative planning, forecasting, and replenishment (CPFR) system.

• Perform a pilot test for the global logistics hub. • Implement an radio frequency identification (RFID)

application system following globally accepted standardization among the up-stream and down-stream supply chain.

checks the documents and systems listed in the proposal. Furthermore, the examination committee also questions and provides the suggestions for future hub development. The guidance company is required to reply to the committee's requests and implement changes and modifications are reported.

This paper reviews the development of the six industries' integrated logistics hub over the past five years. Some of the manufacturers implemented RFID technology (e.g., RFID electronic seals and Electronic Product Code Network) to enhance operational performance and reduce management cost. Since different industries have their own character, business strategy, and logistics models, this paper organizes the problems and the corresponding solutions by manufacturers in Section 2. Section 3 depicts the case companies' executive experience and presents the future outlook for other companies and industry sectors. Finally, conclusions are drawn in Section 4.

2.

Review

of

integrated

logistics

hub

development

2.1. Achievements and benefits of the selected industry sectors

The integrated logistics hubs were developed for six industrial sectors that linked 986 upstream and downstream supply chain firms, 25 logistics service providers (LSPs), and 11 information service providers (ISPs) with s combined investment of almost US$ 9.7 million. The executive achievement and benefits of each industry sectors are depicted as follows.

Figure 2.Executive approach of the development project The development project begins on the date the manufacturer passes the peer review. The development project executive agent (i.e., ITRI) is designated by the government to sign contracts with the selected companies and offer consulting services. The company fulfils the works and the execution steps of the proposal and is subjected to a midterm evaluation and final examination of progress according to the proposed specifications. An on-site visit is scheduled for the final examination of the new logistics facilities. The examination committee checks the achievements, key performance indicators (KPIs), and

2.1.1. Electronics industry. In this industry, the long lead time for procurement and high inventory cost due to difficult to integrate material and information flows. The manufacturer lacked of real time communications between upstream and downstream supply chain members. In addition, repeated data entry from manual operations and inefficient labor handling decreased logistics operation efficiency. For these reasons, when the project was proposed and implemented from 2004 to 2005, following specifications were achieved. First, the logistics hub was required to support shipment consolidation from multiple suppliers and to stably material supply. The outsource logistics operations members were also advised to enhance logistics efficiency. Second, the business hub was required to integrate logistics information from the aligned members including inventory and safety stock management, order tracking management, goods tracking management, demand forecasting management, and collaborative replenishment management.

2.1.2. Automotive industry. In this industry, the logistics operations for finished cars are managed by different brands' dealers at different locations. Each dealer set up its own equipments for pre-delivery inspection (PDI) and retrofit operations which is a redundant use of resources. Finished cars can potentially be damaged during the transportation processes. Landing times were also too long since dealers required a long order-to-delivery lead time and

Achievements Published Project Progress

Report Integrated Industrial

Logistics Hub Plan

Final On-Site Visit and Examination Announcement and Advertisement Operating Guidelines

only used the telephone to track the delivery status. Further, the slot spaces and materials in the warehouse of the car factory are insufficient due to too many types of parts and high frequency supply. Given the analysis, the development project implemented from 2005 to 2008 focused on the creation of the hubs for the export of aftermarket parts, the domestic sales of aftermarket parts, the linkage with local manufacturer, the import of multi-brands of automobile, the export of automobiles and knock-down parts, and the creation of multi-brands of a production line. The detailed specifications required building an RFID-based goods tracking system for the export aftermarket parts to increase information transparency and customers' satisfaction. For the domestic market, the hub was designed to integrate the logistics operations of aftermarket parts for different dealers and construct the automatic replenishment mechanism. Since the manufacturer wanted to centralize the retrofit operations and inspections, RFID technology was proposed to control and monitor finished cars. The storage facility was designed so that multi-brands of cars could be imported to a bonded warehouse at the Taipei Port. Upon receipt from ships, pre-delivery inspection is performed and delivered directly to dealers to reduce the risk of damaging the automobiles. In order to control the automobiles' export processes, inland transportation, export preparation, and dock loading operations also implemented RFID technology. The hub assigned local logistics service provider that had solid reputation and were flexible enough to adopt new technology and service other brands' automobiles. The manufacturer intends to merge the multi-brand production lines into single line that can handle small-quantity demand. The hub utilized an automatic material supply and replenishment system to save factory space, manpower, and cost. For knock-down parts, the manufacturer well set up a tax bonded warehouse within the factory. The import parts will be stored in the hub, then assembled into the cars which are shipped directly overseas. This approach simplifies the tax refund processes and reduces the customs duties fees. 2.1.3. Integrated circuit industry. The logistics operations of the integrated circuit company are overloaded and provided insufficient automation which affects order processing (e.g., emergency order and order status management). Since more and more customers require vendor managed inventory service, the application of this approach will shorten lead time and transportation distance. Low information transparency and a lack of visibility lead to high inventory levels and long lead times. When the project was implemented from 2006 to 2007, this project also covered the implementation of a Hong Kong transfer hub, a Taiwan logistics hub, an overseas logistics hub, and a business hub. The first step for the manufacturer was to construct an international logistics channel for finished products moving from Taiwan to Hong Kong and to outsource related logistics operations including warehousing, transportation, export operations, custom clearance, and tax bonded processes. The focus of the Taiwan logistics hub was to use RFID to better manage incoming and outgoing shipment operations. The overseas logistics hub implemented vender managed inventory services for

overseas customers and the business hub provided a supply chain information platform to manage order processing, shipping processing and tracing, material and parts receiving, inspection, and inventory control.

2.1.4. Automotive materials supply industry. The automotive materials supply industry was facing difficulty delivering goods to location on time. In addition, the distribution costs were high due to dispread geographic distribution and the over use of manual communication. Without professional service provider, the manufacturer had reached a deadlock in development. When the hub was implemented from 2006 to 2007, several key steps were taken to improve efficiencies. For the logistics hub, the manufacturer transferred its original transportation fleet, warehouses, operators, and equipments to a newly third party logistics company. The hub applied the use of a joint-inventory and joint-distribution process to consolidate goods shipments from multiple suppliers to multiple customers. The target of development for the business hub was to implement a supply chain management system to integrate logistics information between upstream and downstream members to include order processing, transportation, goods tracking, and replenishment.

2.1.5. Automotive aftermarket part industry. The automotive aftermarket part company was under great pressure to shorten due dates and provide online shipment status for its dealers in North America. The development project for aftermarket product manufacturer was implemented from 2007.to 2008. This project rebuilt the supply chain management system and added an RFID-based goods tracking system. In order to improve the cooperative between distribution and transportation services with service provider in Taiwan and North America, the design of the network became a key focus of the project. A new supply chain system was implemented to integrate the logistics information and provide due date reply, and forecasting to the logistics service provider and clients. An

RFID-based goods tracking system was also implemented. The RFID technology was used to track the export container from the production line, to inland transportation, to the dock terminal, to the overseas container terminal, and finally to the overseas logistics hub.

2.1.6. Semiconductor manufacturing industry. The sources for raw materials are widespread and supply is frequently uncertain in the semiconductor manufacturing industry. The suppliers had real-time replenishment system, but, low information transparency causes longer lead times and slow reaction when shortage. Thus, the manufacturer experienced difficult in preparing and maintaining raw materials. This development project implemented in 2008 with a focus on the creating a vendor managed logistics hub and a manufacturer's business hub. The logistics hub was designed to provide warehouse management, real-time delivery, and replenishment for material supplies. The objectives of the business hub were to provide information links between suppliers, manufacturers, and logistics service providers. The business hub manages and integrates the procurement, order processing, storage, goods tracking, and collaborative planning and replenishment of materials. The

achievements and benefits is provided in Table 1. db fi b

summary for the proposed integrated logistics hub

T bl 1a e Ac levements anh· ene Its .ymanu acturers

Manufacturer Proposed Achievements Benefits

(1) Logistics hub implementation: Support shipment (1) Upgrade information systems to share and exchange consolidation and stable material supply. logistics information.

Conventional (2) Business hub implementation: Integrate logistics (2) Reduce inventory by increasing supply chain electronics information and related functions. inventory visibility.

industry (3) Use E-document to replace fax and telephone.

(4) Shorten supply chain shipping time by integrating orderprocessin~operations.

(1) Export aftermarket parts hub: Build an RFID-based (1) Reduce dealer's order-to-delivery lead time. goods tracking system for export parts. (2) Integrate pre-delivery inspection and retrofit (2) Aftermarket parts for domestic sales: Integrate the operations at the Taipei Port.

logistics operations of aftermarket parts for different (3) Outsource logistics operations to professional logistics dealers. service providers to decrease operational costs and (3) Crate a locally manufactured automobile hub: encourage innovation.

Centralize the retrofit operations and inspections. (4) Provide timely shipment status via an RFID-based Automotive (4) Create multi-brands automobile import hub: goods tracking system.

industry Perform pre-delivery inspection and deliver cars (5) Decrease landing times to reduce the potential risk of directly to dealers. damage to automobiles in port.

(5) Export automobile hub: Control the automobile (6) Build an automatic material supply and replenishment export processes. system to save factory space, manpower, and cost. In (6) Multi-brands automobile production line hub: addition, the suppliers can directly ship materials and

Merge the multi-brands' production lines into one. parts to the assembly line. (7) Knock-down imported parts hub: Set up a tax

bonded warehouse within manufacturer's factory.

(1) Hong Kong transfer hub implementation: Fulfill (1) Outsource logistics operations to decrease the logistics logistics service with logistics service providers cost (limited space and high rental) and let the from Taiwan and Hong Kong. manufacturer focus on core competencies.

(2) Taiwan logistics hub implementation: Establish (2) Vendor managed inventories enhance service quality Integrated RFID-based incoming and outgoing shipment and provide an international competitive advantage. circuit industry operations. (3) Enhance supply chain information transparency to

(3) Overseas logistics hub implementation: Offer balance demand and supply and decrease inventory vender managed inventory services for overseas levels.

customers. (4) Increase the data exchange efficiency with customers (4) Business hub implementation: Develop a supply to improve order processing, and shipment processing.

chain information platform.

(1) Logistics hub implementation: Apply the joint- (1) Institutionalize the inventory and joint-Automotive inventory and joint-distribution mechanism. distribution mechanism to increase shipment speed

materials (2) Business hub implementation: Integrate logistics and share logistics costs.

supply industry information between upstream and downstreammembers. (2) Establish a new third party logistics company to assistsupply chain participants as active members of the logistics operations.

(1) International transportation and trade channel (1) Achieve tighter corporation with suppliers and construction: Fulfill logistics service with logistics promote industry upgrade.

Automotive service providers from Taiwan and North America. (2) Shorten supply chain response time, deliver goods on-aftermarket part (2) Supply chain management system implementation: time, and increase customer satisfaction.

industry Integrate and manage logistics information. (3) Enhance the container and goods tracking ability and (3) RFID-based goods tracking system implementation: logistics service quality.

Monitor the export container throughout the journey to abroad customers.

(1) Vendor managed inventory logistics hub (1) Logistics service providers take charge of the logistics Semiconductor implementation: Provide better warehouse hub operations and consolidate goods shipments from manufacturing management for stable material supply. multiple suppliers.

industry (2) Business hub implementation: Build visibleinformation connections between suppliers, (2) Using vendor managed inventories, the lead time isshortened (from warehouse to production line) and manufacturers, and logistics service providers. inventory levels are reduced.

2.2. Problems and solutions for the industry sectors

This section describes the deficiencies and problems experienced when the six companies implemented the hubs. The solutions are provided as references

suggestions for future companies planning to implement similar situations.

(1) Implementation of business models. Some of the business models implemented failed to demonstrate improved of logistics performance between manufacturers, suppliers, and logistics service providers. The manufacturer reviewed the supply chain and

provided the following parts of discussion for hub improvement.

(2) Suppliers' resistance.Some suppliers disputed the new logistics policy during the initial promotion of the logistics hub. Therefore, the manufacturer convened supplier seminars to explain the suppliers' responsibility and reinforced the direction and goal of the project.

(3) Logistics service provider selection and cooperation. Domestic service providers are mostly small and medium sized enterprises with limited capability to operate logistics hub. Thus, the manufacturers interviewed several companies to select candidate. The manufacturers were required to arrange different logistics operation models based on the different suppliers' logistics requirements and capabilities.

(4) Project key performance indicators selection.

The manufacturers were requested by project sponsors to use key performance indicators to demonstrate improvement.

(5) Information transmission. The manufacturers were changed with the responsibility to understand and adopt to the different computerization levels of supply chain partners. Some members had ERP or MRP system but others used PC or manual operations (fax and telephone). The manufacturers planed two kinds of approaches (application-to-application and web-based) to exchange data for different levels of computerization among partners.

(6) Explanation and negotiations. During the system requirement development phase, manufacturers experienced difficulty in collecting and coordinating different departments' data and opinions. The manufacturers added project executive with the authority to control resources, hold monthly meetings, and monitor the progress of each department.

(7) Application of RFID. The manufacturers experienced some difficulties in using RFID including low recognition rate by the tag reader and high cost of RFID equipments. Therefore, the review of technologies was conducted and caused the industry sectors hang back. The upgrade of RFID technology and cost down of RFID equipments are sought to assist the logistics service providers and manufacturers.

3. Future outlook for integrated logistics

hubs

This paper presents a future outlook and suggestions for government and industry sectors to develop follow-up industrial logistics hub. The future outlook is divided into six parts including (1) logistics outsourcing service aspect, (2) information and communication technologies (ICT) aspect, (3) supply chain security aspect, (4) general model and key performance indicator (KPI) aspect (5) green environmental

protection aspect, and (6) cooperation with free trade zone (FTZ) aspect.

3.1. Logistics outsourcing service aspect

The logistics outsourcing service is a strategy of modem supply chain management [2]. It is also a critical implementation issue of industrial logistics hub development project to help grow domestic LSPs. According to Aberdeen Group's global supply chain benchmark report which surveyed 150 companies, fully 87% of large enterprises (annual sales more than 1 billion USD) indicated that their company's staffing for managing global supply chain processes is inadequate [3]. The leading multinational firms have decentralized their operations to LSPs in order to focus more on their core competitiveness such as research and development (R & D), manufacturing, and marketing [4]. This is triggering increased attention on outsourcing logistics operations to LSPs.

In Morgan Stanley's report [5], the LSPs can be classified as five types according to the concept of reflect the evolving demands of supply chain management from first party logistics (IPL) to fifth party logistics (5PL). The IPL (i.e., manufacturer) essentially owns and handles all self-logistics functions. The 2PL is generally a conventional capacity provider that services for a single (or small number) functions in the supply chain, such as trucking and warehousing. The 3PL performs a large portion of clients' supply chain logistics activities. The 4PL provides integrated logistic service for the logistics outsourcing requirements. The 5PL focuses on providing overall e-logistics solutions for the entire supply chain. According to the survey of Industrial Economics & Knowledge Center (IEK) about current service model of Taiwan's LSPs, Taiwan's LSPs are mainly IPL (28.7%) and 2PL (58.2%) and provide fundamental support services due to they are mostly small and medium sized enterprises (SMEs). Less LSPs are involved in customers' main supply chain and logistics activities, among them 3PL only occupied 9.8%, 4PL occupied 1.3%, and 5PL occupied 1.4% of the logistics market. Hence, Taiwan's LSPs only provide basic storage and transportation services for their customers.

The suggestions of logistics outsourcing strategy are divided into two directions: central manufacturer and LSPs. On the side of the central manufacturer, some manufacturers never applied logistics outsourcing. It is hard to select appropriate 3PL for operating logistics hub during the project implementation. This research recommends that the manufacturer should consider its strategy and examine the cooperated LSPs' service items, scope of logistics network, information technology ability, and service quality when choosing LSPs to be business partner. In addition, some central manufacturer have already owned individual logistics department as a result of the industry property and

While relying more and more on logistics and supply chain outsourcing service, enterprises simultaneously increase the collaboration with supply chain partners. Besides establishing the management mechanism, they also strengthen cooperative information operations, especially the investments and applications of information and communication technologies (ICT). According to Aberdeen Group's global supply chain benchmark report which surveyed 150 companies, 79% of large companies and 51 % of respondents expressed that the lack of supply chain process visibility is their top concern. Three-quarters of firms lack enterprise-wide automation for global supply chain processes [3]. Among the top 10 enhancements planned in next 2 years, "expand number of trading partners providing status information," "incorporate additional status events," and "add warning alerts" are the top that the respondents plan to enhance. In addition, 43% and 41 % of respondents indicated that wanted to add RFID and mobile technologies into their supply chain visibility solutions. Therefore, the globalization market has stimulated the enterprises on the use of ICT for their global supply chains. The information flow of industrial operation strategy. The logistics outsourcing strategy is difficult to apply due to cost and convenience considerations. In this case, manufacturer can consider the feasibility of converting its logistics department into independent 3PL company which integrates suppliers and establishes a supplier site's logistics hub to expand added value.

As mentioned above, LSPs companies are thriving in their business because of the globalization of markets and operations. However, the abilities and services of Taiwan's LSPs are insufficient when facing the foreign large-sized competitors. The foreign leading LSPs such as DHL, UPS, and FedEx have been used merge, acquisition, or alliance to become the supply chain solution providers which offer one-stop shopping services. Furthermore, the leading LSPs actively apply information technology to expedite comprehensive and profound e-Iogistics services. This research suggests that the industrial logistics hub can be developed by 2-3 LSPs which should be complementary to each other. Except strengthen the scope and depth of physical logistic services, the domestic LSPs also should enhance their information technology ability. The domestic LSPs can refer foreign leading LSP to adopt horizontal and vertical integration via strategic alliance and electronic commerce. The horizontal integration between the same business groups can increase the economy scale. And, the vertical integration between different business groups can improve information transparency and supply chain visibility.

3.2. Information technologies aspect

and communication

logistics hub is divided into two parts including (1) physical goods' information collection, and (2) supply chain information share and transmission. The paper presents the suggestions of ICT from these two parts separately.

In order to enable tracking more logistics status events, enterprise has to collect physical goods' information in the supply chain. Nowadays, barcode is widely used in the supply chain. However, barcode has several disadvantages such as limited capacity for storing information and the print quality of the barcode directly affects its readability. Furthermore, barcode takes a lot of time to identify large number of objects since each item must be manual-scanned [6]. Those restrictions make barcode unable to handle the timely demand of modem supply chain. The emergence of new technologies, RFID, is expected to revolutionize supply chain by offering new possibilities for timely tracking unique product [7]. Gao et al. [8] outline serveral properties which RFID is superior to bar codes for tracking product over the supply chain including RFID tags can be read without direct physical contact or require individually scan each item, the read range of RFID is larger than bar code reader, multiple RFID tags can be read simultaneously and wireless, and RFID tags can store more data than bar codes. The expected benefits of RFID in the logistics and supply chain management include better tracking of product logistics, improved efficiency and accuracy in warehouse management, reduced counterfeits, and better control of stealing.

Indeed, RFID offers a number of significant advantages and has ignited the interest of firms that want to increase the accuracy and flexibility of production, logistics and selling activities across many industry sectors, notably manufacturing, transportation, wholesale and retail. Although RFID is applicable in industrial sectors, few firms have found a way to demonstrate a solid business case for implementing RFID. Due to the cost of RFID software and equipments are prohibitive and the techniques of domestic RFID service providers are immature, seldom enterprises want to make the investment in RFID. Therefore, domestic industry sectors and LSPs are at preliminary stage of looking, studying, and trying. The implementation of RFID may be decided by customer mandates, enactments, and self-demands. Before establishing the RFID-based system, firms must identify the company's RFID needs and added value. In addition, firms also need to establish return-on-investment (ROI) analysis to evaluate the long-term viability. Each company must evaluate the product characteristic and the impact of RFID functions on their business process to consider implementing RFID or other alternate plans. The read rate can be highly affected by the content of the tagged products. If firms need to spend a lot of operation cost identifying products when transferring and the products' unit price

can afford the cost of RFID tag, it is advisable to use RFID to enhance the efficiency of logistics operations. Finally, the prerequisites of a successful RFID project are basic level of e-business, appropriated environment and equipments, the level of technology adoption by all supply chain partners, and the support of supervisor. Furthermore, firms should follow the evolution of RFID standards closely. These international standards will evolve in time, and firms must be aware of the latest trends and future vision in order to develop a sustainable global RFID strategy.

Besides RFID, many advanced technologies such as mobile technology, wireless, and global positioning satellite (GPS) have recently been applied in the manufacturing, and logistics service [9] [10] [11]. Kim et al. [12] suggested that firm can achieve a distinct competitive advantage through innovative information technology (i.e., RFID and mobile technologies), which has enabled it to create the e-Iogistics services. This research also introduced a real case of a third-party logistics (3PL) provider in South Korea to show how it aspired to be a leader in the 3PL industry.

Besides collecting the physical goods' information, enterprises have begun pursuing greater efficiency in sharing and transmitting supply chain information. In the supply chain activities, different companies use different kinds of system architecture, data format, and system functions [13]. It takes a lot of time to transmit and process the data. Therefore, how to build an effective data exchange mechanism and construct a logistics information management system to manage the logistics and supply chain operations becomes a critical issue. It is suggested that the firm can consider the emerging information technology, such as web-service technology, to extract and exchange data and enhance information efficiency [14].

Further, the enterprises should examine the level of satisfaction and the actual need on effective use of information systems for their logistics and supply chain management [15]. There were a deep divide between actual system and original expectation in the previous implemented business hub system. Most previous systems were drawn up by application service provider (ASP) and central manufacturer and seldom discussed the system demand with all system users (e.g., transporter, supplier, broker, and carrier). The company needs to communicate and makes a common consensus with all system users to gain the maximum benefit of the business hub system.

3.3. Supply chain security aspect

After 911 terrorist attacks, the issues of supply chain security concerns and fast customs clearance raise public respect. In response to growing concerns, there are many ideas and practices on supply chain security management such as customs-trade partnership against terrorism (C-TPAT), container security initiative (CSI), and freight security requirement (FSR). Among the

number of security InItIatIves, the security and facilitation in a global environment (called WCO SAFE) framework which is proposed by World Customs Organization (WCO) in 2005 is admitted and adopted mostly at present.

The WCO SAFE is a voluntary compliance program. It aims to enhance the certainty and predictability of high-risk consignments detection and secure the seamless movement of goods throughout the global supply chains. The SAFE framework consists of four core elements. First, it harmonizes the advance electronic cargo information requirements on inbound, outbound and transit shipments based on WCO data model. Second, each country that joins the SAFE framework must commit to employing a consistent risk management approach to address security threats. Third, the framework requires that at the reasonable request of the receiving nation, the sending nation's customs administration will perform the inspection of outbound high-risk containers by non-intrusive detection instruments such as large-scale X-ray inspection machines and radiation detectors. Fourth, it defines the concrete benefits to be received by businesses that commit to implementing the framework's standards.

In addition to the four core elements, the framework also has two major pillars. The first pillar is customs-to-customs network arrangements. It transfers the responsibility and authority of import custom to export custom. Besides, the customs administrations should apply the unique consignment reference (UCR) number and its accompanying guidelines. The UCR is a reference number for customs use and may be required to be reported to customs at any point during the customs procedures. The second pillar is customs-to-business partnerships. It introduces the authorized economic operator (AEO) concept to enhance the cooperation between customs administrations and private enterprises. The WCO SAFE participants who voluntarily meet the highest level of security can acquire the benefits such as speedier clearance of low-risk consignments, fewer customs inspections, and reduced border wait times. These two pillars involve a set of subordinate standards and the detail explanations are depicted in the WCO SAFE document released by WCO [16]. It presents them for adoption as a minimal threshold of what must be done by WCO members.

Until April 2008, there are 152 out of 173 member countries of the WCO and 80% of APEC member countries expressing their wills to implement the framework [17]. The United States., the European Union, and nations of Asia-Pacific region have set up the implementation date. For example, the European Union will practice AEO criteria at 2008 and will fill out the entire implementation at 2009. Presently, the European Union are proceeding pilot project with China and selects three harbors (i.e., Rotterdam, Felixstowe, and Shenzhen) to proceed to the cooperation among those customs. Above-mentioned

information presents that the maJonty of countries participate positively in WCO SAFE and avoid to be disconnected with international trade [3].

The activities of WCO SAFE are involved very widely, its main measures include: advance electronic information communication, AEO criteria, customs-to-customs network arrangements, and outbound security inspections. If the government and industry sectors fail to response the WCO SAFE, commodities export to countries which have already followed WCO SAFE will be unable to acquire fast customs clearance service. Therefore, government and industry sectors need to closely pay more attention to international situation and take corresponding actions as soon as possible. The WCO SAFE framework is one of the future directions of industrial logistics hub. The company can consider constructing a trade lane which is based onVCR and RFID technology. The proposal company has to understandVCR'sinformation requirements, design the RFID tracking mechanism, and pilot run in a multinational environment.

3.4. General model and key performance indicator aspect

In the industrial logistics hub development project, the improvement or innovation of business model is essential part. For example, adjusting the purchase and delivery models of raw materials or establishing VMI warehouse to enhance response ability is one kind of approaches. Researches have proposed general logistics model for specific industry sector. Trappey et al. [18] provided the operational and business model of the precision machine tool industry. The scholars surveyed optoelectronics firms in Taiwan and modelled their global logistics business processes [19]. Trappey et al. [20] presented the analysis of cross-strait logistics model for automobile industry. In addition, the previous executive achievements can be organized to be the general model (e.g., suppliers integrating model of the automotive industry and logistic outsourcing model of the IC industry) to encourage other supply chain members to join or imitate.

How to set up the distinct and appropriate key performance indicators (KPI) and measure them is another key factor of industrial logistics hub. The performance measurement no only merely is the internal evaluation of the specific company. It has to reveal entire supply chain participants' performance. Each company should establish the KPIs according to its project scope and industry characteristics when deciding to construct the industrial logistics hub. The scholars [21] [22] presented the logistics and supply chain KPIs including inventory turnover, order fill rate, on-time delivery, transportation cost (inbound and outbound), customer complaints, inventory overstock/shortage/harm, inventory accuracy, order cycle time, cash to cash cycle time, inventory days of supply, supply chain response time, perfect order

fulfilment, and order processing response time. The company needs to select and set up appropriate KPIs. The quantitative KPIs should have sufficient descriptions.

This paper suggests that companies can use supply chain operation reference (SCOR) model to represent their business activities and processes. The SCOR model is initiated by Supply Chain Council (SCC) in 1996. SCOR is not a standard. It is a process reference model which integrates the well-known concepts of business process reengineering (BPR), benchmarking, and best practices analysis into a cross-functional framework to support description, measure, and analysis the supply chain. Vp to now, the SCOR model has been developed to Version 9.0 [23]. The SCOR has been applied in many practical cases such as TFT-LCD manufacturing industry [24]. In fact, the definitions of the SCOR processes and metrics are the conceptual ideas for reference. The enterprises need to adjust according to their real status. However, the SCOR model has sufficient capability and potentiality to offer process analysis and evaluative indicators for enterprises to improve their supply chain.

3.5. Green environmental protection aspect

The corporate social responsibility (CSR) has become a common recognition and one of important strategies for enterprise management. Growing environmental protection concerns and the advancement of green supply chain management concepts and practices are gaining interest in business and research [25]. Green logistics is one of the major elements and is gradually gaining attention. The objective of the green logistics is the improvement in logistics operations such as transportation, storage, packing, loading, and circulation process using the view of environmental protection to decrease environmental pollution and resource consumption. Green logistics is divided into green supply logistics, green production logistics, green market logistics (the top three items called green forward logistics), and green reverse logistics, and includes the following contents:

• Green transportation and storage: apply green transportation strategy, plan logistics network and distribution route effectively, and use green vehicle (e.g., the vehicle bums the fuel which is mixed by natural gas, alcohol, and gasoline). • Green packing and circulation process: adopt the

green packing that fulfill the 4R request requirement (i.e., reduction, reuse, reclaim, and recycle) and labeled protect environment. The circulation process should obey the green principles such as low energy consumption, high environmental protection, and avoiding harm and secondary pollution in process.

• Green reverse logistics: construct reasonable collection and recycling of product returns to

reduce the pollution on environment and increase the maximum reuse.

Green logistics is one trend of current logistic development, however, it grows slowly in Taiwan due to economic concern and the cognitive deficit of green logistics. Some companies consider that green logistics is just a kind of environmental protection concepts. It can't bring any economic benefits and increases enterprises' logistics cost. In fact, put environmental activities (e.g., concentrated utilize of resources and optimal arrange of transportation) into practice in the logistics activities of enterprises' supply chains can effectively reduce the resource consumption and environment pollution, decrease enterprises' economy cost, conducive to set up high quality enterprise image, and response international environmental protection trend and policy.

3.6. Cooperation with free trade zone aspect

With the rapid development of global logistics, the role of international logistics zones has become increasingly important. From a logistics perspective, it provides a comprehensive range of logistics services including consolidation, packing, simple or in-depth processing, land, sea, air transportation, storage, and customs-clearance in order to achieve the efficient distribution of commodities. Many firms are intent to invest in international logistics zones [26]. Therefore, a number of countries' governments (e.g., Singapore, Hong Kong, Korea, and Japan) have constructed and or plan to establish international logistics zones at major airports and seaports to expand the capacity of existing transport infrastructure and further the national economic development and competitiveness.

Taiwan has also followed the development and constructed five international logistics zones for firms, called Free Trade Zones (FTZ), in Keelung (seaport), Taipei (seaport), Tao-Yuan (airport), Taichung (seaport), and Kaohsiung (seaport). FTZs in Taiwan can benefit companies in many aspects as following [27]: • Allowing in-depth value-added processing:

provide several kinds of production activities (e.g. assembling, packaging, and manufacturing). • Relaxing hiring ratio for foreign labor: provide

highly flexible manpower arrangements. FTZ enterprises can hire foreign workers up to 40% of their total work force.

• Duty and tax exemption: provide a substantial saving on costs. The goods within FTZs are exempt from the payment of customs duties, commodity tax, business tax, tobacco and wine tax, health donation for tobacco products, harbor service fee.

• Within national territory, but outside the customs territory: allow companies to take autonomous management. Products in the FTZs may be transported freely and flexibly without

examination, inspection, customs clearance, or escorted shipment.

• Attracting business activities streamline procedures for granting entry and issue landing visas to business personnel; provide exhibition facilities and services.

• Ease of financial operations: permit setup of financial holding companies for offshore investment, and allowing offshore banking units (OBUs) to handle foreign currency transactions. The enterprises most suitable for applying to operate in FTZs are those seeking highly efficient delivery and low operating costs, and those that focus on cross-strait division of labor. Many companies are applied to become the FTZs' enterprises such as Tonglit Logistics Co. (Taipei FTZ), Far Glory Group (Taoyuan FTZ), and Kaochun Stevedoring Co. (Kaohsiung FTZ). Therefore, manufacturers and LSPs can set up logistics hubs within the FTZs to promote their competitiveness in logistic operation.

4. Conclusion

Globalization of markets and competitiveness has forced many enterprises to adopt global logistics and production models. In this situation, enterprises can't ignore the potential foreign markets and must search for comparatively low cost environments all over the world. Due to the globalization of business operations, the supply chain participants are more complicated and spread worldwide. The competitive type of a firm is no longer a matter of "company versus company" and has turned to "supply chain versus supply chain". Therefore, how to enhance the efficiency of the entire global supply chain is an essential topic for the industries. This necessitates the use of appropriate logistics resources to ensure the timely reaching of the right products and services to the market.

Considering the importance of logistics and its challenges in the global market and operations, the aim of this research is to assist the industry sectors to construct the integrated business and logistics hub model which offers a higher quality and cooperative logistics operations environment. The main functions of the industrial logistics hub undertake the bridge between supply and demand to support the information transmission, delivery service, warehouse management, and customs clearance service. This paper describes the executive achievements of industrial logistics hub. We also review the previous development situation about suffering problems and corresponding solutions. Finally, the research highlights the future outlook in the field of logistics outsourcing service, information and communication technologies, supply chain security, general model and key performance indicator, green environmental protection, and cooperation with Free Trade Zone to better serve the global supply chain.

Acknowledgement

This research was partially supported by the Industrial Technology Research Institute (ITRI), Taiwan.

References

[1] Ministry of Economic Affairs, "2007 Taiwan Logistics Yearbook", 2007.

[2] M.S. Sohail and A.S. Sohal, "The Use of Third Party Logistics Services: a Malaysian Perspective", Technovation, 2003, 23(5),401-408.

[3] Aberdeen Group, "Global Supply Chain Benchmark Report", 2006.

[4] V. Carbone and M.A. Stone, "Growth and Relational Strategies Used by the European Logistics Service Providers: Rationale and Outcomes", Transportation

Research. E, Logistics and Transportation Review, 2005,

41(6),495-510.

[5] H. Ho and C. Lim, "The Logistics Players - from 1PL to 5PL", Morgan Stanley: China Logistics, 2001, 8-9. [6] E. Sahin, Y. Dallery and S. Gershwin, "Performance

Evaluation of a Traceability System", Proceedings of

IEEE International Conference on Systems, Man and Cybernetics (SMC),2002, pp. 210-218.

[7] G. Lekakos, "Exploiting RFID Digital Information in Enterprise Collaboration", Industrial Management and

Data Systems,2007, 107(8), 1110-1122.

[8] X. Gao, Z. Xiang, H. Wang, 1 Shen, 1 Huang and S. Song, "An Approach to Security and Privacy of RFID System for Supply Chain", Proceedings of the IEEE

International Conference on E-Commerce Technology for Dynamic E-Business,2004, pp. 164-168.

[9] G.M. Giaglis, I. Minis, A. Tatarakis and V. Zeimpekis, "Minimizing Logistics Risk through Real-time Vehicle Routing and Mobile Technologies", International Journal

ofPhysical. Distribution & Logistics Management, 2004,

34, 749-764.

[10] B.H. Lu, R.l Bateman and K. Cheng, "RFID-enabled Manufacturing: Fundamentals, Methodology and Applications", International Journal of Agile Systems and Management, 2006, 1, 73-92.

[11] E. Prater, G.V. Frazier and P.M. Reyes, "Future Impacts of RFID on E-supply Chains in Grocery retailing", Supply Chain Management: An International Journal, 2005, 10(2), 134-142.

[12] C. Kim, K.H. Yang and J. Kim, "A Strategy for Third-party Logistics Systems: A Case Analysis Using the Blue Ocean Strategy", Omega, 2008, 36, 522-534.

[13] P.S. Ho, A.1C. Trappey and C.V Trappey, "Data Interchange Services Using an XML Hub Approach for the Aerospace Supply Chain", International Journal of

Technology Management,2004, 28(2) 227-242.

[14] A. White, E.M. Daniel and M. Mohdzain, "The Role of Emergent Information Technologies and Systems in Enabling Supply Chain Agility", International Journal of Information Management, 2005, 25(5), 396-410.

[15] P.H. Ketikidisa, S.C.L. Kohc, N. Dimitriadisa, A. Gunasekarand and M. Kehajovae, "The Use of Information Systems for Logistics and Supply Chain Management in South East Europe: Current Status and Future Direction," Omega, 2008, 36, 592-599.

[16] WCO, "WCO SAFE Framework of Standards," http://www.wcoomd.org/files/l.%20Public%20files/PDFa ndDocuments/SAFE%20Framework_EN_2007_for_publi cation.pdf, 2007.

[17] European Commission, "Customs and Security," http://ec.europa.eultaxation_customs/customs/policy_issu es/customs_security/index_en.htm, 2008.

[18] A.1C. Trappey, C.V. Trappey, G.Y.P. Lin, C.S. Liu and W.T. Lee, "The Evaluation of Advantageous Industries and the Analysis of Their Global Logistics Operations -Case Study of Precision Machine Tool Industry",

Proceedings, CE2006: The 13th ISPE International Conference on Concurrent Engineering: Research and Applications, 2006, September 18-22, French Riviera, France.

[19] A.1C. Trappey, C.V. Trappey, M.S. Lee, I. Hsu and, W.T. Lee, "Modeling the Global Logistics Business Processes for Optoelectronics Firms", Proceedings,

Second International Intelligent Logistics Systems Conference, 2006 (IlLS 2006),2006, Feb 22-23, Brisbane, Australia.

f20} C.V. Trappey, A.J.C. Trappey, C.S. Liu, W.T. Lee and Y.L. Hung, "The Design and Evaluation of a Supply Chain Logistic Hub for Automobile and Parts Distribution", Materials Science Forum, 2008, 594, 119-131.

[21] S.E. Fawcett and M.B. Cooper, "Logistics Performance Measurement and Customer Success", Industrial Marketing Management, 1998, 27(4), 341-357.

[22] lS. Keebler and D.A. Durtsche, "Logistics Performance Measurement and the 3PL Value Proposition", Logistics

Quarterly,2001, 7(2), 10-11.

[23] SCC, "SCOR Overview Version 9.0", Supply-Chain Council, Inc, http://www.supply-chain.org/cs/root/scor_tooIs_resources/scor_model/scor_ model, 2008.

[24] IT. Lin, T.L. Chen, T. Tsai, 11 Lai and T.C. Huang, "A SCOR-based Methodology for Analyzing and Designing Supply Chain", International Journal of

Electronic Business Management,2005, 3(1), 1-7. [25] P.R. Murphy and R.F. Poist, "Green Logistics Strategies:

an Analysis of Usage Patterns", Transportation Journal, 2000, 40(2), 5-16.

[26] C.S. Lu and C.C. Yang, "An Evaluation of the Investment Environment in International Logistics Zones: A Taiwanese Manufacturer's Perspective," International

Journal ofProduction Economics,2007, 107, 279-300.

[27] Taiwan FTZs,